Lithium Fluoride vs. Magnesium Fluoride in Optical Lenses

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Optical Coating Materials Background and Objectives

Optical coating materials have evolved significantly over the past century, with fluoride compounds emerging as critical components in high-performance optical systems. The development trajectory of these materials has been driven by increasing demands for superior optical performance across broader spectral ranges, particularly in ultraviolet and infrared applications. Lithium Fluoride (LiF) and Magnesium Fluoride (MgF2) represent two cornerstone materials in this evolution, each offering distinct advantages that have shaped modern optical technology.

Historically, optical coatings began with simple single-layer designs in the early 20th century, progressing to complex multi-layer systems by mid-century. The 1970s and 1980s saw significant advancements in fluoride coating technologies, with LiF gaining prominence for its exceptional transmission in the deep ultraviolet range. Concurrently, MgF2 established itself as a versatile coating material due to its mechanical durability and broad spectral performance.

The technological progression has been marked by continuous improvements in deposition techniques, from thermal evaporation to advanced ion-assisted deposition methods, enabling better control over film properties and expanding the practical applications of these materials. Recent developments have focused on enhancing the environmental stability and longevity of fluoride coatings, addressing historical limitations in humidity resistance and mechanical robustness.

Current market trends indicate growing demand for high-performance optical components in semiconductor lithography, space-based imaging systems, and advanced medical diagnostics. These applications require increasingly specialized optical properties, driving research into the comparative advantages of different fluoride materials and their optimal implementation in complex optical systems.

The primary technical objective of this analysis is to establish a comprehensive comparison framework between LiF and MgF2 as optical coating materials, evaluating their respective performance characteristics across various application environments. This includes quantitative assessment of their transmission properties, refractive indices across different wavelengths, mechanical durability, and long-term stability under varying environmental conditions.

Secondary objectives include identifying optimal deposition parameters for each material, evaluating their compatibility with different substrate materials, and exploring potential hybrid coating systems that leverage the complementary properties of both materials. Additionally, this analysis aims to forecast future development directions for fluoride coating technologies, considering emerging applications in quantum optics, extreme ultraviolet lithography, and next-generation astronomical instrumentation.

By establishing clear performance benchmarks and application-specific guidelines, this analysis seeks to provide optical system designers with actionable insights for material selection, ultimately contributing to advancements in optical technology across scientific, industrial, and consumer applications.

Historically, optical coatings began with simple single-layer designs in the early 20th century, progressing to complex multi-layer systems by mid-century. The 1970s and 1980s saw significant advancements in fluoride coating technologies, with LiF gaining prominence for its exceptional transmission in the deep ultraviolet range. Concurrently, MgF2 established itself as a versatile coating material due to its mechanical durability and broad spectral performance.

The technological progression has been marked by continuous improvements in deposition techniques, from thermal evaporation to advanced ion-assisted deposition methods, enabling better control over film properties and expanding the practical applications of these materials. Recent developments have focused on enhancing the environmental stability and longevity of fluoride coatings, addressing historical limitations in humidity resistance and mechanical robustness.

Current market trends indicate growing demand for high-performance optical components in semiconductor lithography, space-based imaging systems, and advanced medical diagnostics. These applications require increasingly specialized optical properties, driving research into the comparative advantages of different fluoride materials and their optimal implementation in complex optical systems.

The primary technical objective of this analysis is to establish a comprehensive comparison framework between LiF and MgF2 as optical coating materials, evaluating their respective performance characteristics across various application environments. This includes quantitative assessment of their transmission properties, refractive indices across different wavelengths, mechanical durability, and long-term stability under varying environmental conditions.

Secondary objectives include identifying optimal deposition parameters for each material, evaluating their compatibility with different substrate materials, and exploring potential hybrid coating systems that leverage the complementary properties of both materials. Additionally, this analysis aims to forecast future development directions for fluoride coating technologies, considering emerging applications in quantum optics, extreme ultraviolet lithography, and next-generation astronomical instrumentation.

By establishing clear performance benchmarks and application-specific guidelines, this analysis seeks to provide optical system designers with actionable insights for material selection, ultimately contributing to advancements in optical technology across scientific, industrial, and consumer applications.

Market Analysis for High-Performance Optical Coatings

The global market for high-performance optical coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries including aerospace, defense, medical devices, and consumer electronics. The optical coating market was valued at approximately $13.7 billion in 2022 and is projected to reach $22.4 billion by 2028, growing at a CAGR of 8.5% during the forecast period.

Within this broader market, anti-reflective coatings specifically for optical lenses represent a substantial segment, with particular attention to materials like Lithium Fluoride (LiF) and Magnesium Fluoride (MgF2). These materials serve as critical components in high-performance optical systems where light transmission efficiency and durability are paramount.

The demand for LiF and MgF2 coatings is particularly strong in precision optics applications, with the scientific instruments sector showing the highest growth rate at 9.7% annually. This is largely attributed to increasing investments in research infrastructure and advanced manufacturing capabilities in regions like North America and Europe.

Consumer electronics represents another significant market driver, with smartphone camera lenses and augmented reality displays requiring increasingly sophisticated optical coatings. This segment accounts for approximately 31% of the total market share for high-performance optical coatings, with annual growth exceeding the market average.

Regional analysis indicates that North America currently holds the largest market share at 38%, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing domestic demand for high-quality optical products.

The competitive landscape features both specialized coating manufacturers and integrated optical system providers. Major players include Schott AG, Edmund Optics, and Newport Corporation, who collectively control approximately 45% of the market for high-performance fluoride-based optical coatings.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers prioritize cost-effectiveness, aerospace and defense contractors place greater emphasis on performance specifications and reliability, often willing to pay premium prices for superior coating technologies.

Future market growth is expected to be driven by emerging applications in quantum computing, advanced photonics, and next-generation display technologies, all of which require increasingly sophisticated optical coating solutions with precise spectral characteristics and enhanced durability.

Within this broader market, anti-reflective coatings specifically for optical lenses represent a substantial segment, with particular attention to materials like Lithium Fluoride (LiF) and Magnesium Fluoride (MgF2). These materials serve as critical components in high-performance optical systems where light transmission efficiency and durability are paramount.

The demand for LiF and MgF2 coatings is particularly strong in precision optics applications, with the scientific instruments sector showing the highest growth rate at 9.7% annually. This is largely attributed to increasing investments in research infrastructure and advanced manufacturing capabilities in regions like North America and Europe.

Consumer electronics represents another significant market driver, with smartphone camera lenses and augmented reality displays requiring increasingly sophisticated optical coatings. This segment accounts for approximately 31% of the total market share for high-performance optical coatings, with annual growth exceeding the market average.

Regional analysis indicates that North America currently holds the largest market share at 38%, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing domestic demand for high-quality optical products.

The competitive landscape features both specialized coating manufacturers and integrated optical system providers. Major players include Schott AG, Edmund Optics, and Newport Corporation, who collectively control approximately 45% of the market for high-performance fluoride-based optical coatings.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers prioritize cost-effectiveness, aerospace and defense contractors place greater emphasis on performance specifications and reliability, often willing to pay premium prices for superior coating technologies.

Future market growth is expected to be driven by emerging applications in quantum computing, advanced photonics, and next-generation display technologies, all of which require increasingly sophisticated optical coating solutions with precise spectral characteristics and enhanced durability.

Current State and Challenges in Optical Coating Technology

Optical coating technology has witnessed significant advancements in recent decades, particularly in the application of fluoride materials for high-performance optical lenses. Currently, lithium fluoride (LiF) and magnesium fluoride (MgF2) represent two of the most widely utilized materials in optical coating applications, each with distinct characteristics and performance profiles.

The global optical coating market is experiencing robust growth, valued at approximately $14.5 billion in 2022 and projected to reach $23.4 billion by 2028, with a CAGR of 8.3%. This growth is primarily driven by increasing demands in consumer electronics, medical devices, and advanced optical systems requiring high-performance coatings.

Lithium fluoride coatings currently dominate in applications requiring extreme ultraviolet (EUV) transparency, with transmission capabilities extending to wavelengths as short as 105 nm. The material exhibits exceptional optical properties with a refractive index of approximately 1.39, making it particularly valuable for specialized applications in astronomy and high-energy physics instrumentation.

Magnesium fluoride, meanwhile, has established itself as the industry standard for general anti-reflection coatings, with a slightly higher refractive index of 1.38 at 550 nm. Its superior mechanical durability and environmental stability have positioned it as the preferred choice for commercial optical systems exposed to varying environmental conditions.

Despite these advancements, significant technical challenges persist in optical coating technology. Adhesion issues between fluoride coatings and glass substrates remain problematic, particularly in applications involving thermal cycling or mechanical stress. Current deposition techniques struggle to achieve uniform molecular orientation, resulting in birefringence effects that compromise optical performance in precision applications.

Environmental stability represents another critical challenge, especially for lithium fluoride coatings which demonstrate higher hygroscopic tendencies compared to magnesium fluoride. This moisture sensitivity limits LiF applications in humid environments without additional protective layers, increasing manufacturing complexity and cost.

Production scalability presents ongoing difficulties, particularly for lithium fluoride coatings which require more stringent environmental controls during deposition. The evaporation temperatures and deposition rates must be precisely controlled to achieve optimal film structure, limiting mass production capabilities compared to magnesium fluoride processes.

Recent research has focused on hybrid coating systems combining the beneficial properties of both materials, though integration challenges related to thermal expansion coefficient mismatches and interfacial stress remain unresolved. Additionally, the environmental impact of fluoride material production and disposal has come under increased scrutiny, prompting investigation into more sustainable alternatives and recycling methodologies.

The global optical coating market is experiencing robust growth, valued at approximately $14.5 billion in 2022 and projected to reach $23.4 billion by 2028, with a CAGR of 8.3%. This growth is primarily driven by increasing demands in consumer electronics, medical devices, and advanced optical systems requiring high-performance coatings.

Lithium fluoride coatings currently dominate in applications requiring extreme ultraviolet (EUV) transparency, with transmission capabilities extending to wavelengths as short as 105 nm. The material exhibits exceptional optical properties with a refractive index of approximately 1.39, making it particularly valuable for specialized applications in astronomy and high-energy physics instrumentation.

Magnesium fluoride, meanwhile, has established itself as the industry standard for general anti-reflection coatings, with a slightly higher refractive index of 1.38 at 550 nm. Its superior mechanical durability and environmental stability have positioned it as the preferred choice for commercial optical systems exposed to varying environmental conditions.

Despite these advancements, significant technical challenges persist in optical coating technology. Adhesion issues between fluoride coatings and glass substrates remain problematic, particularly in applications involving thermal cycling or mechanical stress. Current deposition techniques struggle to achieve uniform molecular orientation, resulting in birefringence effects that compromise optical performance in precision applications.

Environmental stability represents another critical challenge, especially for lithium fluoride coatings which demonstrate higher hygroscopic tendencies compared to magnesium fluoride. This moisture sensitivity limits LiF applications in humid environments without additional protective layers, increasing manufacturing complexity and cost.

Production scalability presents ongoing difficulties, particularly for lithium fluoride coatings which require more stringent environmental controls during deposition. The evaporation temperatures and deposition rates must be precisely controlled to achieve optimal film structure, limiting mass production capabilities compared to magnesium fluoride processes.

Recent research has focused on hybrid coating systems combining the beneficial properties of both materials, though integration challenges related to thermal expansion coefficient mismatches and interfacial stress remain unresolved. Additionally, the environmental impact of fluoride material production and disposal has come under increased scrutiny, prompting investigation into more sustainable alternatives and recycling methodologies.

Comparative Technical Analysis of LiF vs MgF2 Coating Solutions

01 Optical coatings and thin films

Lithium fluoride (LiF) and magnesium fluoride (MgF2) are widely used in optical coatings and thin films due to their excellent optical properties. These materials exhibit high transparency in a wide spectral range, from ultraviolet to infrared. They are commonly applied as anti-reflection coatings on optical elements such as lenses, windows, and prisms to reduce reflection losses and improve light transmission. The combination of these fluorides in multilayer coatings can achieve specific optical characteristics tailored for various applications.- Optical coatings and thin films: Lithium fluoride (LiF) and magnesium fluoride (MgF2) are widely used in optical coatings and thin films due to their excellent optical properties. These materials have high transparency in a wide spectral range, particularly in the ultraviolet region. They are commonly used as anti-reflection coatings on optical elements such as lenses, windows, and prisms. The low refractive index of these fluorides makes them ideal for the outermost layer in multilayer coating designs, helping to reduce reflection and increase transmission of light.

- Ultraviolet and vacuum ultraviolet applications: Lithium fluoride and magnesium fluoride exhibit exceptional transmission properties in the ultraviolet (UV) and vacuum ultraviolet (VUV) regions of the electromagnetic spectrum. LiF has the widest transmission range among all optical materials, extending from about 0.1 μm to 7 μm, making it valuable for deep UV applications. MgF2 has excellent transmission from about 0.11 μm to 8.5 μm. These properties make them essential materials for UV optics, space applications, and scientific instruments that operate in the UV and VUV ranges.

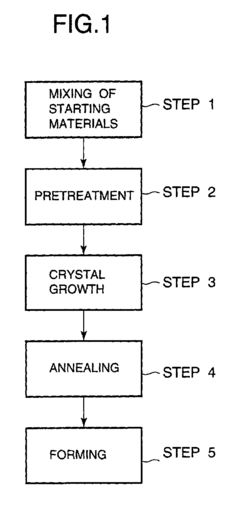

- Crystal growth and fabrication methods: Various methods are employed to grow and fabricate lithium fluoride and magnesium fluoride crystals for optical applications. These include Czochralski method, Bridgman-Stockbarger technique, and physical vapor deposition. The growth conditions significantly affect the optical properties of the resulting crystals. Parameters such as growth rate, temperature gradient, and atmosphere composition are carefully controlled to minimize defects and impurities that could degrade optical performance. Post-growth treatments like annealing can further improve optical quality by reducing internal stresses and defects.

- Refractive index and birefringence properties: Magnesium fluoride is naturally birefringent, meaning it has different refractive indices for different polarizations of light. This property makes it useful for polarizing optics and waveplates. At 550 nm, MgF2 has ordinary and extraordinary refractive indices of approximately 1.375 and 1.387, respectively. Lithium fluoride is isotropic with a refractive index of about 1.39 at 550 nm, which is among the lowest of solid optical materials. The low and stable refractive indices of these materials across a wide spectral range make them valuable for precision optical applications where minimal chromatic aberration is required.

- Radiation resistance and scintillation properties: Lithium fluoride and magnesium fluoride exhibit notable radiation resistance, making them suitable for optical components in high-radiation environments such as space applications and nuclear facilities. LiF is also known for its thermoluminescent properties and is used as a radiation dosimeter. When doped with certain impurities, these fluorides can function as scintillation materials that emit light when exposed to ionizing radiation. Their optical properties remain relatively stable under radiation exposure compared to many other optical materials, which is crucial for maintaining performance in harsh environments.

02 Refractive index and transmission properties

Lithium fluoride and magnesium fluoride possess distinct refractive indices that make them valuable in optical applications. LiF has a refractive index of approximately 1.39, while MgF2 has a slightly higher refractive index of about 1.38-1.40 depending on wavelength. Both materials exhibit exceptional transmission properties across a broad spectrum, with LiF showing excellent transmission in the vacuum ultraviolet region. Their low refractive indices and high transmission make them ideal for applications requiring minimal light loss and optical distortion.Expand Specific Solutions03 Crystal structure and manufacturing methods

The optical properties of lithium fluoride and magnesium fluoride are significantly influenced by their crystal structure and manufacturing methods. Both materials can be grown as single crystals or deposited as thin films using various techniques such as physical vapor deposition, electron beam evaporation, or thermal evaporation. The crystalline orientation, purity, and deposition parameters directly affect their optical performance. Controlled manufacturing processes are essential to achieve desired optical characteristics such as birefringence in magnesium fluoride or specific transmission bands in lithium fluoride.Expand Specific Solutions04 UV and deep UV applications

Lithium fluoride and magnesium fluoride are particularly valuable for ultraviolet (UV) and deep UV optical applications due to their exceptional transparency in these wavelength regions. LiF maintains high transmission down to approximately 105 nm, making it one of the few materials suitable for vacuum UV applications. MgF2 exhibits excellent transmission down to about 120 nm. These properties make them essential materials for UV optics, including windows, lenses, and filters used in spectroscopy, lithography, laser systems, and space-based optical instruments where UV performance is critical.Expand Specific Solutions05 Durability and environmental stability

The optical properties of lithium fluoride and magnesium fluoride are complemented by their durability and environmental stability. MgF2 is particularly noted for its hardness, scratch resistance, and stability in various environmental conditions, making it suitable for protective optical coatings. While LiF offers superior optical properties in some wavelength ranges, it is more hygroscopic and softer than MgF2. Both materials maintain their optical characteristics over extended periods when properly protected, making them reliable choices for long-term optical applications in challenging environments, including space-based instruments and high-power laser systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Optical Coatings

The optical lens industry is in a mature growth phase, with the global market valued at approximately $20 billion and projected to expand at a CAGR of 5-7% through 2028. The comparative analysis between Lithium Fluoride and Magnesium Fluoride coatings reveals a competitive landscape dominated by established optical manufacturers. Carl Zeiss SMT, Nikon, Canon, and EssilorLuxottica lead with advanced technological capabilities in high-precision optics. Chinese companies like Zhejiang Sunny Optics and Chengrui Optics are rapidly gaining market share through cost-effective manufacturing. The technology maturity varies, with MgF2 coatings being more established and widely adopted across consumer and industrial applications, while LiF offers superior performance characteristics for specialized applications in UV optics and semiconductor lithography equipment.

Carl Zeiss SMT GmbH

Technical Solution: Carl Zeiss SMT has developed proprietary multi-layer coating technologies that utilize both LiF and MgF₂ in different applications. Their EUV lithography systems employ specialized LiF coatings for deep ultraviolet applications, achieving transmission rates above 99.8% in specific wavelength ranges. For their high-end microscopy and semiconductor inspection equipment, Zeiss implements MgF₂ coatings with precisely controlled thickness variations (typically 130-150nm) to minimize reflection across broader spectral ranges. Their patented ion-assisted deposition process creates exceptionally dense and durable MgF₂ layers with refractive indices approaching the theoretical minimum of 1.38, significantly enhancing optical performance in harsh environments. Zeiss has also pioneered hybrid coating systems that combine both materials in specialized arrangements to achieve optimal performance across multiple wavelength bands.

Strengths: Superior coating uniformity and precision thickness control; exceptional durability in industrial environments; proprietary deposition technology creating higher density films. Weaknesses: Higher manufacturing costs; complex production processes requiring specialized equipment; longer production cycles compared to single-material coatings.

Corning, Inc.

Technical Solution: Corning has developed specialized coating technologies utilizing both LiF and MgF₂ for different optical applications. Their Advanced Optics division employs precision-controlled MgF₂ coatings for broadband anti-reflection applications, achieving reflection reduction below 0.5% across 400-700nm wavelength ranges. For deep UV applications, Corning utilizes LiF coatings with proprietary stabilization techniques that reduce degradation from atmospheric exposure. Their research has demonstrated that ion-assisted deposition of MgF₂ creates films with packing densities approaching 98% of bulk material, significantly enhancing environmental stability. Corning's patented gradient-index coating technology creates variable-composition layers that transition between materials, reducing internal stress and improving adhesion. For specialized applications in aerospace and defense sectors, Corning has developed composite LiF-MgF₂ coatings that combine the deep UV transmission of LiF with the superior environmental stability of MgF₂, achieving optimal performance in challenging operational environments.

Strengths: Superior environmental durability; excellent broadband performance; advanced gradient-index technology reducing internal stress. Weaknesses: Higher production costs; complex manufacturing process requiring precise control; limited application in extreme temperature environments.

Key Patents and Research Breakthroughs in Fluoride Coatings

Optical member for vacuum ultraviolet, and aligner and device manufacture method using same

PatentInactiveEP1130419A3

Innovation

- Development of an optical member using a substrate or coating based on the AMF3 type perovskite structure crystal, which is free from deliquescence and cleavage, and exhibits low birefringence, allowing for high-quality optical components like lenses and mirrors that minimize absorption in the vacuum ultraviolet region.

Methods for coating a substrate with magnesium fluoride via atomic layer deposition

PatentWO2021021436A1

Innovation

- The method involves atomic layer deposition of magnesium fluoride, where a magnesium oxide layer is formed by exposing a substrate to a magnesium precursor gas and an oxygen-containing gas, followed by conversion to a magnesium fluoride layer using a fluorine source gas and additional oxygen, with controlled temperature and gas types to achieve desired optical properties.

Environmental Impact and Sustainability Considerations

The environmental impact of optical materials has become increasingly important as sustainability considerations gain prominence in manufacturing industries. In the case of Lithium Fluoride (LiF) and Magnesium Fluoride (MgF2), their environmental footprints differ significantly throughout their lifecycle, from raw material extraction to disposal.

The mining processes for lithium and magnesium present distinct environmental challenges. Lithium extraction, particularly from salt flats, requires substantial water usage—approximately 500,000 gallons per ton of lithium—potentially depleting water resources in often arid regions. This has led to documented cases of water table depletion in areas like Chile's Atacama Desert. Conversely, magnesium extraction typically involves less water consumption but may generate more solid waste and require higher energy inputs depending on the extraction method employed.

Manufacturing processes for both fluoride compounds involve energy-intensive crystallization and purification steps. LiF production generally requires higher temperatures (around 845°C melting point) compared to MgF2 (1,261°C but often processed at lower temperatures using different methods), resulting in different carbon footprints. Recent industry analyses suggest MgF2 production may consume approximately 15-20% less energy than LiF when accounting for the entire manufacturing process.

Durability considerations also factor into sustainability assessments. MgF2 coatings and lenses typically demonstrate superior hardness (4.5-5 Mohs vs. 3-4 for LiF) and moisture resistance, potentially extending product lifespans and reducing replacement frequency. This durability advantage translates to reduced material consumption over time, particularly in harsh environmental applications.

End-of-life considerations reveal that neither material is readily biodegradable, though both can be recycled through specialized processes. Recovery rates for optical-grade fluorides remain relatively low (under 30%) due to technical challenges in separating these materials from complex optical assemblies. The presence of fluoride compounds also raises disposal concerns, as improper handling can lead to environmental contamination.

Recent life cycle assessments indicate that MgF2 generally presents a lower overall environmental impact when considering the complete product lifecycle. This advantage stems primarily from its longer service life and potentially lower energy requirements during manufacturing. However, regional factors significantly influence this comparison, as local energy sources, water availability, and recycling infrastructure can dramatically alter the sustainability profile of either material.

The mining processes for lithium and magnesium present distinct environmental challenges. Lithium extraction, particularly from salt flats, requires substantial water usage—approximately 500,000 gallons per ton of lithium—potentially depleting water resources in often arid regions. This has led to documented cases of water table depletion in areas like Chile's Atacama Desert. Conversely, magnesium extraction typically involves less water consumption but may generate more solid waste and require higher energy inputs depending on the extraction method employed.

Manufacturing processes for both fluoride compounds involve energy-intensive crystallization and purification steps. LiF production generally requires higher temperatures (around 845°C melting point) compared to MgF2 (1,261°C but often processed at lower temperatures using different methods), resulting in different carbon footprints. Recent industry analyses suggest MgF2 production may consume approximately 15-20% less energy than LiF when accounting for the entire manufacturing process.

Durability considerations also factor into sustainability assessments. MgF2 coatings and lenses typically demonstrate superior hardness (4.5-5 Mohs vs. 3-4 for LiF) and moisture resistance, potentially extending product lifespans and reducing replacement frequency. This durability advantage translates to reduced material consumption over time, particularly in harsh environmental applications.

End-of-life considerations reveal that neither material is readily biodegradable, though both can be recycled through specialized processes. Recovery rates for optical-grade fluorides remain relatively low (under 30%) due to technical challenges in separating these materials from complex optical assemblies. The presence of fluoride compounds also raises disposal concerns, as improper handling can lead to environmental contamination.

Recent life cycle assessments indicate that MgF2 generally presents a lower overall environmental impact when considering the complete product lifecycle. This advantage stems primarily from its longer service life and potentially lower energy requirements during manufacturing. However, regional factors significantly influence this comparison, as local energy sources, water availability, and recycling infrastructure can dramatically alter the sustainability profile of either material.

Manufacturing Process Optimization for Fluoride Coatings

The manufacturing process optimization for fluoride coatings represents a critical aspect in the comparative analysis of Lithium Fluoride (LiF) and Magnesium Fluoride (MgF2) applications in optical lenses. Current industrial processes for both materials share fundamental similarities but diverge significantly in specific parameters that affect coating quality and performance.

Electron beam evaporation remains the predominant deposition method for both fluoride materials, though LiF requires more stringent temperature control due to its lower melting point (845°C) compared to MgF2 (1,263°C). This temperature sensitivity necessitates precise thermal management systems when processing LiF to prevent material degradation and ensure coating uniformity.

Substrate preparation protocols differ substantially between the two materials. MgF2 coatings demonstrate superior adhesion properties across various substrate materials, whereas LiF often requires specialized surface treatments or primer layers to achieve comparable adhesion strength. Recent advancements in plasma-assisted cleaning techniques have shown promising results in enhancing LiF adhesion without compromising optical properties.

Deposition rate optimization presents another critical manufacturing consideration. LiF typically allows for faster deposition rates (3-5 nm/s) compared to MgF2 (1-3 nm/s), potentially reducing production cycle times. However, accelerated deposition of LiF often results in increased defect density, necessitating a careful balance between production efficiency and coating quality.

Post-deposition annealing processes significantly impact coating durability and optical performance. MgF2 coatings generally require higher annealing temperatures (300-350°C) compared to LiF (200-250°C), but demonstrate superior environmental stability after treatment. Recent research indicates that controlled atmosphere annealing with precise humidity regulation can enhance LiF coating durability by up to 40%.

Quality control methodologies must be tailored specifically to each material. LiF coatings typically require more frequent spectrophotometric analysis during production due to their higher susceptibility to thickness variations. Conversely, MgF2 coatings benefit more from stress measurement techniques to prevent delamination issues that can occur during thermal cycling.

Advanced manufacturing innovations, including atomic layer deposition (ALD) and ion-assisted deposition (IAD), show particular promise for improving MgF2 coating density and reducing water absorption. For LiF, recent developments in co-evaporation techniques with stabilizing agents have demonstrated significant improvements in coating longevity without compromising transmission properties.

Cost-efficiency analysis reveals that while LiF raw materials typically cost 15-20% less than MgF2, the additional processing requirements and higher rejection rates often negate this initial advantage in high-volume production environments. Manufacturers increasingly implement real-time monitoring systems specifically calibrated for fluoride coating processes to optimize material utilization and reduce waste.

Electron beam evaporation remains the predominant deposition method for both fluoride materials, though LiF requires more stringent temperature control due to its lower melting point (845°C) compared to MgF2 (1,263°C). This temperature sensitivity necessitates precise thermal management systems when processing LiF to prevent material degradation and ensure coating uniformity.

Substrate preparation protocols differ substantially between the two materials. MgF2 coatings demonstrate superior adhesion properties across various substrate materials, whereas LiF often requires specialized surface treatments or primer layers to achieve comparable adhesion strength. Recent advancements in plasma-assisted cleaning techniques have shown promising results in enhancing LiF adhesion without compromising optical properties.

Deposition rate optimization presents another critical manufacturing consideration. LiF typically allows for faster deposition rates (3-5 nm/s) compared to MgF2 (1-3 nm/s), potentially reducing production cycle times. However, accelerated deposition of LiF often results in increased defect density, necessitating a careful balance between production efficiency and coating quality.

Post-deposition annealing processes significantly impact coating durability and optical performance. MgF2 coatings generally require higher annealing temperatures (300-350°C) compared to LiF (200-250°C), but demonstrate superior environmental stability after treatment. Recent research indicates that controlled atmosphere annealing with precise humidity regulation can enhance LiF coating durability by up to 40%.

Quality control methodologies must be tailored specifically to each material. LiF coatings typically require more frequent spectrophotometric analysis during production due to their higher susceptibility to thickness variations. Conversely, MgF2 coatings benefit more from stress measurement techniques to prevent delamination issues that can occur during thermal cycling.

Advanced manufacturing innovations, including atomic layer deposition (ALD) and ion-assisted deposition (IAD), show particular promise for improving MgF2 coating density and reducing water absorption. For LiF, recent developments in co-evaporation techniques with stabilizing agents have demonstrated significant improvements in coating longevity without compromising transmission properties.

Cost-efficiency analysis reveals that while LiF raw materials typically cost 15-20% less than MgF2, the additional processing requirements and higher rejection rates often negate this initial advantage in high-volume production environments. Manufacturers increasingly implement real-time monitoring systems specifically calibrated for fluoride coating processes to optimize material utilization and reduce waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!