Duplex Stainless Steel Phase Balance: Austenite Restoration, Sigma Control And Heat Treatment

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DSS Phase Balance Background and Objectives

Duplex Stainless Steel (DSS) has emerged as a critical material in various industrial applications due to its exceptional combination of mechanical properties and corrosion resistance. The development of DSS can be traced back to the 1930s, with significant advancements occurring in the 1970s and 1980s. The evolution of this material has been driven by the need for superior performance in increasingly demanding environments, particularly in oil and gas, chemical processing, and marine applications.

The fundamental characteristic of DSS is its dual-phase microstructure, consisting of approximately equal proportions of austenite and ferrite phases. This balanced microstructure is responsible for the material's unique combination of strength, ductility, and corrosion resistance. However, maintaining this optimal phase balance presents significant challenges during manufacturing processes and in-service conditions, as deviations can severely compromise material performance.

Recent technological trends indicate a growing focus on precise control of phase transformations during heat treatment processes. The industry has been moving toward more sophisticated heat treatment protocols that can achieve consistent phase balance across varying section thicknesses and complex geometries. Additionally, there is increasing interest in developing predictive models that can accurately forecast phase evolution during thermal processing.

The primary technical objective in DSS phase balance management is to develop reliable methodologies for austenite restoration following forming or welding operations, where thermal cycles can disrupt the optimal phase distribution. Equally important is the control of detrimental sigma phase precipitation, which occurs during prolonged exposure to temperatures between 650°C and 950°C and can lead to embrittlement and reduced corrosion resistance.

Another critical goal is the optimization of heat treatment parameters to achieve consistent phase balance across different product forms and dimensions. This includes establishing precise temperature-time profiles that maximize austenite formation while minimizing the risk of intermetallic phase precipitation. The development of non-destructive testing methods for rapid assessment of phase balance in finished components represents another significant objective.

The advancement of computational models capable of predicting phase transformations based on alloy composition and thermal history is gaining momentum. These models aim to reduce the reliance on empirical approaches and enable more efficient process design. Furthermore, there is a growing emphasis on understanding the influence of minor alloying elements on phase stability and transformation kinetics, which could lead to the development of new DSS variants with enhanced phase balance stability.

The fundamental characteristic of DSS is its dual-phase microstructure, consisting of approximately equal proportions of austenite and ferrite phases. This balanced microstructure is responsible for the material's unique combination of strength, ductility, and corrosion resistance. However, maintaining this optimal phase balance presents significant challenges during manufacturing processes and in-service conditions, as deviations can severely compromise material performance.

Recent technological trends indicate a growing focus on precise control of phase transformations during heat treatment processes. The industry has been moving toward more sophisticated heat treatment protocols that can achieve consistent phase balance across varying section thicknesses and complex geometries. Additionally, there is increasing interest in developing predictive models that can accurately forecast phase evolution during thermal processing.

The primary technical objective in DSS phase balance management is to develop reliable methodologies for austenite restoration following forming or welding operations, where thermal cycles can disrupt the optimal phase distribution. Equally important is the control of detrimental sigma phase precipitation, which occurs during prolonged exposure to temperatures between 650°C and 950°C and can lead to embrittlement and reduced corrosion resistance.

Another critical goal is the optimization of heat treatment parameters to achieve consistent phase balance across different product forms and dimensions. This includes establishing precise temperature-time profiles that maximize austenite formation while minimizing the risk of intermetallic phase precipitation. The development of non-destructive testing methods for rapid assessment of phase balance in finished components represents another significant objective.

The advancement of computational models capable of predicting phase transformations based on alloy composition and thermal history is gaining momentum. These models aim to reduce the reliance on empirical approaches and enable more efficient process design. Furthermore, there is a growing emphasis on understanding the influence of minor alloying elements on phase stability and transformation kinetics, which could lead to the development of new DSS variants with enhanced phase balance stability.

Market Applications and Demand Analysis

Duplex stainless steels (DSS) have experienced significant market growth across multiple industries due to their exceptional combination of strength, corrosion resistance, and cost-effectiveness. The global market for DSS is currently valued at over 3 billion USD, with a compound annual growth rate projected between 4-6% through 2028, driven primarily by expanding applications in oil and gas, chemical processing, and marine environments.

The oil and gas sector represents the largest market segment for DSS applications, accounting for approximately 35% of total consumption. This demand is fueled by the material's superior resistance to stress corrosion cracking in chloride-rich environments and its ability to withstand high-pressure, high-temperature conditions in offshore platforms, pipelines, and processing equipment. The recent expansion of deep-sea exploration activities has further intensified demand for DSS with optimized phase balance properties.

Chemical processing industries constitute the second-largest market segment, representing about 25% of DSS consumption. In this sector, the demand for precise austenite-ferrite ratios is particularly critical, as these materials must withstand aggressive chemical environments while maintaining structural integrity. Manufacturers of chemical reactors, heat exchangers, and storage tanks increasingly specify DSS with tightly controlled phase balances to ensure optimal performance and extended service life.

The marine and shipbuilding sector has emerged as a rapidly growing market for DSS, driven by stringent environmental regulations and the need for materials with superior resistance to seawater corrosion. Propeller shafts, pump components, and desalination equipment manufacturers are particularly interested in advanced heat treatment processes that can optimize austenite restoration while minimizing detrimental sigma phase formation.

Regional analysis reveals that Europe leads in DSS consumption (approximately 35% of global demand), followed by North America (25%) and Asia-Pacific (22%). However, the fastest growth is occurring in emerging economies, particularly in Southeast Asia and the Middle East, where infrastructure development and industrial expansion are creating new application opportunities for phase-balanced DSS.

Market research indicates a growing premium for DSS with precisely controlled microstructures. End-users are increasingly willing to pay 15-20% price premiums for materials with guaranteed phase balance properties, reflecting the critical importance of microstructural control in determining in-service performance. This trend has stimulated significant R&D investment in advanced heat treatment protocols and real-time monitoring technologies for phase transformation control.

The oil and gas sector represents the largest market segment for DSS applications, accounting for approximately 35% of total consumption. This demand is fueled by the material's superior resistance to stress corrosion cracking in chloride-rich environments and its ability to withstand high-pressure, high-temperature conditions in offshore platforms, pipelines, and processing equipment. The recent expansion of deep-sea exploration activities has further intensified demand for DSS with optimized phase balance properties.

Chemical processing industries constitute the second-largest market segment, representing about 25% of DSS consumption. In this sector, the demand for precise austenite-ferrite ratios is particularly critical, as these materials must withstand aggressive chemical environments while maintaining structural integrity. Manufacturers of chemical reactors, heat exchangers, and storage tanks increasingly specify DSS with tightly controlled phase balances to ensure optimal performance and extended service life.

The marine and shipbuilding sector has emerged as a rapidly growing market for DSS, driven by stringent environmental regulations and the need for materials with superior resistance to seawater corrosion. Propeller shafts, pump components, and desalination equipment manufacturers are particularly interested in advanced heat treatment processes that can optimize austenite restoration while minimizing detrimental sigma phase formation.

Regional analysis reveals that Europe leads in DSS consumption (approximately 35% of global demand), followed by North America (25%) and Asia-Pacific (22%). However, the fastest growth is occurring in emerging economies, particularly in Southeast Asia and the Middle East, where infrastructure development and industrial expansion are creating new application opportunities for phase-balanced DSS.

Market research indicates a growing premium for DSS with precisely controlled microstructures. End-users are increasingly willing to pay 15-20% price premiums for materials with guaranteed phase balance properties, reflecting the critical importance of microstructural control in determining in-service performance. This trend has stimulated significant R&D investment in advanced heat treatment protocols and real-time monitoring technologies for phase transformation control.

Current Challenges in Phase Balance Control

The current phase balance control in duplex stainless steel (DSS) presents several significant challenges that impede optimal material performance and manufacturing efficiency. One primary challenge is achieving and maintaining the ideal austenite-ferrite ratio of approximately 50:50, which is critical for the desired combination of strength, corrosion resistance, and ductility. Even minor deviations from this balance can substantially compromise the mechanical and corrosion properties of the material.

Temperature control during heat treatment represents another major challenge, as the narrow processing window requires precise temperature management within ±10°C. Industrial-scale operations struggle to maintain such tight tolerances across large components or in continuous production environments, leading to inconsistent microstructures and properties throughout the material.

The formation of detrimental intermetallic phases, particularly sigma phase, poses a persistent challenge during processing. Sigma phase precipitation occurs primarily between 650-950°C and can happen rapidly, sometimes within minutes of exposure. This phase drastically reduces toughness and corrosion resistance, yet its formation kinetics vary significantly with minor compositional variations, making prediction and control difficult.

Cooling rate management presents additional complexity, as it directly influences phase transformation. Too rapid cooling may suppress austenite formation, while too slow cooling in critical temperature ranges promotes intermetallic precipitation. This balance becomes particularly challenging for thick sections where cooling rates vary from surface to core.

Modern manufacturing processes like welding and additive manufacturing introduce localized heating and cooling cycles that disrupt phase balance. The heat-affected zones in welded joints often exhibit depleted austenite content and increased susceptibility to intermetallic formation, compromising joint integrity.

Compositional variations within specification limits can significantly impact phase transformation behavior. Minor fluctuations in nitrogen, nickel, or chromium content can shift transformation temperatures and kinetics, requiring adaptive processing parameters that current industrial practices struggle to implement.

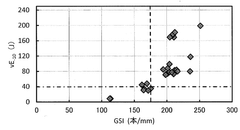

Non-destructive evaluation methods for phase balance assessment remain limited in production environments. Current techniques like ferritoscope measurements provide only surface information and cannot detect intermetallic phases effectively, while more comprehensive methods are typically destructive or laboratory-based, limiting in-process quality control capabilities.

Temperature control during heat treatment represents another major challenge, as the narrow processing window requires precise temperature management within ±10°C. Industrial-scale operations struggle to maintain such tight tolerances across large components or in continuous production environments, leading to inconsistent microstructures and properties throughout the material.

The formation of detrimental intermetallic phases, particularly sigma phase, poses a persistent challenge during processing. Sigma phase precipitation occurs primarily between 650-950°C and can happen rapidly, sometimes within minutes of exposure. This phase drastically reduces toughness and corrosion resistance, yet its formation kinetics vary significantly with minor compositional variations, making prediction and control difficult.

Cooling rate management presents additional complexity, as it directly influences phase transformation. Too rapid cooling may suppress austenite formation, while too slow cooling in critical temperature ranges promotes intermetallic precipitation. This balance becomes particularly challenging for thick sections where cooling rates vary from surface to core.

Modern manufacturing processes like welding and additive manufacturing introduce localized heating and cooling cycles that disrupt phase balance. The heat-affected zones in welded joints often exhibit depleted austenite content and increased susceptibility to intermetallic formation, compromising joint integrity.

Compositional variations within specification limits can significantly impact phase transformation behavior. Minor fluctuations in nitrogen, nickel, or chromium content can shift transformation temperatures and kinetics, requiring adaptive processing parameters that current industrial practices struggle to implement.

Non-destructive evaluation methods for phase balance assessment remain limited in production environments. Current techniques like ferritoscope measurements provide only surface information and cannot detect intermetallic phases effectively, while more comprehensive methods are typically destructive or laboratory-based, limiting in-process quality control capabilities.

Current Austenite Restoration Methodologies

01 Composition control for phase balance in duplex stainless steel

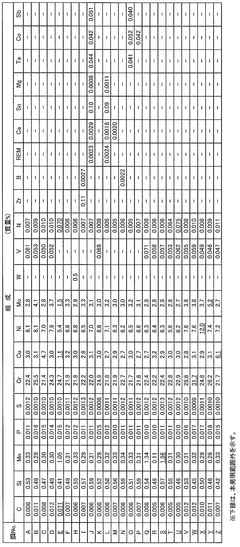

Controlling the chemical composition of duplex stainless steel is crucial for achieving optimal phase balance between austenite and ferrite phases. Specific elements like nickel, nitrogen, manganese, and chromium can be adjusted to promote either austenite or ferrite formation. The proper balance of these elements ensures the desired microstructure and mechanical properties while maintaining corrosion resistance. Heat treatment parameters must be carefully controlled alongside composition to achieve the target phase ratio.- Chemical composition control for phase balance: Controlling the chemical composition of duplex stainless steel is crucial for achieving optimal phase balance between austenite and ferrite. Specific elements like nickel, nitrogen, manganese, and chromium can be adjusted to promote either austenite or ferrite formation. The proper balance of these alloying elements ensures the desired microstructure and mechanical properties while maintaining corrosion resistance.

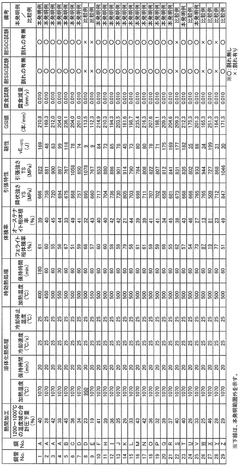

- Heat treatment processes for phase balance optimization: Various heat treatment processes including solution annealing, quenching, and controlled cooling are employed to achieve optimal phase balance in duplex stainless steel. The temperature, duration, and cooling rate during these treatments significantly influence the austenite-ferrite ratio. Proper heat treatment prevents the formation of detrimental phases and ensures uniform microstructure throughout the material.

- Microstructural analysis and phase quantification methods: Advanced techniques for analyzing and quantifying the phase balance in duplex stainless steel include optical microscopy, electron microscopy, X-ray diffraction, and magnetic measurements. These methods allow for precise determination of austenite-ferrite ratios and detection of unwanted phases. Accurate phase quantification is essential for quality control and ensuring that the material meets specified performance requirements.

- Influence of processing parameters on phase balance: Manufacturing processes such as hot rolling, cold working, welding, and forming significantly impact the phase balance in duplex stainless steel. Parameters like deformation degree, working temperature, and cooling conditions must be carefully controlled to maintain the desired austenite-ferrite ratio. Process optimization prevents phase imbalance that could lead to reduced corrosion resistance or mechanical properties.

- Phase balance for specific applications and environments: The optimal phase balance in duplex stainless steel varies depending on the intended application and service environment. For high-temperature applications, a different austenite-ferrite ratio may be required compared to cryogenic uses. Similarly, environments with specific corrosive media may necessitate tailored phase balances to maximize resistance to particular corrosion mechanisms while maintaining mechanical integrity.

02 Heat treatment processes for phase balance optimization

Heat treatment processes significantly influence the phase balance in duplex stainless steel. Solution annealing, quenching, and controlled cooling rates are employed to achieve the desired austenite-ferrite ratio. Specific temperature ranges and holding times during heat treatment can promote the transformation of ferrite to austenite or prevent the formation of detrimental intermetallic phases. Post-welding heat treatments are particularly important to restore phase balance in the heat-affected zone of welded components.Expand Specific Solutions03 Microstructural analysis and control techniques

Various analytical techniques are employed to assess and control the phase balance in duplex stainless steel. These include optical microscopy, electron microscopy, X-ray diffraction, and magnetic measurement methods. Image analysis software can quantify the volume fractions of austenite and ferrite phases. These techniques help manufacturers monitor the microstructure during production and adjust processing parameters to maintain the optimal phase balance, typically around 50% austenite and 50% ferrite, which provides the best combination of strength and corrosion resistance.Expand Specific Solutions04 Alloying elements and their effects on phase stability

Specific alloying elements have distinct effects on phase stability in duplex stainless steel. Austenite-promoting elements include nickel, nitrogen, carbon, copper, and manganese, while ferrite-promoting elements include chromium, molybdenum, silicon, and tungsten. The balance between these elements must be carefully controlled to achieve the desired microstructure. Nitrogen is particularly effective in promoting austenite formation while simultaneously enhancing strength and corrosion resistance. Modern duplex grades often use precise combinations of these elements to achieve optimal properties.Expand Specific Solutions05 Processing techniques for maintaining phase balance

Various processing techniques are employed to maintain phase balance during the manufacturing of duplex stainless steel products. These include controlled hot and cold working, precise cooling rates after hot working, and specialized welding procedures. The deformation temperature and degree of reduction during rolling significantly affect the resulting microstructure. For welded components, controlling heat input, interpass temperature, and filler metal composition is essential to maintain proper phase balance in the weld and heat-affected zones. Post-processing treatments may be required to restore balance after manufacturing operations.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The duplex stainless steel phase balance market is currently in a growth phase, with increasing demand driven by applications requiring superior corrosion resistance and mechanical properties. The global market size for duplex stainless steel is expanding at approximately 4-5% annually, reaching about $3 billion. Technologically, the field is maturing with established players like NIPPON STEEL, POSCO Holdings, and Outokumpu leading innovation in austenite restoration techniques and sigma phase control. Research institutions including Central Iron & Steel Research Institute and University of Science & Technology Beijing are advancing heat treatment protocols. Companies such as Sandvik Intellectual Property and JFE Steel are developing proprietary methods for optimizing phase balance, while emerging players like Zhejiang Jiuli Hi-Tech Metals are introducing competitive solutions for specialized applications in harsh environments.

NIPPON STEEL CORP.

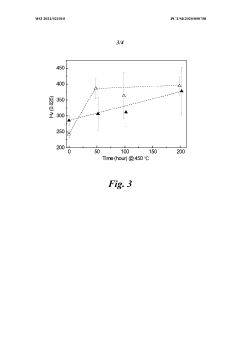

Technical Solution: NIPPON STEEL has developed advanced heat treatment protocols for duplex stainless steel (DSS) that optimize phase balance between austenite and ferrite phases. Their approach involves precise temperature control during solution annealing (1020-1100°C) followed by controlled cooling rates to achieve the desired 50:50 austenite-ferrite ratio. For austenite restoration after welding or forming operations, they employ post-weld heat treatments at specific temperature ranges (1050-1080°C) with controlled holding times to regenerate austenite content lost during processing. Their proprietary sigma phase control strategy involves rapid cooling through critical temperature ranges (700-950°C) where detrimental sigma phase forms, minimizing its precipitation. For thicker sections, they've developed specialized quenching techniques to ensure uniform cooling throughout the material cross-section.

Strengths: Superior control of microstructure through precisely calibrated heat treatment parameters; excellent corrosion resistance maintenance through optimized phase balance; advanced capability to restore austenite content after welding operations. Weaknesses: Their processes may require more sophisticated equipment and longer processing times compared to conventional methods; potential challenges in scaling to very large components.

POSCO Holdings, Inc.

Technical Solution: POSCO has pioneered a multi-stage heat treatment approach for duplex stainless steels that addresses phase balance challenges across various product forms. Their technology employs precise temperature control during solution annealing (1040-1120°C) with specific holding times calculated based on section thickness to achieve optimal austenite-ferrite ratios. For austenite restoration, POSCO utilizes a nitrogen-enriched atmosphere during heat treatment, which promotes austenite formation and stability. Their sigma phase control strategy involves both compositional design (controlling Mo and Cr distribution) and processing parameters, including rapid cooling through the 650-950°C range where sigma precipitation occurs. For thick sections, they've developed a specialized quenching system that ensures uniform cooling rates throughout the material, preventing detrimental phase transformations in core regions. POSCO's approach also includes post-processing verification using advanced ferritescopes and image analysis techniques to confirm phase balance meets specifications.

Strengths: Comprehensive approach combining compositional control and processing parameters; excellent adaptability to different product geometries; advanced monitoring systems for quality assurance. Weaknesses: Higher production costs due to specialized equipment requirements; potential limitations in very large component manufacturing; possible challenges in maintaining consistent results across global production facilities.

Key Innovations in Sigma Phase Control

Duplex stainless steel with improved embrittlement properties and method of producing such

PatentWO2021021010A1

Innovation

- A heat treatment method involving isothermal heating of DSS at 750 to 900 °C for 10 seconds to 10 minutes, followed by rapid quenching, effectively slows down the embrittlement process and improves the resistance to 475 °C embrittlement by maintaining the ductility and toughness of the steel.

Duplex stainless steel and method for manufacturing same

PatentWO2018043214A1

Innovation

- A duplex stainless steel composition with 20-70% austenite phase and 30-80% ferrite phase, optimized with elements like Cu, reduced N content, and specific heat treatment processes to achieve a yield strength of 95 ksi (655 MPa) and improved toughness, along with enhanced corrosion resistance through microstructural refinement and suppression of nitride formation.

Corrosion Performance vs. Phase Balance

The corrosion resistance of duplex stainless steels (DSS) is intrinsically linked to their phase balance between austenite and ferrite. Optimal corrosion performance typically requires a balanced microstructure with approximately 50% austenite and 50% ferrite. Deviations from this equilibrium can significantly impact corrosion behavior across different environments.

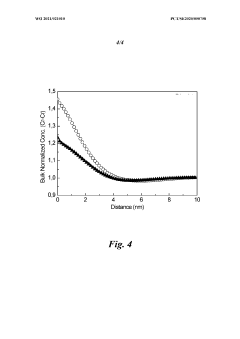

In chloride-containing environments, the austenite phase generally exhibits superior resistance to pitting and crevice corrosion due to its higher nickel content. However, the ferrite phase contributes essential chromium and molybdenum, which form protective passive films. When the phase balance shifts toward excessive ferrite, localized corrosion susceptibility increases, particularly at ferrite-austenite boundaries where chromium-depleted zones may form.

Conversely, austenite-rich microstructures may demonstrate reduced resistance to stress corrosion cracking (SCC) in certain environments. Research has shown that DSS with austenite content exceeding 60% can experience accelerated crack propagation rates in hot chloride solutions compared to properly balanced structures.

The precipitation of deleterious sigma phase during improper heat treatment dramatically compromises corrosion resistance. Even small amounts (2-3%) of sigma phase can reduce the critical pitting temperature (CPT) by 20°C or more. This occurs because sigma formation depletes surrounding areas of chromium and molybdenum, creating vulnerable regions susceptible to preferential attack.

Intergranular corrosion resistance is also phase-balance dependent. Sensitization resulting from chromium carbide precipitation at grain boundaries is more pronounced when the carbon partitioning between phases is unbalanced. Properly balanced DSS with controlled interstitial elements demonstrates superior resistance to intergranular attack.

Modern super duplex grades achieve exceptional corrosion performance through precise phase balance control. For instance, UNS S32750 with optimal phase distribution exhibits pitting resistance equivalent numbers (PREN) exceeding 40, enabling application in aggressive offshore environments. However, this performance rapidly deteriorates if phase balance shifts beyond 45-55% austenite-ferrite ratio.

The relationship between phase balance and corrosion performance varies with specific corrosion mechanisms. While general corrosion rates may not show dramatic sensitivity to moderate phase balance variations, localized corrosion forms—particularly pitting, crevice corrosion, and SCC—demonstrate pronounced dependence on microstructural equilibrium. This underscores the critical importance of proper heat treatment protocols that maintain optimal phase distribution throughout manufacturing processes.

In chloride-containing environments, the austenite phase generally exhibits superior resistance to pitting and crevice corrosion due to its higher nickel content. However, the ferrite phase contributes essential chromium and molybdenum, which form protective passive films. When the phase balance shifts toward excessive ferrite, localized corrosion susceptibility increases, particularly at ferrite-austenite boundaries where chromium-depleted zones may form.

Conversely, austenite-rich microstructures may demonstrate reduced resistance to stress corrosion cracking (SCC) in certain environments. Research has shown that DSS with austenite content exceeding 60% can experience accelerated crack propagation rates in hot chloride solutions compared to properly balanced structures.

The precipitation of deleterious sigma phase during improper heat treatment dramatically compromises corrosion resistance. Even small amounts (2-3%) of sigma phase can reduce the critical pitting temperature (CPT) by 20°C or more. This occurs because sigma formation depletes surrounding areas of chromium and molybdenum, creating vulnerable regions susceptible to preferential attack.

Intergranular corrosion resistance is also phase-balance dependent. Sensitization resulting from chromium carbide precipitation at grain boundaries is more pronounced when the carbon partitioning between phases is unbalanced. Properly balanced DSS with controlled interstitial elements demonstrates superior resistance to intergranular attack.

Modern super duplex grades achieve exceptional corrosion performance through precise phase balance control. For instance, UNS S32750 with optimal phase distribution exhibits pitting resistance equivalent numbers (PREN) exceeding 40, enabling application in aggressive offshore environments. However, this performance rapidly deteriorates if phase balance shifts beyond 45-55% austenite-ferrite ratio.

The relationship between phase balance and corrosion performance varies with specific corrosion mechanisms. While general corrosion rates may not show dramatic sensitivity to moderate phase balance variations, localized corrosion forms—particularly pitting, crevice corrosion, and SCC—demonstrate pronounced dependence on microstructural equilibrium. This underscores the critical importance of proper heat treatment protocols that maintain optimal phase distribution throughout manufacturing processes.

Environmental Impact of DSS Processing

The processing of Duplex Stainless Steel (DSS) presents significant environmental considerations that merit careful examination within the broader context of sustainable manufacturing. The production and heat treatment of DSS involve energy-intensive processes that contribute to carbon emissions, particularly during the melting, casting, and heat treatment stages. Conventional DSS processing typically requires temperatures exceeding 1000°C for solution annealing, resulting in substantial energy consumption and associated greenhouse gas emissions.

Water usage represents another critical environmental factor in DSS processing. Quenching operations and cooling processes consume significant quantities of water, while the generation of contaminated wastewater containing heavy metals and processing chemicals necessitates comprehensive treatment before discharge. Modern DSS facilities have increasingly implemented closed-loop water systems to minimize consumption and environmental impact.

Material efficiency in DSS production directly influences its environmental footprint. The extraction and processing of alloying elements—particularly chromium, nickel, and molybdenum—involve energy-intensive mining operations with substantial environmental consequences. Optimizing phase balance through precise heat treatment protocols can reduce material waste and improve the longevity of DSS components, thereby enhancing overall resource efficiency.

Recent advancements in DSS processing technologies have demonstrated promising environmental benefits. Induction heating methods for austenite restoration have shown energy efficiency improvements of 25-40% compared to conventional furnace treatments. Similarly, controlled cooling techniques for sigma phase management have reduced water consumption by up to 30% in some manufacturing operations.

Life cycle assessment (LCA) studies indicate that the environmental impact of DSS processing must be evaluated against the extended service life and superior performance these materials offer. The enhanced corrosion resistance and mechanical properties of properly heat-treated DSS typically result in longer component lifespans, reducing replacement frequency and associated environmental costs. Research suggests that DSS components with optimized phase balance can extend service life by 1.5-2 times compared to conventional stainless steels in aggressive environments.

Regulatory frameworks increasingly influence DSS processing practices. Stringent emissions standards and waste management regulations in major manufacturing regions have accelerated the adoption of cleaner production technologies. The European Union's Industrial Emissions Directive and similar regulations worldwide have established benchmarks for best available techniques in stainless steel processing, driving continuous improvement in environmental performance across the industry.

Water usage represents another critical environmental factor in DSS processing. Quenching operations and cooling processes consume significant quantities of water, while the generation of contaminated wastewater containing heavy metals and processing chemicals necessitates comprehensive treatment before discharge. Modern DSS facilities have increasingly implemented closed-loop water systems to minimize consumption and environmental impact.

Material efficiency in DSS production directly influences its environmental footprint. The extraction and processing of alloying elements—particularly chromium, nickel, and molybdenum—involve energy-intensive mining operations with substantial environmental consequences. Optimizing phase balance through precise heat treatment protocols can reduce material waste and improve the longevity of DSS components, thereby enhancing overall resource efficiency.

Recent advancements in DSS processing technologies have demonstrated promising environmental benefits. Induction heating methods for austenite restoration have shown energy efficiency improvements of 25-40% compared to conventional furnace treatments. Similarly, controlled cooling techniques for sigma phase management have reduced water consumption by up to 30% in some manufacturing operations.

Life cycle assessment (LCA) studies indicate that the environmental impact of DSS processing must be evaluated against the extended service life and superior performance these materials offer. The enhanced corrosion resistance and mechanical properties of properly heat-treated DSS typically result in longer component lifespans, reducing replacement frequency and associated environmental costs. Research suggests that DSS components with optimized phase balance can extend service life by 1.5-2 times compared to conventional stainless steels in aggressive environments.

Regulatory frameworks increasingly influence DSS processing practices. Stringent emissions standards and waste management regulations in major manufacturing regions have accelerated the adoption of cleaner production technologies. The European Union's Industrial Emissions Directive and similar regulations worldwide have established benchmarks for best available techniques in stainless steel processing, driving continuous improvement in environmental performance across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!