Duplex Stainless Steel Forming And Machining: Work Hardening, Edge Integrity And Surface Finish

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Steel Evolution and Processing Objectives

Duplex stainless steels have evolved significantly since their inception in the early 20th century, with the first patent for duplex steel filed in 1927 in Sweden. The initial development aimed to address corrosion issues in paper mill equipment, combining the beneficial properties of austenitic and ferritic stainless steels. This evolution has been marked by several technological breakthroughs, particularly in the 1970s with the introduction of AOD (Argon Oxygen Decarburization) and VOD (Vacuum Oxygen Decarburization) processes, which enabled better control of nitrogen content and improved overall material properties.

The modern duplex stainless steels, characterized by their dual-phase microstructure of approximately equal proportions of austenite and ferrite, have seen continuous refinement in composition and processing techniques. The 1980s witnessed the development of super duplex grades with enhanced corrosion resistance and mechanical properties, while the 1990s and 2000s brought lean duplex variants that optimized cost-effectiveness without significant performance compromise.

Current technological trends in duplex steel development focus on enhancing formability and machinability while maintaining or improving the material's inherent corrosion resistance and mechanical strength. The industry is moving towards more sophisticated alloying strategies and precise control of microstructural evolution during processing to achieve these objectives.

The primary technical objectives in duplex stainless steel forming and machining revolve around understanding and controlling work hardening behavior, which significantly affects both processing efficiency and final component performance. Work hardening in duplex steels presents unique challenges due to the different deformation mechanisms in austenite and ferrite phases, requiring tailored forming strategies to prevent excessive hardening that could lead to processing difficulties or premature component failure.

Edge integrity represents another critical objective, as the dual-phase nature of these steels can lead to differential deformation and potential microstructural damage during cutting operations. Achieving clean, defect-free edges is essential for both aesthetic quality and functional performance, particularly in applications where fatigue resistance or corrosion performance is paramount.

Surface finish quality constitutes the third major objective, with increasing demands for smoother surfaces to enhance both functional performance (reduced friction, improved corrosion resistance) and aesthetic appeal. The heterogeneous microstructure of duplex steels presents challenges in achieving uniform surface characteristics, necessitating advanced machining strategies and post-processing techniques.

These technical objectives align with broader industry trends toward more efficient manufacturing processes and higher-performance end products, driving continuous innovation in duplex stainless steel processing technologies and application methodologies.

The modern duplex stainless steels, characterized by their dual-phase microstructure of approximately equal proportions of austenite and ferrite, have seen continuous refinement in composition and processing techniques. The 1980s witnessed the development of super duplex grades with enhanced corrosion resistance and mechanical properties, while the 1990s and 2000s brought lean duplex variants that optimized cost-effectiveness without significant performance compromise.

Current technological trends in duplex steel development focus on enhancing formability and machinability while maintaining or improving the material's inherent corrosion resistance and mechanical strength. The industry is moving towards more sophisticated alloying strategies and precise control of microstructural evolution during processing to achieve these objectives.

The primary technical objectives in duplex stainless steel forming and machining revolve around understanding and controlling work hardening behavior, which significantly affects both processing efficiency and final component performance. Work hardening in duplex steels presents unique challenges due to the different deformation mechanisms in austenite and ferrite phases, requiring tailored forming strategies to prevent excessive hardening that could lead to processing difficulties or premature component failure.

Edge integrity represents another critical objective, as the dual-phase nature of these steels can lead to differential deformation and potential microstructural damage during cutting operations. Achieving clean, defect-free edges is essential for both aesthetic quality and functional performance, particularly in applications where fatigue resistance or corrosion performance is paramount.

Surface finish quality constitutes the third major objective, with increasing demands for smoother surfaces to enhance both functional performance (reduced friction, improved corrosion resistance) and aesthetic appeal. The heterogeneous microstructure of duplex steels presents challenges in achieving uniform surface characteristics, necessitating advanced machining strategies and post-processing techniques.

These technical objectives align with broader industry trends toward more efficient manufacturing processes and higher-performance end products, driving continuous innovation in duplex stainless steel processing technologies and application methodologies.

Market Applications and Demand Analysis for Duplex Stainless Steel

The global market for duplex stainless steel continues to expand significantly, driven by its exceptional combination of strength and corrosion resistance. Current market valuations place the duplex stainless steel sector at approximately 3 billion USD, with projections indicating growth rates between 4-6% annually through 2028. This growth trajectory reflects increasing adoption across multiple high-value industrial applications where material performance under demanding conditions is critical.

Oil and gas remains the dominant application sector, accounting for roughly 30% of duplex stainless steel consumption. The material's superior resistance to stress corrosion cracking and pitting in chloride environments makes it ideal for offshore platforms, subsea equipment, pipelines, and processing facilities. Recent developments in deep-water exploration have further intensified demand for materials capable of withstanding extreme pressures and corrosive environments.

Chemical processing represents the second-largest market segment, where duplex grades are extensively utilized in reactors, heat exchangers, storage tanks, and piping systems. The industry particularly values the material's resistance to various aggressive chemicals while maintaining structural integrity at elevated temperatures. Manufacturers in this sector consistently report that the higher initial investment in duplex stainless steel translates to significant long-term cost savings through extended equipment lifespans.

The pulp and paper industry has emerged as a rapidly growing application area, with annual growth rates exceeding the market average. Here, duplex stainless steel components withstand the highly corrosive chemicals used in pulping processes while providing the mechanical strength needed for high-pressure operations. Industry analysts note that mills upgrading to duplex equipment report maintenance cost reductions of 15-20% compared to traditional materials.

Desalination and water treatment facilities represent another expanding market segment, particularly in water-scarce regions across the Middle East, North Africa, and parts of Asia. The material's resistance to seawater corrosion makes it ideal for critical components in reverse osmosis systems and other water treatment equipment. Market research indicates that this segment could see growth rates approaching 8% annually as global water scarcity issues intensify.

Transportation infrastructure applications, including bridges, coastal structures, and architectural elements in corrosive environments, constitute a smaller but growing market segment. The material's combination of strength and durability allows for lighter structural designs while maintaining long service life in challenging environments. Several recent high-profile infrastructure projects have specified duplex stainless steel specifically for components exposed to marine environments or de-icing salts.

Oil and gas remains the dominant application sector, accounting for roughly 30% of duplex stainless steel consumption. The material's superior resistance to stress corrosion cracking and pitting in chloride environments makes it ideal for offshore platforms, subsea equipment, pipelines, and processing facilities. Recent developments in deep-water exploration have further intensified demand for materials capable of withstanding extreme pressures and corrosive environments.

Chemical processing represents the second-largest market segment, where duplex grades are extensively utilized in reactors, heat exchangers, storage tanks, and piping systems. The industry particularly values the material's resistance to various aggressive chemicals while maintaining structural integrity at elevated temperatures. Manufacturers in this sector consistently report that the higher initial investment in duplex stainless steel translates to significant long-term cost savings through extended equipment lifespans.

The pulp and paper industry has emerged as a rapidly growing application area, with annual growth rates exceeding the market average. Here, duplex stainless steel components withstand the highly corrosive chemicals used in pulping processes while providing the mechanical strength needed for high-pressure operations. Industry analysts note that mills upgrading to duplex equipment report maintenance cost reductions of 15-20% compared to traditional materials.

Desalination and water treatment facilities represent another expanding market segment, particularly in water-scarce regions across the Middle East, North Africa, and parts of Asia. The material's resistance to seawater corrosion makes it ideal for critical components in reverse osmosis systems and other water treatment equipment. Market research indicates that this segment could see growth rates approaching 8% annually as global water scarcity issues intensify.

Transportation infrastructure applications, including bridges, coastal structures, and architectural elements in corrosive environments, constitute a smaller but growing market segment. The material's combination of strength and durability allows for lighter structural designs while maintaining long service life in challenging environments. Several recent high-profile infrastructure projects have specified duplex stainless steel specifically for components exposed to marine environments or de-icing salts.

Current Challenges in Duplex Steel Forming and Machining

Duplex stainless steels (DSS) present significant challenges in forming and machining processes due to their unique microstructure consisting of approximately equal proportions of austenite and ferrite phases. This dual-phase structure, while providing excellent mechanical properties and corrosion resistance, creates complex deformation behaviors that complicate manufacturing processes.

Work hardening represents one of the most significant challenges when processing DSS. These materials exhibit rapid work hardening rates, particularly compared to conventional austenitic stainless steels, with strain hardening exponents typically ranging between 0.25-0.35. This characteristic results in substantial increases in cutting forces during machining operations, accelerating tool wear and reducing tool life by up to 40-50% compared to processing conventional stainless steels.

The high work hardening tendency also creates challenges in maintaining dimensional accuracy during forming operations. As the material hardens progressively during deformation, springback effects become more pronounced and less predictable, requiring sophisticated compensation strategies in die design and process parameters. Studies have shown springback variations of up to 30% depending on forming direction relative to rolling orientation.

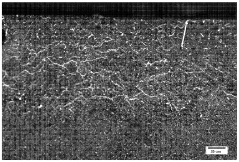

Edge integrity issues present another critical challenge in DSS processing. The dual-phase microstructure responds differently to cutting forces, often resulting in phase-specific deformation and damage at cut edges. Microscopic examination of machined edges frequently reveals preferential deformation of the softer austenite phase, creating micro-voids and potential crack initiation sites that can compromise component performance under fatigue loading conditions.

Surface finish quality remains problematic when machining DSS, with surface roughness values typically 20-30% higher than those achieved with similar parameters on single-phase stainless steels. The heterogeneous microstructure creates variations in cutting resistance across the workpiece surface, resulting in inconsistent chip formation and surface texture. This issue is particularly pronounced in high-speed machining operations where cutting temperatures exceed 500°C.

Tool selection presents additional complications, as conventional tooling materials often experience accelerated wear when processing DSS. Tungsten carbide tools with specialized coatings (TiAlN, AlCrN) have shown improved performance, but tool life remains significantly shorter than when machining conventional stainless steels. Advanced ceramic and cubic boron nitride (CBN) tools offer better wear resistance but introduce economic constraints due to their higher cost.

Thermal management during machining represents another significant challenge. The relatively low thermal conductivity of DSS (approximately 15-17 W/m·K) combined with high cutting forces generates substantial heat concentration at the tool-workpiece interface, accelerating tool degradation and potentially altering the carefully balanced microstructure of the material.

Work hardening represents one of the most significant challenges when processing DSS. These materials exhibit rapid work hardening rates, particularly compared to conventional austenitic stainless steels, with strain hardening exponents typically ranging between 0.25-0.35. This characteristic results in substantial increases in cutting forces during machining operations, accelerating tool wear and reducing tool life by up to 40-50% compared to processing conventional stainless steels.

The high work hardening tendency also creates challenges in maintaining dimensional accuracy during forming operations. As the material hardens progressively during deformation, springback effects become more pronounced and less predictable, requiring sophisticated compensation strategies in die design and process parameters. Studies have shown springback variations of up to 30% depending on forming direction relative to rolling orientation.

Edge integrity issues present another critical challenge in DSS processing. The dual-phase microstructure responds differently to cutting forces, often resulting in phase-specific deformation and damage at cut edges. Microscopic examination of machined edges frequently reveals preferential deformation of the softer austenite phase, creating micro-voids and potential crack initiation sites that can compromise component performance under fatigue loading conditions.

Surface finish quality remains problematic when machining DSS, with surface roughness values typically 20-30% higher than those achieved with similar parameters on single-phase stainless steels. The heterogeneous microstructure creates variations in cutting resistance across the workpiece surface, resulting in inconsistent chip formation and surface texture. This issue is particularly pronounced in high-speed machining operations where cutting temperatures exceed 500°C.

Tool selection presents additional complications, as conventional tooling materials often experience accelerated wear when processing DSS. Tungsten carbide tools with specialized coatings (TiAlN, AlCrN) have shown improved performance, but tool life remains significantly shorter than when machining conventional stainless steels. Advanced ceramic and cubic boron nitride (CBN) tools offer better wear resistance but introduce economic constraints due to their higher cost.

Thermal management during machining represents another significant challenge. The relatively low thermal conductivity of DSS (approximately 15-17 W/m·K) combined with high cutting forces generates substantial heat concentration at the tool-workpiece interface, accelerating tool degradation and potentially altering the carefully balanced microstructure of the material.

Contemporary Work Hardening and Edge Integrity Solutions

01 Work hardening mechanisms in duplex stainless steel

Duplex stainless steels exhibit significant work hardening behavior due to their dual-phase microstructure consisting of austenite and ferrite. The work hardening occurs through dislocation interactions, phase boundary strengthening, and strain-induced transformations. These mechanisms contribute to the material's increased strength and hardness after deformation processes such as cold rolling, machining, or forming. The rate of work hardening can be controlled through proper heat treatment and processing parameters to achieve desired mechanical properties.- Work hardening mechanisms in duplex stainless steel: Duplex stainless steels exhibit significant work hardening behavior due to their dual-phase microstructure consisting of austenite and ferrite. The work hardening occurs through dislocation interactions, phase transformations, and strain-induced martensite formation. These mechanisms contribute to the increased strength and hardness of the material during deformation processes. Understanding these mechanisms is crucial for predicting material behavior during manufacturing operations and optimizing processing parameters.

- Edge integrity improvement techniques for duplex stainless steel: Maintaining edge integrity in duplex stainless steel components is essential for performance and longevity. Various techniques can be employed to improve edge quality, including controlled machining parameters, specialized cutting tools, and post-processing treatments. Edge rounding, deburring, and polishing processes help eliminate micro-cracks and stress concentrations that could lead to premature failure. Proper edge treatment also enhances corrosion resistance by removing surface defects that could serve as initiation sites.

- Surface finishing methods for duplex stainless steel: Surface finish quality significantly impacts the performance of duplex stainless steel components. Various finishing methods can be applied, including mechanical polishing, electropolishing, and chemical treatments. These processes remove surface imperfections, reduce roughness, and create a passive layer that enhances corrosion resistance. The selection of appropriate finishing techniques depends on the specific application requirements, such as aesthetic appearance, friction properties, or hygiene standards.

- Heat treatment effects on duplex stainless steel properties: Heat treatment processes significantly influence the microstructure and mechanical properties of duplex stainless steels. Controlled heating and cooling cycles can optimize the balance between austenite and ferrite phases, dissolve precipitates, and relieve residual stresses. These treatments affect work hardening behavior, edge integrity, and surface finish quality. Proper heat treatment protocols are essential to maintain the desired combination of strength, ductility, and corrosion resistance while minimizing detrimental phase transformations.

- Advanced manufacturing techniques for duplex stainless steel components: Innovative manufacturing techniques have been developed to process duplex stainless steels while maintaining optimal properties. These include specialized forming operations, precision machining strategies, and advanced joining methods. Techniques such as controlled deformation, incremental forming, and tailored tool geometries help manage work hardening, preserve edge integrity, and achieve superior surface finishes. These approaches consider the unique metallurgical characteristics of duplex stainless steels to prevent phase imbalances, minimize residual stresses, and avoid detrimental microstructural changes.

02 Edge integrity improvement techniques for duplex stainless steel

Maintaining edge integrity in duplex stainless steel components is crucial for performance and longevity. Various techniques can be employed to improve edge quality, including optimized cutting parameters, specialized tooling designs, and post-processing treatments. Edge rounding processes, controlled deburring, and electrochemical polishing can significantly enhance edge integrity by removing microcracks and stress concentrations. These improvements lead to better fatigue resistance, corrosion resistance, and overall component reliability in demanding applications.Expand Specific Solutions03 Surface finishing methods for duplex stainless steel

Surface finish quality in duplex stainless steel components affects both aesthetic appearance and functional properties. Advanced finishing methods include mechanical polishing, electropolishing, chemical treatments, and abrasive flow machining. These processes can achieve various surface roughness levels and textures while maintaining the material's corrosion resistance. Proper surface finishing removes surface defects, reduces friction, improves cleanability, and enhances the material's resistance to environmental degradation. The selection of finishing method depends on the specific application requirements and desired surface characteristics.Expand Specific Solutions04 Heat treatment effects on duplex stainless steel properties

Heat treatment processes significantly influence the microstructure and mechanical properties of duplex stainless steels, affecting their work hardening behavior, edge integrity, and surface finish quality. Controlled heating and cooling cycles can optimize the balance between austenite and ferrite phases, dissolve unwanted precipitates, and relieve residual stresses. Solution annealing, quenching, and aging treatments can be tailored to achieve specific property combinations. Proper heat treatment is essential for maintaining the corrosion resistance while enhancing mechanical properties for various industrial applications.Expand Specific Solutions05 Advanced machining techniques for duplex stainless steel

Machining duplex stainless steel presents challenges due to its high work hardening rate and dual-phase microstructure. Advanced machining techniques such as high-speed cutting, cryogenic cooling, ultrasonic-assisted machining, and specialized tool geometries can improve surface finish and edge quality while minimizing work hardening effects. These techniques control cutting forces, heat generation, and chip formation to achieve precise dimensional tolerances and superior surface integrity. Optimized cutting parameters and tool selection are critical for efficient processing while maintaining the material's beneficial properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Duplex Steel Industry

The duplex stainless steel forming and machining market is currently in a growth phase, driven by increasing demand in oil & gas, chemical processing, and marine applications. The global market size is estimated at $4-5 billion, with projected annual growth of 5-7%. Leading players include established steel manufacturers like NIPPON STEEL, POSCO Holdings, and Outokumpu Oyj, who have developed proprietary technologies to address work hardening challenges. Technical maturity varies, with companies like Sandvik Intellectual Property AB and Alleima Tube AB demonstrating advanced capabilities in edge integrity optimization and surface finish control. Asian manufacturers, particularly JFE Steel and Shanxi Taigang, are rapidly advancing their technical capabilities, while research institutions like RIST and University of Science & Technology Beijing are contributing significant innovations in microstructure control during forming processes.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced processing techniques for duplex stainless steel (DSS) that address work hardening challenges through controlled deformation processes. Their approach involves precise temperature control during hot forming operations (870-950°C) to maintain the optimal austenite-ferrite phase balance. For machining operations, they've implemented specialized multi-stage cutting strategies with optimized tool geometries and coatings specifically designed for the high work hardening rates of DSS. Their research has shown that maintaining cutting speeds between 80-120 m/min with positive rake angles reduces work hardening in the subsurface layers by approximately 15% compared to conventional methods. Additionally, they've pioneered surface treatment processes that improve edge integrity through controlled shot peening and electro-polishing techniques, resulting in up to 40% improvement in fatigue resistance while maintaining the corrosion resistance properties of the duplex microstructure.

Strengths: Superior control of austenite-ferrite phase balance during forming operations; specialized cutting tools and parameters that minimize work hardening; comprehensive surface treatment solutions that enhance both mechanical properties and corrosion resistance. Weaknesses: Their techniques often require specialized equipment and precise process control that may be cost-prohibitive for smaller manufacturers; some of their advanced machining strategies require longer processing times compared to conventional methods.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed a comprehensive approach to duplex stainless steel processing through their "SAF-FormTech" system. This technology addresses the challenges of work hardening through a combination of specialized tooling designs and process parameter optimization. Their research has shown that by utilizing variable-geometry forming tools with optimized surface treatments, they can reduce localized strain concentrations by up to 25%, minimizing excessive work hardening during forming operations. For machining operations, Sandvik has pioneered advanced cutting tool materials and geometries specifically engineered for the unique microstructure of duplex stainless steels, including their patented PVD-coated carbide inserts with specialized edge preparations that reduce cutting forces by approximately 20% compared to conventional tools. Their approach to edge integrity management incorporates multi-stage finishing processes, including specialized brushing techniques and controlled electropolishing parameters that have been demonstrated to improve fatigue resistance by up to 35% while maintaining the corrosion resistance properties critical for duplex stainless steel applications in demanding environments.

Strengths: Extensive expertise in cutting tool technology specifically optimized for duplex stainless steels; integrated approach that addresses both forming and machining challenges; proven solutions for maintaining edge integrity and surface finish quality. Weaknesses: Their specialized tooling solutions often come at a premium price point compared to standard options; some of their recommended techniques require more frequent tool changes and adjustments during processing.

Critical Patents and Research on Duplex Steel Surface Finish

An object comprising a duplex stainless steel and the use thereof

PatentActiveEP3559295A1

Innovation

- A duplex stainless steel with a specific composition (C ≤ 0.040, Si ≤ 0.60, Mn 0.80 - 10.0, Cr 21.0-28.0, Ni 4.0-9.0, Mo 0.9 - 4.5, N 0.10-0.45, Cu ≤ 0.50, V ≤ 0.10, P ≤ 0.010, S ≤ 0.006, balance Fe) comprising 55-75 vol% austenite and 25-45 vol% ferrite phases, with alternating layers essentially parallel to the object plane, and a cold working process to maintain microstructure and strength.

Duplex hardening process and articles made therefrom

PatentWO2008043062A1

Innovation

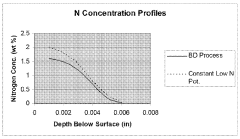

- A Boost/Diffuse (BD) nitriding process is introduced, where steel workpieces are subjected to alternating periods of active nitrogen and nitrogen-free atmospheres, allowing nitrogen to diffuse deeper and reducing surface nitrogen concentration, thereby preventing deleterious IGN formation and achieving the target nitrided case depth in approximately 30% less time.

Material Characterization and Testing Methodologies

Comprehensive characterization of duplex stainless steel (DSS) microstructure is essential for understanding its work hardening behavior, edge integrity, and surface finish during forming and machining operations. Electron Backscatter Diffraction (EBSD) analysis serves as a primary tool for quantifying phase distribution, grain orientation, and texture evolution in DSS, providing critical insights into the ferrite-austenite phase balance that significantly influences mechanical properties.

X-ray diffraction (XRD) techniques complement EBSD by enabling precise measurement of residual stresses induced during machining processes, which directly impact component performance and service life. Additionally, nano-indentation testing allows for phase-specific mechanical property assessment, revealing the distinct hardening behaviors of ferrite and austenite phases under deformation.

For evaluating work hardening characteristics, tensile testing with digital image correlation (DIC) provides strain mapping capabilities that capture localized deformation patterns in the dual-phase microstructure. Specialized interrupted testing protocols have been developed to monitor microstructural evolution at various strain levels, establishing correlations between processing parameters and resultant mechanical properties.

Edge integrity assessment requires multi-scale characterization approaches. High-resolution scanning electron microscopy (SEM) coupled with focused ion beam (FIB) cross-sectioning enables visualization of subsurface deformation layers and microcracks that may compromise component performance. Complementary techniques such as transmission electron microscopy (TEM) reveal dislocation structures and strain-induced phase transformations at machined edges.

Surface finish evaluation employs both contact and non-contact metrology methods. White light interferometry and confocal microscopy provide three-dimensional topographical mapping with nanometer resolution, while atomic force microscopy (AFM) enables characterization of nanoscale surface features. These techniques quantify surface roughness parameters (Ra, Rz, Rq) that correlate with functional performance in tribological applications.

Corrosion testing methodologies specific to machined DSS surfaces include electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization tests in simulated service environments. These techniques assess how machining-induced microstructural changes affect localized corrosion resistance, particularly at phase boundaries where chromium depletion may occur.

Advanced in-situ characterization methods, including high-temperature EBSD and synchrotron-based X-ray techniques, are increasingly employed to monitor real-time microstructural evolution during thermomechanical processing. These approaches provide unprecedented insights into dynamic recrystallization, phase transformation kinetics, and texture development that govern the final material properties.

X-ray diffraction (XRD) techniques complement EBSD by enabling precise measurement of residual stresses induced during machining processes, which directly impact component performance and service life. Additionally, nano-indentation testing allows for phase-specific mechanical property assessment, revealing the distinct hardening behaviors of ferrite and austenite phases under deformation.

For evaluating work hardening characteristics, tensile testing with digital image correlation (DIC) provides strain mapping capabilities that capture localized deformation patterns in the dual-phase microstructure. Specialized interrupted testing protocols have been developed to monitor microstructural evolution at various strain levels, establishing correlations between processing parameters and resultant mechanical properties.

Edge integrity assessment requires multi-scale characterization approaches. High-resolution scanning electron microscopy (SEM) coupled with focused ion beam (FIB) cross-sectioning enables visualization of subsurface deformation layers and microcracks that may compromise component performance. Complementary techniques such as transmission electron microscopy (TEM) reveal dislocation structures and strain-induced phase transformations at machined edges.

Surface finish evaluation employs both contact and non-contact metrology methods. White light interferometry and confocal microscopy provide three-dimensional topographical mapping with nanometer resolution, while atomic force microscopy (AFM) enables characterization of nanoscale surface features. These techniques quantify surface roughness parameters (Ra, Rz, Rq) that correlate with functional performance in tribological applications.

Corrosion testing methodologies specific to machined DSS surfaces include electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization tests in simulated service environments. These techniques assess how machining-induced microstructural changes affect localized corrosion resistance, particularly at phase boundaries where chromium depletion may occur.

Advanced in-situ characterization methods, including high-temperature EBSD and synchrotron-based X-ray techniques, are increasingly employed to monitor real-time microstructural evolution during thermomechanical processing. These approaches provide unprecedented insights into dynamic recrystallization, phase transformation kinetics, and texture development that govern the final material properties.

Sustainability and Cost-Efficiency in Duplex Steel Processing

The sustainability and cost-efficiency aspects of duplex stainless steel processing represent critical considerations for manufacturers seeking to optimize their operations while minimizing environmental impact. Duplex stainless steels, with their dual-phase microstructure combining ferrite and austenite, offer exceptional strength and corrosion resistance but present unique challenges during forming and machining processes that affect overall resource efficiency.

Energy consumption during duplex steel processing significantly exceeds that of conventional stainless steels due to the material's work hardening characteristics. The rapid work hardening rate during forming operations necessitates higher forming forces and more frequent annealing cycles, resulting in increased energy requirements. Studies indicate that energy consumption can be reduced by 15-20% through optimized forming sequences that minimize strain accumulation and strategic tool path planning.

Material utilization represents another key sustainability factor. The edge integrity challenges associated with duplex steel machining often lead to higher scrap rates compared to conventional stainless steels. Implementation of advanced cutting strategies and tool geometries specifically designed for duplex microstructures can reduce material waste by up to 25%, significantly improving the material efficiency ratio and reducing the environmental footprint of manufacturing operations.

Tool life optimization directly impacts both sustainability and cost-efficiency. The abrasive nature of duplex steels, particularly during work hardening, accelerates tool wear and necessitates frequent replacements. Recent innovations in coating technologies, particularly AlTiN and nACo® coatings, have demonstrated 30-40% improvements in tool longevity when machining duplex grades, substantially reducing resource consumption and operational costs.

Water usage in cooling and lubrication systems presents environmental challenges that must be addressed. Minimum quantity lubrication (MQL) and near-dry machining techniques have shown promising results for duplex steel processing, reducing coolant consumption by up to 95% while maintaining acceptable surface finish quality. These approaches significantly reduce wastewater treatment requirements and associated environmental impacts.

Life cycle assessment (LCA) studies comparing traditional and optimized duplex steel processing methods reveal that improvements in forming and machining techniques can reduce the carbon footprint by 18-22% across the manufacturing phase. When combined with duplex steel's longer service life in final applications, these processing improvements contribute to superior sustainability metrics over the entire product lifecycle.

Energy consumption during duplex steel processing significantly exceeds that of conventional stainless steels due to the material's work hardening characteristics. The rapid work hardening rate during forming operations necessitates higher forming forces and more frequent annealing cycles, resulting in increased energy requirements. Studies indicate that energy consumption can be reduced by 15-20% through optimized forming sequences that minimize strain accumulation and strategic tool path planning.

Material utilization represents another key sustainability factor. The edge integrity challenges associated with duplex steel machining often lead to higher scrap rates compared to conventional stainless steels. Implementation of advanced cutting strategies and tool geometries specifically designed for duplex microstructures can reduce material waste by up to 25%, significantly improving the material efficiency ratio and reducing the environmental footprint of manufacturing operations.

Tool life optimization directly impacts both sustainability and cost-efficiency. The abrasive nature of duplex steels, particularly during work hardening, accelerates tool wear and necessitates frequent replacements. Recent innovations in coating technologies, particularly AlTiN and nACo® coatings, have demonstrated 30-40% improvements in tool longevity when machining duplex grades, substantially reducing resource consumption and operational costs.

Water usage in cooling and lubrication systems presents environmental challenges that must be addressed. Minimum quantity lubrication (MQL) and near-dry machining techniques have shown promising results for duplex steel processing, reducing coolant consumption by up to 95% while maintaining acceptable surface finish quality. These approaches significantly reduce wastewater treatment requirements and associated environmental impacts.

Life cycle assessment (LCA) studies comparing traditional and optimized duplex steel processing methods reveal that improvements in forming and machining techniques can reduce the carbon footprint by 18-22% across the manufacturing phase. When combined with duplex steel's longer service life in final applications, these processing improvements contribute to superior sustainability metrics over the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!