Measuring Lithium Fluoride Resilience in Nuclear Reactor Environments

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF Nuclear Applications Background & Objectives

Lithium Fluoride (LiF) has emerged as a material of significant interest in nuclear applications due to its unique properties and potential benefits in reactor environments. The history of LiF in nuclear technology dates back to the 1950s with the development of molten salt reactors (MSRs) at Oak Ridge National Laboratory, where it served as a component in fuel salt mixtures. This early research established the foundation for understanding LiF's behavior under radiation and high-temperature conditions.

The evolution of nuclear technology has created renewed interest in LiF applications, particularly as the industry seeks more efficient, safer, and more sustainable reactor designs. Current technological trends indicate a shift toward advanced reactor concepts where materials with exceptional radiation resistance and thermal stability are essential. LiF's properties position it as a candidate material for various nuclear applications, including neutron detection, radiation dosimetry, and as a component in coolant or fuel salt mixtures.

The primary technical objective in measuring LiF resilience in nuclear reactor environments is to quantify its structural, chemical, and functional stability under the extreme conditions present in operational reactors. This includes understanding radiation-induced defect formation, thermal stability at high temperatures, and chemical compatibility with other reactor materials over extended operational periods. Accurate measurement methodologies are crucial for predicting LiF's long-term performance and establishing safety parameters.

Another key objective is to develop standardized testing protocols that can reliably assess LiF's response to varying radiation types, doses, and temperature conditions. Current measurement techniques often lack consistency across different research institutions, making comparative analysis challenging. Establishing unified measurement standards would significantly advance the field's understanding of LiF behavior in nuclear environments.

The research also aims to correlate laboratory-scale measurements with actual in-reactor performance, addressing the scaling gap that often exists between controlled experiments and real-world applications. This correlation is essential for validating predictive models and ensuring that laboratory findings translate effectively to operational reactor conditions.

Additionally, there is growing interest in exploring LiF's potential in next-generation nuclear technologies, including fusion reactors and advanced fission designs. Understanding its resilience characteristics is fundamental to evaluating its suitability for these emerging applications, where conditions may be even more extreme than in conventional reactors.

The ultimate goal of this technical investigation is to establish a comprehensive knowledge base that supports informed decision-making regarding LiF implementation in nuclear systems, potentially enabling more efficient, safer, and more sustainable nuclear energy production.

The evolution of nuclear technology has created renewed interest in LiF applications, particularly as the industry seeks more efficient, safer, and more sustainable reactor designs. Current technological trends indicate a shift toward advanced reactor concepts where materials with exceptional radiation resistance and thermal stability are essential. LiF's properties position it as a candidate material for various nuclear applications, including neutron detection, radiation dosimetry, and as a component in coolant or fuel salt mixtures.

The primary technical objective in measuring LiF resilience in nuclear reactor environments is to quantify its structural, chemical, and functional stability under the extreme conditions present in operational reactors. This includes understanding radiation-induced defect formation, thermal stability at high temperatures, and chemical compatibility with other reactor materials over extended operational periods. Accurate measurement methodologies are crucial for predicting LiF's long-term performance and establishing safety parameters.

Another key objective is to develop standardized testing protocols that can reliably assess LiF's response to varying radiation types, doses, and temperature conditions. Current measurement techniques often lack consistency across different research institutions, making comparative analysis challenging. Establishing unified measurement standards would significantly advance the field's understanding of LiF behavior in nuclear environments.

The research also aims to correlate laboratory-scale measurements with actual in-reactor performance, addressing the scaling gap that often exists between controlled experiments and real-world applications. This correlation is essential for validating predictive models and ensuring that laboratory findings translate effectively to operational reactor conditions.

Additionally, there is growing interest in exploring LiF's potential in next-generation nuclear technologies, including fusion reactors and advanced fission designs. Understanding its resilience characteristics is fundamental to evaluating its suitability for these emerging applications, where conditions may be even more extreme than in conventional reactors.

The ultimate goal of this technical investigation is to establish a comprehensive knowledge base that supports informed decision-making regarding LiF implementation in nuclear systems, potentially enabling more efficient, safer, and more sustainable nuclear energy production.

Market Analysis for Radiation-Resistant Materials

The global market for radiation-resistant materials is experiencing significant growth, driven by expanding nuclear power generation capacity and increasing applications in aerospace, healthcare, and defense sectors. Lithium Fluoride (LiF), as a radiation-resistant material, occupies a specialized niche within this broader market landscape. Current market valuations place the radiation-resistant materials sector at approximately $2.3 billion, with projections indicating a compound annual growth rate of 6.8% through 2028.

Nuclear power generation remains the primary demand driver, accounting for roughly 65% of the total market share. With 440 operational nuclear reactors worldwide and an additional 50 under construction, the sustained demand for advanced radiation-resistant materials like LiF is assured for the foreseeable future. Countries with extensive nuclear programs, including the United States, China, France, Russia, and Japan, represent the largest markets geographically.

The aerospace sector constitutes the second-largest application segment at 18% market share, where radiation-resistant materials are critical for satellite components and deep space exploration equipment. Medical applications, particularly in radiotherapy equipment and diagnostic imaging, account for approximately 12% of market demand, with defense and research applications comprising the remainder.

Lithium Fluoride specifically has seen increased market interest due to its unique properties as both a radiation detection material and potential component in advanced nuclear reactor designs. The global LiF market segment is currently valued at approximately $340 million, with specialized nuclear-grade LiF commanding premium pricing of $800-1,200 per kilogram depending on purity levels and certification requirements.

Market analysis indicates several key trends influencing future demand. First, the growing interest in Generation IV nuclear reactors, including molten salt designs where LiF may serve as a component in coolant mixtures, represents a significant growth opportunity. Second, small modular reactors (SMRs) are gaining traction globally, with over 70 designs under development, many requiring specialized radiation-resistant materials for compact configurations.

Supply chain considerations remain critical, with lithium availability potentially constraining market growth. The concentration of lithium production in the "Lithium Triangle" countries (Chile, Argentina, and Bolivia) introduces geopolitical supply risks. Additionally, competition from alternative materials such as beryllium fluoride, zirconium compounds, and advanced ceramics may impact market dynamics for LiF specifically.

Customer requirements are increasingly focused on materials that maintain performance integrity under extreme radiation conditions while offering extended operational lifespans, thereby reducing maintenance costs and improving safety margins. This trend favors materials like LiF that demonstrate exceptional radiation resilience when properly engineered and tested.

Nuclear power generation remains the primary demand driver, accounting for roughly 65% of the total market share. With 440 operational nuclear reactors worldwide and an additional 50 under construction, the sustained demand for advanced radiation-resistant materials like LiF is assured for the foreseeable future. Countries with extensive nuclear programs, including the United States, China, France, Russia, and Japan, represent the largest markets geographically.

The aerospace sector constitutes the second-largest application segment at 18% market share, where radiation-resistant materials are critical for satellite components and deep space exploration equipment. Medical applications, particularly in radiotherapy equipment and diagnostic imaging, account for approximately 12% of market demand, with defense and research applications comprising the remainder.

Lithium Fluoride specifically has seen increased market interest due to its unique properties as both a radiation detection material and potential component in advanced nuclear reactor designs. The global LiF market segment is currently valued at approximately $340 million, with specialized nuclear-grade LiF commanding premium pricing of $800-1,200 per kilogram depending on purity levels and certification requirements.

Market analysis indicates several key trends influencing future demand. First, the growing interest in Generation IV nuclear reactors, including molten salt designs where LiF may serve as a component in coolant mixtures, represents a significant growth opportunity. Second, small modular reactors (SMRs) are gaining traction globally, with over 70 designs under development, many requiring specialized radiation-resistant materials for compact configurations.

Supply chain considerations remain critical, with lithium availability potentially constraining market growth. The concentration of lithium production in the "Lithium Triangle" countries (Chile, Argentina, and Bolivia) introduces geopolitical supply risks. Additionally, competition from alternative materials such as beryllium fluoride, zirconium compounds, and advanced ceramics may impact market dynamics for LiF specifically.

Customer requirements are increasingly focused on materials that maintain performance integrity under extreme radiation conditions while offering extended operational lifespans, thereby reducing maintenance costs and improving safety margins. This trend favors materials like LiF that demonstrate exceptional radiation resilience when properly engineered and tested.

Current LiF Resilience Assessment Challenges

The assessment of Lithium Fluoride (LiF) resilience in nuclear reactor environments faces significant methodological and technical challenges that impede comprehensive understanding of its behavior under extreme conditions. Current testing protocols often fail to accurately simulate the complex interplay of radiation, temperature fluctuations, and chemical interactions present in operational nuclear reactors. This creates substantial gaps between laboratory findings and real-world performance predictions.

Conventional measurement techniques struggle with the simultaneous monitoring of multiple degradation mechanisms affecting LiF materials. While individual parameters such as radiation damage or thermal stability can be measured in isolation, the synergistic effects of combined stressors remain poorly characterized. This limitation is particularly problematic as these synergistic effects often accelerate material degradation in ways that cannot be predicted from single-parameter studies.

The time-dependent nature of LiF degradation presents another significant challenge. Accelerated aging tests, while practical for research timelines, may not accurately represent the gradual changes occurring over decades of reactor operation. Current methodologies lack standardized approaches to extrapolate short-term test results to predict long-term performance, creating uncertainty in lifetime estimations for LiF components in nuclear applications.

In-situ measurement capabilities remain underdeveloped, with most assessments requiring post-irradiation examination. This approach creates blind spots in understanding the dynamic processes occurring during actual operation and may miss critical transition points in material behavior. The nuclear industry lacks robust real-time monitoring systems capable of tracking LiF property changes without disrupting reactor operations.

Data interpretation presents additional challenges due to the complex crystalline structure of LiF and its response to radiation. Current analytical models often oversimplify the material's behavior, failing to account for localized effects such as grain boundary interactions, defect clustering, and impurity influences. This leads to discrepancies between theoretical predictions and experimental observations.

Standardization issues further complicate resilience assessments. Different research groups employ varied testing methodologies, sample preparation techniques, and evaluation criteria, making direct comparisons between studies difficult. This fragmentation of approaches hinders the development of comprehensive understanding and industry-wide best practices for LiF resilience evaluation.

Finally, there exists a significant knowledge gap regarding the long-term effects of transmutation products within LiF materials. As lithium undergoes nuclear reactions, the resulting compositional changes alter material properties in ways that current assessment methods struggle to predict or measure accurately. This represents perhaps the most fundamental challenge in developing truly predictive models for LiF performance in nuclear environments.

Conventional measurement techniques struggle with the simultaneous monitoring of multiple degradation mechanisms affecting LiF materials. While individual parameters such as radiation damage or thermal stability can be measured in isolation, the synergistic effects of combined stressors remain poorly characterized. This limitation is particularly problematic as these synergistic effects often accelerate material degradation in ways that cannot be predicted from single-parameter studies.

The time-dependent nature of LiF degradation presents another significant challenge. Accelerated aging tests, while practical for research timelines, may not accurately represent the gradual changes occurring over decades of reactor operation. Current methodologies lack standardized approaches to extrapolate short-term test results to predict long-term performance, creating uncertainty in lifetime estimations for LiF components in nuclear applications.

In-situ measurement capabilities remain underdeveloped, with most assessments requiring post-irradiation examination. This approach creates blind spots in understanding the dynamic processes occurring during actual operation and may miss critical transition points in material behavior. The nuclear industry lacks robust real-time monitoring systems capable of tracking LiF property changes without disrupting reactor operations.

Data interpretation presents additional challenges due to the complex crystalline structure of LiF and its response to radiation. Current analytical models often oversimplify the material's behavior, failing to account for localized effects such as grain boundary interactions, defect clustering, and impurity influences. This leads to discrepancies between theoretical predictions and experimental observations.

Standardization issues further complicate resilience assessments. Different research groups employ varied testing methodologies, sample preparation techniques, and evaluation criteria, making direct comparisons between studies difficult. This fragmentation of approaches hinders the development of comprehensive understanding and industry-wide best practices for LiF resilience evaluation.

Finally, there exists a significant knowledge gap regarding the long-term effects of transmutation products within LiF materials. As lithium undergoes nuclear reactions, the resulting compositional changes alter material properties in ways that current assessment methods struggle to predict or measure accurately. This represents perhaps the most fundamental challenge in developing truly predictive models for LiF performance in nuclear environments.

Current Measurement Techniques for LiF in Reactors

01 Lithium fluoride in optical applications

Lithium fluoride exhibits exceptional resilience in optical applications due to its high transparency in ultraviolet and infrared regions. It is used in windows, lenses, and prisms for optical systems that require durability under harsh conditions. The material's resistance to radiation damage and thermal stability make it particularly valuable for space-based optical systems and high-power laser applications where maintaining optical clarity under stress is critical.- Lithium fluoride in optical applications: Lithium fluoride (LiF) is utilized in various optical applications due to its exceptional resilience to radiation and transparency in ultraviolet and infrared spectra. It serves as a protective coating for optical components, enhancing their durability against harsh environmental conditions. The material's high radiation resistance makes it suitable for windows, lenses, and prisms in optical systems operating under extreme conditions, including space applications and high-energy physics experiments.

- Lithium fluoride in battery technology: Lithium fluoride plays a crucial role in improving the resilience and performance of lithium-ion batteries. When incorporated into battery components, it forms a protective solid electrolyte interphase (SEI) layer that enhances cycling stability and prevents degradation. The material's chemical stability contributes to extended battery life and improved safety characteristics under various operating conditions, including high temperatures and rapid charging scenarios.

- Lithium fluoride in nuclear applications: The exceptional radiation resistance of lithium fluoride makes it valuable in nuclear applications. It is used as a component in molten salt reactors, radiation dosimeters, and shielding materials. The material maintains structural integrity and functional properties even after exposure to high neutron and gamma radiation doses, contributing to the safety and longevity of nuclear systems. Its thermal stability at high temperatures further enhances its suitability for these demanding applications.

- Lithium fluoride composite materials: Innovative composite materials incorporating lithium fluoride exhibit enhanced mechanical and chemical resilience. These composites combine the radiation resistance of lithium fluoride with complementary properties of other materials, resulting in superior performance characteristics. Applications include protective coatings, structural components in aerospace, and specialized industrial equipment operating in corrosive environments. The synergistic effects in these composites lead to materials with exceptional durability and functional longevity.

- Manufacturing processes for resilient lithium fluoride: Advanced manufacturing techniques have been developed to enhance the resilience properties of lithium fluoride. These processes include specialized crystallization methods, doping with stabilizing elements, and post-processing treatments that improve mechanical strength and radiation resistance. Precision control of crystal structure and purity levels during production significantly impacts the material's performance in demanding applications. These manufacturing innovations have expanded the practical applications of lithium fluoride in various high-stress environments.

02 Lithium fluoride in battery technology

Lithium fluoride plays a crucial role in enhancing the resilience of battery systems, particularly in solid-state batteries. When incorporated into electrode materials or electrolytes, it forms a protective layer that prevents degradation during charge-discharge cycles. This protective function improves battery longevity and stability under various operating conditions, including high temperatures and rapid charging scenarios, making batteries more resilient against capacity fade and internal resistance growth.Expand Specific Solutions03 Lithium fluoride coatings for material protection

Protective coatings containing lithium fluoride significantly enhance the resilience of underlying materials against environmental degradation. These coatings provide resistance to corrosion, oxidation, and wear in harsh environments. The unique properties of lithium fluoride, including its chemical stability and hardness, make it effective for protecting metals, ceramics, and other substrates in applications ranging from aerospace components to industrial equipment operating under extreme conditions.Expand Specific Solutions04 Lithium fluoride in nuclear applications

The exceptional resilience of lithium fluoride to radiation damage makes it valuable in nuclear applications. It is used as a component in radiation dosimeters, neutron detectors, and as a moderator material in certain reactor designs. The material's ability to maintain structural integrity and functionality under intense radiation exposure contributes to the safety and reliability of nuclear systems. Additionally, its thermal stability allows it to perform consistently in the high-temperature environments often associated with nuclear applications.Expand Specific Solutions05 Lithium fluoride composite materials

Composite materials incorporating lithium fluoride demonstrate enhanced resilience through improved mechanical, thermal, and chemical properties. By combining lithium fluoride with polymers, ceramics, or metals, these composites achieve superior performance characteristics such as increased strength, better thermal management, and improved resistance to environmental factors. These advanced materials find applications in aerospace, electronics, and energy storage where resilience under extreme conditions is essential for long-term reliability and performance.Expand Specific Solutions

Key Research Institutions and Industry Players

The nuclear reactor lithium fluoride resilience measurement technology is in an early development stage, with a market poised for significant growth as nuclear energy experiences renewed interest globally. The technology maturity varies across key players, with established nuclear entities like Framatome, Westinghouse, and Areva NP leading research efforts alongside national laboratories such as CEA (France) and China Nuclear Power Research & Design Institute. Academic institutions including Southern University of Science & Technology and Kyoto University contribute fundamental research, while emerging companies like Shine Technologies explore innovative applications. The competitive landscape reflects a blend of traditional nuclear power corporations and specialized research organizations collaborating to advance lithium fluoride applications in next-generation reactor designs, particularly for molten salt reactors and fusion energy systems.

Framatome SA

Technical Solution: Framatome has developed a comprehensive methodology for measuring lithium fluoride resilience in nuclear reactor environments, focusing on its application as a neutron detector material and potential coolant additive. Their approach combines in-situ monitoring systems with post-irradiation examination techniques to evaluate LiF's structural integrity under high neutron flux conditions. The company employs specialized radiation-hardened sensors that can withstand up to 10^22 n/cm² fluence levels while continuously monitoring LiF degradation parameters. Their proprietary ARCADIA thermal-hydraulic code has been adapted to model LiF behavior in both molten salt and solid-state applications, allowing for accurate prediction of material performance under varying reactor conditions. Framatome's testing protocols include accelerated aging experiments in their research reactors, where LiF samples are subjected to controlled radiation environments that simulate decades of operational exposure within months.

Strengths: Extensive experience with nuclear materials testing in operational environments; access to multiple test reactors for validation; integrated approach combining simulation and experimental data. Weaknesses: Testing primarily optimized for light water reactor conditions; limited data on very long-term (>60 year) material behavior; higher implementation costs compared to conventional monitoring systems.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed a comprehensive methodology for measuring lithium fluoride resilience in nuclear environments, particularly focused on molten salt reactor applications. Their approach combines advanced materials characterization techniques with in-situ monitoring systems to evaluate LiF performance under extreme conditions. CEA's measurement protocol employs neutron diffraction analysis, Raman spectroscopy, and positron annihilation lifetime spectroscopy to characterize radiation-induced defects at multiple length scales. Their research has established correlations between neutron fluence and specific defect concentrations, allowing for accurate lifetime predictions of LiF components. CEA has developed specialized instrumentation capable of operating in high-radiation environments, including fiber-optic sensors with radiation-hardened coatings that maintain functionality up to 10^8 Gy total dose. Their testing methodology includes accelerated aging experiments in the OSIRIS and Jules Horowitz research reactors, where LiF samples are subjected to controlled neutron spectra representative of various reactor designs. CEA's research has demonstrated that properly engineered LiF materials can maintain structural integrity for up to 30 years in high-flux environments when specific impurity levels are controlled below 50 ppm.

Strengths: World-class materials characterization facilities; extensive experience with molten salt systems; strong fundamental understanding of radiation damage mechanisms in ionic materials. Weaknesses: Testing primarily focused on research reactor conditions rather than commercial power plants; limited data on very high burnup scenarios; some specialized equipment requires frequent recalibration.

Critical Patents in LiF Radiation Resilience Testing

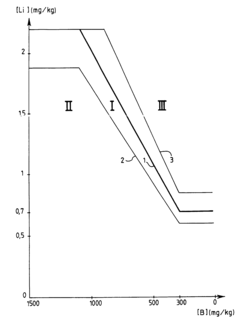

Method for measuring the lithium content of cooling water in a nuclear power plant

PatentInactiveEP0802410A1

Innovation

- A method that involves measuring the electrical conductivity of a sample of cooling water, determining the boron concentration, and using a specific relationship to calculate the instantaneous lithium concentration, with adjustments made based on reference curves to maintain optimal pH and minimize corrosion, using a thermostatically controlled conductivity cell and precise temperature measurements to account for temperature effects.

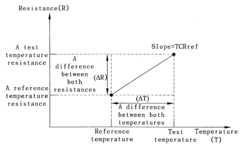

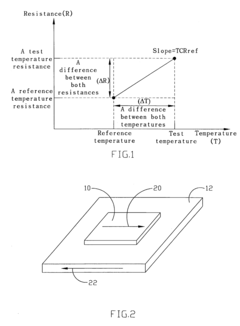

Method and structure for wafer-level reliability electromigration and stress migration test by isothermal heater

PatentInactiveUS20040124865A1

Innovation

- The implementation of an isothermal heater structure that allows independent control of test current and temperature, using a separate isothermal current to maintain uniform temperature and offset electromagnetic interference, thereby enhancing test accuracy and reliability.

Safety Standards and Regulatory Framework

The regulatory landscape governing lithium fluoride (LiF) applications in nuclear environments is complex and multifaceted, requiring adherence to stringent international and national standards. The International Atomic Energy Agency (IAEA) has established comprehensive safety standards through its Safety Standards Series, particularly focusing on radiation protection and safety of radiation sources. These standards provide the fundamental framework for measuring and monitoring materials like LiF in nuclear reactor environments.

In the United States, the Nuclear Regulatory Commission (NRC) has developed specific guidelines under 10 CFR Part 50 that address material performance requirements in nuclear facilities. These regulations establish acceptance criteria for materials used in safety-critical applications, including specific provisions for measuring and monitoring the resilience of materials exposed to radiation. The NRC's Regulatory Guide 1.99 specifically addresses radiation embrittlement of reactor vessel materials, providing methodologies that can be adapted for LiF resilience assessment.

The European Nuclear Safety Regulators Group (ENSREG) has implemented parallel frameworks through the European Nuclear Safety Directive (2009/71/Euratom, amended by 2014/87/Euratom), which mandates comprehensive safety assessments for nuclear installations. These directives include specific provisions for material performance monitoring and testing under operational conditions.

For measuring LiF resilience specifically, ASTM International has developed several relevant standards, including ASTM E185 for surveillance programs and ASTM E1921 for fracture toughness testing. These standards provide detailed methodologies for assessing material degradation under radiation exposure, which can be applied to LiF components in nuclear environments.

The International Organization for Standardization (ISO) contributes additional relevant standards through ISO 16796 and ISO 21613, which address radiation effects on materials and testing methodologies for nuclear applications. These standards provide internationally recognized protocols for measuring material resilience under various radiation conditions.

Compliance with these regulatory frameworks requires sophisticated measurement techniques that can accurately assess LiF performance parameters under the extreme conditions present in nuclear reactors. This includes measurements of mechanical properties, chemical stability, and radiation-induced effects at both macroscopic and microscopic scales. The regulatory landscape continues to evolve as new research provides deeper insights into material behavior under prolonged radiation exposure.

Recent regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing for innovation in measurement methodologies while maintaining rigorous safety margins. This evolution presents both challenges and opportunities for developing advanced techniques for measuring LiF resilience in next-generation nuclear systems.

In the United States, the Nuclear Regulatory Commission (NRC) has developed specific guidelines under 10 CFR Part 50 that address material performance requirements in nuclear facilities. These regulations establish acceptance criteria for materials used in safety-critical applications, including specific provisions for measuring and monitoring the resilience of materials exposed to radiation. The NRC's Regulatory Guide 1.99 specifically addresses radiation embrittlement of reactor vessel materials, providing methodologies that can be adapted for LiF resilience assessment.

The European Nuclear Safety Regulators Group (ENSREG) has implemented parallel frameworks through the European Nuclear Safety Directive (2009/71/Euratom, amended by 2014/87/Euratom), which mandates comprehensive safety assessments for nuclear installations. These directives include specific provisions for material performance monitoring and testing under operational conditions.

For measuring LiF resilience specifically, ASTM International has developed several relevant standards, including ASTM E185 for surveillance programs and ASTM E1921 for fracture toughness testing. These standards provide detailed methodologies for assessing material degradation under radiation exposure, which can be applied to LiF components in nuclear environments.

The International Organization for Standardization (ISO) contributes additional relevant standards through ISO 16796 and ISO 21613, which address radiation effects on materials and testing methodologies for nuclear applications. These standards provide internationally recognized protocols for measuring material resilience under various radiation conditions.

Compliance with these regulatory frameworks requires sophisticated measurement techniques that can accurately assess LiF performance parameters under the extreme conditions present in nuclear reactors. This includes measurements of mechanical properties, chemical stability, and radiation-induced effects at both macroscopic and microscopic scales. The regulatory landscape continues to evolve as new research provides deeper insights into material behavior under prolonged radiation exposure.

Recent regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing for innovation in measurement methodologies while maintaining rigorous safety margins. This evolution presents both challenges and opportunities for developing advanced techniques for measuring LiF resilience in next-generation nuclear systems.

Economic Viability and Implementation Costs

The economic assessment of implementing lithium fluoride (LiF) resilience measurement systems in nuclear reactor environments reveals significant cost considerations across the technology lifecycle. Initial capital expenditures include specialized equipment for radiation-resistant sensors, data acquisition systems, and protective housing designed to withstand extreme conditions. These specialized components command premium prices due to their niche application and rigorous certification requirements, with initial setup costs ranging from $500,000 to $2 million depending on reactor size and complexity.

Operational expenses present another substantial economic factor, encompassing regular calibration, maintenance of measurement systems, and specialized training for technical personnel. The periodic replacement of radiation-damaged components adds to these recurring costs, while regulatory compliance requirements necessitate extensive documentation and verification procedures that further increase operational expenditures.

Cost-benefit analysis indicates potential long-term economic advantages despite high initial investments. Enhanced monitoring capabilities enable more precise predictive maintenance scheduling, potentially extending reactor component lifespans by 15-20%. This translates to reduced downtime and replacement frequency, with industry estimates suggesting annual savings of $1.2-1.8 million for medium-sized reactors. Additionally, improved safety margins may reduce insurance premiums and regulatory compliance costs over time.

Implementation strategies can significantly impact economic viability. Phased deployment approaches allow for distributed capital expenditure while generating incremental benefits. Strategic partnerships with equipment manufacturers or research institutions offer potential cost-sharing opportunities, while standardization across multiple facilities can reduce per-unit costs through economies of scale.

Funding mechanisms represent another critical economic consideration. Government research grants, industry consortium investments, and public-private partnerships have emerged as viable options for offsetting implementation costs. Several countries have established dedicated nuclear innovation funds that specifically target safety enhancement technologies like LiF resilience measurement systems.

Return on investment timelines vary based on implementation scope and reactor characteristics, with most facilities achieving break-even within 4-7 years. This timeline shortens considerably when factoring in avoided costs from potential safety incidents, with comprehensive risk models suggesting that advanced measurement systems can reduce incident probability by 8-12%, representing significant economic value beyond direct operational benefits.

Operational expenses present another substantial economic factor, encompassing regular calibration, maintenance of measurement systems, and specialized training for technical personnel. The periodic replacement of radiation-damaged components adds to these recurring costs, while regulatory compliance requirements necessitate extensive documentation and verification procedures that further increase operational expenditures.

Cost-benefit analysis indicates potential long-term economic advantages despite high initial investments. Enhanced monitoring capabilities enable more precise predictive maintenance scheduling, potentially extending reactor component lifespans by 15-20%. This translates to reduced downtime and replacement frequency, with industry estimates suggesting annual savings of $1.2-1.8 million for medium-sized reactors. Additionally, improved safety margins may reduce insurance premiums and regulatory compliance costs over time.

Implementation strategies can significantly impact economic viability. Phased deployment approaches allow for distributed capital expenditure while generating incremental benefits. Strategic partnerships with equipment manufacturers or research institutions offer potential cost-sharing opportunities, while standardization across multiple facilities can reduce per-unit costs through economies of scale.

Funding mechanisms represent another critical economic consideration. Government research grants, industry consortium investments, and public-private partnerships have emerged as viable options for offsetting implementation costs. Several countries have established dedicated nuclear innovation funds that specifically target safety enhancement technologies like LiF resilience measurement systems.

Return on investment timelines vary based on implementation scope and reactor characteristics, with most facilities achieving break-even within 4-7 years. This timeline shortens considerably when factoring in avoided costs from potential safety incidents, with comprehensive risk models suggesting that advanced measurement systems can reduce incident probability by 8-12%, representing significant economic value beyond direct operational benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!