Lithium Fluoride: Maximize Yield in Chemical Vapor Deposition

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF CVD Technology Background and Objectives

Lithium Fluoride (LiF) Chemical Vapor Deposition (CVD) technology has evolved significantly over the past decades, transitioning from experimental laboratory techniques to industrially viable processes. Initially developed in the 1960s for optical applications, LiF CVD has expanded into semiconductor manufacturing, photonics, and advanced materials science. The fundamental principle involves the vapor-phase reaction of lithium and fluorine precursors to form high-purity LiF films on various substrates.

The evolution of LiF CVD technology has been driven by increasing demands for higher purity films, better uniformity, and enhanced process control. Early systems suffered from contamination issues and limited deposition rates, whereas modern approaches incorporate advanced precursor delivery systems, precise temperature control mechanisms, and optimized reactor designs. Recent technological breakthroughs include the development of atomic layer deposition (ALD) variants for LiF, enabling atomic-level thickness control.

Current industry trends point toward the integration of LiF CVD processes with other manufacturing steps, creating seamless production workflows for complex devices. The miniaturization of electronic components and the growing importance of quantum technologies have further accelerated research in this field, as LiF films with precisely controlled properties are essential for these applications.

The primary technical objective for LiF CVD yield maximization involves achieving consistent, high-quality film deposition with minimal waste of precursor materials. This encompasses several specific goals: increasing the conversion efficiency of precursors to deposited film, improving thickness uniformity across large substrate areas, reducing defect densities, and enhancing adhesion properties between LiF films and various substrate materials.

Secondary objectives include reducing energy consumption during the deposition process, minimizing hazardous waste generation, and developing in-situ monitoring techniques for real-time process control. The industry also aims to extend the scalability of LiF CVD processes to accommodate larger substrate sizes while maintaining quality metrics.

From a technological roadmap perspective, the next five years are expected to focus on precursor chemistry innovations, reactor design optimizations, and the integration of machine learning algorithms for process parameter optimization. Long-term goals include the development of room-temperature deposition techniques, which would significantly reduce energy requirements and enable deposition on temperature-sensitive substrates.

The intersection of LiF CVD technology with emerging fields such as flexible electronics, quantum computing, and advanced photonics presents both challenges and opportunities. As these applications demand increasingly specialized film properties, the technology must evolve to meet these requirements while maintaining economic viability and environmental sustainability.

The evolution of LiF CVD technology has been driven by increasing demands for higher purity films, better uniformity, and enhanced process control. Early systems suffered from contamination issues and limited deposition rates, whereas modern approaches incorporate advanced precursor delivery systems, precise temperature control mechanisms, and optimized reactor designs. Recent technological breakthroughs include the development of atomic layer deposition (ALD) variants for LiF, enabling atomic-level thickness control.

Current industry trends point toward the integration of LiF CVD processes with other manufacturing steps, creating seamless production workflows for complex devices. The miniaturization of electronic components and the growing importance of quantum technologies have further accelerated research in this field, as LiF films with precisely controlled properties are essential for these applications.

The primary technical objective for LiF CVD yield maximization involves achieving consistent, high-quality film deposition with minimal waste of precursor materials. This encompasses several specific goals: increasing the conversion efficiency of precursors to deposited film, improving thickness uniformity across large substrate areas, reducing defect densities, and enhancing adhesion properties between LiF films and various substrate materials.

Secondary objectives include reducing energy consumption during the deposition process, minimizing hazardous waste generation, and developing in-situ monitoring techniques for real-time process control. The industry also aims to extend the scalability of LiF CVD processes to accommodate larger substrate sizes while maintaining quality metrics.

From a technological roadmap perspective, the next five years are expected to focus on precursor chemistry innovations, reactor design optimizations, and the integration of machine learning algorithms for process parameter optimization. Long-term goals include the development of room-temperature deposition techniques, which would significantly reduce energy requirements and enable deposition on temperature-sensitive substrates.

The intersection of LiF CVD technology with emerging fields such as flexible electronics, quantum computing, and advanced photonics presents both challenges and opportunities. As these applications demand increasingly specialized film properties, the technology must evolve to meet these requirements while maintaining economic viability and environmental sustainability.

Market Analysis for High-Yield LiF Films

The global market for high-yield Lithium Fluoride (LiF) films has experienced significant growth in recent years, driven primarily by expanding applications in optical coatings, semiconductor manufacturing, and advanced electronics. Current market estimates value the LiF thin film sector at approximately $320 million, with projections indicating a compound annual growth rate of 7.8% through 2028.

The optical industry represents the largest market segment for high-quality LiF films, accounting for roughly 42% of total demand. LiF's exceptional transparency in the ultraviolet spectrum and its high laser damage threshold make it indispensable for precision optical components in aerospace, defense, and scientific instrumentation applications.

Semiconductor manufacturing constitutes the fastest-growing segment, with demand increasing at nearly 12% annually. This surge is attributed to LiF's emerging role in advanced lithography processes and as a dielectric material in next-generation microelectronics. The push toward smaller node sizes in semiconductor fabrication has intensified the need for ultra-pure, defect-free LiF films with precisely controlled thicknesses.

Regionally, North America and Asia-Pacific dominate the market landscape. North America leads in high-end applications requiring premium-quality films, while Asia-Pacific, particularly China, South Korea, and Taiwan, drives volume demand through their extensive electronics manufacturing ecosystems. European demand centers primarily around scientific instrumentation and specialized optical applications.

Customer requirements are increasingly stringent, with specifications demanding yield rates exceeding 95%, thickness uniformity within ±2%, and impurity levels below 10 parts per million. These exacting standards reflect the critical role LiF films play in high-value applications where performance cannot be compromised.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers prioritize cost efficiency, aerospace and defense contractors emphasize performance reliability over price considerations. This bifurcation has created distinct market tiers with corresponding quality-price relationships.

Supply chain dynamics present both opportunities and challenges. Raw material availability remains stable, though fluctuations in lithium pricing occasionally impact production economics. More significant constraints exist in specialized deposition equipment, where only a limited number of manufacturers can deliver systems capable of meeting the highest yield specifications.

Market forecasts indicate particularly strong growth potential in quantum computing applications, where LiF films serve as key components in qubit isolation systems. Similarly, the emerging field of extreme ultraviolet lithography represents a high-value niche with stringent requirements that command premium pricing for manufacturers capable of delivering consistent high-yield production.

The optical industry represents the largest market segment for high-quality LiF films, accounting for roughly 42% of total demand. LiF's exceptional transparency in the ultraviolet spectrum and its high laser damage threshold make it indispensable for precision optical components in aerospace, defense, and scientific instrumentation applications.

Semiconductor manufacturing constitutes the fastest-growing segment, with demand increasing at nearly 12% annually. This surge is attributed to LiF's emerging role in advanced lithography processes and as a dielectric material in next-generation microelectronics. The push toward smaller node sizes in semiconductor fabrication has intensified the need for ultra-pure, defect-free LiF films with precisely controlled thicknesses.

Regionally, North America and Asia-Pacific dominate the market landscape. North America leads in high-end applications requiring premium-quality films, while Asia-Pacific, particularly China, South Korea, and Taiwan, drives volume demand through their extensive electronics manufacturing ecosystems. European demand centers primarily around scientific instrumentation and specialized optical applications.

Customer requirements are increasingly stringent, with specifications demanding yield rates exceeding 95%, thickness uniformity within ±2%, and impurity levels below 10 parts per million. These exacting standards reflect the critical role LiF films play in high-value applications where performance cannot be compromised.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers prioritize cost efficiency, aerospace and defense contractors emphasize performance reliability over price considerations. This bifurcation has created distinct market tiers with corresponding quality-price relationships.

Supply chain dynamics present both opportunities and challenges. Raw material availability remains stable, though fluctuations in lithium pricing occasionally impact production economics. More significant constraints exist in specialized deposition equipment, where only a limited number of manufacturers can deliver systems capable of meeting the highest yield specifications.

Market forecasts indicate particularly strong growth potential in quantum computing applications, where LiF films serve as key components in qubit isolation systems. Similarly, the emerging field of extreme ultraviolet lithography represents a high-value niche with stringent requirements that command premium pricing for manufacturers capable of delivering consistent high-yield production.

Current CVD Challenges for LiF Deposition

Chemical Vapor Deposition (CVD) of Lithium Fluoride (LiF) faces several significant challenges that limit production yield and quality. The primary obstacle lies in the high reactivity of lithium precursors, which often leads to premature reactions before reaching the substrate surface. This results in particle formation in the gas phase rather than film deposition, substantially reducing yield and creating non-uniform coatings.

Temperature control presents another critical challenge in LiF CVD processes. The narrow processing window requires precise temperature regulation throughout the deposition chamber. Even minor temperature fluctuations can cause significant variations in film growth rates and crystallinity. This sensitivity makes scaling up particularly difficult, as maintaining uniform temperature profiles across larger substrates becomes exponentially more challenging.

Precursor selection and delivery pose persistent problems for LiF deposition. Traditional lithium precursors such as lithium tert-butoxide and lithium hexamethyldisilazide (LiHMDS) exhibit poor vapor pressure characteristics and thermal stability issues. The fluorine sources, typically HF or NF3, introduce additional complexity due to their corrosive nature and safety concerns. The precise stoichiometric delivery of both precursors remains difficult to achieve consistently.

Chamber contamination represents another yield-limiting factor. LiF is highly sensitive to moisture and oxygen contamination, which can lead to the formation of lithium hydroxide or lithium oxide instead of the desired LiF. Even trace amounts of these contaminants can significantly degrade film quality and reduce yield. Current reactor designs struggle to maintain the ultra-high purity environment required for optimal LiF deposition.

Substrate compatibility issues further complicate the process. LiF films often exhibit poor adhesion to many common substrate materials, leading to delamination and reduced yield. Surface preparation techniques that work well for other materials may not be effective for LiF deposition, necessitating specialized approaches that are not yet fully optimized.

Process monitoring and control systems for LiF CVD remain underdeveloped compared to those for more established materials. Real-time monitoring of film thickness, composition, and crystallinity during deposition is limited, making it difficult to implement feedback control systems that could potentially improve yield. The lack of in-situ analytical capabilities hampers process optimization efforts and increases development time for new LiF deposition recipes.

Finally, the post-deposition handling of LiF films presents challenges due to their hygroscopic nature. Exposure to ambient conditions can rapidly degrade film quality, necessitating specialized handling and packaging solutions that add complexity and cost to the manufacturing process. These combined factors create significant barriers to achieving high-yield, cost-effective LiF deposition via CVD methods.

Temperature control presents another critical challenge in LiF CVD processes. The narrow processing window requires precise temperature regulation throughout the deposition chamber. Even minor temperature fluctuations can cause significant variations in film growth rates and crystallinity. This sensitivity makes scaling up particularly difficult, as maintaining uniform temperature profiles across larger substrates becomes exponentially more challenging.

Precursor selection and delivery pose persistent problems for LiF deposition. Traditional lithium precursors such as lithium tert-butoxide and lithium hexamethyldisilazide (LiHMDS) exhibit poor vapor pressure characteristics and thermal stability issues. The fluorine sources, typically HF or NF3, introduce additional complexity due to their corrosive nature and safety concerns. The precise stoichiometric delivery of both precursors remains difficult to achieve consistently.

Chamber contamination represents another yield-limiting factor. LiF is highly sensitive to moisture and oxygen contamination, which can lead to the formation of lithium hydroxide or lithium oxide instead of the desired LiF. Even trace amounts of these contaminants can significantly degrade film quality and reduce yield. Current reactor designs struggle to maintain the ultra-high purity environment required for optimal LiF deposition.

Substrate compatibility issues further complicate the process. LiF films often exhibit poor adhesion to many common substrate materials, leading to delamination and reduced yield. Surface preparation techniques that work well for other materials may not be effective for LiF deposition, necessitating specialized approaches that are not yet fully optimized.

Process monitoring and control systems for LiF CVD remain underdeveloped compared to those for more established materials. Real-time monitoring of film thickness, composition, and crystallinity during deposition is limited, making it difficult to implement feedback control systems that could potentially improve yield. The lack of in-situ analytical capabilities hampers process optimization efforts and increases development time for new LiF deposition recipes.

Finally, the post-deposition handling of LiF films presents challenges due to their hygroscopic nature. Exposure to ambient conditions can rapidly degrade film quality, necessitating specialized handling and packaging solutions that add complexity and cost to the manufacturing process. These combined factors create significant barriers to achieving high-yield, cost-effective LiF deposition via CVD methods.

Current Yield Optimization Approaches

01 Production methods for lithium fluoride

Various methods can be employed to produce lithium fluoride with high yield. These include precipitation reactions between lithium salts and fluoride sources, hydrothermal synthesis, and solid-state reactions. The choice of precursors, reaction conditions, and processing parameters significantly affects the yield and purity of the final lithium fluoride product.- Production methods for lithium fluoride: Various methods can be employed to produce lithium fluoride with high yield. These include precipitation reactions between lithium salts and fluoride sources, hydrothermal synthesis, and solid-state reactions. The choice of precursors, reaction conditions, and processing parameters significantly affects the yield and purity of the final product. Optimization of reaction temperature, time, and stoichiometry can lead to improved lithium fluoride yields.

- Purification techniques for improving lithium fluoride yield: Purification processes play a crucial role in enhancing the yield of lithium fluoride production. Techniques such as recrystallization, filtration, washing, and drying are employed to remove impurities and increase the purity of lithium fluoride. Advanced separation methods, including selective precipitation and solvent extraction, can further improve the yield by recovering lithium fluoride from process streams and reducing losses during production.

- Recovery and recycling processes for lithium fluoride: Recovery and recycling processes are essential for maximizing the overall yield of lithium fluoride in industrial applications. These processes involve the collection and treatment of waste streams containing lithium fluoride, extraction from spent materials, and regeneration of lithium fluoride from by-products. Implementing efficient recovery systems can significantly increase the effective yield by reducing material losses and enabling the reuse of lithium fluoride in subsequent production cycles.

- Catalytic processes for enhancing lithium fluoride synthesis: Catalytic processes can significantly enhance the synthesis of lithium fluoride and improve yield. The use of specific catalysts can lower reaction energy barriers, accelerate reaction rates, and improve selectivity toward lithium fluoride formation. Catalyst selection, preparation methods, and optimization of catalytic conditions are critical factors that influence the efficiency of lithium fluoride production and ultimately the yield of the desired product.

- Advanced technologies for high-yield lithium fluoride production: Advanced technologies are being developed to achieve high-yield lithium fluoride production. These include continuous flow processes, microwave-assisted synthesis, electrochemical methods, and mechanochemical approaches. Such technologies offer advantages such as better control over reaction parameters, reduced reaction times, lower energy consumption, and minimized waste generation. Implementation of these advanced methods can lead to significant improvements in lithium fluoride yield compared to conventional batch processes.

02 Purification techniques to improve lithium fluoride yield

Purification techniques play a crucial role in improving the yield of lithium fluoride production. These techniques include recrystallization, filtration, washing procedures, and solvent extraction. Advanced purification methods can remove impurities and byproducts, resulting in higher-quality lithium fluoride with improved yield efficiency.Expand Specific Solutions03 Optimization of reaction parameters for enhanced yield

Optimizing reaction parameters such as temperature, pressure, pH, reaction time, and reagent concentrations can significantly enhance lithium fluoride yield. Controlled reaction environments and precise parameter adjustments help maximize conversion rates and minimize side reactions, leading to improved overall yield and product quality.Expand Specific Solutions04 Novel catalysts and additives for lithium fluoride synthesis

The use of novel catalysts and additives can substantially improve lithium fluoride synthesis yield. These materials can facilitate reaction pathways, lower activation energies, and promote selective formation of lithium fluoride. Certain additives also help prevent agglomeration and improve crystallization processes, resulting in higher yields of well-defined lithium fluoride crystals.Expand Specific Solutions05 Recycling and recovery processes for lithium fluoride

Recycling and recovery processes are essential for maximizing the overall yield of lithium fluoride production. These processes involve the reclamation of unreacted precursors, recovery from waste streams, and regeneration of lithium fluoride from spent materials. Efficient recycling methods can significantly increase the effective yield by reducing material losses throughout the production cycle.Expand Specific Solutions

Leading Companies in LiF CVD Technology

The lithium fluoride chemical vapor deposition market is currently in a growth phase, with increasing applications in semiconductor manufacturing, optical coatings, and battery technologies. The global market size is estimated to reach $1.2 billion by 2025, driven by demand for high-purity thin films in electronics and energy storage. Leading players include Applied Materials, which dominates with advanced CVD equipment solutions, Samsung Electronics with significant R&D investments in semiconductor applications, and specialized materials suppliers like Do-Fluoride New Materials and Ganfeng Lithium Group. The technology maturity varies across applications, with established processes in semiconductor manufacturing but emerging innovations in battery technology and optical coatings, where companies like Ilika Technologies and Micron Technology are developing proprietary deposition techniques to maximize yield and film quality.

Applied Materials, Inc.

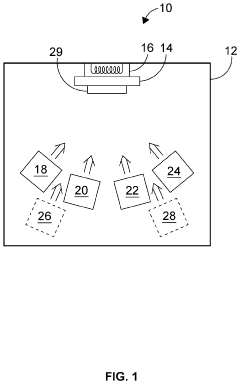

Technical Solution: Applied Materials has developed advanced Chemical Vapor Deposition (CVD) systems specifically optimized for lithium fluoride thin film deposition. Their technology utilizes a dual-chamber design with precise temperature control mechanisms that maintain optimal substrate temperatures between 300-450°C during deposition. The company's proprietary gas flow management system enables uniform precursor distribution across large wafer surfaces, achieving thickness uniformity of ±2% across 300mm wafers. Their process employs lithium and fluorine precursors with controlled reaction kinetics, utilizing plasma enhancement at specific power densities (0.5-2.0 W/cm²) to activate reactions at lower temperatures while maintaining film stoichiometry. Real-time monitoring systems with integrated sensors provide feedback for automated process adjustments, significantly improving yield consistency compared to conventional methods.

Strengths: Industry-leading process control systems with exceptional uniformity across large substrates; integrated metrology capabilities for real-time adjustments; scalable to high-volume manufacturing. Weaknesses: Higher initial capital investment compared to simpler deposition systems; requires specialized maintenance expertise; process optimization can be complex for new material combinations.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has pioneered a specialized CVD process for lithium fluoride deposition targeting next-generation semiconductor and display applications. Their approach utilizes atomic layer deposition (ALD) principles within a modified CVD framework, enabling precise control over film thickness at the atomic scale (±0.5Å precision). The company's technology employs sequential pulsing of lithium and fluorine precursors with optimized purge cycles, achieving growth rates of approximately 0.8-1.2Å per cycle while maintaining exceptional film purity (>99.9%). Samsung's system incorporates advanced plasma treatment steps between deposition cycles to enhance film crystallinity and reduce defect density. Their process operates at relatively low temperatures (180-250°C), making it compatible with temperature-sensitive substrates used in advanced semiconductor fabrication. The company has also developed proprietary precursor delivery systems that minimize precursor degradation and maximize utilization efficiency.

Strengths: Exceptional thickness control and uniformity; compatibility with existing semiconductor manufacturing infrastructure; lower temperature processing enables integration with sensitive materials. Weaknesses: Slower deposition rates compared to traditional CVD methods; higher complexity in process control; requires specialized precursors that may have limited commercial availability.

Key Patents in LiF CVD Yield Enhancement

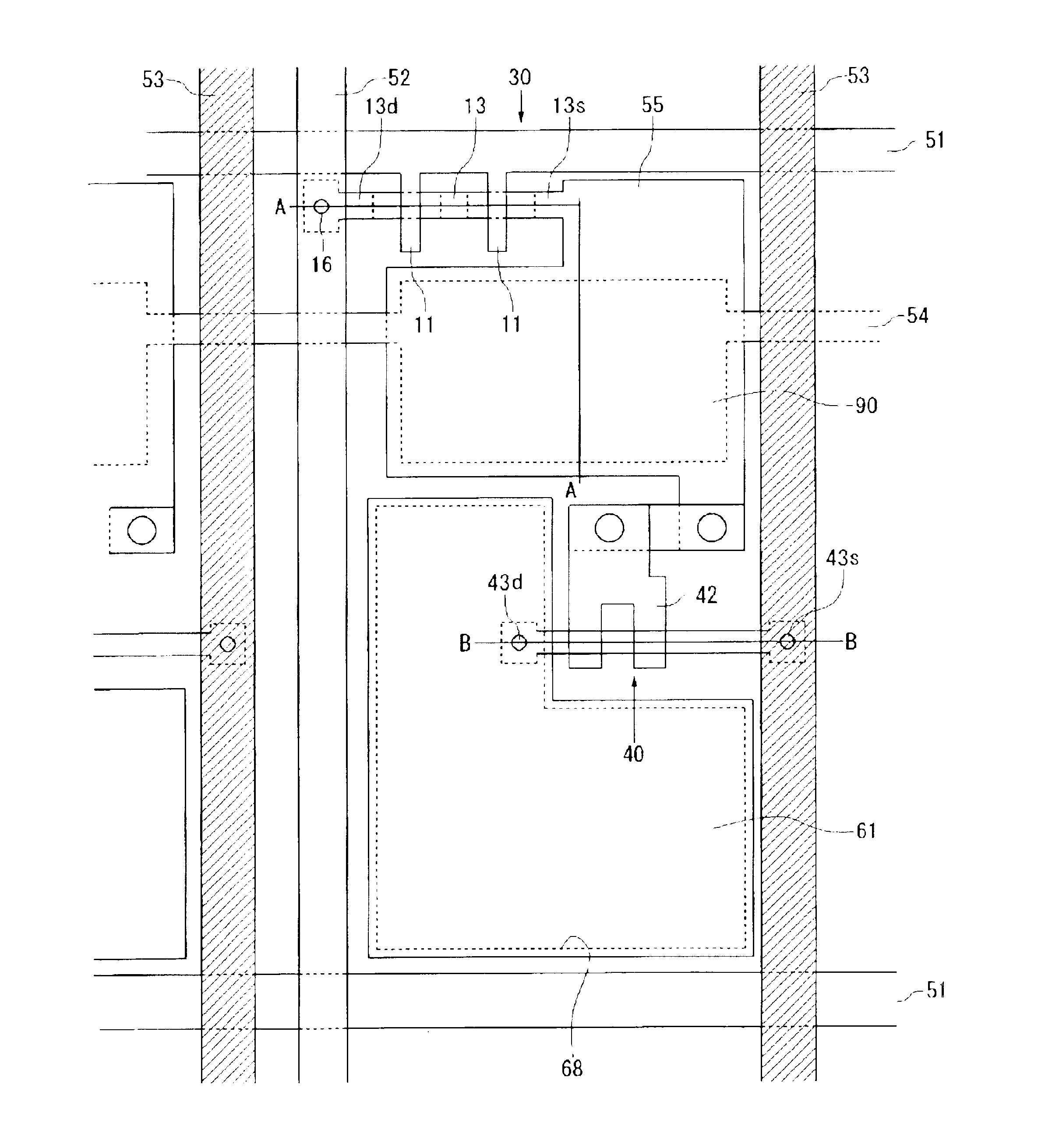

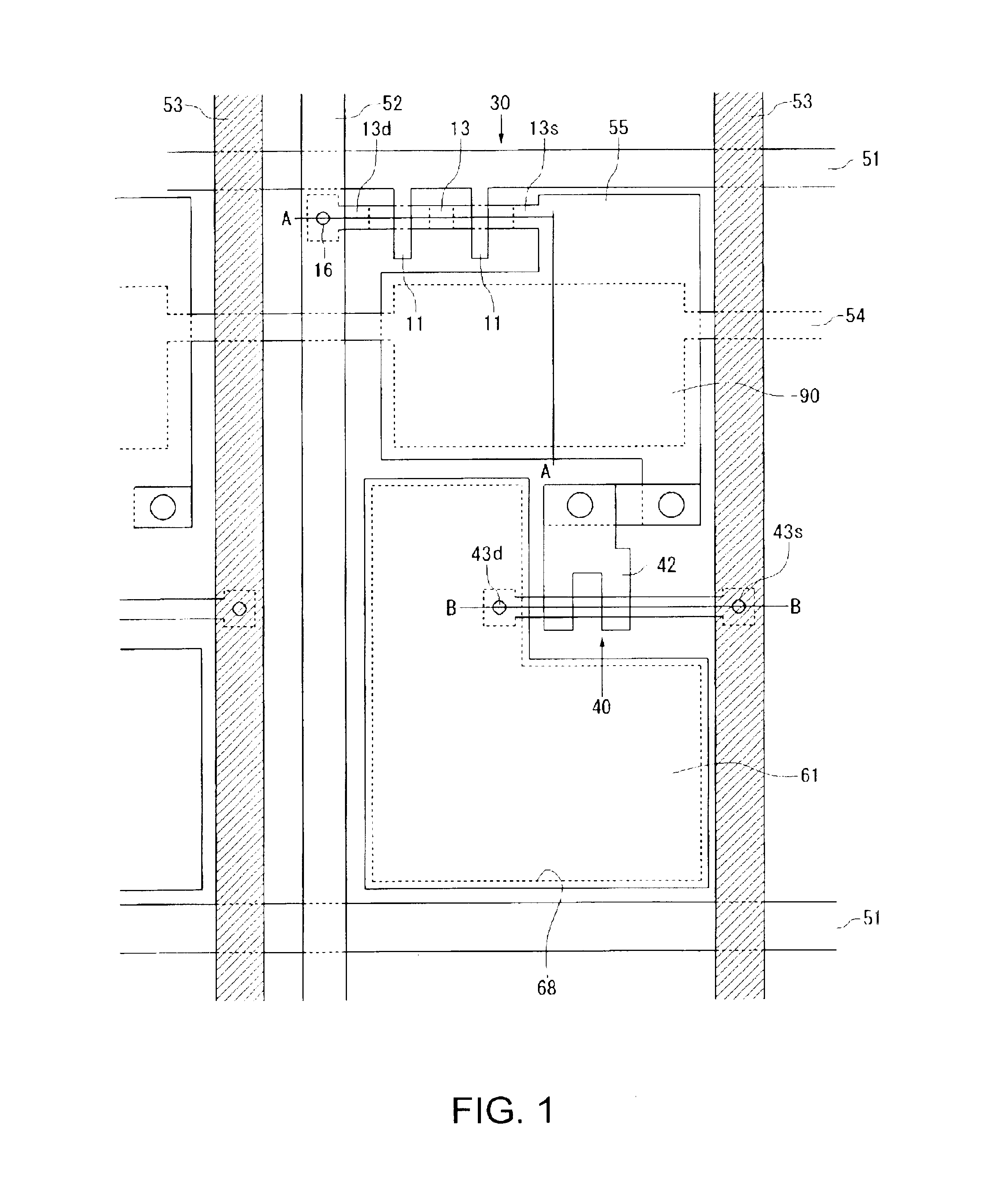

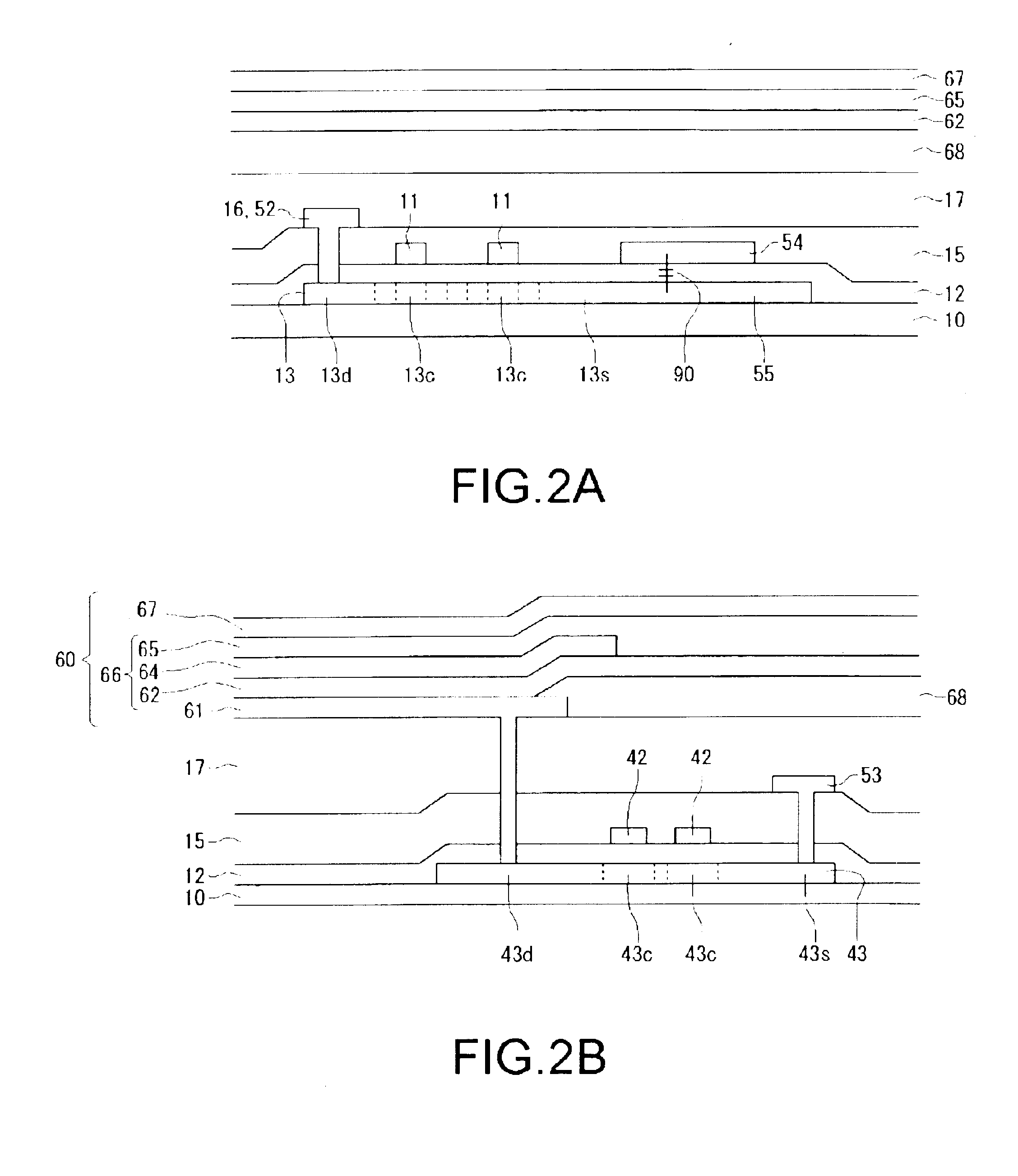

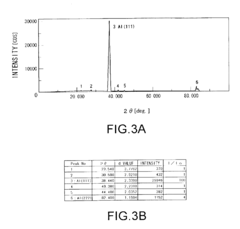

Optical element and manufacturing method therefor

PatentInactiveUS7009749B2

Innovation

- A cathode made of aluminum with a substantially uniform surface orientation, combined with a lithium fluoride layer and a low oxygen content, is used to achieve consistent electron injection and reduce impurity segregation, thereby stabilizing the luminance and extending the lifespan of the optical element.

method

PatentPendingUS20230044368A1

Innovation

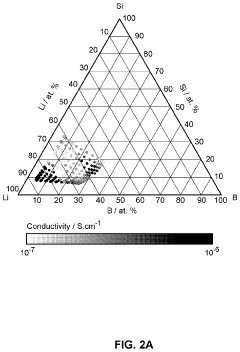

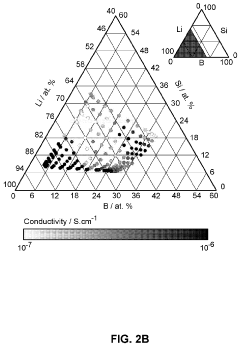

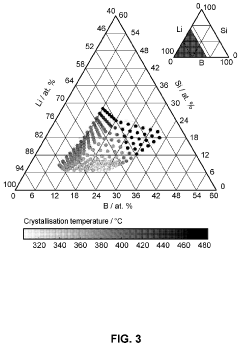

- A vapour deposition method is employed to form amorphous lithium borosilicate or doped lithium borosilicate compounds by co-depositing lithium, oxygen, boron, and silicon vapour sources onto a substrate, with optional dopant elements, achieving a lithium content range of 40-65 atomic %, thereby enhancing ionic conductivity and stability.

Environmental Impact Assessment

The chemical vapor deposition (CVD) process for Lithium Fluoride production presents several environmental considerations that must be carefully assessed and managed. The process typically involves precursor gases containing lithium and fluorine compounds which, if released untreated, can contribute to air pollution and potentially harm local ecosystems. Hydrogen fluoride, a common byproduct, is particularly concerning due to its corrosive nature and potential for causing respiratory issues in exposed populations.

Water usage represents another significant environmental factor in LiF CVD operations. The process requires substantial amounts of ultra-pure water for cleaning substrates and equipment, with wastewater potentially containing trace amounts of lithium and fluorine compounds. Without proper treatment, these elements can contaminate local water bodies, affecting aquatic life and potentially entering drinking water supplies.

Energy consumption during CVD processes contributes substantially to the carbon footprint of LiF production. The high temperatures required for deposition reactions (typically 500-800°C) demand significant energy inputs, particularly when maintaining precise temperature control for optimal yield. Facilities utilizing fossil fuel-based energy sources indirectly contribute to greenhouse gas emissions, while those employing renewable energy can significantly reduce this impact.

Waste management presents ongoing challenges, particularly regarding spent precursors, unreacted materials, and cleaning solutions. Many of these substances require specialized disposal protocols to prevent environmental contamination. Advanced facilities have implemented closed-loop systems that capture and recycle precursor materials, significantly reducing waste generation while simultaneously improving economic efficiency.

Recent technological innovations have focused on developing more environmentally sustainable CVD processes for LiF production. These include low-temperature deposition techniques that reduce energy requirements, catalyst systems that improve reaction efficiency while minimizing byproduct formation, and advanced filtration systems that capture potentially harmful emissions before they enter the environment.

Regulatory frameworks governing LiF CVD operations vary globally but generally trend toward increasingly stringent environmental protection standards. Companies at the forefront of environmental compliance have implemented comprehensive monitoring systems that track emissions, water usage, and waste generation in real-time, allowing for immediate intervention when parameters exceed acceptable thresholds.

The environmental impact of LiF CVD processes must be considered within the broader context of the material's applications, particularly in sustainable technologies like advanced batteries and optical components for solar energy systems. The environmental benefits derived from these end-use applications may partially offset the environmental costs of production when evaluated from a lifecycle perspective.

Water usage represents another significant environmental factor in LiF CVD operations. The process requires substantial amounts of ultra-pure water for cleaning substrates and equipment, with wastewater potentially containing trace amounts of lithium and fluorine compounds. Without proper treatment, these elements can contaminate local water bodies, affecting aquatic life and potentially entering drinking water supplies.

Energy consumption during CVD processes contributes substantially to the carbon footprint of LiF production. The high temperatures required for deposition reactions (typically 500-800°C) demand significant energy inputs, particularly when maintaining precise temperature control for optimal yield. Facilities utilizing fossil fuel-based energy sources indirectly contribute to greenhouse gas emissions, while those employing renewable energy can significantly reduce this impact.

Waste management presents ongoing challenges, particularly regarding spent precursors, unreacted materials, and cleaning solutions. Many of these substances require specialized disposal protocols to prevent environmental contamination. Advanced facilities have implemented closed-loop systems that capture and recycle precursor materials, significantly reducing waste generation while simultaneously improving economic efficiency.

Recent technological innovations have focused on developing more environmentally sustainable CVD processes for LiF production. These include low-temperature deposition techniques that reduce energy requirements, catalyst systems that improve reaction efficiency while minimizing byproduct formation, and advanced filtration systems that capture potentially harmful emissions before they enter the environment.

Regulatory frameworks governing LiF CVD operations vary globally but generally trend toward increasingly stringent environmental protection standards. Companies at the forefront of environmental compliance have implemented comprehensive monitoring systems that track emissions, water usage, and waste generation in real-time, allowing for immediate intervention when parameters exceed acceptable thresholds.

The environmental impact of LiF CVD processes must be considered within the broader context of the material's applications, particularly in sustainable technologies like advanced batteries and optical components for solar energy systems. The environmental benefits derived from these end-use applications may partially offset the environmental costs of production when evaluated from a lifecycle perspective.

Cost-Benefit Analysis of Yield Improvement Methods

Improving the yield of Lithium Fluoride in Chemical Vapor Deposition (CVD) processes requires careful evaluation of various enhancement methods against their associated costs. When analyzing the economic viability of yield improvement techniques, it is essential to consider both immediate implementation expenses and long-term operational benefits.

Primary cost factors include equipment modifications, which may range from $50,000 to $500,000 depending on the complexity of upgrades required. Precursor purification systems represent another significant investment, typically costing between $30,000 and $150,000, but potentially increasing yield by 15-25%. Process parameter optimization software, while less expensive at $10,000-$40,000, can provide yield improvements of 8-12% through statistical process control.

Advanced in-situ monitoring systems present a compelling case with costs of $75,000-$200,000 and potential yield improvements of 20-30%. These systems enable real-time adjustments that significantly reduce waste and improve consistency. The return on investment typically occurs within 12-18 months of implementation.

Labor costs must also be factored into the equation. Training personnel on new protocols and equipment operation requires approximately 40-80 hours per technician, with associated costs of $5,000-$15,000 per employee. However, this investment typically results in a 5-10% yield improvement through enhanced operator expertise and reduced human error.

Energy consumption presents another critical consideration. While some yield improvement methods may increase energy usage by 10-30%, the corresponding yield improvements often outweigh these costs. For instance, maintaining more precise temperature control during deposition increases energy consumption by approximately 15% but can improve yield by up to 25%.

Maintenance requirements vary significantly between different improvement methods. Automated systems with advanced monitoring capabilities may reduce routine maintenance costs by 20-30% while simultaneously improving yield. Conversely, more complex deposition systems may increase maintenance expenses by 15-25%, necessitating careful evaluation of the net benefit.

The time-to-market advantage of improved yields must also be quantified. Reducing production cycles by 20-30% through enhanced yield can provide competitive advantages worth $100,000-$500,000 annually, depending on market conditions and product applications. This factor is particularly significant for high-value applications in optical components and semiconductor industries.

When evaluating these methods holistically, the most economically viable approaches typically combine process parameter optimization with targeted equipment upgrades, providing the optimal balance between implementation costs and yield improvements.

Primary cost factors include equipment modifications, which may range from $50,000 to $500,000 depending on the complexity of upgrades required. Precursor purification systems represent another significant investment, typically costing between $30,000 and $150,000, but potentially increasing yield by 15-25%. Process parameter optimization software, while less expensive at $10,000-$40,000, can provide yield improvements of 8-12% through statistical process control.

Advanced in-situ monitoring systems present a compelling case with costs of $75,000-$200,000 and potential yield improvements of 20-30%. These systems enable real-time adjustments that significantly reduce waste and improve consistency. The return on investment typically occurs within 12-18 months of implementation.

Labor costs must also be factored into the equation. Training personnel on new protocols and equipment operation requires approximately 40-80 hours per technician, with associated costs of $5,000-$15,000 per employee. However, this investment typically results in a 5-10% yield improvement through enhanced operator expertise and reduced human error.

Energy consumption presents another critical consideration. While some yield improvement methods may increase energy usage by 10-30%, the corresponding yield improvements often outweigh these costs. For instance, maintaining more precise temperature control during deposition increases energy consumption by approximately 15% but can improve yield by up to 25%.

Maintenance requirements vary significantly between different improvement methods. Automated systems with advanced monitoring capabilities may reduce routine maintenance costs by 20-30% while simultaneously improving yield. Conversely, more complex deposition systems may increase maintenance expenses by 15-25%, necessitating careful evaluation of the net benefit.

The time-to-market advantage of improved yields must also be quantified. Reducing production cycles by 20-30% through enhanced yield can provide competitive advantages worth $100,000-$500,000 annually, depending on market conditions and product applications. This factor is particularly significant for high-value applications in optical components and semiconductor industries.

When evaluating these methods holistically, the most economically viable approaches typically combine process parameter optimization with targeted equipment upgrades, providing the optimal balance between implementation costs and yield improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!