How Duplex Stainless Steel Meets NORSOK/ISO Requirements In Offshore Structures?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Steel Evolution and Offshore Application Goals

Duplex stainless steel has undergone significant evolution since its inception in the 1930s, with the first commercial duplex alloy, type 329, being developed by J. Holtzer Company. The early duplex steels suffered from limitations in weldability and corrosion resistance, particularly in the heat-affected zones. A major breakthrough came in the 1970s with the introduction of nitrogen as an alloying element, which substantially improved the balance between austenite and ferrite phases while enhancing corrosion resistance.

The 1980s marked a pivotal era with the development of second-generation duplex stainless steels, notably the 2205 grade (22% chromium, 5% nickel), which became the industry standard due to its excellent combination of mechanical properties and corrosion resistance. This period coincided with increased offshore exploration activities, creating demand for materials capable of withstanding harsh marine environments.

The 1990s witnessed the emergence of super duplex grades (25-27% chromium) and hyper duplex grades (>30% chromium), specifically engineered to meet the increasingly stringent requirements of deepwater offshore applications. These advanced grades offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive chloride-containing environments.

In offshore structures, duplex stainless steels aim to fulfill several critical objectives. Primary among these is ensuring structural integrity under extreme environmental conditions, including exposure to seawater, variable temperatures, and high-pressure environments. The material must maintain its mechanical properties while resisting various forms of corrosion that are accelerated in marine settings.

Cost-effectiveness represents another key goal, as duplex steels offer potential lifecycle cost advantages over traditional materials through reduced maintenance requirements and extended service life. The higher initial investment is often justified by lower total ownership costs when considering the harsh operating conditions of offshore installations.

Weight reduction is particularly significant for floating structures, where duplex steels' higher strength-to-weight ratio compared to conventional austenitic stainless steels enables lighter designs without compromising structural integrity. This characteristic becomes increasingly important as offshore structures move into deeper waters and more remote locations.

Compliance with international standards, particularly NORSOK M-630 and ISO 15156 (NACE MR0175), has become a fundamental objective in offshore applications. These standards establish stringent requirements for materials used in oil and gas production environments, focusing on resistance to sulfide stress cracking, hydrogen-induced cracking, and general corrosion resistance parameters that duplex steels must satisfy.

The ongoing evolution of duplex stainless steels continues to be driven by the offshore industry's push toward more challenging environments, including deeper waters, higher temperatures, and more corrosive conditions, necessitating continuous improvement in material performance and reliability.

The 1980s marked a pivotal era with the development of second-generation duplex stainless steels, notably the 2205 grade (22% chromium, 5% nickel), which became the industry standard due to its excellent combination of mechanical properties and corrosion resistance. This period coincided with increased offshore exploration activities, creating demand for materials capable of withstanding harsh marine environments.

The 1990s witnessed the emergence of super duplex grades (25-27% chromium) and hyper duplex grades (>30% chromium), specifically engineered to meet the increasingly stringent requirements of deepwater offshore applications. These advanced grades offer superior resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive chloride-containing environments.

In offshore structures, duplex stainless steels aim to fulfill several critical objectives. Primary among these is ensuring structural integrity under extreme environmental conditions, including exposure to seawater, variable temperatures, and high-pressure environments. The material must maintain its mechanical properties while resisting various forms of corrosion that are accelerated in marine settings.

Cost-effectiveness represents another key goal, as duplex steels offer potential lifecycle cost advantages over traditional materials through reduced maintenance requirements and extended service life. The higher initial investment is often justified by lower total ownership costs when considering the harsh operating conditions of offshore installations.

Weight reduction is particularly significant for floating structures, where duplex steels' higher strength-to-weight ratio compared to conventional austenitic stainless steels enables lighter designs without compromising structural integrity. This characteristic becomes increasingly important as offshore structures move into deeper waters and more remote locations.

Compliance with international standards, particularly NORSOK M-630 and ISO 15156 (NACE MR0175), has become a fundamental objective in offshore applications. These standards establish stringent requirements for materials used in oil and gas production environments, focusing on resistance to sulfide stress cracking, hydrogen-induced cracking, and general corrosion resistance parameters that duplex steels must satisfy.

The ongoing evolution of duplex stainless steels continues to be driven by the offshore industry's push toward more challenging environments, including deeper waters, higher temperatures, and more corrosive conditions, necessitating continuous improvement in material performance and reliability.

Market Demand Analysis for Offshore Structural Materials

The offshore industry has witnessed a significant surge in demand for high-performance structural materials, particularly in harsh marine environments. The global offshore structures market, valued at approximately $145 billion in 2022, is projected to grow at a CAGR of 4.8% through 2030, driven primarily by increased deep-water exploration activities and renewable energy installations such as offshore wind farms.

Duplex stainless steel (DSS) has emerged as a critical material in this sector due to its exceptional combination of mechanical strength and corrosion resistance. Market analysis indicates that DSS consumption in offshore applications has increased by 37% over the past five years, outpacing traditional materials like carbon steel and conventional stainless steel grades.

The North Sea region, governed by stringent NORSOK standards, represents approximately 28% of the global demand for high-performance offshore structural materials. This regional concentration is followed by the Gulf of Mexico (22%), Asia-Pacific (19%), and Brazil's pre-salt fields (14%), with remaining markets constituting 17% of global demand.

Key market drivers include the industry's push toward extended service life expectations for offshore installations, with operators now demanding 30+ year lifespans compared to the previous 20-25 year standard. This shift has intensified focus on materials that can withstand prolonged exposure to seawater, chlorides, and microbiologically influenced corrosion while maintaining structural integrity.

Cost analysis reveals that while DSS carries a 2.5-3x higher initial material cost compared to carbon steel, the total lifecycle cost analysis demonstrates 22-30% savings when factoring in reduced maintenance, downtime, and replacement expenses over a 30-year service period. This economic advantage has strengthened DSS market position despite its premium pricing.

Market segmentation shows topside structures represent 42% of DSS applications in offshore platforms, followed by subsea components (31%), risers and flowlines (18%), and miscellaneous applications (9%). The fastest growth segment is in subsea tie-backs and manifolds, expanding at 7.3% annually due to increased deep-water development.

Supply chain analysis indicates potential constraints in DSS availability, with current global production capacity meeting approximately 85% of projected demand through 2025. This supply-demand gap has prompted major steel producers to announce capacity expansions totaling 120,000 tons annually, expected to come online between 2023-2025.

Customer requirements are increasingly focused on documented compliance with NORSOK M-630/M-650 and ISO 15156 (NACE MR0175) standards, with procurement specifications now routinely requiring full traceability and comprehensive material certification packages.

Duplex stainless steel (DSS) has emerged as a critical material in this sector due to its exceptional combination of mechanical strength and corrosion resistance. Market analysis indicates that DSS consumption in offshore applications has increased by 37% over the past five years, outpacing traditional materials like carbon steel and conventional stainless steel grades.

The North Sea region, governed by stringent NORSOK standards, represents approximately 28% of the global demand for high-performance offshore structural materials. This regional concentration is followed by the Gulf of Mexico (22%), Asia-Pacific (19%), and Brazil's pre-salt fields (14%), with remaining markets constituting 17% of global demand.

Key market drivers include the industry's push toward extended service life expectations for offshore installations, with operators now demanding 30+ year lifespans compared to the previous 20-25 year standard. This shift has intensified focus on materials that can withstand prolonged exposure to seawater, chlorides, and microbiologically influenced corrosion while maintaining structural integrity.

Cost analysis reveals that while DSS carries a 2.5-3x higher initial material cost compared to carbon steel, the total lifecycle cost analysis demonstrates 22-30% savings when factoring in reduced maintenance, downtime, and replacement expenses over a 30-year service period. This economic advantage has strengthened DSS market position despite its premium pricing.

Market segmentation shows topside structures represent 42% of DSS applications in offshore platforms, followed by subsea components (31%), risers and flowlines (18%), and miscellaneous applications (9%). The fastest growth segment is in subsea tie-backs and manifolds, expanding at 7.3% annually due to increased deep-water development.

Supply chain analysis indicates potential constraints in DSS availability, with current global production capacity meeting approximately 85% of projected demand through 2025. This supply-demand gap has prompted major steel producers to announce capacity expansions totaling 120,000 tons annually, expected to come online between 2023-2025.

Customer requirements are increasingly focused on documented compliance with NORSOK M-630/M-650 and ISO 15156 (NACE MR0175) standards, with procurement specifications now routinely requiring full traceability and comprehensive material certification packages.

Current Status and Challenges in Duplex Steel Technology

Duplex stainless steels have gained significant traction in offshore applications due to their exceptional combination of mechanical properties and corrosion resistance. Currently, the global market for duplex stainless steel in offshore structures is experiencing steady growth, with a compound annual growth rate of approximately 5-7%. This growth is primarily driven by increased deep-water exploration activities and the need for materials that can withstand harsh marine environments.

The current technological landscape of duplex stainless steel is characterized by continuous improvements in manufacturing processes, particularly in controlling the balance between austenite and ferrite phases. Modern production techniques have achieved remarkable consistency in maintaining the ideal 50:50 phase ratio, which is crucial for meeting the stringent NORSOK M-630 and ISO 15156 standards required for offshore applications.

Despite these advancements, several significant challenges persist in duplex steel technology. One major obstacle is the susceptibility to hydrogen-induced stress cracking (HISC) in cathodically protected structures, which remains a concern for components exposed to seawater. Research indicates that even super duplex grades can experience embrittlement under certain conditions, particularly at temperatures below -50°C or above 250°C, limiting their application range.

Another technical challenge involves welding procedures for thick-section duplex components. Maintaining proper heat input and cooling rates during welding is critical to preserve the balanced microstructure and avoid precipitation of detrimental intermetallic phases. Industry data shows that approximately 65% of duplex steel failures in offshore applications are related to improper welding practices or heat treatment.

The geographical distribution of duplex steel technology shows concentration in Northern Europe, particularly Norway and Sweden, where most innovation patents originate. Asian manufacturers, especially in China and Japan, are rapidly closing the technology gap, offering more cost-competitive solutions but sometimes struggling with consistent quality control to meet NORSOK standards.

Recent metallurgical research has focused on developing lean duplex grades that maintain critical performance characteristics while reducing costly alloying elements like nickel and molybdenum. These efforts aim to address the volatility in raw material costs, which has seen fluctuations of up to 30% in the past five years, significantly impacting project economics for offshore structures.

The integration of digital monitoring systems with duplex steel components represents an emerging technological frontier. Advanced sensors capable of detecting microstructural changes or early signs of corrosion are being developed, though their implementation in offshore environments remains limited by reliability concerns and the need for robust validation protocols under actual service conditions.

The current technological landscape of duplex stainless steel is characterized by continuous improvements in manufacturing processes, particularly in controlling the balance between austenite and ferrite phases. Modern production techniques have achieved remarkable consistency in maintaining the ideal 50:50 phase ratio, which is crucial for meeting the stringent NORSOK M-630 and ISO 15156 standards required for offshore applications.

Despite these advancements, several significant challenges persist in duplex steel technology. One major obstacle is the susceptibility to hydrogen-induced stress cracking (HISC) in cathodically protected structures, which remains a concern for components exposed to seawater. Research indicates that even super duplex grades can experience embrittlement under certain conditions, particularly at temperatures below -50°C or above 250°C, limiting their application range.

Another technical challenge involves welding procedures for thick-section duplex components. Maintaining proper heat input and cooling rates during welding is critical to preserve the balanced microstructure and avoid precipitation of detrimental intermetallic phases. Industry data shows that approximately 65% of duplex steel failures in offshore applications are related to improper welding practices or heat treatment.

The geographical distribution of duplex steel technology shows concentration in Northern Europe, particularly Norway and Sweden, where most innovation patents originate. Asian manufacturers, especially in China and Japan, are rapidly closing the technology gap, offering more cost-competitive solutions but sometimes struggling with consistent quality control to meet NORSOK standards.

Recent metallurgical research has focused on developing lean duplex grades that maintain critical performance characteristics while reducing costly alloying elements like nickel and molybdenum. These efforts aim to address the volatility in raw material costs, which has seen fluctuations of up to 30% in the past five years, significantly impacting project economics for offshore structures.

The integration of digital monitoring systems with duplex steel components represents an emerging technological frontier. Advanced sensors capable of detecting microstructural changes or early signs of corrosion are being developed, though their implementation in offshore environments remains limited by reliability concerns and the need for robust validation protocols under actual service conditions.

NORSOK/ISO Compliance Solutions for Duplex Steel

01 Composition and microstructure of duplex stainless steel

Duplex stainless steels are characterized by a two-phase microstructure consisting of austenite and ferrite phases. The balanced composition typically includes chromium, nickel, molybdenum, and nitrogen in specific proportions to achieve optimal mechanical properties and corrosion resistance. The microstructure usually aims for a 50:50 ratio of austenite to ferrite, which provides the combination of strength and ductility that makes these steels valuable for various applications.- Composition and microstructure of duplex stainless steel: Duplex stainless steels are characterized by a two-phase microstructure consisting of austenite and ferrite phases. The balanced composition typically includes chromium, nickel, molybdenum, and nitrogen in specific proportions to achieve optimal mechanical properties and corrosion resistance. The microstructure typically aims for a 50/50 ratio of austenite to ferrite, which provides the combination of strength and ductility that makes these steels valuable for various applications.

- Heat treatment and processing methods: Various heat treatment processes are applied to duplex stainless steels to optimize their properties. These include solution annealing, quenching, and controlled cooling to achieve the desired phase balance and prevent the formation of detrimental intermetallic phases. Processing methods such as hot rolling, forging, and welding require specific parameters to maintain the beneficial duplex structure and avoid phase imbalances that could compromise performance.

- Corrosion resistance enhancement: Duplex stainless steels are engineered for superior corrosion resistance in aggressive environments. This is achieved through alloying with elements like chromium, molybdenum, and nitrogen, which enhance pitting and crevice corrosion resistance. Surface treatments and passivation processes can further improve corrosion performance. The balanced microstructure contributes to stress corrosion cracking resistance, making these steels suitable for applications in marine environments, chemical processing, and oil and gas industries.

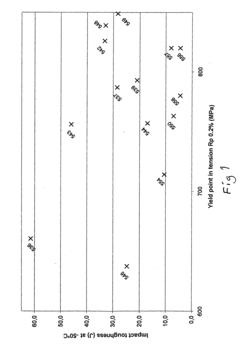

- Mechanical properties and strengthening mechanisms: Duplex stainless steels exhibit high strength combined with good ductility due to their dual-phase structure. Various strengthening mechanisms are employed, including grain refinement, solid solution strengthening, and precipitation hardening. The balance between austenite and ferrite phases can be adjusted to optimize specific mechanical properties such as yield strength, tensile strength, impact toughness, and fatigue resistance for different applications.

- Applications and fabrication techniques: Duplex stainless steels are used in various industries including oil and gas, chemical processing, pulp and paper, and marine applications. Fabrication techniques have been developed to address the challenges associated with these materials, including specialized welding procedures to maintain phase balance, forming methods that accommodate their higher strength, and machining approaches that deal with their work hardening tendency. These techniques enable the production of components ranging from pressure vessels and heat exchangers to offshore structures and desalination equipment.

02 Heat treatment and processing methods

Various heat treatment processes are employed to optimize the properties of duplex stainless steels. These include solution annealing, quenching, and controlled cooling to achieve the desired phase balance and prevent the formation of detrimental intermetallic phases. Processing methods such as hot rolling, forging, and welding require specific parameters to maintain the beneficial duplex microstructure and avoid phase imbalances that could compromise the material's performance.Expand Specific Solutions03 Corrosion resistance enhancement

Duplex stainless steels are engineered for superior corrosion resistance in aggressive environments. This is achieved through alloying with elements like chromium, molybdenum, and nitrogen, which enhance pitting and crevice corrosion resistance. Surface treatments and passivation processes can further improve corrosion performance. The balanced microstructure contributes to stress corrosion cracking resistance, making these steels suitable for applications in marine environments, chemical processing, and oil and gas industries.Expand Specific Solutions04 Mechanical properties and strengthening mechanisms

Duplex stainless steels exhibit high strength combined with good ductility due to their dual-phase microstructure. Various strengthening mechanisms are employed, including grain refinement, solid solution strengthening, and precipitation hardening. The balance between austenite and ferrite phases can be tailored to optimize specific mechanical properties such as yield strength, tensile strength, impact toughness, and fatigue resistance for different applications and service conditions.Expand Specific Solutions05 Applications and specialized grades

Various grades of duplex stainless steels have been developed for specific applications. These include lean duplex grades with lower nickel content for cost-effective applications, super duplex grades with enhanced corrosion resistance for severe environments, and hyper duplex grades for extreme conditions. These specialized steels find applications in offshore structures, desalination plants, chemical processing equipment, pulp and paper industry, and structural components where a combination of strength and corrosion resistance is required.Expand Specific Solutions

Key Manufacturers and Suppliers in Duplex Steel Industry

The duplex stainless steel market for offshore structures is in a mature growth phase, with stringent NORSOK/ISO requirements driving innovation. The global market size is estimated at $3-4 billion annually, growing steadily due to increasing offshore development. Leading players include NIPPON STEEL, JFE Steel, Sandvik, and Alleima Tube, who have developed advanced duplex grades meeting corrosion resistance and mechanical property requirements. POSCO, voestalpine BÖHLER, and Carpenter Technology are investing in R&D to enhance duplex steel performance in harsh marine environments. Technical maturity is high, with established manufacturing processes, though continuous innovation focuses on improving weldability and corrosion resistance in increasingly demanding offshore applications.

NIPPON STEEL CORP.

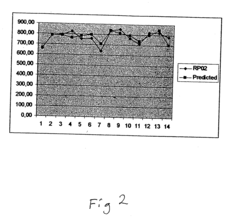

Technical Solution: NIPPON STEEL has developed advanced duplex stainless steel grades specifically engineered to meet NORSOK M-650/ISO 15156 requirements for offshore applications. Their proprietary manufacturing process involves precise control of chemical composition with optimized nitrogen content (0.14-0.20%) and carefully balanced chromium (22-25%) and molybdenum (3-4%) levels to enhance pitting resistance. The company employs a sophisticated solution annealing treatment at temperatures between 1050-1150°C followed by rapid quenching to achieve the ideal austenite-ferrite phase balance (approximately 50:50). Their duplex stainless steels demonstrate exceptional resistance to chloride-induced stress corrosion cracking (CSCC) in marine environments, with critical pitting temperatures exceeding 35°C and PREN values above 40 for super duplex grades. NIPPON STEEL's products undergo rigorous quality control including ultrasonic testing, microstructure examination, and mechanical property verification to ensure compliance with NORSOK standards for offshore structural applications.

Strengths: Superior corrosion resistance in aggressive marine environments; excellent mechanical properties with yield strength typically exceeding 450 MPa; proven track record in offshore applications with documented case studies. Weaknesses: Higher initial cost compared to conventional stainless steels; requires specialized welding procedures to maintain corrosion resistance in the heat-affected zone; limited availability in some product forms.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has pioneered hyper-duplex stainless steel technology specifically designed for extreme offshore environments where NORSOK/ISO compliance is critical. Their SAF 2507® and SAF 3207™ grades feature precisely controlled microstructures with 50:50 austenite-ferrite phase balance achieved through proprietary heat treatment processes. The company's manufacturing approach includes electroslag remelting (ESR) technology to ensure exceptional cleanliness and homogeneity, critical for meeting the stringent inclusion requirements of NORSOK M-650. Sandvik's duplex materials demonstrate superior chloride resistance with CPT (Critical Pitting Temperature) values exceeding 50°C in the most aggressive grades, and PREN values ranging from 40-45, significantly above NORSOK minimum requirements. Their materials undergo comprehensive testing including ferrite measurements, impact testing at -46°C, and accelerated corrosion testing to verify compliance with NORSOK M-601 and M-630 standards. Sandvik has developed specialized welding consumables and procedures that maintain the corrosion resistance and mechanical properties in welded joints, addressing one of the key challenges in offshore applications.

Strengths: Industry-leading pitting corrosion resistance with documented performance in North Sea conditions; comprehensive technical support including welding procedure specifications; extensive qualification testing data available to customers. Weaknesses: Premium pricing compared to standard duplex grades; requires specialized fabrication expertise; limited global production capacity for the most advanced grades.

Critical Patents and Innovations in Duplex Steel Metallurgy

Duplex Stainless Steel

PatentInactiveUS20080138232A1

Innovation

- A duplex stainless steel alloy with optimized composition, including Cr 25-35%, Ni 4-10%, Mo 1-6%, N 0.3-0.6%, and additions of W or Cu and/or Co, which enhances structural stability, corrosion resistance, and weldability by suppressing intermetallic phase precipitation and improving mechanical properties.

Duplex stainless steel having excellent h2s resistance and seawater corrosion resistance

PatentInactiveJP1990205658A

Innovation

- A dual-phase stainless steel composition with balanced components such as C < 0.015%, Si ≤ 1.0%, P ≤ 0.030%, S ≤ 0.015%, Ni 13-18%, Mo 4-8%, and (Cr + 3Mo) ≥ 37% is developed, enhancing seawater corrosion resistance and SSC resistance without requiring cathodic protection, allowing for solid pipe usage without excessive Ni content.

Environmental Impact Assessment of Duplex Steel Applications

The environmental impact of duplex stainless steel applications in offshore structures represents a critical consideration in the context of NORSOK/ISO compliance. Duplex stainless steel demonstrates significant environmental advantages compared to conventional materials used in marine environments. The reduced need for protective coatings eliminates the release of volatile organic compounds (VOCs) and other harmful substances typically associated with painting and coating processes, thereby minimizing air and water pollution during installation and maintenance operations.

The exceptional corrosion resistance of duplex stainless steel substantially extends the service life of offshore structures, reducing the frequency of replacements and repairs. This longevity translates directly into reduced resource consumption and waste generation over the lifecycle of the structure. Life Cycle Assessment (LCA) studies indicate that despite the higher initial embodied energy in duplex steel production, the total environmental footprint is often lower than alternatives when considering the full lifecycle perspective.

Duplex stainless steel's recyclability presents another significant environmental benefit. With recycling rates exceeding 90% in many industrial applications, the material supports circular economy principles. The high scrap value incentivizes recovery at end-of-life, further reducing environmental impact through resource conservation and minimized waste disposal requirements.

In terms of marine ecosystem protection, duplex stainless steel's inert nature minimizes leaching of harmful substances into seawater. Unlike some competing materials that may release heavy metals or other contaminants through corrosion processes, duplex steel maintains its integrity in harsh marine environments, protecting surrounding aquatic ecosystems from potential contamination.

The material's contribution to weight reduction in offshore structures also yields environmental benefits. Lighter structures require less energy during transportation and installation, reducing associated carbon emissions. Additionally, the reduced weight can decrease the environmental disturbance to the seabed during installation processes, particularly important in ecologically sensitive areas.

NORSOK and ISO standards increasingly incorporate environmental performance metrics alongside traditional mechanical and durability requirements. Duplex stainless steel's alignment with these evolving standards positions it favorably as regulatory frameworks continue to emphasize sustainability alongside operational performance. The material's ability to meet stringent environmental criteria while simultaneously satisfying mechanical requirements represents a key advantage in contemporary offshore engineering practice.

The exceptional corrosion resistance of duplex stainless steel substantially extends the service life of offshore structures, reducing the frequency of replacements and repairs. This longevity translates directly into reduced resource consumption and waste generation over the lifecycle of the structure. Life Cycle Assessment (LCA) studies indicate that despite the higher initial embodied energy in duplex steel production, the total environmental footprint is often lower than alternatives when considering the full lifecycle perspective.

Duplex stainless steel's recyclability presents another significant environmental benefit. With recycling rates exceeding 90% in many industrial applications, the material supports circular economy principles. The high scrap value incentivizes recovery at end-of-life, further reducing environmental impact through resource conservation and minimized waste disposal requirements.

In terms of marine ecosystem protection, duplex stainless steel's inert nature minimizes leaching of harmful substances into seawater. Unlike some competing materials that may release heavy metals or other contaminants through corrosion processes, duplex steel maintains its integrity in harsh marine environments, protecting surrounding aquatic ecosystems from potential contamination.

The material's contribution to weight reduction in offshore structures also yields environmental benefits. Lighter structures require less energy during transportation and installation, reducing associated carbon emissions. Additionally, the reduced weight can decrease the environmental disturbance to the seabed during installation processes, particularly important in ecologically sensitive areas.

NORSOK and ISO standards increasingly incorporate environmental performance metrics alongside traditional mechanical and durability requirements. Duplex stainless steel's alignment with these evolving standards positions it favorably as regulatory frameworks continue to emphasize sustainability alongside operational performance. The material's ability to meet stringent environmental criteria while simultaneously satisfying mechanical requirements represents a key advantage in contemporary offshore engineering practice.

Lifecycle Cost Analysis of Duplex Steel in Offshore Structures

When evaluating the economic viability of duplex stainless steel in offshore structures, lifecycle cost analysis provides a comprehensive framework that extends beyond initial investment considerations. The total cost of ownership encompasses acquisition, installation, maintenance, replacement, and eventual decommissioning expenses over the structure's operational lifespan, typically 25-30 years for offshore installations.

Initial capital expenditure for duplex stainless steel is approximately 15-20% higher than conventional carbon steel alternatives. However, this premium is offset by significant long-term economic advantages. The superior corrosion resistance of duplex grades reduces maintenance frequency by an estimated 60-70% compared to carbon steel, translating to lower operational expenditures and extended service intervals.

Maintenance cost differentials become particularly pronounced in the aggressive marine environment. While carbon steel structures may require comprehensive maintenance every 3-5 years, duplex stainless steel installations can operate effectively for 10-15 years between major maintenance cycles. This reduction in downtime delivers substantial indirect economic benefits through increased operational availability.

The extended service life of duplex stainless steel—often exceeding design specifications by 5-10 years—further enhances its economic proposition. This longevity effectively amortizes the initial investment over a longer period, improving return on investment metrics. Industry case studies indicate that the break-even point typically occurs between years 7-10 of operation, after which duplex installations demonstrate clear economic advantages.

Risk mitigation represents another significant economic factor. The reduced probability of catastrophic failure with duplex stainless steel minimizes potential financial exposure from production interruptions, environmental remediation, and regulatory penalties. Quantitative risk assessments suggest that this risk reduction can be valued at 5-8% of total project costs.

Energy efficiency during manufacturing processes must also be considered. While duplex steel production requires approximately 12% more energy than carbon steel manufacturing, this is counterbalanced by reduced material requirements due to duplex's superior strength-to-weight ratio. The net environmental impact assessment typically favors duplex when evaluated across the complete lifecycle.

Recent advancements in manufacturing technologies have progressively reduced the cost premium for duplex grades, improving their competitive position. Market analysis indicates a downward trend in the price differential between duplex and conventional alternatives, enhancing the economic case for duplex adoption in offshore applications where compliance with NORSOK/ISO standards is mandatory.

Initial capital expenditure for duplex stainless steel is approximately 15-20% higher than conventional carbon steel alternatives. However, this premium is offset by significant long-term economic advantages. The superior corrosion resistance of duplex grades reduces maintenance frequency by an estimated 60-70% compared to carbon steel, translating to lower operational expenditures and extended service intervals.

Maintenance cost differentials become particularly pronounced in the aggressive marine environment. While carbon steel structures may require comprehensive maintenance every 3-5 years, duplex stainless steel installations can operate effectively for 10-15 years between major maintenance cycles. This reduction in downtime delivers substantial indirect economic benefits through increased operational availability.

The extended service life of duplex stainless steel—often exceeding design specifications by 5-10 years—further enhances its economic proposition. This longevity effectively amortizes the initial investment over a longer period, improving return on investment metrics. Industry case studies indicate that the break-even point typically occurs between years 7-10 of operation, after which duplex installations demonstrate clear economic advantages.

Risk mitigation represents another significant economic factor. The reduced probability of catastrophic failure with duplex stainless steel minimizes potential financial exposure from production interruptions, environmental remediation, and regulatory penalties. Quantitative risk assessments suggest that this risk reduction can be valued at 5-8% of total project costs.

Energy efficiency during manufacturing processes must also be considered. While duplex steel production requires approximately 12% more energy than carbon steel manufacturing, this is counterbalanced by reduced material requirements due to duplex's superior strength-to-weight ratio. The net environmental impact assessment typically favors duplex when evaluated across the complete lifecycle.

Recent advancements in manufacturing technologies have progressively reduced the cost premium for duplex grades, improving their competitive position. Market analysis indicates a downward trend in the price differential between duplex and conventional alternatives, enhancing the economic case for duplex adoption in offshore applications where compliance with NORSOK/ISO standards is mandatory.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!