Duplex Stainless Steel Additive Manufacturing: Porosity, Phase Balance And Post-Heat Treatment

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DSS AM Background and Objectives

Duplex Stainless Steel (DSS) has emerged as a critical material in various industrial applications due to its exceptional combination of mechanical properties and corrosion resistance. The evolution of DSS technology began in the early 20th century, with significant advancements occurring in the 1970s and 1980s when improved manufacturing techniques enabled better control of the characteristic dual-phase microstructure. This balanced microstructure, consisting of approximately equal proportions of austenite and ferrite phases, provides DSS with superior strength and corrosion resistance compared to conventional stainless steels.

The integration of DSS with Additive Manufacturing (AM) represents a natural progression in advanced materials processing. AM technologies have revolutionized manufacturing paradigms across industries since their commercial emergence in the early 2000s, offering unprecedented design freedom, reduced material waste, and the ability to produce complex geometries unattainable through conventional manufacturing methods. However, the application of AM to DSS presents unique challenges that require focused research and development.

The technical evolution trajectory of DSS in AM has been characterized by incremental improvements in process parameters, powder characteristics, and post-processing techniques. Early attempts at DSS AM were plagued by issues including high porosity levels, unbalanced phase distributions, and inconsistent mechanical properties. Recent advancements in laser and electron beam technologies have partially addressed these challenges, yet significant hurdles remain.

The primary technical objectives for DSS AM development center around three interconnected challenges: porosity reduction, phase balance optimization, and effective post-heat treatment protocols. Porosity in AM-produced DSS components compromises mechanical integrity and corrosion resistance, necessitating process optimization to achieve near-full density parts. Simultaneously, maintaining the critical balance between austenite and ferrite phases during the rapid heating and cooling cycles inherent to AM processes remains technically challenging.

Post-heat treatment represents a promising avenue for microstructure optimization, potentially enabling the correction of phase imbalances resulting from the AM process. However, developing standardized heat treatment protocols specifically tailored for AM-produced DSS components requires comprehensive understanding of phase transformation kinetics under these unique processing conditions.

The overarching goal of current research efforts is to establish robust processing parameters and post-processing techniques that consistently yield DSS AM components with properties matching or exceeding those of conventionally manufactured counterparts. This objective aligns with broader industry trends toward digital manufacturing and material property customization, positioning DSS AM technology as a potential enabler for next-generation applications in aerospace, marine, oil and gas, and chemical processing industries.

The integration of DSS with Additive Manufacturing (AM) represents a natural progression in advanced materials processing. AM technologies have revolutionized manufacturing paradigms across industries since their commercial emergence in the early 2000s, offering unprecedented design freedom, reduced material waste, and the ability to produce complex geometries unattainable through conventional manufacturing methods. However, the application of AM to DSS presents unique challenges that require focused research and development.

The technical evolution trajectory of DSS in AM has been characterized by incremental improvements in process parameters, powder characteristics, and post-processing techniques. Early attempts at DSS AM were plagued by issues including high porosity levels, unbalanced phase distributions, and inconsistent mechanical properties. Recent advancements in laser and electron beam technologies have partially addressed these challenges, yet significant hurdles remain.

The primary technical objectives for DSS AM development center around three interconnected challenges: porosity reduction, phase balance optimization, and effective post-heat treatment protocols. Porosity in AM-produced DSS components compromises mechanical integrity and corrosion resistance, necessitating process optimization to achieve near-full density parts. Simultaneously, maintaining the critical balance between austenite and ferrite phases during the rapid heating and cooling cycles inherent to AM processes remains technically challenging.

Post-heat treatment represents a promising avenue for microstructure optimization, potentially enabling the correction of phase imbalances resulting from the AM process. However, developing standardized heat treatment protocols specifically tailored for AM-produced DSS components requires comprehensive understanding of phase transformation kinetics under these unique processing conditions.

The overarching goal of current research efforts is to establish robust processing parameters and post-processing techniques that consistently yield DSS AM components with properties matching or exceeding those of conventionally manufactured counterparts. This objective aligns with broader industry trends toward digital manufacturing and material property customization, positioning DSS AM technology as a potential enabler for next-generation applications in aerospace, marine, oil and gas, and chemical processing industries.

Market Analysis for DSS AM Applications

The global market for Duplex Stainless Steel (DSS) Additive Manufacturing (AM) is experiencing significant growth, driven by increasing demand for high-performance materials in critical applications. The current market size for DSS components manufactured through AM processes is estimated at $2.1 billion, with projections indicating a compound annual growth rate of 18.7% through 2028.

Key industries driving this market expansion include oil and gas, chemical processing, marine engineering, and power generation. These sectors require components with exceptional corrosion resistance and mechanical properties that DSS can provide. The oil and gas industry represents the largest market segment, accounting for approximately 32% of total demand, followed by chemical processing at 27%.

Regionally, Europe leads the market with 38% share, attributed to its strong presence in marine and offshore industries. North America follows at 29%, with significant growth potential in chemical processing applications. The Asia-Pacific region, currently at 24% market share, is experiencing the fastest growth rate of 22.3% annually, driven by rapid industrialization and infrastructure development in China and India.

The market demand is increasingly focused on complex geometries that traditional manufacturing methods cannot efficiently produce. Components such as heat exchangers, impellers, and specialized valves with intricate internal channels represent high-value opportunities for DSS AM applications. These components benefit from the design freedom offered by additive manufacturing while leveraging the superior properties of duplex stainless steel.

Customer requirements are evolving toward higher performance specifications, particularly regarding porosity control and consistent phase balance. End-users are willing to pay premium prices for DSS AM components that demonstrate verified mechanical properties and corrosion resistance comparable to traditionally manufactured alternatives. This trend is creating a market segment for certified DSS AM parts with documented post-heat treatment protocols.

Market barriers include the high cost of DSS powders, which are approximately 30% more expensive than conventional stainless steel powders, and the technical challenges associated with achieving optimal phase balance. However, as production volumes increase and technical solutions for porosity and phase control improve, these barriers are expected to diminish.

Emerging applications in biomedical implants and renewable energy systems are creating new market opportunities, with potential to add $450 million to the market by 2026. These applications are particularly sensitive to material quality and consistency, driving innovation in post-processing techniques for DSS AM components.

Key industries driving this market expansion include oil and gas, chemical processing, marine engineering, and power generation. These sectors require components with exceptional corrosion resistance and mechanical properties that DSS can provide. The oil and gas industry represents the largest market segment, accounting for approximately 32% of total demand, followed by chemical processing at 27%.

Regionally, Europe leads the market with 38% share, attributed to its strong presence in marine and offshore industries. North America follows at 29%, with significant growth potential in chemical processing applications. The Asia-Pacific region, currently at 24% market share, is experiencing the fastest growth rate of 22.3% annually, driven by rapid industrialization and infrastructure development in China and India.

The market demand is increasingly focused on complex geometries that traditional manufacturing methods cannot efficiently produce. Components such as heat exchangers, impellers, and specialized valves with intricate internal channels represent high-value opportunities for DSS AM applications. These components benefit from the design freedom offered by additive manufacturing while leveraging the superior properties of duplex stainless steel.

Customer requirements are evolving toward higher performance specifications, particularly regarding porosity control and consistent phase balance. End-users are willing to pay premium prices for DSS AM components that demonstrate verified mechanical properties and corrosion resistance comparable to traditionally manufactured alternatives. This trend is creating a market segment for certified DSS AM parts with documented post-heat treatment protocols.

Market barriers include the high cost of DSS powders, which are approximately 30% more expensive than conventional stainless steel powders, and the technical challenges associated with achieving optimal phase balance. However, as production volumes increase and technical solutions for porosity and phase control improve, these barriers are expected to diminish.

Emerging applications in biomedical implants and renewable energy systems are creating new market opportunities, with potential to add $450 million to the market by 2026. These applications are particularly sensitive to material quality and consistency, driving innovation in post-processing techniques for DSS AM components.

Porosity Challenges in DSS Additive Manufacturing

Porosity remains one of the most significant challenges in Duplex Stainless Steel (DSS) additive manufacturing processes. The formation of pores during fabrication substantially compromises the mechanical properties, corrosion resistance, and overall structural integrity of DSS components. Current research indicates that porosity in DSS additive manufacturing primarily manifests in three forms: gas-induced porosity, lack-of-fusion defects, and keyhole porosity.

Gas-induced porosity typically results from entrapped gas within the powder feedstock or from gas evolution during the melting process. This type of porosity is characterized by spherical voids distributed throughout the material matrix. Studies have shown that powder quality significantly influences gas porosity formation, with moisture content and particle size distribution being critical factors. Recent quantitative analyses reveal that gas porosity can account for 0.5-2% of the total volume in as-built DSS components.

Lack-of-fusion defects present a more complex challenge, occurring when adjacent melt pools fail to fully coalesce. These irregularly shaped voids typically form at layer interfaces and are strongly correlated with insufficient energy input during the manufacturing process. The dual-phase nature of DSS exacerbates this issue, as the different thermal properties of austenite and ferrite phases create non-uniform melting behaviors. Research indicates that lack-of-fusion porosity can reach levels of 3-5% in suboptimally processed DSS parts.

Keyhole porosity, characterized by deep, narrow voids, results from vapor cavity collapse during high-energy density processing. This phenomenon is particularly problematic in laser powder bed fusion of DSS, where the balance between power density and scan speed is critical. Recent high-speed imaging studies have captured the dynamic formation of these defects, revealing their correlation with specific processing parameter combinations.

The impact of porosity on DSS performance is multifaceted. Mechanical testing shows that a 1% increase in porosity can reduce tensile strength by approximately 4-7% and fatigue life by up to 30%. Furthermore, pores act as preferential sites for corrosion initiation, significantly compromising the inherent corrosion resistance that makes DSS valuable in harsh environments.

Current mitigation strategies focus on process parameter optimization, with recent studies establishing processing windows that minimize porosity while maintaining phase balance. Advanced monitoring systems utilizing in-situ sensors have demonstrated potential for real-time defect detection and process adjustment. Post-processing techniques such as hot isostatic pressing (HIP) have shown promise in reducing porosity levels to below 0.2%, though the high temperatures involved present challenges for maintaining the critical austenite-ferrite phase balance in DSS.

Gas-induced porosity typically results from entrapped gas within the powder feedstock or from gas evolution during the melting process. This type of porosity is characterized by spherical voids distributed throughout the material matrix. Studies have shown that powder quality significantly influences gas porosity formation, with moisture content and particle size distribution being critical factors. Recent quantitative analyses reveal that gas porosity can account for 0.5-2% of the total volume in as-built DSS components.

Lack-of-fusion defects present a more complex challenge, occurring when adjacent melt pools fail to fully coalesce. These irregularly shaped voids typically form at layer interfaces and are strongly correlated with insufficient energy input during the manufacturing process. The dual-phase nature of DSS exacerbates this issue, as the different thermal properties of austenite and ferrite phases create non-uniform melting behaviors. Research indicates that lack-of-fusion porosity can reach levels of 3-5% in suboptimally processed DSS parts.

Keyhole porosity, characterized by deep, narrow voids, results from vapor cavity collapse during high-energy density processing. This phenomenon is particularly problematic in laser powder bed fusion of DSS, where the balance between power density and scan speed is critical. Recent high-speed imaging studies have captured the dynamic formation of these defects, revealing their correlation with specific processing parameter combinations.

The impact of porosity on DSS performance is multifaceted. Mechanical testing shows that a 1% increase in porosity can reduce tensile strength by approximately 4-7% and fatigue life by up to 30%. Furthermore, pores act as preferential sites for corrosion initiation, significantly compromising the inherent corrosion resistance that makes DSS valuable in harsh environments.

Current mitigation strategies focus on process parameter optimization, with recent studies establishing processing windows that minimize porosity while maintaining phase balance. Advanced monitoring systems utilizing in-situ sensors have demonstrated potential for real-time defect detection and process adjustment. Post-processing techniques such as hot isostatic pressing (HIP) have shown promise in reducing porosity levels to below 0.2%, though the high temperatures involved present challenges for maintaining the critical austenite-ferrite phase balance in DSS.

Current Porosity Reduction Strategies

01 Porosity control in duplex stainless steel additive manufacturing

Porosity is a critical issue in additive manufacturing of duplex stainless steel that affects mechanical properties and corrosion resistance. Various techniques have been developed to minimize porosity, including optimized laser parameters, powder characteristics control, and post-processing treatments. Proper energy density during the printing process helps achieve densification while preventing defects like gas entrapment. Heat treatment after printing can further reduce porosity by promoting pore closure through diffusion mechanisms.- Porosity control in duplex stainless steel additive manufacturing: Porosity is a critical issue in additive manufacturing of duplex stainless steel that affects mechanical properties and corrosion resistance. Various techniques have been developed to minimize porosity, including optimized process parameters, post-processing heat treatments, and specialized powder characteristics. Controlling laser power, scanning speed, and layer thickness can significantly reduce void formation. Hot isostatic pressing (HIP) is commonly employed as a post-processing technique to eliminate residual porosity and improve the overall density of the printed components.

- Phase balance optimization in duplex stainless steel AM: Maintaining the proper balance between ferrite and austenite phases is crucial for achieving optimal mechanical and corrosion properties in additively manufactured duplex stainless steel. The rapid cooling rates inherent to additive manufacturing processes often result in excessive ferrite content. Various approaches to achieve balanced microstructure include controlled cooling strategies, specific heat treatment protocols, and alloying element adjustments. Post-build heat treatments are particularly effective in promoting austenite formation and achieving the desired phase ratio, typically around 50:50 ferrite-austenite.

- Alloy composition modifications for AM duplex stainless steel: Modifying the chemical composition of duplex stainless steel for additive manufacturing can help address porosity issues and improve phase balance. Adjustments to nitrogen, nickel, and chromium content can promote austenite formation during the rapid solidification characteristic of AM processes. Some compositions include increased manganese to enhance nitrogen solubility or added elements that serve as nucleation sites for austenite formation. These tailored compositions help compensate for the unique thermal conditions in AM processes while maintaining the corrosion resistance and mechanical properties expected from duplex stainless steels.

- Process parameter optimization for duplex stainless steel AM: Optimizing process parameters is essential for controlling microstructure and reducing defects in additively manufactured duplex stainless steel. Key parameters include laser power, scanning speed, hatch spacing, layer thickness, and build platform temperature. The energy density must be carefully controlled to ensure complete melting while avoiding excessive heat input that could lead to undesirable phase transformations. Preheating the build platform can reduce thermal gradients and associated residual stresses. Advanced scanning strategies, such as island scanning or checkerboard patterns, can further improve microstructural homogeneity and reduce porosity.

- Post-processing treatments for AM duplex stainless steel: Post-processing treatments are critical for achieving desired properties in additively manufactured duplex stainless steel components. Solution annealing followed by controlled cooling can restore phase balance and homogenize the microstructure. Hot isostatic pressing (HIP) effectively reduces porosity while simultaneously promoting phase transformation. Surface treatments such as machining, polishing, or shot peening can improve surface finish and mechanical properties. Some advanced treatments combine thermal and mechanical processing to optimize both microstructure and mechanical performance, resulting in properties comparable to conventionally manufactured duplex stainless steel.

02 Phase balance optimization in duplex stainless steel

Maintaining the proper balance between ferrite and austenite phases is essential for achieving optimal mechanical and corrosion properties in duplex stainless steel. The rapid heating and cooling cycles in additive manufacturing processes can disrupt this balance, often resulting in excessive ferrite content. Controlled cooling rates, specific alloying elements, and post-processing heat treatments are employed to achieve the desired phase ratio, typically around 50:50 austenite to ferrite. Nitrogen content and processing temperature are particularly important factors in controlling phase transformation.Expand Specific Solutions03 Heat treatment strategies for microstructure control

Post-processing heat treatments are crucial for optimizing the microstructure of additively manufactured duplex stainless steel. Solution annealing followed by controlled cooling helps dissolve unwanted precipitates and establish the desired phase balance. Specific heat treatment protocols have been developed to address the unique microstructural challenges of additively manufactured duplex stainless steel, including stress relief, homogenization, and phase transformation treatments. These treatments can significantly improve mechanical properties and corrosion resistance by refining grain structure and promoting proper phase distribution.Expand Specific Solutions04 Alloying element effects on microstructure and properties

The composition of duplex stainless steel significantly influences its behavior during additive manufacturing. Elements like chromium, nickel, molybdenum, and nitrogen play critical roles in determining phase stability, porosity formation, and mechanical properties. Nitrogen, in particular, is a strong austenite stabilizer that helps maintain phase balance during rapid solidification. Careful adjustment of alloying elements can mitigate issues like sigma phase formation and improve weldability in the additive manufacturing process. Optimized compositions have been developed specifically for additive manufacturing to address the unique challenges of this processing method.Expand Specific Solutions05 Process parameter optimization for additive manufacturing

The selection and control of process parameters significantly impact the quality of additively manufactured duplex stainless steel components. Parameters such as laser power, scan speed, layer thickness, and build orientation affect porosity formation, phase balance, and mechanical properties. Optimized processing windows have been established to achieve high-density parts with controlled microstructure. Advanced monitoring and control systems help maintain consistent quality throughout the build process. Pre-heating the build platform and controlling the build chamber atmosphere can further improve microstructural control and reduce defects in the final components.Expand Specific Solutions

Leading Companies in DSS AM Industry

Duplex Stainless Steel Additive Manufacturing is currently in an early growth phase, with the market expanding as industries recognize its potential for corrosion-resistant components with superior mechanical properties. The global market size is estimated to be relatively modest but growing rapidly at 15-20% annually. Technologically, the field is still maturing, with significant challenges in controlling porosity and phase balance during printing processes. Leading players include EOS GmbH, which has pioneered powder bed fusion systems for stainless steels, and major steel producers like NIPPON STEEL, POSCO Holdings, and JFE Steel that are investing in R&D. Research institutions such as Central Iron & Steel Research Institute and Harbin University of Science & Technology are advancing post-heat treatment protocols to optimize microstructure. The technology is approaching commercial viability but requires further development to address quality consistency issues.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed an advanced approach to duplex stainless steel additive manufacturing that focuses on microstructural control throughout the process chain. Their technology utilizes gas atomized powders with optimized nitrogen content (0.14-0.18 wt%) specifically designed to promote balanced austenite-ferrite formation during solidification. NIPPON STEEL employs a proprietary laser parameter optimization methodology that systematically evaluates energy density variations to identify processing windows that minimize both lack-of-fusion and keyhole porosity. Their process incorporates controlled preheating (200-300°C) of the build platform to reduce thermal gradients and associated residual stresses. For phase balance management, NIPPON STEEL has developed specialized post-build heat treatment protocols involving solution annealing at precisely controlled temperatures (1050-1080°C) with optimized holding times followed by controlled cooling rates to achieve the target austenite-ferrite ratio of approximately 50:50[4]. Their approach includes comprehensive microstructural characterization using EBSD and XRD techniques to validate phase distributions and identify potential intermetallic precipitates. NIPPON STEEL has also pioneered the use of nitrogen-enriched atmospheres during the AM process to compensate for nitrogen loss during laser melting.

Strengths: Extensive metallurgical expertise in stainless steel compositions; integrated production capability from powder manufacturing to final heat treatment; sophisticated characterization capabilities for process validation. Weaknesses: Process parameters highly sensitive to specific alloy compositions; limited build volumes restrict production scaling; relatively slower build rates compared to conventional manufacturing.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed a comprehensive approach to duplex stainless steel additive manufacturing that addresses key challenges of porosity and phase balance. Their technology utilizes optimized powder characteristics with controlled particle size distribution (15-45μm) and spherical morphology to minimize porosity formation during the laser powder bed fusion (LPBF) process. Sandvik employs proprietary parameter sets that carefully balance laser power, scan speed, and hatch spacing to achieve melt pool stability while preventing keyhole porosity. Their process includes in-situ monitoring systems that detect and correct anomalies during printing. For phase balance control, Sandvik has developed specialized heat treatment protocols that ensure the ideal austenite-ferrite ratio (approximately 50:50) through controlled cooling rates and holding times. Their Osprey® metal powders are specifically engineered for AM applications with nitrogen content precisely adjusted to promote austenite formation during solidification and subsequent heat treatment[1][2]. Sandvik has also pioneered hybrid manufacturing approaches that combine the design freedom of AM with conventional processing to optimize microstructure.

Strengths: Superior powder quality control minimizes porosity; proprietary heat treatment protocols achieve optimal phase balance; extensive metallurgical expertise in stainless steels. Weaknesses: Higher cost compared to conventional manufacturing; limited build volumes restrict production of larger components; process parameters require careful optimization for each specific duplex grade.

Phase Balance Control Mechanisms

Duplex stainless steel structure manufacturing method and heat treatment device

PatentInactiveJP2015098036A

Innovation

- A method and apparatus for manufacturing duplex stainless steel structures that perform solution heat treatment immediately after welding, utilizing the heat generated during welding, and include induction heating and controlled cooling to optimize the α/γ phase ratio and reduce σ phase precipitation, allowing for efficient and cost-effective corrosion resistance enhancement.

Duplex stainless steel with improved embrittlement properties and method of producing such

PatentWO2021021010A1

Innovation

- A heat treatment method involving isothermal heating of DSS at 750 to 900 °C for 10 seconds to 10 minutes, followed by rapid quenching, effectively slows down the embrittlement process and improves the resistance to 475 °C embrittlement by maintaining the ductility and toughness of the steel.

Material Characterization Methods

Material characterization is essential for understanding the microstructural features and properties of duplex stainless steel (DSS) components produced through additive manufacturing (AM). The complex interplay between porosity, phase balance, and heat treatment necessitates a comprehensive suite of characterization techniques to evaluate material quality and performance.

X-ray computed tomography (XCT) serves as a non-destructive method for three-dimensional visualization and quantification of internal porosity within AM-DSS components. This technique enables researchers to assess pore size distribution, morphology, and spatial arrangement throughout the build volume, providing critical insights into process-induced defects and their correlation with printing parameters.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) allows for high-resolution imaging of microstructural features and elemental mapping. These techniques are particularly valuable for examining the austenite-ferrite phase boundaries and identifying potential segregation of alloying elements that may occur during rapid solidification in AM processes.

X-ray diffraction (XRD) analysis provides quantitative assessment of phase fractions, enabling precise determination of the austenite-ferrite balance in DSS components. This technique is instrumental in monitoring phase transformations during post-processing heat treatments and establishing correlations between processing parameters and resultant phase proportions.

Electron backscatter diffraction (EBSD) offers detailed crystallographic information, revealing grain orientation, texture, and phase distribution within the material. EBSD mapping can elucidate the influence of thermal history on grain morphology and preferred orientation, which significantly impact mechanical properties of AM-DSS components.

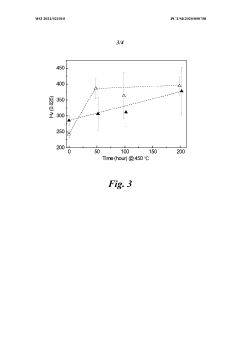

Mechanical testing protocols, including tensile testing, hardness measurements, and impact testing, provide direct assessment of material performance. These tests are essential for establishing relationships between microstructural features (porosity, phase balance) and mechanical behavior, particularly when evaluating the effectiveness of post-build heat treatments.

Corrosion testing methods, such as potentiodynamic polarization and electrochemical impedance spectroscopy, evaluate the electrochemical behavior of AM-DSS components in various environments. These techniques are crucial for assessing how microstructural heterogeneities and phase balance influence corrosion resistance, a defining characteristic of duplex stainless steels.

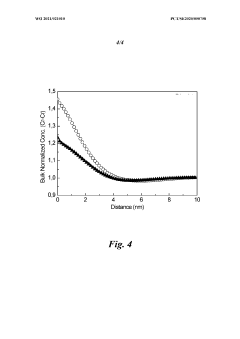

Advanced techniques like atom probe tomography (APT) and transmission electron microscopy (TEM) offer atomic-scale characterization capabilities, enabling investigation of nanoscale precipitates and phase transformations that may occur during AM processing or subsequent heat treatments. These insights are particularly valuable for optimizing post-processing protocols to achieve desired microstructural features and properties.

X-ray computed tomography (XCT) serves as a non-destructive method for three-dimensional visualization and quantification of internal porosity within AM-DSS components. This technique enables researchers to assess pore size distribution, morphology, and spatial arrangement throughout the build volume, providing critical insights into process-induced defects and their correlation with printing parameters.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) allows for high-resolution imaging of microstructural features and elemental mapping. These techniques are particularly valuable for examining the austenite-ferrite phase boundaries and identifying potential segregation of alloying elements that may occur during rapid solidification in AM processes.

X-ray diffraction (XRD) analysis provides quantitative assessment of phase fractions, enabling precise determination of the austenite-ferrite balance in DSS components. This technique is instrumental in monitoring phase transformations during post-processing heat treatments and establishing correlations between processing parameters and resultant phase proportions.

Electron backscatter diffraction (EBSD) offers detailed crystallographic information, revealing grain orientation, texture, and phase distribution within the material. EBSD mapping can elucidate the influence of thermal history on grain morphology and preferred orientation, which significantly impact mechanical properties of AM-DSS components.

Mechanical testing protocols, including tensile testing, hardness measurements, and impact testing, provide direct assessment of material performance. These tests are essential for establishing relationships between microstructural features (porosity, phase balance) and mechanical behavior, particularly when evaluating the effectiveness of post-build heat treatments.

Corrosion testing methods, such as potentiodynamic polarization and electrochemical impedance spectroscopy, evaluate the electrochemical behavior of AM-DSS components in various environments. These techniques are crucial for assessing how microstructural heterogeneities and phase balance influence corrosion resistance, a defining characteristic of duplex stainless steels.

Advanced techniques like atom probe tomography (APT) and transmission electron microscopy (TEM) offer atomic-scale characterization capabilities, enabling investigation of nanoscale precipitates and phase transformations that may occur during AM processing or subsequent heat treatments. These insights are particularly valuable for optimizing post-processing protocols to achieve desired microstructural features and properties.

Sustainability Aspects of DSS AM

The sustainability of Duplex Stainless Steel (DSS) Additive Manufacturing represents a critical dimension in evaluating its industrial viability. DSS AM processes demonstrate significant environmental advantages compared to conventional manufacturing methods, primarily through material efficiency. The powder-based nature of AM technologies enables near-net-shape production, substantially reducing material waste compared to traditional subtractive manufacturing approaches where up to 90% of the original material may be discarded as scrap.

Energy consumption patterns in DSS AM present a complex sustainability profile. While the energy intensity during the printing process is relatively high due to the power requirements of laser or electron beam systems, this is counterbalanced by lifecycle benefits. The ability to produce optimized geometries with reduced weight contributes to energy savings during the operational phase of components, particularly in transportation applications where lighter DSS parts reduce fuel consumption and associated emissions.

Supply chain considerations further enhance the sustainability credentials of DSS AM. The technology enables on-demand, localized production capabilities, potentially reducing transportation-related carbon emissions associated with global supply chains. Additionally, the digital nature of AM workflows facilitates inventory reduction, as parts can be produced when needed rather than warehoused, decreasing the environmental footprint associated with storage and logistics.

The recyclability of DSS powders represents another significant sustainability advantage. Unused powder from build processes can be reclaimed, sieved, and reused in subsequent manufacturing cycles, creating a more circular material flow. However, challenges remain regarding powder degradation after multiple recycling iterations, which can affect phase balance and mechanical properties of the final components.

Water usage in DSS AM processes is substantially lower than in conventional manufacturing, where cutting fluids and cooling systems often require significant water resources. This reduced water footprint contributes positively to the overall environmental assessment of DSS AM technologies, particularly in regions facing water scarcity challenges.

From a lifecycle perspective, the ability to repair and remanufacture DSS components using AM technologies extends product lifespans, reducing the need for complete replacement and associated resource consumption. This aspect is particularly valuable for high-value components in industries such as aerospace, energy, and marine applications, where DSS is commonly employed for its corrosion resistance and mechanical properties.

Energy consumption patterns in DSS AM present a complex sustainability profile. While the energy intensity during the printing process is relatively high due to the power requirements of laser or electron beam systems, this is counterbalanced by lifecycle benefits. The ability to produce optimized geometries with reduced weight contributes to energy savings during the operational phase of components, particularly in transportation applications where lighter DSS parts reduce fuel consumption and associated emissions.

Supply chain considerations further enhance the sustainability credentials of DSS AM. The technology enables on-demand, localized production capabilities, potentially reducing transportation-related carbon emissions associated with global supply chains. Additionally, the digital nature of AM workflows facilitates inventory reduction, as parts can be produced when needed rather than warehoused, decreasing the environmental footprint associated with storage and logistics.

The recyclability of DSS powders represents another significant sustainability advantage. Unused powder from build processes can be reclaimed, sieved, and reused in subsequent manufacturing cycles, creating a more circular material flow. However, challenges remain regarding powder degradation after multiple recycling iterations, which can affect phase balance and mechanical properties of the final components.

Water usage in DSS AM processes is substantially lower than in conventional manufacturing, where cutting fluids and cooling systems often require significant water resources. This reduced water footprint contributes positively to the overall environmental assessment of DSS AM technologies, particularly in regions facing water scarcity challenges.

From a lifecycle perspective, the ability to repair and remanufacture DSS components using AM technologies extends product lifespans, reducing the need for complete replacement and associated resource consumption. This aspect is particularly valuable for high-value components in industries such as aerospace, energy, and marine applications, where DSS is commonly employed for its corrosion resistance and mechanical properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!