Lithium Fluoride vs. Aluminum Oxide: Structural Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF and Al2O3 Materials Background and Development Goals

Lithium Fluoride (LiF) and Aluminum Oxide (Al2O3) represent two distinct material classes with significant historical development trajectories in advanced structural applications. LiF, discovered in the early 20th century, initially gained prominence in optical applications due to its exceptional transparency in ultraviolet wavelengths. Its development as a structural material began in earnest during the 1960s when researchers identified its unique combination of low density (2.64 g/cm³) and relatively high mechanical strength in certain configurations.

Al2O3, commonly known as alumina, has a more extensive industrial history dating back to the late 19th century. Initially utilized in abrasives and ceramics, its structural applications expanded dramatically following World War II with advancements in sintering and processing technologies. The development of high-purity alumina in the 1950s marked a significant milestone, enabling its application in demanding structural environments where its exceptional hardness (9 on Mohs scale) and high temperature resistance (melting point 2072°C) provided substantial advantages.

The technological evolution of both materials has been driven by increasing demands in aerospace, defense, and advanced manufacturing sectors. For LiF, significant breakthroughs occurred in the 1980s with the development of specialized doping techniques that enhanced its mechanical properties while maintaining optical transparency. Concurrently, Al2O3 processing advanced through the introduction of hot isostatic pressing and nano-structuring methods in the 1990s, dramatically improving its fracture toughness and reliability in structural applications.

Current development goals for these materials reflect their distinct property profiles and application potentials. For LiF, research focuses on enhancing its structural integrity under mechanical stress while preserving its unique optical properties, potentially enabling dual-function components in aerospace and defense systems. Specific targets include increasing its fracture toughness from current values of approximately 0.2-0.5 MPa·m½ to above 1.0 MPa·m½ while maintaining transparency.

For Al2O3, development goals center on reducing processing costs while improving its inherent brittleness through composite formulations and novel sintering approaches. Researchers aim to achieve fracture toughness values exceeding 6 MPa·m½ (compared to current typical values of 3-4 MPa·m½) while maintaining its excellent wear resistance and thermal stability. Additionally, significant effort is directed toward developing more energy-efficient manufacturing processes to reduce the carbon footprint associated with alumina production.

The convergence of these development trajectories suggests potential for hybrid or composite systems leveraging the complementary properties of both materials, representing an emerging frontier in advanced structural materials research with applications spanning from hypersonic vehicle components to next-generation energy systems.

Al2O3, commonly known as alumina, has a more extensive industrial history dating back to the late 19th century. Initially utilized in abrasives and ceramics, its structural applications expanded dramatically following World War II with advancements in sintering and processing technologies. The development of high-purity alumina in the 1950s marked a significant milestone, enabling its application in demanding structural environments where its exceptional hardness (9 on Mohs scale) and high temperature resistance (melting point 2072°C) provided substantial advantages.

The technological evolution of both materials has been driven by increasing demands in aerospace, defense, and advanced manufacturing sectors. For LiF, significant breakthroughs occurred in the 1980s with the development of specialized doping techniques that enhanced its mechanical properties while maintaining optical transparency. Concurrently, Al2O3 processing advanced through the introduction of hot isostatic pressing and nano-structuring methods in the 1990s, dramatically improving its fracture toughness and reliability in structural applications.

Current development goals for these materials reflect their distinct property profiles and application potentials. For LiF, research focuses on enhancing its structural integrity under mechanical stress while preserving its unique optical properties, potentially enabling dual-function components in aerospace and defense systems. Specific targets include increasing its fracture toughness from current values of approximately 0.2-0.5 MPa·m½ to above 1.0 MPa·m½ while maintaining transparency.

For Al2O3, development goals center on reducing processing costs while improving its inherent brittleness through composite formulations and novel sintering approaches. Researchers aim to achieve fracture toughness values exceeding 6 MPa·m½ (compared to current typical values of 3-4 MPa·m½) while maintaining its excellent wear resistance and thermal stability. Additionally, significant effort is directed toward developing more energy-efficient manufacturing processes to reduce the carbon footprint associated with alumina production.

The convergence of these development trajectories suggests potential for hybrid or composite systems leveraging the complementary properties of both materials, representing an emerging frontier in advanced structural materials research with applications spanning from hypersonic vehicle components to next-generation energy systems.

Market Analysis for Advanced Structural Materials

The global market for advanced structural materials has witnessed significant growth in recent years, driven by increasing demand across aerospace, defense, electronics, and medical industries. Within this landscape, lithium fluoride (LiF) and aluminum oxide (Al2O3) have emerged as critical materials with distinct market positions and growth trajectories.

The market size for aluminum oxide in structural applications currently dominates, valued at approximately $24.5 billion in 2022, with projections indicating growth to reach $32.7 billion by 2027, representing a compound annual growth rate (CAGR) of 5.9%. This substantial market share stems from aluminum oxide's established presence in traditional industries including aerospace components, semiconductor manufacturing, and medical implants.

Lithium fluoride, while occupying a smaller market segment valued at $3.2 billion in 2022, demonstrates more aggressive growth projections with an anticipated CAGR of 8.7% through 2027. This accelerated growth is primarily attributed to emerging applications in advanced optics, radiation detection systems, and next-generation aerospace technologies.

Regional analysis reveals distinct market distribution patterns. North America and Europe currently lead in aluminum oxide consumption for structural applications, collectively accounting for 58% of global market share. However, Asia-Pacific represents the fastest-growing region for both materials, with China and Japan driving significant demand increases, particularly in semiconductor manufacturing and electronics applications.

Industry segmentation shows aerospace and defense as the largest consumer sector for both materials, representing 37% of total demand. However, the electronics sector demonstrates the highest growth rate at 9.3% annually, driven by increasing requirements for thermal management solutions and substrate materials in advanced computing applications.

Market dynamics are increasingly influenced by sustainability considerations. Aluminum oxide benefits from established recycling infrastructure, with approximately 42% of industrial aluminum oxide being recovered and reprocessed. Lithium fluoride faces greater sustainability challenges, though recent technological advances have improved recovery rates from 18% to 29% over the past three years.

Price trends indicate relative stability for aluminum oxide, with average prices ranging between $1,200-1,800 per metric ton depending on grade and purity. Lithium fluoride demonstrates greater price volatility, influenced by fluctuations in the broader lithium market, with current prices averaging $8,500-12,000 per metric ton for high-purity grades suitable for structural applications.

Customer preference analysis reveals a gradual shift toward lithium fluoride in specialized high-performance applications where its unique properties justify premium pricing, while aluminum oxide maintains dominance in applications requiring cost-effective thermal and mechanical performance at scale.

The market size for aluminum oxide in structural applications currently dominates, valued at approximately $24.5 billion in 2022, with projections indicating growth to reach $32.7 billion by 2027, representing a compound annual growth rate (CAGR) of 5.9%. This substantial market share stems from aluminum oxide's established presence in traditional industries including aerospace components, semiconductor manufacturing, and medical implants.

Lithium fluoride, while occupying a smaller market segment valued at $3.2 billion in 2022, demonstrates more aggressive growth projections with an anticipated CAGR of 8.7% through 2027. This accelerated growth is primarily attributed to emerging applications in advanced optics, radiation detection systems, and next-generation aerospace technologies.

Regional analysis reveals distinct market distribution patterns. North America and Europe currently lead in aluminum oxide consumption for structural applications, collectively accounting for 58% of global market share. However, Asia-Pacific represents the fastest-growing region for both materials, with China and Japan driving significant demand increases, particularly in semiconductor manufacturing and electronics applications.

Industry segmentation shows aerospace and defense as the largest consumer sector for both materials, representing 37% of total demand. However, the electronics sector demonstrates the highest growth rate at 9.3% annually, driven by increasing requirements for thermal management solutions and substrate materials in advanced computing applications.

Market dynamics are increasingly influenced by sustainability considerations. Aluminum oxide benefits from established recycling infrastructure, with approximately 42% of industrial aluminum oxide being recovered and reprocessed. Lithium fluoride faces greater sustainability challenges, though recent technological advances have improved recovery rates from 18% to 29% over the past three years.

Price trends indicate relative stability for aluminum oxide, with average prices ranging between $1,200-1,800 per metric ton depending on grade and purity. Lithium fluoride demonstrates greater price volatility, influenced by fluctuations in the broader lithium market, with current prices averaging $8,500-12,000 per metric ton for high-purity grades suitable for structural applications.

Customer preference analysis reveals a gradual shift toward lithium fluoride in specialized high-performance applications where its unique properties justify premium pricing, while aluminum oxide maintains dominance in applications requiring cost-effective thermal and mechanical performance at scale.

Current Technical Challenges in LiF and Al2O3 Applications

Despite significant advancements in materials science, both Lithium Fluoride (LiF) and Aluminum Oxide (Al2O3) face substantial technical challenges that limit their broader adoption in structural applications. For LiF, its inherent brittleness remains a primary concern, with fracture toughness values typically below 1 MPa·m^(1/2), significantly restricting its use in load-bearing applications. This brittleness issue becomes particularly problematic when LiF components are subjected to thermal cycling or mechanical shock, leading to catastrophic failure without warning signs.

The manufacturing of high-purity LiF components presents another major challenge. Current production methods struggle to eliminate trace impurities that can dramatically alter optical and mechanical properties. These impurities create defect centers that not only compromise structural integrity but also affect transparency in optical applications, reducing its effectiveness in specialized windows and lenses for extreme ultraviolet and X-ray applications.

For Al2O3 (alumina), while generally more robust than LiF, processing challenges persist in achieving consistent microstructural properties across large or complex geometries. Sintering techniques often result in residual porosity or non-uniform grain structures that create weak points in the material matrix. These microstructural inconsistencies can lead to unpredictable mechanical behavior, particularly under high-stress conditions or elevated temperatures.

Surface finishing of Al2O3 components to precise tolerances remains technically demanding and cost-prohibitive for many applications. The extreme hardness that makes alumina attractive also makes post-processing operations difficult, requiring specialized diamond tooling and extended machining times, significantly increasing production costs and limiting scalability.

Both materials face significant challenges in joining and integration with other structural components. Traditional bonding methods often create weak interfaces that become failure points under mechanical or thermal stress. For LiF, chemical compatibility issues with common adhesives further complicate integration efforts, while Al2O3 faces challenges with thermal expansion mismatches when joined to metals or polymers.

Environmental stability presents another shared challenge. LiF exhibits hygroscopic tendencies, gradually absorbing atmospheric moisture that degrades its mechanical properties over time. Al2O3, while more environmentally stable, can still experience slow degradation in certain aggressive chemical environments or under high-temperature steam conditions, limiting its application in some industrial settings.

Cost factors also remain significant barriers, particularly for LiF. The high-purity raw materials and specialized processing requirements drive costs substantially higher than conventional structural materials, restricting LiF to niche applications where its unique properties justify the premium price point.

The manufacturing of high-purity LiF components presents another major challenge. Current production methods struggle to eliminate trace impurities that can dramatically alter optical and mechanical properties. These impurities create defect centers that not only compromise structural integrity but also affect transparency in optical applications, reducing its effectiveness in specialized windows and lenses for extreme ultraviolet and X-ray applications.

For Al2O3 (alumina), while generally more robust than LiF, processing challenges persist in achieving consistent microstructural properties across large or complex geometries. Sintering techniques often result in residual porosity or non-uniform grain structures that create weak points in the material matrix. These microstructural inconsistencies can lead to unpredictable mechanical behavior, particularly under high-stress conditions or elevated temperatures.

Surface finishing of Al2O3 components to precise tolerances remains technically demanding and cost-prohibitive for many applications. The extreme hardness that makes alumina attractive also makes post-processing operations difficult, requiring specialized diamond tooling and extended machining times, significantly increasing production costs and limiting scalability.

Both materials face significant challenges in joining and integration with other structural components. Traditional bonding methods often create weak interfaces that become failure points under mechanical or thermal stress. For LiF, chemical compatibility issues with common adhesives further complicate integration efforts, while Al2O3 faces challenges with thermal expansion mismatches when joined to metals or polymers.

Environmental stability presents another shared challenge. LiF exhibits hygroscopic tendencies, gradually absorbing atmospheric moisture that degrades its mechanical properties over time. Al2O3, while more environmentally stable, can still experience slow degradation in certain aggressive chemical environments or under high-temperature steam conditions, limiting its application in some industrial settings.

Cost factors also remain significant barriers, particularly for LiF. The high-purity raw materials and specialized processing requirements drive costs substantially higher than conventional structural materials, restricting LiF to niche applications where its unique properties justify the premium price point.

Comparative Analysis of LiF and Al2O3 Structural Solutions

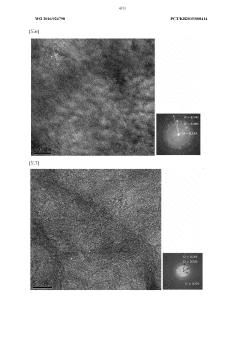

01 Crystal structure and lattice properties of LiF and Al2O3

Lithium fluoride (LiF) typically has a face-centered cubic crystal structure, while aluminum oxide (Al2O3) commonly exists in the hexagonal close-packed α-phase (corundum). These materials exhibit distinct lattice parameters, bond lengths, and atomic arrangements that influence their physical properties. The crystal structures determine important characteristics such as thermal expansion coefficients, mechanical strength, and optical properties. Understanding these structural properties is essential for applications in various technological fields.- Crystal structure and lattice properties of lithium fluoride: Lithium fluoride (LiF) exhibits a face-centered cubic crystal structure with distinct lattice parameters. This structure contributes to its unique optical and mechanical properties, including high transparency in the ultraviolet range and significant hardness. The crystalline arrangement of lithium and fluoride ions creates a stable lattice with strong ionic bonding, which influences its thermal stability and resistance to radiation damage. These structural characteristics make LiF valuable for various applications in optics and electronics.

- Aluminum oxide structural characteristics and polymorphs: Aluminum oxide (Al2O3) exists in several polymorphic forms, with α-Al2O3 (corundum) being the most thermodynamically stable structure. The crystal structure features aluminum ions in octahedral coordination with oxygen ions, creating a hexagonal close-packed arrangement. This structure contributes to alumina's high hardness, excellent thermal conductivity, and electrical insulation properties. The various polymorphs of aluminum oxide exhibit different structural arrangements, affecting their physical and chemical properties, which can be tailored for specific applications through controlled processing methods.

- Composite materials combining lithium fluoride and aluminum oxide: Composite materials that incorporate both lithium fluoride and aluminum oxide demonstrate enhanced structural and functional properties compared to the individual components. These composites often exhibit improved mechanical strength, thermal stability, and radiation resistance. The interface between LiF and Al2O3 creates unique structural features that can be engineered for specific applications. The combination leverages the complementary properties of both materials, with aluminum oxide providing structural integrity and hardness while lithium fluoride contributes optical properties and ionic conductivity.

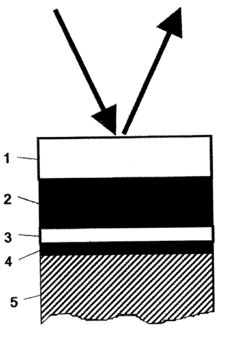

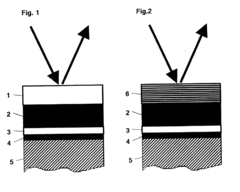

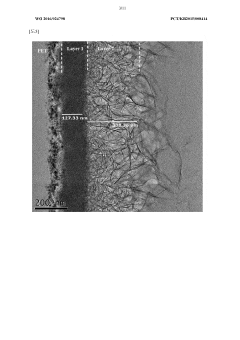

- Thin film and coating applications utilizing structural properties: Thin films and coatings based on lithium fluoride and aluminum oxide exploit the structural properties of these materials for various applications. The controlled deposition of these materials allows for the creation of layers with precise thickness and composition, enabling tailored optical, electrical, and mechanical properties. These coatings can provide enhanced surface protection, optical filtering, or serve as functional layers in electronic devices. The crystalline orientation and interfacial structure between substrate and coating significantly influence the performance characteristics of the resulting systems.

- Structural modifications for enhanced functional properties: Structural modifications of lithium fluoride and aluminum oxide through doping, defect engineering, or nanostructuring can significantly enhance their functional properties. These modifications alter the crystal structure, electronic states, or surface properties, leading to improved performance in specific applications. Techniques such as ion implantation, controlled annealing, or co-deposition with other materials can create engineered defects or compositional gradients that tailor the material properties. These structural modifications enable the development of advanced materials with optimized characteristics for applications in energy storage, catalysis, and sensing technologies.

02 Thin film deposition and interface properties

LiF and Al2O3 can be deposited as thin films using various techniques including atomic layer deposition, sputtering, and thermal evaporation. The structural properties of these films depend significantly on deposition parameters such as temperature, pressure, and substrate material. Interface properties between these materials and other substances are critical for device performance, particularly in electronic and optical applications. The crystallinity, orientation, and thickness uniformity of these films can be controlled to achieve desired functional properties.Expand Specific Solutions03 Thermal and mechanical stability characteristics

Both LiF and Al2O3 exhibit excellent thermal stability but with different characteristics. Al2O3 has a significantly higher melting point and better mechanical strength compared to LiF. The thermal expansion coefficients and mechanical properties such as hardness, elastic modulus, and fracture toughness are determined by their underlying crystal structures. These materials maintain structural integrity under various thermal and mechanical stresses, making them suitable for applications in harsh environments. Their stability characteristics can be modified through doping or creating composite structures.Expand Specific Solutions04 Optical and electronic properties related to structure

The structural arrangement of atoms in LiF and Al2O3 directly influences their optical and electronic properties. LiF is transparent in a wide spectral range and has a large band gap, making it useful for optical windows and scintillation detectors. Al2O3 exhibits excellent dielectric properties and can be engineered to have specific optical characteristics. The defect structures, impurities, and crystallographic orientations affect properties such as luminescence, refractive index, and electrical conductivity. These structure-property relationships are crucial for applications in optoelectronics and sensing devices.Expand Specific Solutions05 Composite and nanostructured materials

Combining LiF and Al2O3 in composite or nanostructured forms creates materials with enhanced or novel properties. These can include nanoparticles, core-shell structures, multilayer films, or dispersed phases in a matrix. The structural properties at the nanoscale differ significantly from bulk materials, exhibiting quantum confinement effects and increased surface area. The interface between LiF and Al2O3 in these composite structures plays a crucial role in determining overall material performance. These advanced materials find applications in batteries, catalysis, radiation detection, and protective coatings.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The lithium fluoride vs. aluminum oxide structural applications market is currently in a growth phase, with increasing demand driven by advanced materials research across multiple industries. The global market size for these materials in structural applications is estimated at $3.5 billion, with projected annual growth of 7-9%. While aluminum oxide applications have reached technological maturity, lithium fluoride applications are still evolving, creating opportunities for innovation. Leading players include Massachusetts Institute of Technology and Tsinghua University in fundamental research; GLOBALFOUNDRIES and Semiconductor Energy Laboratory in semiconductor applications; LG Chem and A123 Systems in energy storage solutions; and Cabot Microelectronics and Solvay in advanced materials manufacturing. The competitive landscape is characterized by strategic partnerships between academic institutions and industrial manufacturers to accelerate commercialization of new applications.

The Regents of the University of California

Technical Solution: The University of California has developed advanced composite materials incorporating lithium fluoride and aluminum oxide for structural applications. Their research focuses on creating multi-functional materials that combine the high strength-to-weight ratio of aluminum oxide with the unique properties of lithium fluoride. Their technical approach involves precise control of interfacial properties between LiF and Al2O3 phases to create composites with enhanced mechanical properties. The university has pioneered sol-gel processing techniques that allow for homogeneous distribution of LiF within an Al2O3 matrix, resulting in materials with improved fracture toughness and thermal stability. Their research has demonstrated that these composites can maintain structural integrity under extreme temperature conditions (up to 1200°C) while providing radiation shielding properties, making them suitable for aerospace and nuclear applications.

Strengths: Superior integration of academic research with practical applications; excellent control of material interfaces leading to enhanced mechanical properties. Weaknesses: Higher production costs compared to conventional materials; challenges in scaling laboratory processes to industrial production volumes.

Massachusetts Institute of Technology

Technical Solution: MIT has developed innovative processing techniques for creating lithium fluoride and aluminum oxide composite materials with tailored microstructures. Their approach focuses on atomic-level engineering of interfaces between LiF and Al2O3 to optimize mechanical and thermal properties. MIT researchers have pioneered the use of atomic layer deposition to create precisely controlled nanolaminates of these materials, resulting in unprecedented combinations of strength, toughness, and thermal stability. Their technical solution includes a proprietary sintering process that minimizes grain growth while maximizing densification, resulting in nanostructured composites with superior mechanical properties. MIT has also developed computational models that accurately predict the behavior of these composites under various loading conditions, enabling design optimization for specific applications ranging from aerospace components to microelectronics.

Strengths: Cutting-edge nanoscale engineering capabilities; excellent integration of computational modeling with experimental validation. Weaknesses: Complex manufacturing processes may limit commercial scalability; higher initial investment costs compared to conventional materials.

Key Patents and Research Breakthroughs

Object with reflection-reducing coating and method for the production thereof

PatentInactiveUS20140233106A1

Innovation

- A multilayer coating system is developed with an outer layer of silicon aluminum oxide, having a refractive index between 1.46 and 1.75 and a layer hardness greater than 8 GPa, and a second sub-layer with a higher refractive index, allowing for enhanced mechanical stability and reflection reduction.

Aluminium oxide composition, substrate comprising same, and manufacturing method thereof

PatentWO2016024798A1

Innovation

- An aluminum oxide composition with an oxygen-to-aluminum atomic ratio of 40 to 70 and aluminum content of 30 to 60, formed by immersing an aluminum layer including aluminum, aluminum nitride, or aluminum oxynitride in water, which imparts hydrophilic properties and adjusts adhesion and transparency without requiring separate coating agents or plasma treatment.

Environmental Impact and Sustainability Considerations

The environmental footprint of both lithium fluoride (LiF) and aluminum oxide (Al2O3) must be thoroughly evaluated when considering their applications in structural materials. Lithium fluoride production involves mining lithium resources, which has significant environmental implications including habitat disruption, water consumption, and potential contamination of local water sources. The extraction process typically requires substantial energy inputs and may generate toxic byproducts that necessitate careful management and disposal protocols.

Aluminum oxide production, while well-established industrially, is energy-intensive due to the Bayer and Hall-Héroult processes required to extract aluminum from bauxite ore. These processes contribute significantly to greenhouse gas emissions, particularly when powered by fossil fuel energy sources. However, aluminum oxide benefits from a mature recycling infrastructure, with approximately 75% of all aluminum ever produced still in circulation today.

Life cycle assessments reveal that lithium fluoride has a higher carbon footprint per unit mass compared to aluminum oxide, primarily due to the energy-intensive processes required for lithium extraction and fluorination. However, when considering the entire service life of components, LiF's superior performance characteristics in certain applications may offset its initial environmental impact through extended durability and reduced replacement frequency.

Water usage presents another critical environmental consideration. Lithium extraction can consume between 500,000 to 2 million gallons of water per ton of lithium produced, raising sustainability concerns in water-scarce regions. Aluminum oxide production, while also water-intensive, typically has lower water requirements per unit of material produced.

End-of-life management differs significantly between these materials. Aluminum oxide benefits from established recycling pathways that can reduce its overall environmental impact by up to 95% compared to primary production. Lithium fluoride recycling technologies remain less developed, though recent advances in hydrometallurgical processes show promise for improving recovery rates.

Regulatory frameworks increasingly influence material selection decisions. The European Union's REACH regulations and similar global initiatives have placed greater scrutiny on fluoride compounds, potentially affecting the long-term viability of LiF in certain applications. Meanwhile, aluminum oxide generally faces fewer regulatory restrictions due to its established safety profile and recycling infrastructure.

Sustainable innovation pathways are emerging for both materials. Research into less energy-intensive lithium extraction methods and closed-loop fluoride recovery systems could significantly improve LiF's environmental profile. For aluminum oxide, advancements in low-carbon production technologies and renewable energy integration offer pathways to further reduce its environmental footprint.

Aluminum oxide production, while well-established industrially, is energy-intensive due to the Bayer and Hall-Héroult processes required to extract aluminum from bauxite ore. These processes contribute significantly to greenhouse gas emissions, particularly when powered by fossil fuel energy sources. However, aluminum oxide benefits from a mature recycling infrastructure, with approximately 75% of all aluminum ever produced still in circulation today.

Life cycle assessments reveal that lithium fluoride has a higher carbon footprint per unit mass compared to aluminum oxide, primarily due to the energy-intensive processes required for lithium extraction and fluorination. However, when considering the entire service life of components, LiF's superior performance characteristics in certain applications may offset its initial environmental impact through extended durability and reduced replacement frequency.

Water usage presents another critical environmental consideration. Lithium extraction can consume between 500,000 to 2 million gallons of water per ton of lithium produced, raising sustainability concerns in water-scarce regions. Aluminum oxide production, while also water-intensive, typically has lower water requirements per unit of material produced.

End-of-life management differs significantly between these materials. Aluminum oxide benefits from established recycling pathways that can reduce its overall environmental impact by up to 95% compared to primary production. Lithium fluoride recycling technologies remain less developed, though recent advances in hydrometallurgical processes show promise for improving recovery rates.

Regulatory frameworks increasingly influence material selection decisions. The European Union's REACH regulations and similar global initiatives have placed greater scrutiny on fluoride compounds, potentially affecting the long-term viability of LiF in certain applications. Meanwhile, aluminum oxide generally faces fewer regulatory restrictions due to its established safety profile and recycling infrastructure.

Sustainable innovation pathways are emerging for both materials. Research into less energy-intensive lithium extraction methods and closed-loop fluoride recovery systems could significantly improve LiF's environmental profile. For aluminum oxide, advancements in low-carbon production technologies and renewable energy integration offer pathways to further reduce its environmental footprint.

Material Processing and Manufacturing Techniques

The processing and manufacturing techniques for both Lithium Fluoride (LiF) and Aluminum Oxide (Al2O3) significantly influence their structural applications and performance characteristics. These materials require distinct approaches due to their inherent properties and intended use cases.

Lithium Fluoride processing typically begins with the synthesis of high-purity crystals through melt growth techniques, particularly the Czochralski or Bridgman-Stockbarger methods. These approaches enable the production of large single crystals with minimal defects, crucial for optical and radiation detection applications. Post-growth processing includes precision cutting, polishing, and annealing to relieve internal stresses and improve optical transparency. The material's sensitivity to moisture necessitates controlled environment processing, often utilizing dry rooms or inert gas atmospheres.

Aluminum Oxide, conversely, offers greater manufacturing versatility. The Bayer process remains the predominant method for extracting alumina from bauxite, followed by calcination to produce α-Al2O3 (corundum). For structural applications, several forming techniques are employed: slip casting for complex geometries, isostatic pressing for uniform density components, and extrusion for continuous profiles. Advanced manufacturing methods include chemical vapor deposition (CVD) for thin films and spark plasma sintering for nanostructured ceramics with enhanced mechanical properties.

Surface treatment processes differ substantially between these materials. LiF requires careful handling during polishing to achieve optical-grade surfaces without introducing subsurface damage. Specialized polishing compounds and techniques are employed to achieve surface roughness below 10 nm. For Al2O3, grinding with diamond tools followed by multi-stage polishing is standard practice, with additional treatments like laser texturing or chemical etching available for specific surface requirements.

The sintering behavior represents another critical manufacturing distinction. Al2O3 components typically undergo sintering at temperatures between 1500-1700°C, with various additives employed to control grain growth and densification. In contrast, LiF components are rarely sintered in conventional ceramic processing, instead relying on hot pressing or hot isostatic pressing when consolidation of powder is required.

Recent manufacturing innovations have expanded the application potential for both materials. Additive manufacturing techniques, including selective laser melting for Al2O3 and specialized binder jetting processes for LiF composites, enable complex geometries previously unattainable through conventional methods. These advances have opened new possibilities for customized structural components with optimized mechanical and functional properties.

Lithium Fluoride processing typically begins with the synthesis of high-purity crystals through melt growth techniques, particularly the Czochralski or Bridgman-Stockbarger methods. These approaches enable the production of large single crystals with minimal defects, crucial for optical and radiation detection applications. Post-growth processing includes precision cutting, polishing, and annealing to relieve internal stresses and improve optical transparency. The material's sensitivity to moisture necessitates controlled environment processing, often utilizing dry rooms or inert gas atmospheres.

Aluminum Oxide, conversely, offers greater manufacturing versatility. The Bayer process remains the predominant method for extracting alumina from bauxite, followed by calcination to produce α-Al2O3 (corundum). For structural applications, several forming techniques are employed: slip casting for complex geometries, isostatic pressing for uniform density components, and extrusion for continuous profiles. Advanced manufacturing methods include chemical vapor deposition (CVD) for thin films and spark plasma sintering for nanostructured ceramics with enhanced mechanical properties.

Surface treatment processes differ substantially between these materials. LiF requires careful handling during polishing to achieve optical-grade surfaces without introducing subsurface damage. Specialized polishing compounds and techniques are employed to achieve surface roughness below 10 nm. For Al2O3, grinding with diamond tools followed by multi-stage polishing is standard practice, with additional treatments like laser texturing or chemical etching available for specific surface requirements.

The sintering behavior represents another critical manufacturing distinction. Al2O3 components typically undergo sintering at temperatures between 1500-1700°C, with various additives employed to control grain growth and densification. In contrast, LiF components are rarely sintered in conventional ceramic processing, instead relying on hot pressing or hot isostatic pressing when consolidation of powder is required.

Recent manufacturing innovations have expanded the application potential for both materials. Additive manufacturing techniques, including selective laser melting for Al2O3 and specialized binder jetting processes for LiF composites, enable complex geometries previously unattainable through conventional methods. These advances have opened new possibilities for customized structural components with optimized mechanical and functional properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!