Duplex Stainless Steel Sour Service: Sulfide Stress Cracking, Standards And Qualification

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex Stainless Steel in Sour Service: Background and Objectives

Duplex stainless steels (DSS) have emerged as a critical material class in the oil and gas industry over the past four decades, offering an optimal balance between mechanical properties and corrosion resistance. The evolution of these materials began in the 1930s, but significant commercial development only occurred in the 1970s with the introduction of 2205 grade (UNS S31803/S32205), which remains the most widely used DSS today.

The technological trajectory of DSS has been characterized by continuous metallurgical advancements aimed at enhancing performance in increasingly harsh environments. From first-generation duplex alloys to modern super duplex and hyper duplex grades, the microstructural engineering has focused on achieving balanced austenite-ferrite phases while controlling detrimental intermetallic precipitates.

Sour service environments, containing hydrogen sulfide (H₂S), present particularly challenging conditions for metallic materials. The combination of H₂S, chlorides, and CO₂ creates highly corrosive conditions that can lead to various degradation mechanisms, with sulfide stress cracking (SSC) being one of the most severe and unpredictable failure modes.

The primary technical objective in this field is to establish reliable performance boundaries for DSS in sour service applications. This includes determining critical environmental parameters (H₂S partial pressure, chloride concentration, pH, temperature) and material factors (composition, microstructure, heat treatment) that govern SSC susceptibility.

Industry standards have evolved significantly, with NACE MR0175/ISO 15156 serving as the cornerstone document for material qualification in sour service. However, the complex metallurgy of DSS has created challenges in developing comprehensive acceptance criteria that adequately address all potential failure mechanisms.

Recent research has focused on understanding the fundamental mechanisms of hydrogen-induced cracking in the dual-phase microstructure of DSS. The interaction between hydrogen and the austenite-ferrite interface, along with the role of microalloying elements and precipitates, represents a frontier in materials science with significant practical implications.

The technological goals for DSS in sour service applications include expanding the operational envelope to more severe conditions, developing more reliable qualification methodologies, and establishing predictive models for long-term performance. Additionally, there is growing interest in correlating laboratory testing with actual field performance to bridge the gap between theoretical understanding and practical application.

As global energy demands drive exploration and production into more challenging environments, the development of DSS with enhanced sour service resistance represents a critical enabling technology for the industry's future.

The technological trajectory of DSS has been characterized by continuous metallurgical advancements aimed at enhancing performance in increasingly harsh environments. From first-generation duplex alloys to modern super duplex and hyper duplex grades, the microstructural engineering has focused on achieving balanced austenite-ferrite phases while controlling detrimental intermetallic precipitates.

Sour service environments, containing hydrogen sulfide (H₂S), present particularly challenging conditions for metallic materials. The combination of H₂S, chlorides, and CO₂ creates highly corrosive conditions that can lead to various degradation mechanisms, with sulfide stress cracking (SSC) being one of the most severe and unpredictable failure modes.

The primary technical objective in this field is to establish reliable performance boundaries for DSS in sour service applications. This includes determining critical environmental parameters (H₂S partial pressure, chloride concentration, pH, temperature) and material factors (composition, microstructure, heat treatment) that govern SSC susceptibility.

Industry standards have evolved significantly, with NACE MR0175/ISO 15156 serving as the cornerstone document for material qualification in sour service. However, the complex metallurgy of DSS has created challenges in developing comprehensive acceptance criteria that adequately address all potential failure mechanisms.

Recent research has focused on understanding the fundamental mechanisms of hydrogen-induced cracking in the dual-phase microstructure of DSS. The interaction between hydrogen and the austenite-ferrite interface, along with the role of microalloying elements and precipitates, represents a frontier in materials science with significant practical implications.

The technological goals for DSS in sour service applications include expanding the operational envelope to more severe conditions, developing more reliable qualification methodologies, and establishing predictive models for long-term performance. Additionally, there is growing interest in correlating laboratory testing with actual field performance to bridge the gap between theoretical understanding and practical application.

As global energy demands drive exploration and production into more challenging environments, the development of DSS with enhanced sour service resistance represents a critical enabling technology for the industry's future.

Market Demand Analysis for Sour Service Applications

The global market for sour service applications has experienced significant growth over the past decade, primarily driven by the increasing exploration and production activities in oil and gas fields with high hydrogen sulfide (H2S) content. These environments, characterized by their corrosive nature, require specialized materials such as duplex stainless steel (DSS) that can withstand sulfide stress cracking (SSC) while maintaining structural integrity.

The oil and gas industry remains the dominant consumer of sour service-capable materials, accounting for approximately 70% of the total market demand. Within this sector, offshore deep-water developments and unconventional resource extraction have emerged as key growth segments, as these operations frequently encounter sour conditions requiring specialized metallurgical solutions.

Market analysis indicates that the Middle East, North America, and parts of Asia-Pacific represent the largest regional markets for sour service applications. The Middle East, with its extensive sour gas reserves, has seen particularly strong demand growth, with Saudi Arabia, UAE, and Qatar leading regional investments in sour service infrastructure.

Beyond oil and gas, chemical processing industries have emerged as significant secondary markets, particularly in applications involving sulfuric acid production, petrochemical processing, and fertilizer manufacturing. These sectors collectively represent about 20% of the total market demand for sour service-capable materials.

The global market value for duplex stainless steel in sour service applications reached substantial levels in recent years, with annual growth rates consistently outpacing those of conventional stainless steel products. This premium pricing reflects both the specialized nature of these materials and their critical importance in preventing catastrophic failures in sour environments.

Industry forecasts suggest continued market expansion, driven by several factors: increasing development of sour oil and gas fields, aging infrastructure requiring replacement with more corrosion-resistant materials, and stricter regulatory requirements regarding material qualification and safety standards for sour service.

Customer requirements in this market segment emphasize reliable performance under extreme conditions, with particular focus on resistance to sulfide stress cracking, pitting corrosion resistance, and mechanical properties retention in sour environments. These demanding specifications have created opportunities for premium material suppliers who can demonstrate comprehensive qualification testing and compliance with international standards such as NACE MR0175/ISO 15156.

The competitive landscape features both integrated steel manufacturers and specialized alloy producers, with market differentiation increasingly based on technical service capabilities, material qualification expertise, and ability to provide customized solutions for specific sour service applications.

The oil and gas industry remains the dominant consumer of sour service-capable materials, accounting for approximately 70% of the total market demand. Within this sector, offshore deep-water developments and unconventional resource extraction have emerged as key growth segments, as these operations frequently encounter sour conditions requiring specialized metallurgical solutions.

Market analysis indicates that the Middle East, North America, and parts of Asia-Pacific represent the largest regional markets for sour service applications. The Middle East, with its extensive sour gas reserves, has seen particularly strong demand growth, with Saudi Arabia, UAE, and Qatar leading regional investments in sour service infrastructure.

Beyond oil and gas, chemical processing industries have emerged as significant secondary markets, particularly in applications involving sulfuric acid production, petrochemical processing, and fertilizer manufacturing. These sectors collectively represent about 20% of the total market demand for sour service-capable materials.

The global market value for duplex stainless steel in sour service applications reached substantial levels in recent years, with annual growth rates consistently outpacing those of conventional stainless steel products. This premium pricing reflects both the specialized nature of these materials and their critical importance in preventing catastrophic failures in sour environments.

Industry forecasts suggest continued market expansion, driven by several factors: increasing development of sour oil and gas fields, aging infrastructure requiring replacement with more corrosion-resistant materials, and stricter regulatory requirements regarding material qualification and safety standards for sour service.

Customer requirements in this market segment emphasize reliable performance under extreme conditions, with particular focus on resistance to sulfide stress cracking, pitting corrosion resistance, and mechanical properties retention in sour environments. These demanding specifications have created opportunities for premium material suppliers who can demonstrate comprehensive qualification testing and compliance with international standards such as NACE MR0175/ISO 15156.

The competitive landscape features both integrated steel manufacturers and specialized alloy producers, with market differentiation increasingly based on technical service capabilities, material qualification expertise, and ability to provide customized solutions for specific sour service applications.

Current Challenges in Sulfide Stress Cracking Resistance

Sulfide Stress Cracking (SSC) presents significant challenges for duplex stainless steels in sour service environments, with several persistent technical obstacles impeding optimal performance. The primary challenge lies in accurately predicting SSC behavior across varying environmental conditions, as the interaction between hydrogen sulfide concentration, pH levels, temperature, and mechanical stress creates complex failure mechanisms that current models struggle to fully capture.

Material qualification standards such as NACE MR0175/ISO 15156 provide guidelines for duplex stainless steel usage in sour environments, but these standards often lag behind industry needs for innovative alloy compositions. The qualification process itself remains time-consuming and expensive, requiring extensive laboratory testing that may not perfectly simulate real-world service conditions, particularly for the newer generation of super and hyper duplex stainless steels.

Microstructural control presents another significant challenge, as the balance between austenite and ferrite phases critically influences SSC resistance. Achieving and maintaining the optimal phase ratio (typically 50:50) during manufacturing processes like welding, heat treatment, and forming operations requires precise control that can be difficult to maintain consistently in industrial settings. The ferrite phase, being more susceptible to hydrogen embrittlement, often becomes the weak link in SSC resistance.

The presence of secondary phases such as sigma, chi, and various carbides and nitrides further complicates SSC resistance. These phases, which can form during improper heat treatment or welding, create preferential paths for crack initiation and propagation. Current non-destructive testing methods have limitations in detecting these microstructural features at early stages, particularly in field conditions.

Environmental variability in actual service conditions introduces additional complexity. Fluctuating H₂S concentrations, CO₂ partial pressures, chloride content, and temperature cycling can all influence SSC susceptibility in ways that are difficult to predict from standard laboratory tests. This variability makes it challenging to establish definitive safe operating envelopes for specific duplex grades.

The industry also faces challenges in developing standardized testing protocols that accurately reflect real-world service conditions. Current test methods like NACE TM0177 and NACE TM0316 have limitations in simulating the complex stress states and environmental conditions encountered in actual operations, potentially leading to either overly conservative or insufficiently protective material selections.

Knowledge gaps persist regarding the fundamental mechanisms of hydrogen diffusion and trapping in the dual-phase microstructure of duplex stainless steels, hampering the development of more resistant alloys. Additionally, the long-term effects of aging and cyclic loading on SSC resistance remain inadequately understood, creating uncertainty for applications with extended service life requirements.

Material qualification standards such as NACE MR0175/ISO 15156 provide guidelines for duplex stainless steel usage in sour environments, but these standards often lag behind industry needs for innovative alloy compositions. The qualification process itself remains time-consuming and expensive, requiring extensive laboratory testing that may not perfectly simulate real-world service conditions, particularly for the newer generation of super and hyper duplex stainless steels.

Microstructural control presents another significant challenge, as the balance between austenite and ferrite phases critically influences SSC resistance. Achieving and maintaining the optimal phase ratio (typically 50:50) during manufacturing processes like welding, heat treatment, and forming operations requires precise control that can be difficult to maintain consistently in industrial settings. The ferrite phase, being more susceptible to hydrogen embrittlement, often becomes the weak link in SSC resistance.

The presence of secondary phases such as sigma, chi, and various carbides and nitrides further complicates SSC resistance. These phases, which can form during improper heat treatment or welding, create preferential paths for crack initiation and propagation. Current non-destructive testing methods have limitations in detecting these microstructural features at early stages, particularly in field conditions.

Environmental variability in actual service conditions introduces additional complexity. Fluctuating H₂S concentrations, CO₂ partial pressures, chloride content, and temperature cycling can all influence SSC susceptibility in ways that are difficult to predict from standard laboratory tests. This variability makes it challenging to establish definitive safe operating envelopes for specific duplex grades.

The industry also faces challenges in developing standardized testing protocols that accurately reflect real-world service conditions. Current test methods like NACE TM0177 and NACE TM0316 have limitations in simulating the complex stress states and environmental conditions encountered in actual operations, potentially leading to either overly conservative or insufficiently protective material selections.

Knowledge gaps persist regarding the fundamental mechanisms of hydrogen diffusion and trapping in the dual-phase microstructure of duplex stainless steels, hampering the development of more resistant alloys. Additionally, the long-term effects of aging and cyclic loading on SSC resistance remain inadequately understood, creating uncertainty for applications with extended service life requirements.

Existing Standards and Testing Methodologies

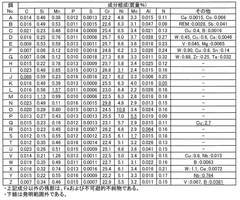

01 Composition modifications to improve SSC resistance

Specific alloying elements can be added to duplex stainless steel to enhance its resistance to sulfide stress cracking (SSC). These modifications typically involve optimizing the balance of chromium, nickel, molybdenum, and nitrogen content. Increasing molybdenum content particularly improves resistance in H2S environments, while controlled nitrogen additions help maintain the austenite-ferrite phase balance while enhancing corrosion resistance. These compositional adjustments create a microstructure that is more resistant to crack initiation and propagation in sulfidic environments.- Composition modifications to improve SSC resistance: Specific alloying elements can be added to duplex stainless steel to improve resistance to sulfide stress cracking (SSC). These modifications typically include optimizing the balance of chromium, nickel, molybdenum, and nitrogen content. Increasing molybdenum content particularly enhances SSC resistance in hydrogen sulfide environments. Controlled additions of elements like tungsten and copper can also contribute to improved corrosion resistance in sulfide-containing environments.

- Heat treatment processes for SSC prevention: Specific heat treatment processes can significantly improve the resistance of duplex stainless steel to sulfide stress cracking. Solution annealing followed by controlled cooling helps achieve optimal phase balance between ferrite and austenite phases. Post-weld heat treatment is particularly important to restore the microstructure after welding operations. Proper heat treatment can dissolve detrimental precipitates and ensure uniform distribution of alloying elements, thereby enhancing resistance to hydrogen-induced cracking in sulfide environments.

- Microstructure control for enhanced SSC resistance: Controlling the microstructure of duplex stainless steel is crucial for preventing sulfide stress cracking. Maintaining an optimal ferrite-austenite phase balance (typically 40-60% ferrite) helps distribute mechanical stresses and corrosion resistance properties. Avoiding detrimental intermetallic phases such as sigma phase and chi phase, which can form during improper processing, is essential. Fine grain structure and uniform distribution of alloying elements throughout the microstructure significantly improve resistance to hydrogen embrittlement in sulfide environments.

- Surface treatments and coatings for SSC protection: Various surface treatments and coating methods can be applied to duplex stainless steel to enhance its resistance to sulfide stress cracking. Shot peening and other mechanical surface treatments can introduce compressive stresses that inhibit crack initiation. Specialized coatings and surface modifications can create protective barriers against sulfide environments. Electrochemical treatments may also be employed to modify the surface properties and enhance resistance to hydrogen penetration, which is a key factor in sulfide stress cracking mechanisms.

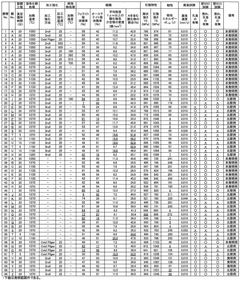

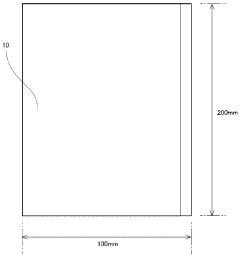

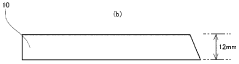

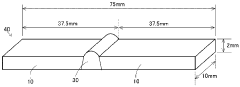

- Testing and evaluation methods for SSC susceptibility: Specific testing methodologies have been developed to evaluate the susceptibility of duplex stainless steel to sulfide stress cracking. These include NACE standard tests in hydrogen sulfide environments under various pH conditions and temperatures. Slow strain rate testing (SSRT) and constant load testing are commonly employed to assess material performance. Electrochemical testing methods can also be used to determine critical parameters related to SSC resistance. These testing protocols help in material selection and qualification for applications in sulfide-containing environments.

02 Heat treatment processes for SSC resistance

Specific heat treatment protocols can significantly improve the sulfide stress cracking resistance of duplex stainless steels. These processes typically involve solution annealing followed by controlled cooling to achieve optimal phase balance between austenite and ferrite. The heat treatment temperature, duration, and cooling rate are critical parameters that affect the precipitation of secondary phases and the distribution of alloying elements between the phases. Proper heat treatment can dissolve detrimental precipitates at grain boundaries and create a more homogeneous microstructure with enhanced resistance to hydrogen-induced cracking in sulfide environments.Expand Specific Solutions03 Surface treatments and coatings for SSC protection

Various surface treatments and coating technologies can be applied to duplex stainless steels to enhance their resistance to sulfide stress cracking. These include nitriding processes, specialized passivation treatments, and protective overlay coatings. Surface modification techniques create a barrier layer that prevents direct contact between the steel substrate and the corrosive sulfide environment. Some treatments also induce compressive stresses in the surface layer, which counteract the tensile stresses that drive crack propagation. These approaches are particularly effective for components operating in severe sour service conditions.Expand Specific Solutions04 Testing and evaluation methods for SSC susceptibility

Specialized testing methodologies have been developed to evaluate the susceptibility of duplex stainless steels to sulfide stress cracking. These include slow strain rate testing in H2S environments, four-point bend tests, and electrochemical hydrogen permeation measurements. Testing protocols typically involve exposing stressed specimens to simulated sour service conditions and measuring time to failure or crack initiation. These evaluation methods help in material selection, quality control, and predicting in-service performance of duplex stainless steels in sulfidic environments. The test results can be correlated with microstructural features to develop improved alloys with enhanced SSC resistance.Expand Specific Solutions05 Microstructural control for improved SSC performance

Controlling the microstructure of duplex stainless steels is crucial for enhancing resistance to sulfide stress cracking. This involves optimizing the austenite-ferrite phase ratio, minimizing detrimental precipitates such as sigma phase and chromium nitrides, and refining grain size. Processing techniques such as controlled rolling, quenching, and tempering can be employed to achieve the desired microstructure. A balanced phase distribution with fine grain size reduces hydrogen diffusion paths and trapping sites, thereby improving resistance to hydrogen embrittlement in sulfide environments. The absence of intermetallic phases at grain boundaries also prevents preferential corrosion attack and crack initiation.Expand Specific Solutions

Key Industry Players and Material Suppliers

The duplex stainless steel sour service market is currently in a growth phase, with increasing demand driven by oil and gas exploration in harsh environments. The global market size is estimated to exceed $5 billion, expanding at 5-7% annually due to rising energy infrastructure investments. Technologically, companies like NIPPON STEEL, JFE Steel, and Sandvik Intellectual Property AB lead innovation in sulfide stress cracking resistance, while POSCO Holdings and Alleima Tube AB have developed proprietary alloy compositions that exceed NACE MR0175 standards. Chinese manufacturers including Shanxi Taigang and Baoshan Iron & Steel are rapidly advancing their capabilities, particularly in qualification testing methodologies that align with international standards for high-pressure sour service applications.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced duplex stainless steel grades specifically engineered for sour service environments. Their proprietary NSSC® 2120 duplex stainless steel demonstrates exceptional resistance to sulfide stress cracking (SSC) through optimized chemical composition with controlled nitrogen content (0.14-0.20%) and precise microstructural balance (approximately 50:50 ferrite-austenite ratio). The company employs a specialized heat treatment process that includes solution annealing at temperatures between 1050-1100°C followed by rapid quenching to prevent detrimental phase precipitation. Their manufacturing protocol includes rigorous quality control measures with 100% ultrasonic testing and comprehensive mechanical property verification including NACE TM0177 Method A testing at H2S partial pressures exceeding 10 kPa to ensure SSC resistance in severe sour service conditions.

Strengths: Superior SSC resistance in high H2S environments; excellent combination of mechanical properties and corrosion resistance; comprehensive quality control system ensuring consistent performance. Weaknesses: Higher production costs compared to standard stainless steels; limited application in extremely high chloride environments; requires careful control during welding to maintain corrosion resistance.

JFE Steel Corp.

Technical Solution: JFE Steel has developed the JFE-SUS 329J4L duplex stainless steel specifically engineered for sour service applications. Their approach focuses on microstructural optimization through precise control of alloying elements, particularly nitrogen (0.15-0.22%) and molybdenum (3-4%), to achieve superior resistance to sulfide stress cracking. JFE employs a proprietary thermomechanical processing technique that includes controlled hot rolling followed by specialized heat treatment at temperatures between 1050-1080°C to establish an optimal phase balance of approximately 50% ferrite and 50% austenite. Their qualification methodology incorporates extensive testing according to NACE TM0177 Method A with H2S partial pressures up to 15 kPa and temperatures ranging from ambient to 120°C. JFE's manufacturing process includes comprehensive quality control measures with advanced non-destructive testing techniques and microstructural verification to ensure consistent SSC resistance across production batches.

Strengths: Excellent balance of mechanical properties and SSC resistance; comprehensive quality control system; extensive field performance data supporting reliability. Weaknesses: Somewhat lower resistance to extremely aggressive environments compared to hyper-duplex grades; requires careful control of welding parameters; limited availability in certain specialized product forms.

Critical Metallurgical Factors Affecting SSC Resistance

Duplex stainless steel and seamless duplex stainless steel pipe

PatentWO2021246118A1

Innovation

- A duplex stainless steel with specific composition and microstructure, including 20-70% austenite and 30-80% ferrite phases, controlled oxide inclusions, and reduced Al2O3 inclusions, achieving a yield strength of 448 MPa or more and improved sulfide stress corrosion cracking resistance.

Two-phase stainless steel

PatentWO2011030709A1

Innovation

- A duplex stainless steel composition is developed with specific chemical ratios of Cr, Mo, Cu, Ni, and N to strengthen the passive film and suppress intermetallic compound precipitation, ensuring excellent weldability and stress corrosion cracking resistance by satisfying the relationships 2.2Cr + 7Mo + 3Cu > 66 and Cr + 11Mo + 10Ni < 12(Cu + 30N, with additional elements like V, Ca, Mg, B, and rare earth elements to enhance properties.

Regulatory Compliance and Industry Specifications

The regulatory landscape for duplex stainless steel (DSS) in sour service environments is governed by a comprehensive framework of international standards and industry specifications. NACE MR0175/ISO 15156 stands as the cornerstone document, establishing the fundamental requirements for materials used in hydrogen sulfide (H₂S) containing environments. This standard specifically addresses the qualification procedures for DSS, detailing the acceptable microstructural characteristics, chemical composition limits, and mechanical property thresholds necessary to mitigate sulfide stress cracking (SSC) risks.

European standards, particularly EN 10088 and EN 10283, provide complementary specifications for DSS products, with special provisions for sour service applications. These standards incorporate stringent testing protocols to verify material performance under simulated sour conditions, including slow strain rate testing (SSRT) and four-point bend testing methodologies.

The American Petroleum Institute (API) has developed several specifications directly applicable to DSS in sour environments, notably API 6A and API 17D for wellhead and subsea equipment respectively. These documents establish material qualification routes specific to the oil and gas industry, with particular emphasis on environmental severity levels that correlate with H₂S concentration, temperature, and pressure parameters.

ASTM International contributes significantly to the regulatory framework with standards such as ASTM A923 for microstructural testing and ASTM G48 for pitting corrosion resistance. These testing methodologies form critical components of the qualification process for DSS intended for sour service applications, ensuring material integrity under aggressive environmental conditions.

Industry-specific requirements are further defined by operator specifications, which often exceed the baseline requirements established by international standards. Major oil and gas companies typically maintain proprietary material specifications that incorporate additional testing requirements, more conservative acceptance criteria, and specific heat treatment parameters for DSS components destined for sour service.

Compliance verification typically involves third-party certification and documentation, with material test reports (MTRs) serving as the primary verification mechanism. These reports must demonstrate adherence to all applicable standards and specifications, including chemical composition, mechanical properties, and specialized corrosion testing results.

Recent regulatory trends indicate a movement toward harmonization of international standards, with increasing emphasis on performance-based qualification rather than prescriptive requirements. This evolution reflects the growing understanding of the complex metallurgical factors influencing DSS performance in sour environments and acknowledges the need for application-specific qualification protocols rather than universal acceptance criteria.

European standards, particularly EN 10088 and EN 10283, provide complementary specifications for DSS products, with special provisions for sour service applications. These standards incorporate stringent testing protocols to verify material performance under simulated sour conditions, including slow strain rate testing (SSRT) and four-point bend testing methodologies.

The American Petroleum Institute (API) has developed several specifications directly applicable to DSS in sour environments, notably API 6A and API 17D for wellhead and subsea equipment respectively. These documents establish material qualification routes specific to the oil and gas industry, with particular emphasis on environmental severity levels that correlate with H₂S concentration, temperature, and pressure parameters.

ASTM International contributes significantly to the regulatory framework with standards such as ASTM A923 for microstructural testing and ASTM G48 for pitting corrosion resistance. These testing methodologies form critical components of the qualification process for DSS intended for sour service applications, ensuring material integrity under aggressive environmental conditions.

Industry-specific requirements are further defined by operator specifications, which often exceed the baseline requirements established by international standards. Major oil and gas companies typically maintain proprietary material specifications that incorporate additional testing requirements, more conservative acceptance criteria, and specific heat treatment parameters for DSS components destined for sour service.

Compliance verification typically involves third-party certification and documentation, with material test reports (MTRs) serving as the primary verification mechanism. These reports must demonstrate adherence to all applicable standards and specifications, including chemical composition, mechanical properties, and specialized corrosion testing results.

Recent regulatory trends indicate a movement toward harmonization of international standards, with increasing emphasis on performance-based qualification rather than prescriptive requirements. This evolution reflects the growing understanding of the complex metallurgical factors influencing DSS performance in sour environments and acknowledges the need for application-specific qualification protocols rather than universal acceptance criteria.

Economic Impact and Total Cost of Ownership Analysis

The economic implications of sulfide stress cracking (SSC) in duplex stainless steel (DSS) applications extend far beyond immediate repair costs. When analyzing the total cost of ownership (TCO) for DSS in sour service environments, organizations must consider both direct and indirect financial impacts across the asset lifecycle.

Initial material selection decisions significantly influence long-term economics. While DSS typically commands a 15-30% premium over conventional carbon steel alternatives, this investment often yields substantial returns through extended service life and reduced maintenance requirements. Industry data suggests that properly qualified DSS can deliver 2-3 times longer operational lifespans in sour environments compared to carbon steel with traditional protective measures.

Failure incidents related to SSC carry severe economic consequences. A single catastrophic failure in critical oil and gas infrastructure can result in production losses exceeding $1 million per day, not including remediation costs. Statistical analysis of offshore platform incidents indicates that SSC-related failures account for approximately 18% of total downtime in sour service operations, with average repair costs ranging from $2-5 million per incident.

Preventive measures, including proper material qualification testing and adherence to standards like NACE MR0175/ISO 15156, represent a fraction of potential failure costs. Comprehensive testing programs typically add 2-5% to initial project costs but can reduce lifetime maintenance expenses by up to 40% and virtually eliminate catastrophic failure risks when properly implemented.

The economic calculus extends to operational considerations as well. DSS installations generally require less frequent inspection intervals than carbon steel alternatives, reducing both direct inspection costs and associated production interruptions. Maintenance savings over a typical 25-year service life can offset the higher initial investment several times over.

Environmental and regulatory compliance factors further influence the TCO equation. Penalties for environmental releases resulting from material failures have increased dramatically, with some jurisdictions imposing fines exceeding $50,000 per day of violation. The reputational damage from such incidents can impact share value and stakeholder relationships for years following an incident.

When properly qualified for sour service conditions, DSS offers compelling economic advantages despite higher upfront costs. Organizations adopting lifecycle cost modeling approaches consistently identify DSS as the most cost-effective solution for critical sour service applications where reliability and longevity are paramount considerations.

Initial material selection decisions significantly influence long-term economics. While DSS typically commands a 15-30% premium over conventional carbon steel alternatives, this investment often yields substantial returns through extended service life and reduced maintenance requirements. Industry data suggests that properly qualified DSS can deliver 2-3 times longer operational lifespans in sour environments compared to carbon steel with traditional protective measures.

Failure incidents related to SSC carry severe economic consequences. A single catastrophic failure in critical oil and gas infrastructure can result in production losses exceeding $1 million per day, not including remediation costs. Statistical analysis of offshore platform incidents indicates that SSC-related failures account for approximately 18% of total downtime in sour service operations, with average repair costs ranging from $2-5 million per incident.

Preventive measures, including proper material qualification testing and adherence to standards like NACE MR0175/ISO 15156, represent a fraction of potential failure costs. Comprehensive testing programs typically add 2-5% to initial project costs but can reduce lifetime maintenance expenses by up to 40% and virtually eliminate catastrophic failure risks when properly implemented.

The economic calculus extends to operational considerations as well. DSS installations generally require less frequent inspection intervals than carbon steel alternatives, reducing both direct inspection costs and associated production interruptions. Maintenance savings over a typical 25-year service life can offset the higher initial investment several times over.

Environmental and regulatory compliance factors further influence the TCO equation. Penalties for environmental releases resulting from material failures have increased dramatically, with some jurisdictions imposing fines exceeding $50,000 per day of violation. The reputational damage from such incidents can impact share value and stakeholder relationships for years following an incident.

When properly qualified for sour service conditions, DSS offers compelling economic advantages despite higher upfront costs. Organizations adopting lifecycle cost modeling approaches consistently identify DSS as the most cost-effective solution for critical sour service applications where reliability and longevity are paramount considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!