How to Evaluate Lithium Fluoride for High-Vibration Environments

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF Technology Background and Evaluation Goals

Lithium Fluoride (LiF) has emerged as a critical material in various high-tech applications due to its unique optical, mechanical, and radiation-resistant properties. First discovered in the early 20th century, LiF has evolved from a laboratory curiosity to an essential component in aerospace, defense, nuclear, and optical industries. The material's historical development trajectory shows accelerating adoption rates over the past three decades, with significant breakthroughs in manufacturing processes occurring around 2005-2010.

The current technological landscape positions LiF as a material of strategic importance, particularly in environments where stability under extreme conditions is paramount. Recent advancements in crystal growth techniques have enabled the production of higher purity LiF with improved mechanical properties, expanding its potential applications in high-vibration scenarios. The global research focus has shifted toward enhancing LiF's performance under dynamic mechanical stress, with particular emphasis on mitigating microcrack formation and improving fatigue resistance.

The primary evaluation goal for LiF in high-vibration environments is to establish comprehensive performance metrics that accurately predict material behavior under various vibrational frequencies, amplitudes, and temperature conditions. This includes quantifying the relationship between vibration exposure and optical transmission degradation, mechanical strength reduction, and overall component lifespan. Additionally, we aim to develop standardized testing protocols that can reliably simulate real-world high-vibration scenarios across multiple industry applications.

Secondary objectives include identifying optimal crystal orientation and mounting configurations to minimize vibration-induced stress, determining effective damping mechanisms compatible with LiF's chemical properties, and exploring potential surface treatments or composite structures that could enhance vibration resistance without compromising other desirable properties. These evaluations must consider both short-term acute vibration events and long-term fatigue effects.

The technological evolution trajectory suggests that next-generation LiF components will need to withstand increasingly demanding vibration profiles as they are deployed in more extreme operational environments. Current industry benchmarks indicate that vibration tolerance improvements of 30-40% will be required within the next five years to meet emerging application requirements, particularly in space-based systems and hypersonic platforms.

This evaluation initiative aligns with broader industry trends toward miniaturization, increased reliability requirements, and deployment in previously inaccessible environments. Success will be measured by establishing clear correlations between material properties, manufacturing parameters, and vibration performance, ultimately enabling predictive modeling capabilities for LiF component design in high-vibration applications.

The current technological landscape positions LiF as a material of strategic importance, particularly in environments where stability under extreme conditions is paramount. Recent advancements in crystal growth techniques have enabled the production of higher purity LiF with improved mechanical properties, expanding its potential applications in high-vibration scenarios. The global research focus has shifted toward enhancing LiF's performance under dynamic mechanical stress, with particular emphasis on mitigating microcrack formation and improving fatigue resistance.

The primary evaluation goal for LiF in high-vibration environments is to establish comprehensive performance metrics that accurately predict material behavior under various vibrational frequencies, amplitudes, and temperature conditions. This includes quantifying the relationship between vibration exposure and optical transmission degradation, mechanical strength reduction, and overall component lifespan. Additionally, we aim to develop standardized testing protocols that can reliably simulate real-world high-vibration scenarios across multiple industry applications.

Secondary objectives include identifying optimal crystal orientation and mounting configurations to minimize vibration-induced stress, determining effective damping mechanisms compatible with LiF's chemical properties, and exploring potential surface treatments or composite structures that could enhance vibration resistance without compromising other desirable properties. These evaluations must consider both short-term acute vibration events and long-term fatigue effects.

The technological evolution trajectory suggests that next-generation LiF components will need to withstand increasingly demanding vibration profiles as they are deployed in more extreme operational environments. Current industry benchmarks indicate that vibration tolerance improvements of 30-40% will be required within the next five years to meet emerging application requirements, particularly in space-based systems and hypersonic platforms.

This evaluation initiative aligns with broader industry trends toward miniaturization, increased reliability requirements, and deployment in previously inaccessible environments. Success will be measured by establishing clear correlations between material properties, manufacturing parameters, and vibration performance, ultimately enabling predictive modeling capabilities for LiF component design in high-vibration applications.

Market Demand Analysis for Vibration-Resistant Materials

The global market for vibration-resistant materials has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, defense, and advanced manufacturing sectors. Lithium Fluoride (LiF), traditionally known for its optical applications, is now being evaluated for its potential in high-vibration environments due to its unique physical and chemical properties.

Market research indicates that industries requiring materials capable of withstanding extreme vibration conditions represent a combined market value of approximately $12.7 billion as of 2023, with a projected annual growth rate of 6.8% through 2028. The aerospace sector alone accounts for nearly 34% of this demand, followed by defense (27%), precision manufacturing (18%), and automotive applications (12%).

Within these sectors, there is a growing need for materials that can maintain structural integrity and functional properties under continuous vibration stress. Current solutions often involve composite materials or specialized alloys, which can be costly to produce and may have limitations in extreme environments. This creates a potential market opportunity for alternative materials like Lithium Fluoride if its vibration-resistant properties can be properly validated and commercialized.

Customer requirements analysis reveals several key performance indicators that drive market demand in this segment: vibration dampening efficiency, thermal stability under vibration stress, weight-to-performance ratio, and long-term reliability. Materials that excel in these areas command premium pricing, with customers willing to pay 15-30% more for solutions that demonstrably outperform conventional options.

Regional market analysis shows North America leading in demand (38%), followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly in countries developing aerospace and defense capabilities, with annual demand increases of 9-12%.

The competitive landscape for vibration-resistant materials is currently dominated by specialized engineering firms and materials science companies. Major players include established corporations with advanced materials divisions and specialized startups focusing on novel material solutions. If Lithium Fluoride proves viable for high-vibration applications, it could disrupt this market by offering a potentially more cost-effective alternative to current solutions.

End-user surveys indicate increasing interest in materials that can perform in multi-stress environments, where vibration is combined with other challenging conditions such as extreme temperatures, radiation exposure, or corrosive environments. This trend suggests that comprehensive testing of Lithium Fluoride should include evaluation under combined stress scenarios to fully assess its market potential.

Market research indicates that industries requiring materials capable of withstanding extreme vibration conditions represent a combined market value of approximately $12.7 billion as of 2023, with a projected annual growth rate of 6.8% through 2028. The aerospace sector alone accounts for nearly 34% of this demand, followed by defense (27%), precision manufacturing (18%), and automotive applications (12%).

Within these sectors, there is a growing need for materials that can maintain structural integrity and functional properties under continuous vibration stress. Current solutions often involve composite materials or specialized alloys, which can be costly to produce and may have limitations in extreme environments. This creates a potential market opportunity for alternative materials like Lithium Fluoride if its vibration-resistant properties can be properly validated and commercialized.

Customer requirements analysis reveals several key performance indicators that drive market demand in this segment: vibration dampening efficiency, thermal stability under vibration stress, weight-to-performance ratio, and long-term reliability. Materials that excel in these areas command premium pricing, with customers willing to pay 15-30% more for solutions that demonstrably outperform conventional options.

Regional market analysis shows North America leading in demand (38%), followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly in countries developing aerospace and defense capabilities, with annual demand increases of 9-12%.

The competitive landscape for vibration-resistant materials is currently dominated by specialized engineering firms and materials science companies. Major players include established corporations with advanced materials divisions and specialized startups focusing on novel material solutions. If Lithium Fluoride proves viable for high-vibration applications, it could disrupt this market by offering a potentially more cost-effective alternative to current solutions.

End-user surveys indicate increasing interest in materials that can perform in multi-stress environments, where vibration is combined with other challenging conditions such as extreme temperatures, radiation exposure, or corrosive environments. This trend suggests that comprehensive testing of Lithium Fluoride should include evaluation under combined stress scenarios to fully assess its market potential.

Current State and Challenges of LiF in High-Vibration Applications

Lithium Fluoride (LiF) has emerged as a critical material in various high-tech applications, particularly in optical systems, radiation detection, and aerospace components. However, its implementation in high-vibration environments presents significant challenges that require comprehensive evaluation and innovative solutions. Currently, LiF is primarily utilized in controlled environments where vibration is minimal or can be effectively dampened.

The global market for LiF applications in high-vibration settings remains relatively nascent, with most implementations being experimental or limited to specialized applications. Research institutions and aerospace companies have conducted extensive testing on LiF components, revealing both promising capabilities and concerning limitations when subjected to continuous or extreme vibration conditions.

One of the primary technical challenges facing LiF in high-vibration environments is its inherent brittleness and susceptibility to fracture under mechanical stress. Crystal structure degradation has been observed in laboratory tests simulating aerospace and industrial vibration profiles, with microfractures developing after extended exposure to frequencies between 20-2000 Hz at varying amplitudes.

Thermal management represents another significant challenge, as vibration-induced heat can alter LiF's optical and structural properties. Studies have shown that temperature fluctuations combined with mechanical vibration can accelerate material degradation, particularly affecting transmission properties in optical applications and detection efficiency in radiation monitoring systems.

Manufacturing consistency poses an additional hurdle, with current production methods struggling to create LiF components with uniform resistance to vibration stress. Variations in crystal growth conditions, dopant distribution, and surface finishing techniques result in inconsistent performance across supposedly identical components when subjected to vibration testing.

Mounting and integration solutions for LiF components remain underdeveloped, with conventional mounting systems often transferring rather than isolating vibration forces. The interface between LiF components and their housing structures frequently becomes a failure point during extended vibration exposure, necessitating specialized mounting solutions that are currently not standardized across the industry.

Evaluation methodologies themselves present a challenge, with no universally accepted testing protocols specifically designed for assessing LiF performance in high-vibration environments. Different sectors employ varied testing approaches, making cross-application comparisons difficult and hindering the development of broadly applicable solutions.

Geographically, research on LiF vibration resistance is concentrated primarily in North America, Europe, and East Asia, with notable contributions from aerospace research centers and materials science institutes. However, knowledge sharing across these regions remains limited, creating information silos that slow overall progress in addressing the fundamental challenges.

The global market for LiF applications in high-vibration settings remains relatively nascent, with most implementations being experimental or limited to specialized applications. Research institutions and aerospace companies have conducted extensive testing on LiF components, revealing both promising capabilities and concerning limitations when subjected to continuous or extreme vibration conditions.

One of the primary technical challenges facing LiF in high-vibration environments is its inherent brittleness and susceptibility to fracture under mechanical stress. Crystal structure degradation has been observed in laboratory tests simulating aerospace and industrial vibration profiles, with microfractures developing after extended exposure to frequencies between 20-2000 Hz at varying amplitudes.

Thermal management represents another significant challenge, as vibration-induced heat can alter LiF's optical and structural properties. Studies have shown that temperature fluctuations combined with mechanical vibration can accelerate material degradation, particularly affecting transmission properties in optical applications and detection efficiency in radiation monitoring systems.

Manufacturing consistency poses an additional hurdle, with current production methods struggling to create LiF components with uniform resistance to vibration stress. Variations in crystal growth conditions, dopant distribution, and surface finishing techniques result in inconsistent performance across supposedly identical components when subjected to vibration testing.

Mounting and integration solutions for LiF components remain underdeveloped, with conventional mounting systems often transferring rather than isolating vibration forces. The interface between LiF components and their housing structures frequently becomes a failure point during extended vibration exposure, necessitating specialized mounting solutions that are currently not standardized across the industry.

Evaluation methodologies themselves present a challenge, with no universally accepted testing protocols specifically designed for assessing LiF performance in high-vibration environments. Different sectors employ varied testing approaches, making cross-application comparisons difficult and hindering the development of broadly applicable solutions.

Geographically, research on LiF vibration resistance is concentrated primarily in North America, Europe, and East Asia, with notable contributions from aerospace research centers and materials science institutes. However, knowledge sharing across these regions remains limited, creating information silos that slow overall progress in addressing the fundamental challenges.

Current Testing Methodologies for High-Vibration Environments

01 Lithium fluoride in battery technology

Lithium fluoride is used as a key component in advanced battery technologies, particularly in lithium-ion batteries. It serves as an electrolyte additive or coating material that enhances battery performance, improves cycle life, and increases energy density. The compound helps form stable solid-electrolyte interfaces that prevent unwanted side reactions and improves the overall safety and efficiency of battery systems.- Production and purification of lithium fluoride: Various methods for producing and purifying lithium fluoride are described, including chemical synthesis processes, crystallization techniques, and purification methods to obtain high-purity lithium fluoride. These processes are essential for applications requiring high-quality lithium fluoride with specific physical and chemical properties. The methods may involve reaction of lithium compounds with fluoride sources, followed by separation and purification steps to remove impurities.

- Lithium fluoride in battery technologies: Lithium fluoride is utilized in advanced battery technologies, particularly in lithium-ion batteries and solid-state batteries. It serves as a component in electrolytes, cathode materials, or protective coatings to enhance battery performance, stability, and safety. The incorporation of lithium fluoride can improve ionic conductivity, prevent dendrite formation, and extend battery cycle life, making it valuable for energy storage applications.

- Optical and radiation detection applications: Lithium fluoride has unique optical properties that make it suitable for various optical and radiation detection applications. It is used in windows, lenses, and prisms for infrared and ultraviolet optics due to its wide transmission range. Additionally, lithium fluoride crystals can be used as radiation dosimeters and detectors, particularly for neutron detection, as they exhibit thermoluminescent properties when exposed to ionizing radiation.

- Lithium fluoride in nuclear applications: Lithium fluoride plays important roles in nuclear applications, including as a component in molten salt reactors, neutron moderators, and tritium breeding materials. Its nuclear properties, particularly when enriched with specific lithium isotopes, make it valuable for fusion energy research and nuclear reactor designs. The material's stability at high temperatures and resistance to radiation damage contribute to its suitability for these applications.

- Composite materials and coatings with lithium fluoride: Lithium fluoride is incorporated into various composite materials and coatings to impart specific properties. These composites may include ceramic matrices, polymer blends, or metal alloys containing lithium fluoride for applications requiring thermal stability, electrical insulation, or specific optical characteristics. Coatings containing lithium fluoride can provide protection against corrosion, radiation, or thermal stress in extreme environments.

02 Lithium fluoride in optical applications

Lithium fluoride is utilized in various optical applications due to its unique properties. It has excellent transmission characteristics in the ultraviolet, visible, and infrared regions of the spectrum. The material is used in the production of optical windows, lenses, and prisms, particularly for specialized scientific instruments. Its low refractive index and high radiation resistance make it valuable for applications requiring high optical clarity and durability.Expand Specific Solutions03 Lithium fluoride in nuclear applications

Lithium fluoride plays an important role in nuclear technology applications. It is used as a component in molten salt reactors, where it serves as part of the coolant and fuel salt mixture. The compound has favorable neutron absorption characteristics and thermal properties that make it suitable for nuclear environments. Additionally, it can be used in radiation dosimetry systems to measure and monitor radiation exposure levels.Expand Specific Solutions04 Lithium fluoride production methods

Various methods have been developed for the production and purification of lithium fluoride. These include direct reaction of lithium compounds with fluorine sources, precipitation techniques, and advanced purification processes. Modern manufacturing approaches focus on producing high-purity lithium fluoride with controlled particle size and morphology for specific applications. These methods often involve careful control of reaction conditions and subsequent processing steps to achieve desired material properties.Expand Specific Solutions05 Lithium fluoride in thin film applications

Lithium fluoride is employed in various thin film applications due to its unique electronic and optical properties. It serves as an electron injection layer in organic light-emitting diodes (OLEDs) and other electronic devices, improving device efficiency and lifetime. The compound is also used as a protective coating or buffer layer in semiconductor manufacturing. Its high bandgap and stability make it valuable for applications requiring insulating or passivation layers.Expand Specific Solutions

Key Industry Players in Lithium Fluoride Development

The lithium fluoride evaluation market for high-vibration environments is in a growth phase, with increasing applications in aerospace, defense, and advanced electronics sectors. The global market size is expanding as industries seek more resilient materials for extreme conditions. Technologically, this field shows moderate maturity with established players like Lockheed Martin and Panasonic leading industrial applications, while research institutions such as California Institute of Technology and Shanghai Jiao Tong University drive innovation. Companies including DuPont, Corning, and Ganfeng Lithium are developing specialized formulations with enhanced vibration resistance properties. Semiconductor Energy Laboratory and NEC are advancing integration with electronic components, while defense contractors are exploring military-grade applications requiring exceptional stability under mechanical stress.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced testing protocols for lithium fluoride components in aerospace and defense applications subject to extreme vibration conditions. Their approach combines computational modeling with physical testing using multi-axis vibration tables that can simulate complex vibrational patterns encountered during rocket launches and supersonic flight. The company employs specialized accelerated life testing methodologies where lithium fluoride components are subjected to vibration frequencies ranging from 20Hz to 2000Hz at varying amplitudes to identify resonance points and potential failure modes. Lockheed's evaluation system incorporates real-time monitoring with high-speed imaging and acoustic emission detection to capture microscopic fracture initiation in lithium fluoride crystals. Their proprietary data analytics platform correlates material performance with specific vibration profiles to predict long-term reliability in mission-critical environments.

Strengths: Comprehensive testing capabilities that simulate real-world aerospace conditions; extensive historical performance data from actual deployment scenarios; advanced computational modeling capabilities. Weaknesses: Highly specialized testing protocols may not translate well to non-aerospace applications; expensive and time-consuming evaluation process requiring specialized equipment.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has established comprehensive evaluation methodologies for lithium fluoride materials in high-vibration environments, particularly focusing on fundamental material science aspects. Their approach combines advanced spectroscopic techniques with mechanical testing to correlate atomic-level structural changes with macroscopic performance. CNRS researchers utilize synchrotron radiation facilities to perform in-situ X-ray diffraction during vibration testing, allowing real-time observation of crystallographic changes at frequencies up to 500Hz. Their evaluation protocol includes acoustic emission monitoring calibrated specifically for lithium fluoride to detect microcrack formation at early stages. CNRS has developed specialized sample holders that enable simultaneous application of controlled mechanical vibration and electrical/thermal stimuli while performing Raman spectroscopy to monitor local bonding changes. Their methodology incorporates multi-scale modeling from atomic to component level, with particular emphasis on grain boundary behavior under cyclic loading conditions typical in high-vibration environments.

Strengths: Fundamental scientific approach providing deep insights into failure mechanisms; access to world-class characterization facilities; comprehensive multi-physics evaluation capabilities. Weaknesses: Research-oriented approach may be less directly applicable to industrial qualification needs; testing sometimes prioritizes scientific understanding over standardized qualification protocols.

Critical Properties Analysis of Lithium Fluoride

Process for the production of a lithium fluoride storage phosphorescent substance

PatentInactiveGB1126777A

Innovation

- A process involving the precipitation of lithium fluoride from hydrofluoric acid and lithium chloride with controlled calcium and magnesium content, followed by heating and after-treatment to achieve a polycrystalline form with a specific thermoluminescence profile, including the addition of magnesium salts and potential enrichment with lithium-6 for enhanced sensitivity.

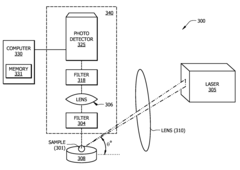

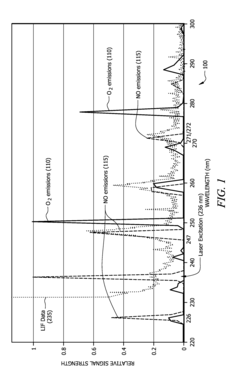

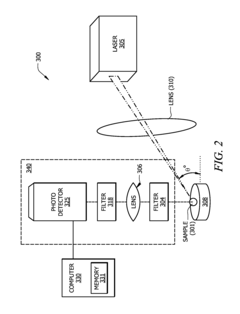

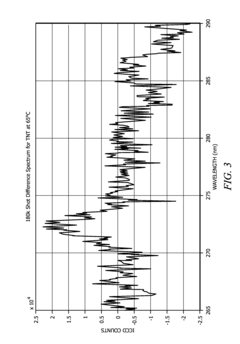

Photofragmentation-laser-induced fluorescence for detection of nitric oxide-bearing explosives

PatentInactiveUS20120145925A1

Innovation

- The method involves detecting nitro-based explosives by utilizing the NO emission line between 270 nm and 274 nm, which is spectrally further from NO and O2 emission peaks, allowing for more transmissive filters and reducing background noise, thereby increasing signal levels detected at the photodetector, and is well within the solar blind UV region for reduced background interference.

Failure Mode Analysis in Extreme Conditions

When evaluating lithium fluoride (LiF) for high-vibration environments, understanding failure modes under extreme conditions is critical. LiF components typically exhibit several distinct failure patterns when subjected to intense mechanical stress. Brittle fracture represents the primary failure mode, characterized by sudden catastrophic breakage along crystallographic planes without significant plastic deformation. This occurs when vibration-induced stresses exceed the material's ultimate tensile strength, particularly problematic given LiF's inherently brittle nature.

Fatigue failure constitutes another significant concern, manifesting as progressive damage accumulation through microcrack formation and propagation during repeated vibration cycles. Even when individual stress events remain below the material's yield strength, cumulative damage can lead to eventual component failure. This is particularly relevant in applications where LiF experiences continuous or intermittent vibration over extended periods.

Surface degradation presents additional challenges, as high-frequency vibrations can cause surface abrasion and microfracturing. These effects are exacerbated in environments with particulate contamination, where vibration-induced movement creates microscopic impact events that gradually erode the LiF surface, compromising optical properties and structural integrity.

Thermal-mechanical coupling represents a complex failure mechanism wherein vibration-induced friction generates localized heating. LiF's poor thermal conductivity can result in thermal gradients that induce additional stress through differential expansion, potentially initiating or accelerating crack propagation. This effect becomes particularly pronounced in vacuum environments where convective cooling is absent.

Environmental interaction failures occur when vibration creates pathways for contaminants to penetrate the material structure. Moisture ingress through vibration-induced microcracks can lead to hydrolysis reactions with LiF, while exposure to other reactive substances during vibration can catalyze degradation processes. These chemical interactions may significantly reduce component lifespan even when mechanical stresses alone would be sustainable.

Mounting interface failures represent a system-level concern, where vibration-induced movement at the interface between LiF components and their mounting structures creates fretting wear. This progressive damage at contact points can undermine the mechanical stability of the entire assembly, potentially leading to catastrophic failure even when the LiF component itself remains structurally sound.

Fatigue failure constitutes another significant concern, manifesting as progressive damage accumulation through microcrack formation and propagation during repeated vibration cycles. Even when individual stress events remain below the material's yield strength, cumulative damage can lead to eventual component failure. This is particularly relevant in applications where LiF experiences continuous or intermittent vibration over extended periods.

Surface degradation presents additional challenges, as high-frequency vibrations can cause surface abrasion and microfracturing. These effects are exacerbated in environments with particulate contamination, where vibration-induced movement creates microscopic impact events that gradually erode the LiF surface, compromising optical properties and structural integrity.

Thermal-mechanical coupling represents a complex failure mechanism wherein vibration-induced friction generates localized heating. LiF's poor thermal conductivity can result in thermal gradients that induce additional stress through differential expansion, potentially initiating or accelerating crack propagation. This effect becomes particularly pronounced in vacuum environments where convective cooling is absent.

Environmental interaction failures occur when vibration creates pathways for contaminants to penetrate the material structure. Moisture ingress through vibration-induced microcracks can lead to hydrolysis reactions with LiF, while exposure to other reactive substances during vibration can catalyze degradation processes. These chemical interactions may significantly reduce component lifespan even when mechanical stresses alone would be sustainable.

Mounting interface failures represent a system-level concern, where vibration-induced movement at the interface between LiF components and their mounting structures creates fretting wear. This progressive damage at contact points can undermine the mechanical stability of the entire assembly, potentially leading to catastrophic failure even when the LiF component itself remains structurally sound.

Standardization and Certification Requirements

The evaluation of lithium fluoride for high-vibration environments must adhere to rigorous standardization and certification requirements to ensure safety, reliability, and performance. Several international standards organizations have established specific protocols for testing and certifying materials used in high-vibration applications, particularly for optical components like lithium fluoride crystals.

The International Organization for Standardization (ISO) provides comprehensive frameworks through standards such as ISO 10816 and ISO 20816, which define vibration measurement and evaluation criteria. For lithium fluoride specifically, ISO 9211 addresses optical coatings and testing methods that can be applied to evaluate durability under mechanical stress. These standards establish baseline requirements for vibration resistance that manufacturers must meet.

Military specifications, particularly MIL-STD-810G, offer detailed testing protocols for environmental factors including vibration. Method 514.7 specifically addresses vibration testing procedures that are essential for lithium fluoride components intended for defense applications. These standards require materials to undergo sinusoidal and random vibration testing across multiple frequency ranges to simulate real-world operational conditions.

The American Society for Testing and Materials (ASTM) provides additional standards, including ASTM F1048 for optical materials and ASTM D3580 for vibration testing of materials. These standards define specific methodologies for evaluating material degradation under vibrational stress, which is critical for lithium fluoride applications in aerospace and other high-reliability sectors.

Certification processes typically require third-party verification through accredited testing laboratories. Organizations such as Underwriters Laboratories (UL) and TÜV offer certification services that validate compliance with these standards. For lithium fluoride components, certification often involves accelerated life testing under vibration conditions that exceed expected operational parameters by 20-50% to establish safety margins.

Industry-specific requirements add another layer of standardization. The aerospace industry follows standards like RTCA DO-160 for environmental conditions and test procedures for airborne equipment, which includes vibration testing protocols. Similarly, the automotive industry applies standards such as ISO 16750-3 for mechanical vibration testing of electronic equipment.

Documentation requirements for certification are extensive, typically including detailed test reports, material composition analyses, manufacturing process validations, and quality control procedures. For lithium fluoride components, this documentation must demonstrate consistent performance across production batches and provide traceability throughout the supply chain.

The International Organization for Standardization (ISO) provides comprehensive frameworks through standards such as ISO 10816 and ISO 20816, which define vibration measurement and evaluation criteria. For lithium fluoride specifically, ISO 9211 addresses optical coatings and testing methods that can be applied to evaluate durability under mechanical stress. These standards establish baseline requirements for vibration resistance that manufacturers must meet.

Military specifications, particularly MIL-STD-810G, offer detailed testing protocols for environmental factors including vibration. Method 514.7 specifically addresses vibration testing procedures that are essential for lithium fluoride components intended for defense applications. These standards require materials to undergo sinusoidal and random vibration testing across multiple frequency ranges to simulate real-world operational conditions.

The American Society for Testing and Materials (ASTM) provides additional standards, including ASTM F1048 for optical materials and ASTM D3580 for vibration testing of materials. These standards define specific methodologies for evaluating material degradation under vibrational stress, which is critical for lithium fluoride applications in aerospace and other high-reliability sectors.

Certification processes typically require third-party verification through accredited testing laboratories. Organizations such as Underwriters Laboratories (UL) and TÜV offer certification services that validate compliance with these standards. For lithium fluoride components, certification often involves accelerated life testing under vibration conditions that exceed expected operational parameters by 20-50% to establish safety margins.

Industry-specific requirements add another layer of standardization. The aerospace industry follows standards like RTCA DO-160 for environmental conditions and test procedures for airborne equipment, which includes vibration testing protocols. Similarly, the automotive industry applies standards such as ISO 16750-3 for mechanical vibration testing of electronic equipment.

Documentation requirements for certification are extensive, typically including detailed test reports, material composition analyses, manufacturing process validations, and quality control procedures. For lithium fluoride components, this documentation must demonstrate consistent performance across production batches and provide traceability throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!