Duplex Stainless Steel Thermal Cycles: Sensitization, Embrittlement And Recovery

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Steel Thermal History and Research Objectives

Duplex stainless steels (DSS) have evolved significantly since their inception in the early 20th century. The first patent for duplex steel was granted in 1927 to Bain and Griffith, with the initial commercial production beginning in the 1930s. These early duplex alloys contained approximately equal amounts of austenite and ferrite phases, providing a combination of strength and corrosion resistance superior to conventional austenitic stainless steels.

The development trajectory of DSS can be divided into distinct generations. First-generation duplex steels (1930s-1960s) faced limitations in weldability and post-weld mechanical properties due to ferrite-austenite phase imbalances. The second generation emerged in the 1970s with the introduction of nitrogen as an alloying element, significantly improving weldability and corrosion resistance, particularly in chloride environments.

The 1980s marked a pivotal advancement with the development of super duplex stainless steels (SDSS), characterized by higher chromium, molybdenum, and nitrogen content. These alloys offered exceptional resistance to pitting and crevice corrosion in aggressive environments, expanding application possibilities in offshore oil and gas, chemical processing, and marine industries.

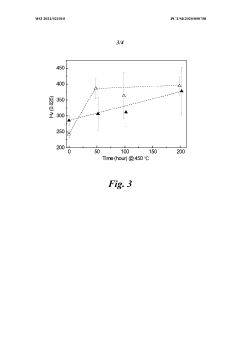

Thermal cycling effects on duplex stainless steels represent a critical area of concern that has gained increasing attention since the 1990s. When exposed to temperatures between 300°C and 1000°C during manufacturing processes or service conditions, DSS can experience microstructural changes leading to sensitization and embrittlement. These phenomena significantly impact mechanical properties and corrosion resistance, potentially causing premature failure in critical applications.

Current research objectives focus on understanding the complex phase transformations during thermal cycling, particularly the precipitation of detrimental intermetallic phases such as sigma (σ), chi (χ), and chromium nitrides. The formation kinetics of these phases and their relationship with alloy composition, temperature ranges, and exposure times remain incompletely understood despite decades of research.

Another key research goal involves developing predictive models for microstructural evolution during thermal cycling. Such models would enable more accurate estimation of material degradation and remaining service life for components subjected to thermal fluctuations. Additionally, researchers aim to establish optimized heat treatment protocols for recovery of properties after sensitization or embrittlement has occurred.

The ultimate objective is to develop next-generation duplex stainless steels with enhanced thermal stability while maintaining or improving their exceptional combination of mechanical properties and corrosion resistance. This would expand their application range to higher temperature environments and more demanding service conditions, potentially creating new market opportunities across multiple industries.

The development trajectory of DSS can be divided into distinct generations. First-generation duplex steels (1930s-1960s) faced limitations in weldability and post-weld mechanical properties due to ferrite-austenite phase imbalances. The second generation emerged in the 1970s with the introduction of nitrogen as an alloying element, significantly improving weldability and corrosion resistance, particularly in chloride environments.

The 1980s marked a pivotal advancement with the development of super duplex stainless steels (SDSS), characterized by higher chromium, molybdenum, and nitrogen content. These alloys offered exceptional resistance to pitting and crevice corrosion in aggressive environments, expanding application possibilities in offshore oil and gas, chemical processing, and marine industries.

Thermal cycling effects on duplex stainless steels represent a critical area of concern that has gained increasing attention since the 1990s. When exposed to temperatures between 300°C and 1000°C during manufacturing processes or service conditions, DSS can experience microstructural changes leading to sensitization and embrittlement. These phenomena significantly impact mechanical properties and corrosion resistance, potentially causing premature failure in critical applications.

Current research objectives focus on understanding the complex phase transformations during thermal cycling, particularly the precipitation of detrimental intermetallic phases such as sigma (σ), chi (χ), and chromium nitrides. The formation kinetics of these phases and their relationship with alloy composition, temperature ranges, and exposure times remain incompletely understood despite decades of research.

Another key research goal involves developing predictive models for microstructural evolution during thermal cycling. Such models would enable more accurate estimation of material degradation and remaining service life for components subjected to thermal fluctuations. Additionally, researchers aim to establish optimized heat treatment protocols for recovery of properties after sensitization or embrittlement has occurred.

The ultimate objective is to develop next-generation duplex stainless steels with enhanced thermal stability while maintaining or improving their exceptional combination of mechanical properties and corrosion resistance. This would expand their application range to higher temperature environments and more demanding service conditions, potentially creating new market opportunities across multiple industries.

Market Applications and Industry Demand Analysis

Duplex stainless steels (DSS) have experienced significant market growth due to their exceptional combination of strength and corrosion resistance, with the global market valued at approximately 3.2 billion USD in 2022 and projected to reach 4.5 billion USD by 2028. This growth is primarily driven by increasing demand from critical industries where material failure can lead to catastrophic consequences.

The oil and gas sector represents the largest application market for DSS, accounting for roughly 35% of total consumption. In this sector, DSS components are exposed to extreme thermal cycles during welding, repair operations, and operational temperature fluctuations. The industry's growing focus on deep-sea exploration and extraction in highly corrosive environments has intensified demand for materials that can withstand thermal cycling without compromising structural integrity.

Chemical processing industries constitute the second-largest market segment, where DSS is utilized in reactors, heat exchangers, and storage tanks. These applications frequently subject materials to thermal cycling during batch processing operations, creating significant concerns regarding sensitization and embrittlement phenomena. Market research indicates that unplanned downtime due to material failure in this sector costs approximately 50,000 USD per hour, highlighting the economic importance of understanding thermal cycle effects.

The power generation sector, particularly nuclear and renewable energy facilities, represents a rapidly growing market for DSS applications. In nuclear plants, DSS components must maintain structural integrity despite thermal cycling during normal operation and potential emergency scenarios. The renewable energy sector, especially concentrated solar power systems, subjects materials to daily thermal cycles that can accelerate degradation mechanisms.

Marine and desalination industries have also emerged as significant consumers of DSS, with seawater applications requiring materials that can withstand both corrosive environments and thermal fluctuations. The global desalination market is expanding at approximately 9% annually, creating substantial demand for corrosion-resistant materials that maintain performance through repeated thermal cycles.

Industry surveys indicate that approximately 65% of end-users consider improved understanding of thermal cycle effects on DSS as "highly important" or "critical" for their material selection processes. This market demand is further evidenced by increasing research funding from both private industry and government agencies, with thermal cycling behavior being identified as a top research priority by major industry associations representing metallurgical and materials engineering sectors.

The oil and gas sector represents the largest application market for DSS, accounting for roughly 35% of total consumption. In this sector, DSS components are exposed to extreme thermal cycles during welding, repair operations, and operational temperature fluctuations. The industry's growing focus on deep-sea exploration and extraction in highly corrosive environments has intensified demand for materials that can withstand thermal cycling without compromising structural integrity.

Chemical processing industries constitute the second-largest market segment, where DSS is utilized in reactors, heat exchangers, and storage tanks. These applications frequently subject materials to thermal cycling during batch processing operations, creating significant concerns regarding sensitization and embrittlement phenomena. Market research indicates that unplanned downtime due to material failure in this sector costs approximately 50,000 USD per hour, highlighting the economic importance of understanding thermal cycle effects.

The power generation sector, particularly nuclear and renewable energy facilities, represents a rapidly growing market for DSS applications. In nuclear plants, DSS components must maintain structural integrity despite thermal cycling during normal operation and potential emergency scenarios. The renewable energy sector, especially concentrated solar power systems, subjects materials to daily thermal cycles that can accelerate degradation mechanisms.

Marine and desalination industries have also emerged as significant consumers of DSS, with seawater applications requiring materials that can withstand both corrosive environments and thermal fluctuations. The global desalination market is expanding at approximately 9% annually, creating substantial demand for corrosion-resistant materials that maintain performance through repeated thermal cycles.

Industry surveys indicate that approximately 65% of end-users consider improved understanding of thermal cycle effects on DSS as "highly important" or "critical" for their material selection processes. This market demand is further evidenced by increasing research funding from both private industry and government agencies, with thermal cycling behavior being identified as a top research priority by major industry associations representing metallurgical and materials engineering sectors.

Current Challenges in Duplex Steel Heat Treatment

Despite significant advancements in duplex stainless steel (DSS) heat treatment technologies, several critical challenges persist that impact manufacturing quality and long-term performance. The primary challenge lies in controlling the delicate balance between ferrite and austenite phases during thermal processing. Even minor deviations in temperature profiles can lead to undesirable microstructural changes, including excessive ferrite formation or precipitation of detrimental intermetallic phases.

Sensitization remains a significant concern during heat treatment, particularly in the temperature range of 650-950°C. In this critical range, chromium carbides precipitate at grain boundaries, creating chromium-depleted zones susceptible to corrosion. Modern production facilities struggle to implement precise cooling rates that minimize the time spent in this sensitization temperature range, especially for complex geometries and varying section thicknesses.

The formation of embrittling phases such as sigma (σ), chi (χ), and alpha prime (α') presents another substantial challenge. These phases form during prolonged exposure to temperatures between 700-950°C and severely compromise mechanical properties and corrosion resistance. Current heat treatment protocols often fail to completely eliminate the risk of these formations, particularly in components with complex geometries where uniform cooling cannot be guaranteed.

Hydrogen embrittlement susceptibility increases during improper heat treatment, creating additional complications. The dual-phase microstructure of DSS creates numerous interfaces that can trap hydrogen, leading to delayed cracking phenomena that may not manifest until the material is in service. Existing degassing treatments are not consistently effective across all DSS grades and geometries.

Recovery heat treatments designed to restore properties after sensitization or embrittlement face their own challenges. The narrow processing windows required for effective recovery without introducing new microstructural issues demand extremely precise temperature control that exceeds the capabilities of many industrial furnaces. Temperature uniformity across large components remains particularly problematic.

Quality control presents additional difficulties, as conventional non-destructive testing methods often fail to detect microscopic phase imbalances or early-stage sensitization. This limitation forces manufacturers to rely on destructive testing of sample pieces, which may not accurately represent the condition of the entire component.

Furthermore, the increasing trend toward lean duplex grades with reduced nickel content has introduced new heat treatment challenges, as these grades exhibit different phase transformation kinetics and narrower processing windows compared to traditional DSS compositions.

Sensitization remains a significant concern during heat treatment, particularly in the temperature range of 650-950°C. In this critical range, chromium carbides precipitate at grain boundaries, creating chromium-depleted zones susceptible to corrosion. Modern production facilities struggle to implement precise cooling rates that minimize the time spent in this sensitization temperature range, especially for complex geometries and varying section thicknesses.

The formation of embrittling phases such as sigma (σ), chi (χ), and alpha prime (α') presents another substantial challenge. These phases form during prolonged exposure to temperatures between 700-950°C and severely compromise mechanical properties and corrosion resistance. Current heat treatment protocols often fail to completely eliminate the risk of these formations, particularly in components with complex geometries where uniform cooling cannot be guaranteed.

Hydrogen embrittlement susceptibility increases during improper heat treatment, creating additional complications. The dual-phase microstructure of DSS creates numerous interfaces that can trap hydrogen, leading to delayed cracking phenomena that may not manifest until the material is in service. Existing degassing treatments are not consistently effective across all DSS grades and geometries.

Recovery heat treatments designed to restore properties after sensitization or embrittlement face their own challenges. The narrow processing windows required for effective recovery without introducing new microstructural issues demand extremely precise temperature control that exceeds the capabilities of many industrial furnaces. Temperature uniformity across large components remains particularly problematic.

Quality control presents additional difficulties, as conventional non-destructive testing methods often fail to detect microscopic phase imbalances or early-stage sensitization. This limitation forces manufacturers to rely on destructive testing of sample pieces, which may not accurately represent the condition of the entire component.

Furthermore, the increasing trend toward lean duplex grades with reduced nickel content has introduced new heat treatment challenges, as these grades exhibit different phase transformation kinetics and narrower processing windows compared to traditional DSS compositions.

Established Thermal Processing Solutions

01 Mechanisms of sensitization in duplex stainless steel

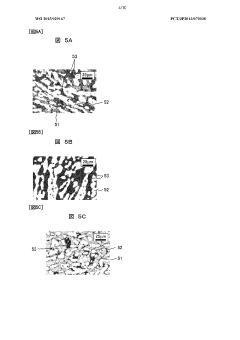

Sensitization in duplex stainless steel occurs primarily through chromium depletion at grain boundaries due to the precipitation of chromium-rich phases. This process typically happens at elevated temperatures (450-950°C) and leads to reduced corrosion resistance. The formation of intermetallic phases such as sigma, chi, and chromium carbides/nitrides contributes to the sensitization phenomenon. The dual microstructure of ferrite and austenite phases in duplex stainless steel makes it susceptible to different sensitization mechanisms compared to conventional stainless steels.- Mechanisms of sensitization in duplex stainless steel: Sensitization in duplex stainless steel occurs primarily through chromium depletion at grain boundaries due to the precipitation of chromium-rich phases. This process typically happens at elevated temperatures (450-950°C) and leads to reduced corrosion resistance. The formation of secondary phases such as sigma, chi, and chromium carbides/nitrides contributes to the sensitization phenomenon. The dual microstructure of ferrite and austenite phases in duplex stainless steel makes it particularly susceptible to sensitization when exposed to critical temperature ranges during processing or service.

- Embrittlement mechanisms and prevention in duplex stainless steel: Embrittlement in duplex stainless steel can occur through various mechanisms including 475°C embrittlement (spinodal decomposition of ferrite), hydrogen embrittlement, and intermetallic phase precipitation. These phenomena result in reduced impact toughness, decreased ductility, and increased susceptibility to cracking. Prevention strategies include controlled cooling rates during processing, optimized heat treatment cycles, and careful control of alloying elements such as nitrogen, molybdenum, and chromium. Maintaining proper ferrite-austenite phase balance is also critical to minimize embrittlement susceptibility.

- Heat treatment processes for recovery of embrittled duplex stainless steel: Recovery of embrittled duplex stainless steel can be achieved through specific heat treatment processes. Solution annealing at temperatures between 1050-1150°C followed by rapid cooling helps dissolve detrimental precipitates and restore the optimal phase balance. For components affected by 475°C embrittlement, heating above 600°C can reverse the spinodal decomposition. Post-weld heat treatments are particularly important to restore properties in heat-affected zones. The effectiveness of recovery treatments depends on the extent of embrittlement, the specific grade of duplex stainless steel, and the precise temperature-time parameters employed.

- Influence of alloying elements on sensitization and embrittlement resistance: The composition of duplex stainless steel significantly affects its susceptibility to sensitization and embrittlement. Higher chromium, molybdenum, and nitrogen contents generally improve resistance to sensitization by promoting stable austenite formation and delaying intermetallic precipitation. However, excessive molybdenum can accelerate sigma phase formation at certain temperatures. Elements like tungsten and copper can be added to enhance specific properties while maintaining resistance to embrittlement. Carbon content is typically kept low to minimize chromium carbide precipitation. Proper balance of ferrite-promoting and austenite-promoting elements is essential for optimal performance.

- Testing and evaluation methods for sensitization and embrittlement: Various testing methods are employed to evaluate sensitization and embrittlement in duplex stainless steel. Electrochemical tests such as Double Loop Electrochemical Potentiokinetic Reactivation (DL-EPR) can quantify the degree of sensitization. Mechanical testing including Charpy impact, tensile, and bend tests help assess embrittlement. Microstructural examination using optical microscopy, scanning electron microscopy, and electron backscatter diffraction provides insights into phase transformations and precipitate formation. Accelerated corrosion tests in specific media can also reveal susceptibility to intergranular corrosion resulting from sensitization. These evaluation methods are crucial for quality control and failure analysis.

02 Embrittlement mechanisms and prevention in duplex stainless steel

Embrittlement in duplex stainless steel can occur through various mechanisms including 475°C embrittlement (spinodal decomposition of ferrite), hydrogen embrittlement, and sigma phase precipitation. These phenomena result in reduced impact toughness, decreased ductility, and increased susceptibility to cracking. Prevention strategies include controlled cooling rates after welding or heat treatment, optimized alloy composition with balanced ferrite-austenite ratios, and limiting exposure to embrittlement-prone temperature ranges. Nitrogen additions can help stabilize the austenite phase and reduce susceptibility to certain types of embrittlement.Expand Specific Solutions03 Heat treatment processes for recovery from sensitization and embrittlement

Recovery from sensitization and embrittlement in duplex stainless steel can be achieved through specific heat treatment processes. Solution annealing at temperatures between 1050-1150°C followed by rapid cooling helps dissolve detrimental precipitates and restore the balanced microstructure. Post-weld heat treatments are particularly important to recover properties after welding-induced sensitization. For recovery from 475°C embrittlement, short-duration high-temperature treatments can reverse the spinodal decomposition. Controlled cooling rates are essential to prevent re-sensitization during the cooling phase of heat treatments.Expand Specific Solutions04 Influence of alloying elements on sensitization and embrittlement resistance

The composition of duplex stainless steel significantly affects its susceptibility to sensitization and embrittlement. Higher chromium, molybdenum, and nitrogen contents generally improve resistance to sensitization by stabilizing the austenite phase and reducing chromium depletion at grain boundaries. However, excessive molybdenum can promote intermetallic phase formation. Elements like tungsten and copper can be added to enhance specific properties but must be carefully balanced. Carbon and nitrogen levels must be controlled to prevent carbide and nitride precipitation that contributes to sensitization. Modern super duplex grades incorporate optimized compositions to minimize these degradation mechanisms.Expand Specific Solutions05 Testing and evaluation methods for sensitization and embrittlement

Various testing methods are employed to evaluate sensitization and embrittlement in duplex stainless steel. Electrochemical tests such as Double Loop Electrochemical Potentiokinetic Reactivation (DL-EPR) can quantify the degree of sensitization. Impact testing at various temperatures helps assess embrittlement. Microstructural examination using optical and electron microscopy reveals precipitate formation and phase distribution. Ferrite content measurements track the phase balance critical to maintaining properties. Non-destructive testing techniques can be used for in-service inspection to detect early signs of degradation before failure occurs.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The duplex stainless steel thermal cycles market is in a growth phase, driven by increasing demand in critical applications requiring both corrosion resistance and mechanical strength. The global market is expanding at approximately 5-7% annually, with major players focusing on understanding sensitization, embrittlement, and recovery mechanisms to enhance product performance. Leading steel manufacturers like NIPPON STEEL, Outokumpu Oyj, and JFE Steel Corp. have established strong positions through advanced R&D capabilities, while specialized research is conducted by academic institutions such as University of Science & Technology Beijing. The technology maturity varies across applications, with established processes for conventional thermal treatments, but ongoing innovation in recovery techniques and microstructure control. Companies like Sandvik Intellectual Property AB and POSCO Holdings are investing in proprietary technologies to address challenges in high-temperature applications.

JFE Steel Corp.

Technical Solution: JFE Steel has developed advanced thermal cycle control technologies for duplex stainless steel (DSS) production that minimize sensitization and embrittlement risks. Their approach involves precise temperature control during hot working and heat treatment processes, utilizing a proprietary cooling rate management system that prevents the formation of detrimental intermetallic phases. JFE's research has established optimal thermal cycle parameters that maintain the balanced ferrite-austenite microstructure (approximately 50:50 ratio) critical for DSS performance. Their technology incorporates in-line monitoring systems that detect microstructural changes during production, allowing real-time adjustments to prevent sensitization. For recovery treatments, JFE employs specialized solution annealing protocols at temperatures between 1050-1150°C followed by controlled rapid cooling, effectively dissolving harmful precipitates while preserving mechanical properties.

Strengths: Superior control of cooling rates during production minimizes sigma and chi phase formation; integrated monitoring systems enable real-time process adjustments; established optimal thermal parameters for specific DSS grades. Weaknesses: Recovery treatments require precise temperature control that may be difficult to achieve in large-scale production; some proprietary techniques may have limited applicability across different DSS compositions.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has pioneered innovative heat treatment protocols specifically designed to address sensitization and embrittlement challenges in duplex stainless steels. Their approach centers on a multi-stage thermal processing technique that carefully controls the precipitation kinetics of detrimental phases. Sandvik's SAF 2507® super duplex stainless steel undergoes proprietary thermal cycling treatments that maintain optimal phase balance while preventing intermetallic precipitation. Their research has identified critical time-temperature-transformation relationships for various DSS grades, enabling precise control of microstructural evolution during manufacturing. Sandvik employs advanced quenching technologies that achieve cooling rates exceeding 50°C/s in critical temperature ranges (950-700°C) where detrimental phases typically form. For recovery treatments, they've developed specialized solution annealing procedures that effectively dissolve harmful precipitates while maintaining mechanical integrity. Their process includes controlled nitrogen management during thermal cycles to stabilize austenite and enhance resistance to embrittlement phenomena.

Strengths: Comprehensive understanding of precipitation kinetics in various DSS grades; proprietary quenching technologies achieve optimal cooling rates; advanced nitrogen management techniques enhance microstructural stability. Weaknesses: High-precision thermal control requirements may increase production costs; recovery treatments may not fully restore properties in severely sensitized materials; techniques optimized for their proprietary alloys may have limited transferability.

Critical Patents and Research on Sensitization Mechanisms

Duplex stainless steel, and duplex stainless steel structure, marine structure, petroleum/gas environment structure, pump impeller, pump casing, and flow adjustment valve body using same

PatentWO2015029167A1

Innovation

- The composition of duplex stainless steel is optimized by limiting nitrogen to 0.3% or less and adding tantalum (Ta) to inhibit the diffusion of intermetallic compound-forming elements, thereby suppressing the formation of embrittlement phases, ensuring improved corrosion resistance, embrittlement resistance, manufacturability, weldability, and heat treatability.

Duplex stainless steel with improved embrittlement properties and method of producing such

PatentWO2021021010A1

Innovation

- A heat treatment method involving isothermal heating of DSS at 750 to 900 °C for 10 seconds to 10 minutes, followed by rapid quenching, effectively slows down the embrittlement process and improves the resistance to 475 °C embrittlement by maintaining the ductility and toughness of the steel.

Corrosion Resistance Enhancement Strategies

Enhancing the corrosion resistance of duplex stainless steels (DSS) after thermal cycling requires strategic approaches that address the microstructural changes occurring during sensitization and embrittlement processes. Surface modification techniques represent a primary strategy, with controlled shot peening introducing compressive residual stresses that impede crack propagation and enhance resistance to stress corrosion cracking. This mechanical treatment creates a nanocrystalline surface layer that improves passivation behavior and overall corrosion resistance.

Advanced coating technologies offer another effective approach, particularly the application of chromium-rich or molybdenum-enhanced protective layers that compensate for chromium depletion in sensitized regions. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods can create uniform, adherent coatings that significantly extend the service life of thermally cycled DSS components in aggressive environments.

Post-weld heat treatments (PWHT) play a crucial role in recovering corrosion resistance after welding or other thermal processes. Carefully controlled solution annealing at temperatures between 1050°C and 1100°C, followed by rapid cooling, can dissolve detrimental precipitates and restore the optimal phase balance. For components that cannot undergo full solution annealing, localized heat treatments using induction heating or laser processing offer targeted recovery of affected zones.

Electrochemical techniques provide both preventive and remedial options for corrosion resistance enhancement. Electropolishing removes the surface layer affected by sensitization, while electrochemical passivation treatments promote the formation of stable protective oxide films. These treatments are particularly valuable for components with complex geometries where mechanical surface treatments may be challenging to apply uniformly.

Alloying modifications represent a fundamental approach to improving DSS corrosion resistance during thermal cycling. Increasing nitrogen content enhances pitting resistance and stabilizes austenite, while controlled additions of tungsten and copper improve resistance to reducing environments. Modern alloy design increasingly focuses on optimizing the PREN (Pitting Resistance Equivalent Number) while maintaining favorable mechanical properties and phase balance.

Inhibitor technologies offer practical solutions for in-service protection, with vapor phase inhibitors providing protection during storage or transportation and liquid phase inhibitors being incorporated into process fluids. Recent developments in "smart" inhibitor systems can respond to environmental changes, releasing protective compounds when corrosion conditions are detected, offering adaptive protection for DSS components experiencing variable service conditions.

Advanced coating technologies offer another effective approach, particularly the application of chromium-rich or molybdenum-enhanced protective layers that compensate for chromium depletion in sensitized regions. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods can create uniform, adherent coatings that significantly extend the service life of thermally cycled DSS components in aggressive environments.

Post-weld heat treatments (PWHT) play a crucial role in recovering corrosion resistance after welding or other thermal processes. Carefully controlled solution annealing at temperatures between 1050°C and 1100°C, followed by rapid cooling, can dissolve detrimental precipitates and restore the optimal phase balance. For components that cannot undergo full solution annealing, localized heat treatments using induction heating or laser processing offer targeted recovery of affected zones.

Electrochemical techniques provide both preventive and remedial options for corrosion resistance enhancement. Electropolishing removes the surface layer affected by sensitization, while electrochemical passivation treatments promote the formation of stable protective oxide films. These treatments are particularly valuable for components with complex geometries where mechanical surface treatments may be challenging to apply uniformly.

Alloying modifications represent a fundamental approach to improving DSS corrosion resistance during thermal cycling. Increasing nitrogen content enhances pitting resistance and stabilizes austenite, while controlled additions of tungsten and copper improve resistance to reducing environments. Modern alloy design increasingly focuses on optimizing the PREN (Pitting Resistance Equivalent Number) while maintaining favorable mechanical properties and phase balance.

Inhibitor technologies offer practical solutions for in-service protection, with vapor phase inhibitors providing protection during storage or transportation and liquid phase inhibitors being incorporated into process fluids. Recent developments in "smart" inhibitor systems can respond to environmental changes, releasing protective compounds when corrosion conditions are detected, offering adaptive protection for DSS components experiencing variable service conditions.

Mechanical Property Testing and Quality Control Methods

The mechanical property testing of duplex stainless steels (DSS) subjected to thermal cycles requires comprehensive methodologies to accurately assess the material's integrity. Tensile testing serves as a fundamental approach, measuring yield strength, ultimate tensile strength, and elongation to evaluate how sensitization and embrittlement affect the material's load-bearing capacity. These parameters typically show degradation after detrimental thermal cycles, with recovery treatments potentially restoring some of these properties.

Impact testing, particularly Charpy V-notch testing, provides critical insights into the toughness degradation caused by thermal embrittlement. The ductile-to-brittle transition temperature often shifts to higher values after sensitization, making this test essential for applications in varying temperature environments. For more precise fracture behavior assessment, fracture toughness testing using J-integral or CTOD methods reveals how crack propagation resistance changes through thermal cycling.

Hardness testing offers a rapid, non-destructive screening method that correlates well with embrittlement phenomena. Microhardness mapping across phase boundaries can detect localized property changes that might be missed in bulk testing. Ferritoscope measurements complement these tests by quantifying ferrite content changes during thermal cycles, as phase balance significantly influences mechanical properties.

For quality control purposes, standardized procedures following ASTM A923, ASTM A262, and ISO 17781 provide consistent evaluation frameworks. These standards include methods for detecting detrimental intermetallic phases and assessing corrosion resistance alongside mechanical properties. Ultrasonic testing and eddy current techniques enable non-destructive evaluation of thermally cycled components, particularly valuable for in-service inspection of critical infrastructure.

Advanced characterization techniques like EBSD (Electron Backscatter Diffraction) allow for microstructural correlation with mechanical properties, revealing how phase transformations during thermal cycling affect mechanical behavior. Digital image correlation during mechanical testing provides strain field visualization, highlighting localized deformation that may indicate embrittlement.

Statistical process control methods are increasingly implemented in production environments, establishing control limits for key mechanical properties and enabling early detection of thermal cycle-induced degradation. Machine learning algorithms are being developed to predict mechanical property changes based on thermal history parameters, potentially revolutionizing quality control approaches for duplex stainless steels in critical applications.

Impact testing, particularly Charpy V-notch testing, provides critical insights into the toughness degradation caused by thermal embrittlement. The ductile-to-brittle transition temperature often shifts to higher values after sensitization, making this test essential for applications in varying temperature environments. For more precise fracture behavior assessment, fracture toughness testing using J-integral or CTOD methods reveals how crack propagation resistance changes through thermal cycling.

Hardness testing offers a rapid, non-destructive screening method that correlates well with embrittlement phenomena. Microhardness mapping across phase boundaries can detect localized property changes that might be missed in bulk testing. Ferritoscope measurements complement these tests by quantifying ferrite content changes during thermal cycles, as phase balance significantly influences mechanical properties.

For quality control purposes, standardized procedures following ASTM A923, ASTM A262, and ISO 17781 provide consistent evaluation frameworks. These standards include methods for detecting detrimental intermetallic phases and assessing corrosion resistance alongside mechanical properties. Ultrasonic testing and eddy current techniques enable non-destructive evaluation of thermally cycled components, particularly valuable for in-service inspection of critical infrastructure.

Advanced characterization techniques like EBSD (Electron Backscatter Diffraction) allow for microstructural correlation with mechanical properties, revealing how phase transformations during thermal cycling affect mechanical behavior. Digital image correlation during mechanical testing provides strain field visualization, highlighting localized deformation that may indicate embrittlement.

Statistical process control methods are increasingly implemented in production environments, establishing control limits for key mechanical properties and enabling early detection of thermal cycle-induced degradation. Machine learning algorithms are being developed to predict mechanical property changes based on thermal history parameters, potentially revolutionizing quality control approaches for duplex stainless steels in critical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!