Duplex Stainless Steel Fail-Safe Design: Notch Sensitivity, Fracture And Inspection

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Steel Fail-Safe Design Background and Objectives

Duplex stainless steels (DSS) have emerged as critical materials in high-performance engineering applications over the past five decades. These alloys, characterized by their dual-phase microstructure of austenite and ferrite, offer an exceptional combination of mechanical properties and corrosion resistance that surpasses conventional stainless steels. The evolution of DSS began in the 1930s, but significant commercial development only accelerated in the 1970s with the introduction of nitrogen as an alloying element, which substantially improved their properties and manufacturability.

The technological trajectory of DSS has been driven by increasing demands from industries operating in aggressive environments, particularly offshore oil and gas, chemical processing, and marine applications. These sectors require materials that can withstand simultaneous challenges of mechanical stress, corrosion, and often elevated temperatures. The development path has progressively moved toward higher alloyed grades, including super duplex and hyper duplex varieties, to meet these escalating performance requirements.

Despite their widespread adoption, a critical gap exists in understanding the fail-safe design principles for DSS components. Fail-safe design philosophy, which originated in aerospace engineering, ensures that systems maintain minimum operational capabilities even after partial failures. When applied to DSS structures, this approach requires comprehensive knowledge of fracture mechanics, notch sensitivity, and damage tolerance—areas where current understanding remains incomplete.

The primary technical objective of this research is to establish a robust framework for fail-safe design methodologies specifically tailored to DSS applications. This includes developing predictive models for crack initiation and propagation in the unique dual-phase microstructure, quantifying notch sensitivity across various environmental conditions, and determining critical inspection parameters to ensure structural integrity throughout service life.

Secondary objectives include mapping the relationship between microstructural variations and fracture behavior, evaluating the impact of manufacturing processes on fail-safe performance, and developing non-destructive testing protocols optimized for DSS components. These objectives align with the industry trend toward condition-based maintenance and predictive failure analysis.

The anticipated technological outcomes include standardized testing methodologies for notch sensitivity assessment, validated computational models for predicting fracture behavior in complex loading scenarios, and inspection interval guidelines based on quantitative risk assessment. These developments would significantly enhance the reliability of critical infrastructure while potentially extending service life and reducing lifecycle costs of DSS components in demanding applications.

The technological trajectory of DSS has been driven by increasing demands from industries operating in aggressive environments, particularly offshore oil and gas, chemical processing, and marine applications. These sectors require materials that can withstand simultaneous challenges of mechanical stress, corrosion, and often elevated temperatures. The development path has progressively moved toward higher alloyed grades, including super duplex and hyper duplex varieties, to meet these escalating performance requirements.

Despite their widespread adoption, a critical gap exists in understanding the fail-safe design principles for DSS components. Fail-safe design philosophy, which originated in aerospace engineering, ensures that systems maintain minimum operational capabilities even after partial failures. When applied to DSS structures, this approach requires comprehensive knowledge of fracture mechanics, notch sensitivity, and damage tolerance—areas where current understanding remains incomplete.

The primary technical objective of this research is to establish a robust framework for fail-safe design methodologies specifically tailored to DSS applications. This includes developing predictive models for crack initiation and propagation in the unique dual-phase microstructure, quantifying notch sensitivity across various environmental conditions, and determining critical inspection parameters to ensure structural integrity throughout service life.

Secondary objectives include mapping the relationship between microstructural variations and fracture behavior, evaluating the impact of manufacturing processes on fail-safe performance, and developing non-destructive testing protocols optimized for DSS components. These objectives align with the industry trend toward condition-based maintenance and predictive failure analysis.

The anticipated technological outcomes include standardized testing methodologies for notch sensitivity assessment, validated computational models for predicting fracture behavior in complex loading scenarios, and inspection interval guidelines based on quantitative risk assessment. These developments would significantly enhance the reliability of critical infrastructure while potentially extending service life and reducing lifecycle costs of DSS components in demanding applications.

Market Demand Analysis for Duplex Steel Applications

The global market for duplex stainless steel has witnessed significant growth in recent years, driven primarily by its superior mechanical properties and corrosion resistance compared to conventional stainless steel grades. The current market valuation stands at approximately USD 3 billion, with projections indicating a compound annual growth rate of 4.2% through 2028, according to industry reports from Metal Market Research.

The oil and gas sector remains the largest consumer of duplex stainless steel, accounting for roughly 35% of total demand. This is attributed to the material's exceptional performance in harsh offshore environments where resistance to stress corrosion cracking and high mechanical strength are critical requirements. Recent developments in deep-sea exploration and extraction have further intensified demand for fail-safe duplex steel components.

Chemical processing industries represent the second-largest market segment, contributing about 28% to overall demand. The growing emphasis on process safety and equipment reliability has led to increased adoption of duplex grades in pressure vessels, heat exchangers, and piping systems where failure could result in catastrophic consequences.

Notably, the power generation sector has emerged as a rapidly growing market for duplex stainless steel applications, particularly in nuclear and renewable energy installations. This sector's demand is expected to grow at 5.7% annually, outpacing the overall market growth rate. The stringent safety requirements and need for long-term reliability in these applications align perfectly with duplex steel's performance characteristics.

Regional analysis reveals that Europe leads in duplex steel consumption with a 38% market share, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is projected in emerging economies of Southeast Asia and the Middle East, where infrastructure development and industrial expansion are creating new application opportunities.

A significant market trend is the increasing demand for advanced inspection technologies and fail-safe design methodologies specific to duplex stainless steel. End-users are willing to pay premium prices for components with verified fracture resistance properties and established inspection protocols. This trend is particularly evident in critical applications where notch sensitivity and fracture mechanics are key considerations.

Industry surveys indicate that 73% of engineering firms consider improved understanding of duplex steel's notch sensitivity and fracture behavior as "very important" or "critical" for future projects. This represents a clear market signal for research and development in this specific technical domain.

The oil and gas sector remains the largest consumer of duplex stainless steel, accounting for roughly 35% of total demand. This is attributed to the material's exceptional performance in harsh offshore environments where resistance to stress corrosion cracking and high mechanical strength are critical requirements. Recent developments in deep-sea exploration and extraction have further intensified demand for fail-safe duplex steel components.

Chemical processing industries represent the second-largest market segment, contributing about 28% to overall demand. The growing emphasis on process safety and equipment reliability has led to increased adoption of duplex grades in pressure vessels, heat exchangers, and piping systems where failure could result in catastrophic consequences.

Notably, the power generation sector has emerged as a rapidly growing market for duplex stainless steel applications, particularly in nuclear and renewable energy installations. This sector's demand is expected to grow at 5.7% annually, outpacing the overall market growth rate. The stringent safety requirements and need for long-term reliability in these applications align perfectly with duplex steel's performance characteristics.

Regional analysis reveals that Europe leads in duplex steel consumption with a 38% market share, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is projected in emerging economies of Southeast Asia and the Middle East, where infrastructure development and industrial expansion are creating new application opportunities.

A significant market trend is the increasing demand for advanced inspection technologies and fail-safe design methodologies specific to duplex stainless steel. End-users are willing to pay premium prices for components with verified fracture resistance properties and established inspection protocols. This trend is particularly evident in critical applications where notch sensitivity and fracture mechanics are key considerations.

Industry surveys indicate that 73% of engineering firms consider improved understanding of duplex steel's notch sensitivity and fracture behavior as "very important" or "critical" for future projects. This represents a clear market signal for research and development in this specific technical domain.

Current Challenges in Notch Sensitivity and Fracture Mechanics

Duplex stainless steels (DSS) present significant challenges in notch sensitivity and fracture mechanics that impact their fail-safe design implementation. The microstructural complexity of DSS, with its dual-phase structure of austenite and ferrite, creates unique stress concentration behaviors at notches that differ substantially from single-phase materials. This heterogeneous microstructure results in complex crack initiation and propagation mechanisms that conventional fracture mechanics models struggle to accurately predict.

Recent research has identified that the ferrite phase in DSS exhibits higher notch sensitivity compared to the austenite phase, creating preferential crack paths along phase boundaries. This phenomenon becomes particularly problematic in hydrogen-containing environments where hydrogen embrittlement can accelerate crack growth rates by orders of magnitude. The industry currently lacks standardized testing protocols specifically designed for evaluating notch sensitivity in DSS under various environmental conditions.

Fracture toughness characterization presents another significant challenge. The anisotropic nature of DSS means that fracture properties vary considerably depending on the orientation relative to the rolling direction. This directional dependency complicates the development of comprehensive fracture assessment criteria. Furthermore, traditional linear elastic fracture mechanics (LEFM) approaches often prove inadequate for DSS due to the extensive plastic deformation that occurs before fracture.

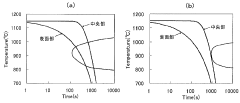

Temperature effects introduce additional complexity, as DSS exhibits a ductile-to-brittle transition that shifts depending on the specific alloy composition and processing history. This transition temperature range is particularly critical for applications in cryogenic environments or those subject to thermal cycling. Current predictive models fail to adequately account for these temperature-dependent fracture behavior variations.

The interaction between mechanical loading and corrosive environments represents perhaps the most significant challenge. Stress corrosion cracking (SCC) susceptibility in DSS is highly dependent on microstructural features that influence notch sensitivity. The synergistic effects of cyclic loading and corrosive media can dramatically accelerate crack growth rates through corrosion fatigue mechanisms that remain poorly understood at the microstructural level.

Non-destructive evaluation (NDE) techniques face limitations in detecting and characterizing small defects in DSS, particularly those at phase boundaries or in weld heat-affected zones. Conventional ultrasonic testing struggles with signal interpretation due to the anisotropic acoustic properties of the dual-phase microstructure. Advanced techniques like phased array ultrasonics show promise but require further development of DSS-specific calibration standards and interpretation protocols.

Recent research has identified that the ferrite phase in DSS exhibits higher notch sensitivity compared to the austenite phase, creating preferential crack paths along phase boundaries. This phenomenon becomes particularly problematic in hydrogen-containing environments where hydrogen embrittlement can accelerate crack growth rates by orders of magnitude. The industry currently lacks standardized testing protocols specifically designed for evaluating notch sensitivity in DSS under various environmental conditions.

Fracture toughness characterization presents another significant challenge. The anisotropic nature of DSS means that fracture properties vary considerably depending on the orientation relative to the rolling direction. This directional dependency complicates the development of comprehensive fracture assessment criteria. Furthermore, traditional linear elastic fracture mechanics (LEFM) approaches often prove inadequate for DSS due to the extensive plastic deformation that occurs before fracture.

Temperature effects introduce additional complexity, as DSS exhibits a ductile-to-brittle transition that shifts depending on the specific alloy composition and processing history. This transition temperature range is particularly critical for applications in cryogenic environments or those subject to thermal cycling. Current predictive models fail to adequately account for these temperature-dependent fracture behavior variations.

The interaction between mechanical loading and corrosive environments represents perhaps the most significant challenge. Stress corrosion cracking (SCC) susceptibility in DSS is highly dependent on microstructural features that influence notch sensitivity. The synergistic effects of cyclic loading and corrosive media can dramatically accelerate crack growth rates through corrosion fatigue mechanisms that remain poorly understood at the microstructural level.

Non-destructive evaluation (NDE) techniques face limitations in detecting and characterizing small defects in DSS, particularly those at phase boundaries or in weld heat-affected zones. Conventional ultrasonic testing struggles with signal interpretation due to the anisotropic acoustic properties of the dual-phase microstructure. Advanced techniques like phased array ultrasonics show promise but require further development of DSS-specific calibration standards and interpretation protocols.

Existing Fail-Safe Design Solutions for Duplex Stainless Steel

01 Composition and microstructure effects on notch sensitivity

The composition and microstructure of duplex stainless steel significantly affect its notch sensitivity and fracture behavior. Specific alloying elements and phase balance between ferrite and austenite can be optimized to improve resistance to notch-induced fracture. Heat treatment processes can be tailored to achieve desired microstructural features that reduce notch sensitivity while maintaining other mechanical properties. The proper balance of elements like chromium, nickel, molybdenum, and nitrogen plays a crucial role in determining fracture resistance at notched areas.- Composition and microstructure effects on notch sensitivity: The composition and microstructure of duplex stainless steel significantly influence its notch sensitivity and fracture behavior. Specific alloying elements like chromium, nickel, molybdenum, and nitrogen can be optimized to achieve a balanced austenite-ferrite microstructure that improves resistance to notch-induced fracture. Heat treatment processes can be tailored to control grain size and phase distribution, which directly affects the material's response to stress concentrations at notches.

- Testing methods for notch sensitivity evaluation: Various testing methodologies have been developed to evaluate the notch sensitivity and fracture properties of duplex stainless steels. These include Charpy impact testing, fracture toughness testing, and specialized notch tensile tests. Testing across different temperatures is crucial as duplex stainless steels can exhibit varying notch sensitivity depending on the service temperature. Advanced non-destructive testing techniques can also be employed to detect potential fracture initiation sites near notches in components made from these materials.

- Environmental factors affecting fracture behavior: Environmental conditions significantly impact the notch sensitivity and fracture behavior of duplex stainless steels. Corrosive environments, particularly those containing chlorides, can lead to stress corrosion cracking at notches. Hydrogen embrittlement can occur in certain service conditions, increasing notch sensitivity. Temperature extremes, both high and low, can alter the fracture mechanism and notch sensitivity characteristics of these steels, with some grades showing increased brittleness at low temperatures.

- Manufacturing processes to reduce notch sensitivity: Specific manufacturing processes can be employed to reduce notch sensitivity in duplex stainless steels. Controlled hot and cold working procedures help optimize grain structure and phase balance. Post-weld heat treatments are crucial for restoring proper microstructure in welded regions that might otherwise be susceptible to notch-induced fracture. Surface treatments such as shot peening or burnishing can introduce compressive residual stresses that improve resistance to notch-induced crack initiation. Advanced forming techniques can minimize the introduction of stress concentrators during component fabrication.

- Design considerations for notch-containing components: Engineering design strategies can mitigate the effects of notch sensitivity in duplex stainless steel components. Proper notch geometry design with adequate radii can reduce stress concentration factors. Finite element analysis can be used to predict stress distributions around notches and optimize component design. Consideration of loading direction relative to material anisotropy is important as duplex stainless steels may exhibit directional properties. Design safety factors should account for potential variations in notch sensitivity due to manufacturing variations or service conditions.

02 Testing methods for notch sensitivity and fracture toughness

Various testing methodologies are employed to evaluate the notch sensitivity and fracture toughness of duplex stainless steels. These include Charpy impact testing, fracture mechanics testing, and specialized notch sensitivity tests under different loading conditions. Testing at various temperatures helps determine the ductile-to-brittle transition behavior, which is critical for applications in extreme environments. Advanced non-destructive testing techniques can also be used to predict fracture behavior in notched components without destroying the sample.Expand Specific Solutions03 Heat treatment and processing effects on fracture resistance

Heat treatment processes and thermomechanical processing significantly influence the fracture resistance and notch sensitivity of duplex stainless steels. Controlled cooling rates, solution annealing temperatures, and aging treatments can be optimized to enhance fracture toughness. Processing parameters during hot and cold working affect grain structure and phase distribution, which in turn impact notch sensitivity. Post-weld heat treatments are particularly important for maintaining fracture resistance in welded components with geometric discontinuities that can act as stress concentrators.Expand Specific Solutions04 Environmental effects on notch-induced fracture

Environmental factors significantly influence the notch sensitivity and fracture behavior of duplex stainless steels. Corrosive environments, hydrogen embrittlement, and elevated temperatures can exacerbate notch sensitivity and reduce fracture resistance. Specific corrosion mechanisms like stress corrosion cracking can initiate at notches and lead to catastrophic failure. Protective measures and material modifications can be implemented to mitigate these environmental effects and improve the overall performance of notched components in aggressive service conditions.Expand Specific Solutions05 Design considerations for notched components

Design strategies can be implemented to minimize the negative effects of notches in duplex stainless steel components. These include geometric optimization to reduce stress concentration, incorporation of gradual transitions instead of sharp notches, and application of surface treatments to induce compressive residual stresses. Finite element analysis and fracture mechanics principles can be used to predict and prevent notch-induced failures. Understanding the relationship between notch geometry and fracture behavior allows for more reliable component design in critical applications where duplex stainless steels are employed.Expand Specific Solutions

Key Industry Players in Duplex Steel Manufacturing and Testing

Duplex stainless steel fail-safe design is currently in a growth phase, with the market expanding due to increasing demand in critical applications requiring high corrosion resistance and mechanical strength. The global market size for duplex stainless steel is projected to reach approximately $3.5 billion by 2025, driven by oil and gas, chemical processing, and marine applications. Leading companies like POSCO Holdings, NIPPON STEEL, Outokumpu Oyj, and Sandvik are advancing technical solutions for notch sensitivity and fracture challenges through sophisticated inspection methodologies. Research institutions such as Central Iron & Steel Research Institute and Suzhou Nuclear Power Research Institute are collaborating with industry to develop improved fracture mechanics models and non-destructive testing techniques, pushing the technology toward greater maturity and reliability in safety-critical applications.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed an integrated approach to duplex stainless steel fail-safe design addressing notch sensitivity through microstructural optimization. Their methodology focuses on controlling intermetallic phase precipitation through precise chemical composition control and optimized thermomechanical processing. POSCO's research has established correlations between processing parameters and resulting mechanical properties, particularly focusing on the transition from ductile to brittle behavior under various loading conditions. Their fracture mechanics approach incorporates elastic-plastic fracture mechanics (EPFM) principles specifically adapted for the dual-phase microstructure of duplex stainless steels. For inspection, POSCO has implemented multi-frequency eddy current testing combined with advanced pattern recognition algorithms to detect microstructural anomalies that could lead to premature failure. Their fail-safe design methodology incorporates damage tolerance principles with defined inspection intervals based on predicted crack growth rates in specific environmental conditions. This comprehensive approach ensures structural integrity throughout the component lifecycle, particularly in demanding applications like chemical processing equipment and offshore structures.

Strengths: Advanced manufacturing capabilities with tight process control; extensive material testing facilities; strong integration between research and production. Weaknesses: Less extensive global technical support network compared to some European competitors; relatively newer entrant to high-performance duplex grades market.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed a comprehensive technical approach to duplex stainless steel fail-safe design focusing on microstructural engineering to control notch sensitivity. Their methodology includes precise control of ferrite-austenite phase balance (typically maintaining 45-55% ferrite) through carefully regulated alloying elements and thermomechanical processing. They've established proprietary heat treatment protocols that minimize detrimental sigma phase formation while optimizing toughness properties. NIPPON STEEL's fracture mechanics approach incorporates J-integral testing and crack tip opening displacement (CTOD) measurements specifically calibrated for duplex microstructures, allowing accurate prediction of critical flaw sizes. Their inspection technology combines phased array ultrasonic testing with advanced signal processing algorithms designed to account for the anisotropic nature of duplex microstructures. This enables reliable detection of potential crack initiation sites even in complex geometries. Their integrated design approach includes material selection guidelines based on environmental factors, stress states, and service temperatures to ensure long-term structural integrity in critical applications.

Strengths: Extensive metallurgical expertise with dedicated research facilities for duplex stainless steel development; comprehensive material characterization capabilities; established quality control systems. Weaknesses: Conservative design approaches may result in material overspecification in some applications; limited flexibility in customizing solutions for unique applications.

Critical Technologies in Notch Sensitivity and Fracture Analysis

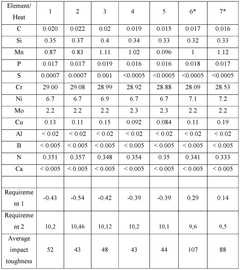

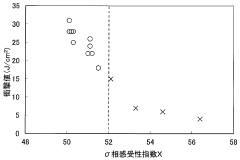

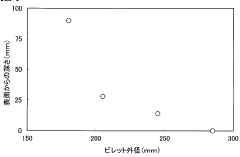

A duplex stainless steel and use thereof

PatentWO2025012182A1

Innovation

- A duplex stainless steel composition with specific ranges of C < 0.030, Si < 0.5, Cr 28.0-29.0, Ni 7.1-7.8, Mo 2.0-3.0, N 0.30-0.36, Cu < 1.0, S < 0.02, P < 0.03, balance Fe, and unavoidable impurities, which enhances impact toughness, ductility, and structural stability, ensuring corrosion resistance and mechanical properties at low temperatures.

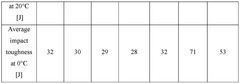

Duplex stainless steel sheet

PatentWO2012121232A1

Innovation

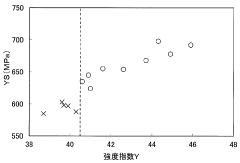

- Adjusting the chemical composition to satisfy specific indices for σ-phase sensitivity and strength, including elements like Si, Cu, Ni, Cr, Mo, W, and N, to suppress σ-phase precipitation and enhance machinability and strength, while maintaining corrosion resistance.

Non-Destructive Inspection Methodologies for Duplex Steel

Non-destructive inspection (NDI) methodologies play a crucial role in ensuring the structural integrity of duplex stainless steel components, particularly in fail-safe design applications. These inspection techniques allow for the detection of potential defects without compromising the material's functionality or structural integrity.

Ultrasonic Testing (UT) stands as one of the primary NDI methods for duplex steel inspection. Advanced techniques such as Phased Array Ultrasonic Testing (PAUT) and Time-of-Flight Diffraction (TOFD) have demonstrated exceptional capability in detecting subsurface flaws, particularly in weld regions where notch sensitivity is a concern. These methods can identify crack initiation sites before they propagate to critical dimensions.

Radiographic Testing (RT) provides complementary capabilities by offering visual representation of internal structures. Digital radiography has significantly enhanced detection sensitivity for duplex steel components, allowing for the identification of minute discontinuities that might serve as fracture initiation points. This technique is particularly valuable for thick-section duplex steel components where ultrasonic penetration may be limited.

Eddy Current Testing (ECT) has proven effective for surface and near-surface inspection of duplex stainless steel. Recent advancements in multi-frequency ECT systems have improved the ability to differentiate between harmless surface anomalies and potentially dangerous crack formations, addressing the unique microstructural characteristics of duplex steel's dual-phase composition.

Magnetic Particle Inspection (MPI) and Dye Penetrant Testing (DPT) remain valuable for surface inspection, though their application requires careful consideration of the duplex steel's magnetic properties and surface condition. These methods are particularly useful for field inspections where more sophisticated equipment may not be readily available.

Acoustic Emission (AE) monitoring represents an emerging technology for continuous assessment of duplex steel components under load. This technique can detect active crack growth in real-time, providing early warning of potential failures before they reach critical dimensions. When integrated with strain monitoring systems, AE offers a comprehensive approach to structural health monitoring.

Recent developments in guided wave technologies have expanded inspection capabilities for duplex steel piping systems, allowing for rapid screening of long pipe sections from a single access point. This approach significantly reduces inspection time while maintaining high detection sensitivity for critical defects.

The selection of appropriate NDI methodologies must consider the specific failure mechanisms associated with duplex stainless steel, particularly its notch sensitivity characteristics and potential fracture modes. A multi-method approach often provides the most comprehensive assessment, combining the strengths of various inspection techniques to ensure reliable detection of all potential defect types.

Ultrasonic Testing (UT) stands as one of the primary NDI methods for duplex steel inspection. Advanced techniques such as Phased Array Ultrasonic Testing (PAUT) and Time-of-Flight Diffraction (TOFD) have demonstrated exceptional capability in detecting subsurface flaws, particularly in weld regions where notch sensitivity is a concern. These methods can identify crack initiation sites before they propagate to critical dimensions.

Radiographic Testing (RT) provides complementary capabilities by offering visual representation of internal structures. Digital radiography has significantly enhanced detection sensitivity for duplex steel components, allowing for the identification of minute discontinuities that might serve as fracture initiation points. This technique is particularly valuable for thick-section duplex steel components where ultrasonic penetration may be limited.

Eddy Current Testing (ECT) has proven effective for surface and near-surface inspection of duplex stainless steel. Recent advancements in multi-frequency ECT systems have improved the ability to differentiate between harmless surface anomalies and potentially dangerous crack formations, addressing the unique microstructural characteristics of duplex steel's dual-phase composition.

Magnetic Particle Inspection (MPI) and Dye Penetrant Testing (DPT) remain valuable for surface inspection, though their application requires careful consideration of the duplex steel's magnetic properties and surface condition. These methods are particularly useful for field inspections where more sophisticated equipment may not be readily available.

Acoustic Emission (AE) monitoring represents an emerging technology for continuous assessment of duplex steel components under load. This technique can detect active crack growth in real-time, providing early warning of potential failures before they reach critical dimensions. When integrated with strain monitoring systems, AE offers a comprehensive approach to structural health monitoring.

Recent developments in guided wave technologies have expanded inspection capabilities for duplex steel piping systems, allowing for rapid screening of long pipe sections from a single access point. This approach significantly reduces inspection time while maintaining high detection sensitivity for critical defects.

The selection of appropriate NDI methodologies must consider the specific failure mechanisms associated with duplex stainless steel, particularly its notch sensitivity characteristics and potential fracture modes. A multi-method approach often provides the most comprehensive assessment, combining the strengths of various inspection techniques to ensure reliable detection of all potential defect types.

Risk Assessment Frameworks for Duplex Steel Structural Applications

Risk assessment frameworks for duplex stainless steel structural applications require comprehensive methodologies that address the unique properties and potential failure modes of these materials. Current frameworks typically integrate probabilistic risk assessment (PRA) with deterministic analysis to evaluate structural integrity under various operating conditions.

The ASME Boiler and Pressure Vessel Code Section VIII and API 579-1/ASME FFS-1 provide foundational assessment protocols specifically adapted for duplex stainless steels, incorporating factors such as notch sensitivity and fracture mechanics principles. These frameworks establish hierarchical assessment levels, progressing from conservative screening criteria to detailed engineering evaluations.

For offshore and marine applications, DNVGL-RP-F112 and NORSOK M-001 standards offer specialized risk assessment guidelines that account for the environmental factors affecting duplex steel performance, including seawater exposure and cathodic protection effects on hydrogen embrittlement susceptibility.

Fitness-for-Service (FFS) methodologies have evolved to include specific considerations for duplex stainless steels, particularly addressing the phase balance sensitivity and its impact on mechanical properties. These frameworks incorporate damage tolerance approaches that quantify acceptable flaw sizes based on fracture mechanics principles and material-specific crack growth rates.

Recent advancements in risk assessment frameworks include Bayesian network models that integrate inspection data with material degradation models, enabling more accurate prediction of remaining useful life. These probabilistic approaches account for uncertainties in material properties, loading conditions, and environmental factors that influence duplex steel performance.

Structural reliability analysis (SRA) techniques have been specifically tailored for duplex stainless steel applications, incorporating limit state functions that address both brittle and ductile failure modes. These frameworks typically employ Monte Carlo simulations or First/Second Order Reliability Methods (FORM/SORM) to calculate failure probabilities under various operational scenarios.

Risk-based inspection (RBI) methodologies for duplex stainless steel structures have evolved to incorporate advanced non-destructive testing techniques, including phased array ultrasonics and guided wave testing, which are particularly effective for detecting phase imbalance and localized corrosion in weld heat-affected zones.

Industry-specific frameworks have emerged for critical applications such as nuclear power components, subsea oil and gas equipment, and chemical processing facilities, where the consequences of failure demand more stringent risk assessment protocols and safety margins for duplex stainless steel components.

The ASME Boiler and Pressure Vessel Code Section VIII and API 579-1/ASME FFS-1 provide foundational assessment protocols specifically adapted for duplex stainless steels, incorporating factors such as notch sensitivity and fracture mechanics principles. These frameworks establish hierarchical assessment levels, progressing from conservative screening criteria to detailed engineering evaluations.

For offshore and marine applications, DNVGL-RP-F112 and NORSOK M-001 standards offer specialized risk assessment guidelines that account for the environmental factors affecting duplex steel performance, including seawater exposure and cathodic protection effects on hydrogen embrittlement susceptibility.

Fitness-for-Service (FFS) methodologies have evolved to include specific considerations for duplex stainless steels, particularly addressing the phase balance sensitivity and its impact on mechanical properties. These frameworks incorporate damage tolerance approaches that quantify acceptable flaw sizes based on fracture mechanics principles and material-specific crack growth rates.

Recent advancements in risk assessment frameworks include Bayesian network models that integrate inspection data with material degradation models, enabling more accurate prediction of remaining useful life. These probabilistic approaches account for uncertainties in material properties, loading conditions, and environmental factors that influence duplex steel performance.

Structural reliability analysis (SRA) techniques have been specifically tailored for duplex stainless steel applications, incorporating limit state functions that address both brittle and ductile failure modes. These frameworks typically employ Monte Carlo simulations or First/Second Order Reliability Methods (FORM/SORM) to calculate failure probabilities under various operational scenarios.

Risk-based inspection (RBI) methodologies for duplex stainless steel structures have evolved to incorporate advanced non-destructive testing techniques, including phased array ultrasonics and guided wave testing, which are particularly effective for detecting phase imbalance and localized corrosion in weld heat-affected zones.

Industry-specific frameworks have emerged for critical applications such as nuclear power components, subsea oil and gas equipment, and chemical processing facilities, where the consequences of failure demand more stringent risk assessment protocols and safety margins for duplex stainless steel components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!