Lithium Fluoride Coatings: Performance in Corrosive Environments

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF Coating Technology Background and Objectives

Lithium fluoride (LiF) coatings have emerged as a significant technological advancement in materials science over the past three decades. Initially developed for optical applications due to their excellent transmission properties in the ultraviolet spectrum, these coatings have gradually expanded into various industrial applications, particularly in environments where corrosion resistance is paramount. The evolution of LiF coating technology has been marked by continuous improvements in deposition techniques, from early thermal evaporation methods to more sophisticated approaches such as atomic layer deposition and magnetron sputtering.

The fundamental properties that make LiF coatings attractive for corrosion protection include their chemical stability, high melting point (845°C), and remarkable resistance to various aggressive media including strong acids and molten salts. These characteristics have positioned LiF as a promising protective layer for components operating in extreme environments, such as nuclear reactors, chemical processing equipment, and high-temperature energy conversion systems.

Recent technological trends indicate a growing interest in hybrid and multilayer coating systems incorporating LiF, designed to overcome the inherent limitations of single-material coatings. These advanced architectures aim to combine the exceptional corrosion resistance of LiF with improved mechanical properties and adhesion characteristics provided by complementary materials. The development trajectory suggests a shift toward more complex, application-specific coating solutions rather than one-size-fits-all approaches.

The primary technical objectives for LiF coating research and development center around enhancing performance in increasingly demanding corrosive environments. Key goals include improving coating adhesion to various substrate materials, particularly metals and alloys used in industrial applications; optimizing coating thickness and microstructure to maximize protection while minimizing material usage; and developing scalable, cost-effective deposition processes suitable for industrial implementation.

Another critical objective involves understanding and mitigating the degradation mechanisms of LiF coatings under combined stressors, such as simultaneous exposure to corrosive media, mechanical stress, and elevated temperatures. This knowledge is essential for predicting coating lifetime and developing more resilient formulations for long-term protection in harsh industrial settings.

The broader technological aim is to establish LiF-based coatings as a viable alternative to traditional corrosion protection methods, particularly in applications where conventional approaches fail or require frequent maintenance. This includes developing standardized testing protocols and performance metrics specific to LiF coatings, which would facilitate their adoption across various industries and regulatory frameworks.

The fundamental properties that make LiF coatings attractive for corrosion protection include their chemical stability, high melting point (845°C), and remarkable resistance to various aggressive media including strong acids and molten salts. These characteristics have positioned LiF as a promising protective layer for components operating in extreme environments, such as nuclear reactors, chemical processing equipment, and high-temperature energy conversion systems.

Recent technological trends indicate a growing interest in hybrid and multilayer coating systems incorporating LiF, designed to overcome the inherent limitations of single-material coatings. These advanced architectures aim to combine the exceptional corrosion resistance of LiF with improved mechanical properties and adhesion characteristics provided by complementary materials. The development trajectory suggests a shift toward more complex, application-specific coating solutions rather than one-size-fits-all approaches.

The primary technical objectives for LiF coating research and development center around enhancing performance in increasingly demanding corrosive environments. Key goals include improving coating adhesion to various substrate materials, particularly metals and alloys used in industrial applications; optimizing coating thickness and microstructure to maximize protection while minimizing material usage; and developing scalable, cost-effective deposition processes suitable for industrial implementation.

Another critical objective involves understanding and mitigating the degradation mechanisms of LiF coatings under combined stressors, such as simultaneous exposure to corrosive media, mechanical stress, and elevated temperatures. This knowledge is essential for predicting coating lifetime and developing more resilient formulations for long-term protection in harsh industrial settings.

The broader technological aim is to establish LiF-based coatings as a viable alternative to traditional corrosion protection methods, particularly in applications where conventional approaches fail or require frequent maintenance. This includes developing standardized testing protocols and performance metrics specific to LiF coatings, which would facilitate their adoption across various industries and regulatory frameworks.

Market Analysis for Corrosion-Resistant Coatings

The global market for corrosion-resistant coatings has been experiencing significant growth, driven by increasing industrial applications across sectors such as aerospace, automotive, marine, and energy production. Currently valued at approximately 7.5 billion USD, this market is projected to reach 9.3 billion USD by 2026, with a compound annual growth rate of 4.8%. Within this broader market, specialized coatings like Lithium Fluoride (LiF) represent an emerging segment with distinctive performance characteristics in highly corrosive environments.

Demand for advanced corrosion-resistant solutions has intensified due to the expanding industrial infrastructure in developing economies, particularly in Asia-Pacific regions where rapid industrialization continues to drive market growth at rates exceeding 6% annually. China and India lead this expansion, with their chemical processing and manufacturing sectors requiring increasingly sophisticated protection against aggressive chemical environments.

The oil and gas industry remains one of the largest consumers of high-performance corrosion-resistant coatings, accounting for approximately 22% of the total market share. This sector's demand for materials capable of withstanding extreme conditions—including high temperatures, chemical exposure, and mechanical stress—creates a natural application space for advanced solutions like LiF coatings.

Market segmentation reveals that while traditional organic coatings (epoxies, polyurethanes) dominate with 65% market share, inorganic and ceramic-based coatings including fluoride compounds are growing at twice the market average rate due to their superior performance in extreme environments. This trend indicates increasing recognition of specialized coating solutions for critical applications where conventional materials fail.

Customer requirements are evolving toward longer service life expectations, with end-users seeking coatings that can extend maintenance intervals and reduce lifetime costs. This shift has created premium market segments where performance rather than initial cost drives purchasing decisions, benefiting technically superior solutions like LiF coatings despite their higher upfront costs.

Regulatory factors significantly influence market dynamics, with environmental regulations increasingly restricting traditional coating formulations containing volatile organic compounds (VOCs) and heavy metals. The European Union's REACH regulations and similar frameworks in North America have accelerated the transition toward environmentally friendly alternatives, creating market opportunities for novel coating technologies.

Competitive analysis indicates that while major coating manufacturers like PPG Industries, AkzoNobel, and Sherwin-Williams control substantial market share in general corrosion protection, specialized segments feature smaller technology-focused companies with expertise in advanced materials. These niche players often command premium pricing through technical differentiation and application-specific performance advantages.

The market for LiF and similar advanced coatings exhibits less price sensitivity compared to conventional solutions, with customers prioritizing performance metrics such as corrosion resistance longevity, temperature stability, and chemical inertness over initial acquisition costs. This value-based purchasing behavior supports higher margins and research investment in next-generation coating technologies.

Demand for advanced corrosion-resistant solutions has intensified due to the expanding industrial infrastructure in developing economies, particularly in Asia-Pacific regions where rapid industrialization continues to drive market growth at rates exceeding 6% annually. China and India lead this expansion, with their chemical processing and manufacturing sectors requiring increasingly sophisticated protection against aggressive chemical environments.

The oil and gas industry remains one of the largest consumers of high-performance corrosion-resistant coatings, accounting for approximately 22% of the total market share. This sector's demand for materials capable of withstanding extreme conditions—including high temperatures, chemical exposure, and mechanical stress—creates a natural application space for advanced solutions like LiF coatings.

Market segmentation reveals that while traditional organic coatings (epoxies, polyurethanes) dominate with 65% market share, inorganic and ceramic-based coatings including fluoride compounds are growing at twice the market average rate due to their superior performance in extreme environments. This trend indicates increasing recognition of specialized coating solutions for critical applications where conventional materials fail.

Customer requirements are evolving toward longer service life expectations, with end-users seeking coatings that can extend maintenance intervals and reduce lifetime costs. This shift has created premium market segments where performance rather than initial cost drives purchasing decisions, benefiting technically superior solutions like LiF coatings despite their higher upfront costs.

Regulatory factors significantly influence market dynamics, with environmental regulations increasingly restricting traditional coating formulations containing volatile organic compounds (VOCs) and heavy metals. The European Union's REACH regulations and similar frameworks in North America have accelerated the transition toward environmentally friendly alternatives, creating market opportunities for novel coating technologies.

Competitive analysis indicates that while major coating manufacturers like PPG Industries, AkzoNobel, and Sherwin-Williams control substantial market share in general corrosion protection, specialized segments feature smaller technology-focused companies with expertise in advanced materials. These niche players often command premium pricing through technical differentiation and application-specific performance advantages.

The market for LiF and similar advanced coatings exhibits less price sensitivity compared to conventional solutions, with customers prioritizing performance metrics such as corrosion resistance longevity, temperature stability, and chemical inertness over initial acquisition costs. This value-based purchasing behavior supports higher margins and research investment in next-generation coating technologies.

Current Status and Challenges in LiF Coating Technology

Lithium Fluoride (LiF) coatings have emerged as a promising solution for protecting surfaces in highly corrosive environments, particularly in advanced energy systems, aerospace applications, and semiconductor manufacturing. Currently, the global research landscape shows significant advancements in LiF coating technologies across North America, Europe, and East Asia, with China and the United States leading in patent applications.

The state-of-the-art LiF coating technologies employ various deposition methods including physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and solution-based approaches. Each method offers distinct advantages in terms of coating uniformity, adhesion strength, and scalability. Recent breakthroughs in ALD techniques have enabled the production of ultra-thin LiF films with exceptional conformality and precise thickness control down to the nanometer scale.

Despite these advancements, several critical challenges persist in LiF coating technology. The inherent brittleness of LiF coatings limits their application in components subjected to mechanical stress or thermal cycling. Current research indicates that LiF coatings typically exhibit microcracking when exposed to temperature fluctuations exceeding 200°C, significantly compromising their protective properties.

Another major technical hurdle involves the hygroscopic nature of LiF, which tends to absorb moisture from the environment, leading to degradation of coating integrity over time. This characteristic necessitates additional protective layers or specialized handling procedures, increasing manufacturing complexity and cost. Studies from the Lawrence Livermore National Laboratory have documented up to 15% performance degradation in humid environments within the first 500 hours of exposure.

Adhesion to various substrate materials remains problematic, particularly for metallic substrates with different thermal expansion coefficients. Current industrial applications report delamination rates of 8-12% for coatings on stainless steel substrates after extended exposure to corrosive media. This issue is exacerbated in environments containing fluoride ions, where galvanic corrosion can accelerate coating failure.

The scalability of high-quality LiF coating processes presents another significant challenge. While laboratory-scale production has demonstrated excellent results, transferring these processes to industrial-scale manufacturing while maintaining coating quality and performance consistency has proven difficult. Current industrial processes show a 30-40% increase in defect density compared to laboratory samples.

Environmental and health concerns associated with fluoride-containing precursors used in certain deposition processes also pose regulatory challenges, particularly in Europe and North America where stringent environmental regulations are enforced. This has prompted research into greener synthesis routes and precursor alternatives, though these often result in compromised coating performance.

The state-of-the-art LiF coating technologies employ various deposition methods including physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and solution-based approaches. Each method offers distinct advantages in terms of coating uniformity, adhesion strength, and scalability. Recent breakthroughs in ALD techniques have enabled the production of ultra-thin LiF films with exceptional conformality and precise thickness control down to the nanometer scale.

Despite these advancements, several critical challenges persist in LiF coating technology. The inherent brittleness of LiF coatings limits their application in components subjected to mechanical stress or thermal cycling. Current research indicates that LiF coatings typically exhibit microcracking when exposed to temperature fluctuations exceeding 200°C, significantly compromising their protective properties.

Another major technical hurdle involves the hygroscopic nature of LiF, which tends to absorb moisture from the environment, leading to degradation of coating integrity over time. This characteristic necessitates additional protective layers or specialized handling procedures, increasing manufacturing complexity and cost. Studies from the Lawrence Livermore National Laboratory have documented up to 15% performance degradation in humid environments within the first 500 hours of exposure.

Adhesion to various substrate materials remains problematic, particularly for metallic substrates with different thermal expansion coefficients. Current industrial applications report delamination rates of 8-12% for coatings on stainless steel substrates after extended exposure to corrosive media. This issue is exacerbated in environments containing fluoride ions, where galvanic corrosion can accelerate coating failure.

The scalability of high-quality LiF coating processes presents another significant challenge. While laboratory-scale production has demonstrated excellent results, transferring these processes to industrial-scale manufacturing while maintaining coating quality and performance consistency has proven difficult. Current industrial processes show a 30-40% increase in defect density compared to laboratory samples.

Environmental and health concerns associated with fluoride-containing precursors used in certain deposition processes also pose regulatory challenges, particularly in Europe and North America where stringent environmental regulations are enforced. This has prompted research into greener synthesis routes and precursor alternatives, though these often result in compromised coating performance.

Existing LiF Coating Application Methods and Performance

01 Optical performance of lithium fluoride coatings

Lithium fluoride coatings exhibit excellent optical properties, including high transparency in ultraviolet and infrared regions. These coatings provide anti-reflective properties and can be used in optical components such as lenses, windows, and sensors. The high transmittance and low refractive index make lithium fluoride an ideal material for optical applications requiring minimal light loss and maximum clarity.- Optical performance of lithium fluoride coatings: Lithium fluoride coatings exhibit excellent optical properties, including high transparency in ultraviolet and infrared regions. These coatings provide anti-reflective properties and can be used in optical components such as lenses, windows, and sensors. The high refractive index and low absorption characteristics make lithium fluoride coatings particularly valuable for applications requiring precise light transmission and manipulation.

- Thermal and radiation resistance properties: Lithium fluoride coatings demonstrate exceptional thermal stability and radiation resistance. These coatings can withstand high temperatures without degradation and maintain their structural integrity when exposed to various forms of radiation. This makes them suitable for applications in extreme environments, such as space technology, nuclear facilities, and high-temperature industrial processes where conventional coatings would fail.

- Protective barrier functionality: When applied to various substrates, lithium fluoride coatings serve as effective protective barriers against corrosion, oxidation, and chemical attack. These coatings create a chemically inert surface that shields the underlying material from environmental degradation. The barrier properties can be enhanced through specific deposition techniques and by controlling the coating thickness and microstructure to optimize protection for different applications.

- Advanced deposition methods for performance enhancement: Various deposition techniques significantly impact the performance of lithium fluoride coatings. Methods such as physical vapor deposition, atomic layer deposition, and magnetron sputtering can be used to create highly uniform and defect-free coatings. The choice of deposition method affects coating adhesion, density, and crystallinity, which in turn influences the overall performance characteristics including durability and functional properties.

- Composite and doped lithium fluoride coatings: Incorporating additional materials into lithium fluoride coatings or creating multi-layer structures can significantly enhance performance characteristics. Doping with other elements or compounds can improve hardness, conductivity, or specific optical properties. Composite structures combining lithium fluoride with other materials can create multifunctional coatings with tailored properties for specialized applications in electronics, energy storage, and advanced optics.

02 Protective properties of lithium fluoride coatings

Lithium fluoride coatings provide excellent protection against environmental factors such as moisture, chemicals, and mechanical wear. These coatings can enhance the durability and longevity of various substrates by forming a chemically stable barrier. The protective properties make lithium fluoride coatings suitable for applications in harsh environments where resistance to corrosion and degradation is essential.Expand Specific Solutions03 Thermal performance of lithium fluoride coatings

Lithium fluoride coatings demonstrate exceptional thermal stability and performance across a wide temperature range. These coatings maintain their structural integrity and functional properties even under extreme thermal conditions. The low thermal expansion coefficient and high melting point make lithium fluoride coatings suitable for applications involving thermal cycling or high-temperature environments.Expand Specific Solutions04 Application of lithium fluoride coatings in battery technology

Lithium fluoride coatings play a crucial role in improving the performance and safety of lithium-ion batteries. When applied to electrode materials, these coatings can enhance ionic conductivity, stabilize the electrode-electrolyte interface, and prevent unwanted side reactions. This results in batteries with improved capacity retention, longer cycle life, and enhanced safety characteristics.Expand Specific Solutions05 Advanced deposition techniques for lithium fluoride coatings

Various advanced deposition techniques have been developed to create high-quality lithium fluoride coatings with controlled thickness, composition, and microstructure. These methods include physical vapor deposition, chemical vapor deposition, atomic layer deposition, and solution-based approaches. Each technique offers specific advantages in terms of coating uniformity, adhesion strength, and scalability for different substrate geometries and applications.Expand Specific Solutions

Leading Companies and Research Institutions in LiF Coatings

The lithium fluoride coatings market is currently in a growth phase, driven by increasing demand for corrosion-resistant materials in harsh environments. The global market size is expanding steadily, estimated to reach significant value by 2030 due to applications in aerospace, electronics, and energy storage sectors. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established chemical companies like DuPont de Nemours and The Chemours Co., alongside specialized coating manufacturers such as Foshan Shunde Jiexin Coating Industry. Research institutions like Southwest Research Institute and Argonne National Laboratory contribute significant advancements, while battery manufacturers including A123 Systems and Ecopro BM are exploring LiF coatings for enhanced battery performance. Academic institutions like Tsinghua University and Wuhan University are driving fundamental research, creating a competitive landscape balanced between commercial applications and scientific development.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed advanced lithium fluoride coating technologies for enhanced corrosion resistance in extreme environments. Their proprietary process involves atomic layer deposition (ALD) of ultra-thin LiF films with precisely controlled thickness (5-50 nm) and composition. These coatings form a protective barrier that prevents direct contact between corrosive media and substrate materials. Argonne's research demonstrates that their LiF coatings can withstand exposure to aggressive environments including strong acids, bases, and salt solutions while maintaining structural integrity. The laboratory has also pioneered composite LiF-based coatings that incorporate secondary phases to enhance mechanical properties and adhesion to various substrates. Their technology has shown particular promise for protecting battery components and nuclear materials from degradation in harsh operating conditions.

Strengths: Superior precision in coating thickness control through ALD technology; excellent uniformity even on complex geometries; strong scientific foundation with comprehensive characterization capabilities. Weaknesses: Higher production costs compared to conventional coating methods; potential challenges in scaling to industrial production volumes; requires specialized equipment for optimal application.

Jiangsu East China Lithium Technology Research Institute Co., Ltd.

Technical Solution: Jiangsu East China Lithium Technology Research Institute has developed a multi-layered lithium fluoride coating system specifically engineered for lithium-ion battery applications in corrosive environments. Their technology utilizes a gradient composition approach where the LiF concentration varies throughout the coating thickness, optimizing both adhesion and protective properties. The institute's process involves a proprietary solution-based deposition method that enables uniform coverage on irregular surfaces while maintaining precise control over coating thickness (typically 100-500 nm). Their research has demonstrated that these coatings can effectively prevent moisture penetration and chemical attack while maintaining excellent ionic conductivity. The institute has also developed specialized post-treatment processes that enhance the crystallinity and density of the LiF layer, further improving its barrier properties against corrosive agents. Testing has shown their coatings maintain integrity even after extended exposure to humid environments with high salt concentrations.

Strengths: Excellent balance between protective properties and electrochemical performance; cost-effective solution-based deposition process suitable for mass production; strong expertise in lithium battery applications. Weaknesses: Limited performance data in extremely acidic environments; potential challenges with mechanical durability under high-stress conditions; primarily optimized for battery applications rather than general corrosion protection.

Critical Patents and Research on LiF Corrosion Resistance

Chromium-free anticorrosive coating composition and article made therefrom

PatentPendingUS20230279238A1

Innovation

- A chromium-free anticorrosive coating composition incorporating a lithium-containing composite metal compound with a spatially stable crystalline structure, comprising transition metal elements like nickel, cobalt, manganese, and iron, which forms a passivation layer to protect metal substrates from corrosion, and is cost-effective.

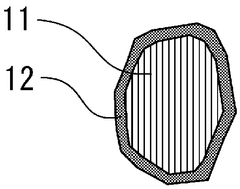

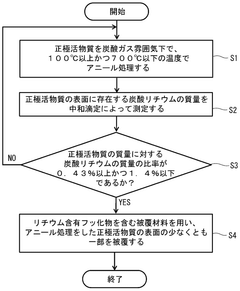

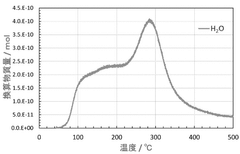

Coated active material, coated active material production method, positive electrode material and battery

PatentWO2024241816A1

Innovation

- A coated active material with a lithium-containing fluoride coating layer is applied to the positive electrode active material, where the lithium carbonate ratio is controlled between 0.43% and 1.4% by mass to suppress the formation of resistance layers, thereby reducing internal resistance.

Environmental Impact and Sustainability of LiF Coatings

The environmental footprint of Lithium Fluoride (LiF) coatings presents a complex sustainability profile that warrants careful consideration in industrial applications. When evaluating the environmental impact of LiF coatings used in corrosive environments, the entire lifecycle must be examined—from raw material extraction through manufacturing, application, service life, to eventual disposal or recycling.

The production of LiF coatings involves mining lithium and fluorine compounds, processes that can lead to habitat disruption, water consumption, and energy expenditure. However, compared to alternative coating technologies, LiF production typically requires lower processing temperatures, resulting in reduced energy consumption and associated carbon emissions during manufacturing.

In application phases, LiF coatings demonstrate exceptional durability in corrosive environments, which translates to extended service life for coated components. This longevity factor significantly reduces the frequency of replacement and maintenance, thereby minimizing waste generation and resource consumption over time. The environmental benefits of this extended service life often outweigh the initial production impacts when assessed through comprehensive lifecycle analysis.

Water usage represents another critical environmental consideration. Traditional coating processes often require substantial water volumes for preparation and application. LiF coating technologies have evolved to incorporate water-efficient application methods, including dry deposition techniques that substantially reduce water consumption and wastewater generation compared to conventional coating processes.

Regarding toxicity concerns, LiF coatings exhibit relatively low environmental toxicity when properly applied and maintained. The stable chemical structure of LiF prevents significant leaching into surrounding environments during normal operation. However, potential fluoride release during extreme degradation scenarios requires monitoring in sensitive ecological settings.

End-of-life management presents both challenges and opportunities for LiF coating sustainability. Current recycling technologies for LiF-coated components remain limited, with most materials directed to conventional waste streams. Emerging recovery processes show promise for reclaiming lithium from coating materials, aligning with circular economy principles and addressing resource scarcity concerns.

Regulatory frameworks increasingly influence LiF coating applications, with particular attention to REACH compliance in European markets and similar regulations globally. Manufacturers have responded by developing low-impact formulations and application methods that maintain performance while reducing environmental footprint, demonstrating the industry's adaptive capacity toward sustainability goals.

The production of LiF coatings involves mining lithium and fluorine compounds, processes that can lead to habitat disruption, water consumption, and energy expenditure. However, compared to alternative coating technologies, LiF production typically requires lower processing temperatures, resulting in reduced energy consumption and associated carbon emissions during manufacturing.

In application phases, LiF coatings demonstrate exceptional durability in corrosive environments, which translates to extended service life for coated components. This longevity factor significantly reduces the frequency of replacement and maintenance, thereby minimizing waste generation and resource consumption over time. The environmental benefits of this extended service life often outweigh the initial production impacts when assessed through comprehensive lifecycle analysis.

Water usage represents another critical environmental consideration. Traditional coating processes often require substantial water volumes for preparation and application. LiF coating technologies have evolved to incorporate water-efficient application methods, including dry deposition techniques that substantially reduce water consumption and wastewater generation compared to conventional coating processes.

Regarding toxicity concerns, LiF coatings exhibit relatively low environmental toxicity when properly applied and maintained. The stable chemical structure of LiF prevents significant leaching into surrounding environments during normal operation. However, potential fluoride release during extreme degradation scenarios requires monitoring in sensitive ecological settings.

End-of-life management presents both challenges and opportunities for LiF coating sustainability. Current recycling technologies for LiF-coated components remain limited, with most materials directed to conventional waste streams. Emerging recovery processes show promise for reclaiming lithium from coating materials, aligning with circular economy principles and addressing resource scarcity concerns.

Regulatory frameworks increasingly influence LiF coating applications, with particular attention to REACH compliance in European markets and similar regulations globally. Manufacturers have responded by developing low-impact formulations and application methods that maintain performance while reducing environmental footprint, demonstrating the industry's adaptive capacity toward sustainability goals.

Cost-Benefit Analysis of LiF vs Alternative Coating Solutions

When evaluating Lithium Fluoride (LiF) coatings for corrosion protection, a comprehensive cost-benefit analysis reveals significant economic considerations compared to alternative solutions. The initial application cost of LiF coatings typically ranges from $8-15 per square meter, positioning it in the mid-range price category among protective coatings. While this represents a higher upfront investment than conventional polymer-based coatings ($3-7/m²), it remains more economical than advanced ceramic coatings ($20-30/m²).

The longevity factor substantially impacts the total cost of ownership. LiF coatings demonstrate an average service life of 7-10 years in highly corrosive environments without requiring significant maintenance, compared to 2-4 years for standard epoxy coatings. This extended lifespan translates to approximately 40-60% reduction in reapplication frequency, generating substantial long-term savings in both material and labor costs.

Energy efficiency represents another critical economic advantage. The thermal properties of LiF coatings contribute to improved energy management in high-temperature applications, potentially reducing operational energy costs by 5-12% compared to conventional alternatives. This benefit becomes particularly significant in continuous industrial processes where even marginal efficiency improvements yield substantial financial returns.

Environmental compliance costs also favor LiF solutions. With increasingly stringent regulations on volatile organic compounds (VOCs) and hazardous materials, LiF coatings' environmentally friendly profile eliminates many compliance-related expenses that burden alternative coating technologies. The reduced environmental liability and waste management costs can save an estimated $2-5 per square meter annually.

The maintenance economics further strengthen LiF's value proposition. Field data indicates that LiF-coated components require 30-50% fewer maintenance interventions than those protected with conventional coatings. This reduction in maintenance frequency not only decreases direct repair costs but also minimizes costly operational downtime, which can range from $10,000-$50,000 per hour in critical industrial applications.

Installation complexity presents a notable disadvantage. LiF coatings typically require more specialized application equipment and expertise, increasing installation costs by 15-25% compared to conventional alternatives. However, this disadvantage diminishes when amortized over the coating's extended service life. The specialized application process also results in more consistent coating quality, reducing the incidence of premature failures that plague less sophisticated coating systems.

The longevity factor substantially impacts the total cost of ownership. LiF coatings demonstrate an average service life of 7-10 years in highly corrosive environments without requiring significant maintenance, compared to 2-4 years for standard epoxy coatings. This extended lifespan translates to approximately 40-60% reduction in reapplication frequency, generating substantial long-term savings in both material and labor costs.

Energy efficiency represents another critical economic advantage. The thermal properties of LiF coatings contribute to improved energy management in high-temperature applications, potentially reducing operational energy costs by 5-12% compared to conventional alternatives. This benefit becomes particularly significant in continuous industrial processes where even marginal efficiency improvements yield substantial financial returns.

Environmental compliance costs also favor LiF solutions. With increasingly stringent regulations on volatile organic compounds (VOCs) and hazardous materials, LiF coatings' environmentally friendly profile eliminates many compliance-related expenses that burden alternative coating technologies. The reduced environmental liability and waste management costs can save an estimated $2-5 per square meter annually.

The maintenance economics further strengthen LiF's value proposition. Field data indicates that LiF-coated components require 30-50% fewer maintenance interventions than those protected with conventional coatings. This reduction in maintenance frequency not only decreases direct repair costs but also minimizes costly operational downtime, which can range from $10,000-$50,000 per hour in critical industrial applications.

Installation complexity presents a notable disadvantage. LiF coatings typically require more specialized application equipment and expertise, increasing installation costs by 15-25% compared to conventional alternatives. However, this disadvantage diminishes when amortized over the coating's extended service life. The specialized application process also results in more consistent coating quality, reducing the incidence of premature failures that plague less sophisticated coating systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!