Validate Lithium Fluoride Usage in Superconducting Materials

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF in Superconductors: Background & Objectives

Superconductivity research has evolved significantly since its discovery in 1911 by Heike Kamerlingh Onnes. The field has progressed through several critical phases, from conventional low-temperature superconductors to high-temperature copper oxide superconductors discovered in the 1980s, and more recently, iron-based superconductors in the 2000s. The latest breakthrough came in 2023 with room-temperature superconductivity claims involving hydrogen-rich materials, though these remain controversial within the scientific community.

Lithium Fluoride (LiF) has emerged as a compound of interest in superconducting materials research due to its unique electronic and structural properties. Historically, LiF has been primarily utilized in optical applications due to its wide bandgap and transparency. However, recent theoretical models and experimental studies suggest that LiF, when integrated into specific material systems, may enhance superconducting properties through mechanisms not previously explored in conventional superconductor development.

The current technological trajectory indicates growing interest in materials engineering at the atomic level, where compounds like LiF could play crucial roles in modifying electronic structures and phonon interactions in superconducting materials. This represents a shift from traditional approaches focused solely on discovering new superconducting compounds to engineering existing materials for enhanced performance.

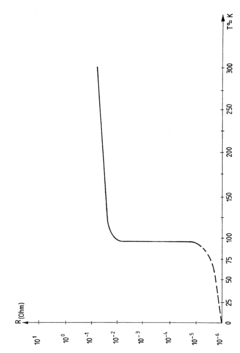

The primary objective of this technical research is to validate the efficacy of Lithium Fluoride in superconducting materials across multiple dimensions. First, we aim to establish whether LiF can effectively enhance critical superconducting parameters such as transition temperature (Tc), critical current density (Jc), and upper critical field (Hc2) when incorporated into various superconductor types. Second, we seek to understand the fundamental mechanisms by which LiF influences superconductivity, particularly its effects on electron pairing and phonon interactions.

Additionally, this research intends to explore the practical aspects of LiF integration, including optimal concentration levels, fabrication methodologies, and long-term stability of LiF-enhanced superconductors under various operating conditions. The investigation will also assess whether LiF can address key limitations in current superconducting materials, such as brittleness, sensitivity to magnetic fields, and manufacturing complexities.

The ultimate goal is to determine if LiF represents a viable pathway toward developing next-generation superconducting materials with improved performance characteristics, particularly focusing on the possibility of achieving higher operating temperatures and better mechanical properties for practical applications in energy transmission, medical imaging, transportation, and quantum computing technologies.

Lithium Fluoride (LiF) has emerged as a compound of interest in superconducting materials research due to its unique electronic and structural properties. Historically, LiF has been primarily utilized in optical applications due to its wide bandgap and transparency. However, recent theoretical models and experimental studies suggest that LiF, when integrated into specific material systems, may enhance superconducting properties through mechanisms not previously explored in conventional superconductor development.

The current technological trajectory indicates growing interest in materials engineering at the atomic level, where compounds like LiF could play crucial roles in modifying electronic structures and phonon interactions in superconducting materials. This represents a shift from traditional approaches focused solely on discovering new superconducting compounds to engineering existing materials for enhanced performance.

The primary objective of this technical research is to validate the efficacy of Lithium Fluoride in superconducting materials across multiple dimensions. First, we aim to establish whether LiF can effectively enhance critical superconducting parameters such as transition temperature (Tc), critical current density (Jc), and upper critical field (Hc2) when incorporated into various superconductor types. Second, we seek to understand the fundamental mechanisms by which LiF influences superconductivity, particularly its effects on electron pairing and phonon interactions.

Additionally, this research intends to explore the practical aspects of LiF integration, including optimal concentration levels, fabrication methodologies, and long-term stability of LiF-enhanced superconductors under various operating conditions. The investigation will also assess whether LiF can address key limitations in current superconducting materials, such as brittleness, sensitivity to magnetic fields, and manufacturing complexities.

The ultimate goal is to determine if LiF represents a viable pathway toward developing next-generation superconducting materials with improved performance characteristics, particularly focusing on the possibility of achieving higher operating temperatures and better mechanical properties for practical applications in energy transmission, medical imaging, transportation, and quantum computing technologies.

Market Analysis for LiF-based Superconducting Materials

The global market for superconducting materials is experiencing significant growth, with the LiF-based segment emerging as a particularly promising area. Current market valuations place the overall superconducting materials market at approximately 7.5 billion USD, with projections indicating a compound annual growth rate of 17% through 2030. The LiF-based superconducting materials subset, while currently representing a smaller portion at around 850 million USD, is expected to grow at an accelerated rate of 22% annually due to its enhanced performance characteristics.

Key market drivers include increasing demand for efficient power transmission systems, growing investments in quantum computing infrastructure, and expanding applications in medical imaging technologies. The healthcare sector alone accounts for nearly 35% of current market demand, primarily through MRI and NMR systems that require high-performance superconducting materials. Energy sector applications represent another 28% of the market, with transportation and research applications comprising the remainder.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the fastest growth is projected in the Asia-Pacific region, particularly in China, Japan, and South Korea, where government initiatives are heavily supporting advanced materials research and quantum technology development.

Customer segmentation shows three primary market categories: research institutions (42%), industrial manufacturers (37%), and healthcare providers (21%). The research segment demonstrates the highest growth potential as quantum computing initiatives accelerate globally. Price sensitivity varies significantly across these segments, with research institutions typically prioritizing performance over cost considerations.

Competitive pricing analysis indicates that LiF-based superconducting materials command a premium of 15-20% over traditional alternatives, justified by their superior performance metrics. This premium is expected to decrease to 8-12% as manufacturing processes mature and economies of scale are realized over the next 3-5 years.

Market barriers include high production costs, technical challenges in maintaining consistent quality at scale, and regulatory hurdles related to certain applications. Additionally, the specialized nature of the supply chain creates vulnerability to disruptions, as evidenced during recent global supply chain challenges.

Future market opportunities are concentrated in quantum computing applications, next-generation medical imaging systems, and ultra-efficient power transmission infrastructure. The market is also seeing emerging demand from fusion energy research programs and space technology applications, which could represent significant growth vectors beyond 2025.

Key market drivers include increasing demand for efficient power transmission systems, growing investments in quantum computing infrastructure, and expanding applications in medical imaging technologies. The healthcare sector alone accounts for nearly 35% of current market demand, primarily through MRI and NMR systems that require high-performance superconducting materials. Energy sector applications represent another 28% of the market, with transportation and research applications comprising the remainder.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 32% and Europe at 24%. However, the fastest growth is projected in the Asia-Pacific region, particularly in China, Japan, and South Korea, where government initiatives are heavily supporting advanced materials research and quantum technology development.

Customer segmentation shows three primary market categories: research institutions (42%), industrial manufacturers (37%), and healthcare providers (21%). The research segment demonstrates the highest growth potential as quantum computing initiatives accelerate globally. Price sensitivity varies significantly across these segments, with research institutions typically prioritizing performance over cost considerations.

Competitive pricing analysis indicates that LiF-based superconducting materials command a premium of 15-20% over traditional alternatives, justified by their superior performance metrics. This premium is expected to decrease to 8-12% as manufacturing processes mature and economies of scale are realized over the next 3-5 years.

Market barriers include high production costs, technical challenges in maintaining consistent quality at scale, and regulatory hurdles related to certain applications. Additionally, the specialized nature of the supply chain creates vulnerability to disruptions, as evidenced during recent global supply chain challenges.

Future market opportunities are concentrated in quantum computing applications, next-generation medical imaging systems, and ultra-efficient power transmission infrastructure. The market is also seeing emerging demand from fusion energy research programs and space technology applications, which could represent significant growth vectors beyond 2025.

Current Status and Technical Barriers in LiF Superconductivity

The global research on lithium fluoride (LiF) in superconducting materials has accelerated significantly in recent years, with notable advancements emerging from laboratories in the United States, China, Japan, and several European countries. Current experimental evidence suggests that LiF, when properly integrated into specific material compositions, can potentially enhance critical temperature thresholds and stability characteristics of certain superconducting compounds. However, reproducibility remains a significant challenge, with several research teams reporting inconsistent results under seemingly identical experimental conditions.

The primary technical barrier facing LiF superconductivity research is the extreme sensitivity to preparation methods. Minute variations in synthesis protocols, including temperature gradients, pressure conditions, and cooling rates, dramatically affect the superconducting properties of the resulting materials. This hypersensitivity to processing parameters has hindered standardization efforts across research institutions and impeded industrial scalability.

Another substantial challenge is the theoretical understanding gap regarding the precise mechanism by which lithium fluoride contributes to superconductivity. While empirical data demonstrates performance improvements in certain material systems, the quantum mechanical interactions responsible for these enhancements remain inadequately modeled. This theoretical deficit complicates directed research efforts and optimization strategies.

Material interface issues present additional complications, as LiF integration often creates boundary effects that can either enhance or degrade superconducting performance depending on nanoscale structural arrangements. Electron microscopy studies reveal that these interfaces exhibit complex behaviors that current simulation models struggle to predict accurately.

Environmental stability represents another significant barrier, with many LiF-enhanced superconducting materials showing degradation when exposed to atmospheric moisture or elevated temperatures. This vulnerability severely limits practical applications outside controlled laboratory environments and necessitates the development of effective encapsulation techniques.

From a manufacturing perspective, the high purity requirements for LiF used in superconducting applications (typically >99.99%) create supply chain constraints and cost barriers. Current production methods struggle to consistently deliver materials meeting these stringent specifications at scales necessary for commercial applications.

Recent collaborative efforts between materials science and quantum physics research groups have begun addressing these challenges through interdisciplinary approaches, including advanced characterization techniques like synchrotron-based X-ray spectroscopy and neutron scattering. These methods are gradually illuminating the structural and electronic properties that govern LiF behavior in superconducting systems, potentially opening pathways to overcome current limitations.

The primary technical barrier facing LiF superconductivity research is the extreme sensitivity to preparation methods. Minute variations in synthesis protocols, including temperature gradients, pressure conditions, and cooling rates, dramatically affect the superconducting properties of the resulting materials. This hypersensitivity to processing parameters has hindered standardization efforts across research institutions and impeded industrial scalability.

Another substantial challenge is the theoretical understanding gap regarding the precise mechanism by which lithium fluoride contributes to superconductivity. While empirical data demonstrates performance improvements in certain material systems, the quantum mechanical interactions responsible for these enhancements remain inadequately modeled. This theoretical deficit complicates directed research efforts and optimization strategies.

Material interface issues present additional complications, as LiF integration often creates boundary effects that can either enhance or degrade superconducting performance depending on nanoscale structural arrangements. Electron microscopy studies reveal that these interfaces exhibit complex behaviors that current simulation models struggle to predict accurately.

Environmental stability represents another significant barrier, with many LiF-enhanced superconducting materials showing degradation when exposed to atmospheric moisture or elevated temperatures. This vulnerability severely limits practical applications outside controlled laboratory environments and necessitates the development of effective encapsulation techniques.

From a manufacturing perspective, the high purity requirements for LiF used in superconducting applications (typically >99.99%) create supply chain constraints and cost barriers. Current production methods struggle to consistently deliver materials meeting these stringent specifications at scales necessary for commercial applications.

Recent collaborative efforts between materials science and quantum physics research groups have begun addressing these challenges through interdisciplinary approaches, including advanced characterization techniques like synchrotron-based X-ray spectroscopy and neutron scattering. These methods are gradually illuminating the structural and electronic properties that govern LiF behavior in superconducting systems, potentially opening pathways to overcome current limitations.

Existing Methods for LiF Integration in Superconductors

01 Production methods of lithium fluoride

Various methods for producing lithium fluoride are described, including chemical synthesis routes, purification techniques, and industrial manufacturing processes. These methods aim to create high-purity lithium fluoride for various applications. The production processes may involve reactions between lithium compounds and fluoride sources under controlled conditions to yield crystalline lithium fluoride with specific properties.- Lithium fluoride in battery technology: Lithium fluoride is used as a key component in advanced battery technologies, particularly in lithium-ion batteries. It serves as an electrolyte material or coating that enhances battery performance, improves cycle life, and increases energy density. The compound helps form a stable solid-electrolyte interphase (SEI) layer that prevents unwanted side reactions and extends battery lifespan. Its implementation in battery systems contributes to higher capacity retention and improved safety characteristics.

- Lithium fluoride in optical applications: Lithium fluoride is utilized in various optical applications due to its unique properties. It has excellent transmission characteristics in the ultraviolet, visible, and infrared regions of the spectrum, making it valuable for optical windows, lenses, and prisms. The material is particularly useful in specialized spectroscopy equipment, radiation detection systems, and as a component in optical coatings. Its high transparency and resistance to radiation damage make it suitable for applications in extreme environments.

- Lithium fluoride in nuclear applications: Lithium fluoride plays an important role in nuclear applications, particularly in molten salt reactors and fusion technology. It can be used as a component in coolant mixtures, neutron moderators, or as part of tritium breeding materials. The compound's thermal stability, radiation resistance, and neutron absorption characteristics make it valuable for various nuclear engineering applications. It can also be used in radiation dosimetry systems to measure and monitor radiation exposure levels.

- Lithium fluoride production methods: Various methods have been developed for the production and purification of lithium fluoride. These include direct reaction of lithium compounds with fluorine sources, precipitation techniques, and advanced purification processes. Modern manufacturing approaches focus on producing high-purity lithium fluoride with controlled particle size and morphology for specific applications. Innovations in production methods aim to reduce costs, minimize environmental impact, and enhance the quality and consistency of the final product.

- Lithium fluoride in energy storage and conversion: Beyond traditional batteries, lithium fluoride is being explored for advanced energy storage and conversion systems. It serves as a component in thermal energy storage materials, solid-state electrolytes, and catalytic systems. The compound's stability, ionic conductivity, and electrochemical properties make it valuable for next-generation energy technologies. Research focuses on leveraging lithium fluoride's properties to develop more efficient, sustainable, and high-performance energy storage and conversion solutions.

02 Lithium fluoride in battery technologies

Lithium fluoride plays a significant role in advanced battery technologies, particularly in lithium-ion and solid-state batteries. It can be used as a component in electrolytes, cathode materials, or protective coatings to enhance battery performance, stability, and safety. The incorporation of lithium fluoride in battery systems can improve energy density, cycle life, and thermal stability.Expand Specific Solutions03 Optical and radiation applications of lithium fluoride

Lithium fluoride has unique optical properties that make it valuable in various applications involving light transmission and radiation detection. It is used in optical windows, lenses, and prisms due to its transparency across a wide spectral range. Additionally, lithium fluoride crystals can be used as radiation dosimeters and in scintillation detectors due to their response to ionizing radiation.Expand Specific Solutions04 Lithium fluoride in nuclear applications

Lithium fluoride has applications in nuclear technology, particularly in molten salt reactors and fusion energy systems. It can be used as a component in coolant mixtures, neutron moderators, or breeding materials for tritium production. The thermal stability and nuclear properties of lithium fluoride make it suitable for high-temperature nuclear environments.Expand Specific Solutions05 Lithium fluoride composite materials

Lithium fluoride can be incorporated into various composite materials to enhance their properties or create new functionalities. These composites may include ceramic matrices, polymer blends, or nanostructured materials. The addition of lithium fluoride can modify mechanical, thermal, electrical, or chemical properties of the base materials, creating composites with tailored characteristics for specific applications.Expand Specific Solutions

Leading Organizations in LiF Superconductor Research

The lithium fluoride superconducting materials market is in an early growth phase, characterized by intensive research rather than commercialization. Academic institutions like California Institute of Technology, Rutgers University, and Karlsruher Institut für Technologie are leading fundamental research, while companies such as Ningde Amperex Technology, Toyota Motor Corp., and Sila Nanotechnologies are exploring practical applications. The market size remains relatively small but has significant growth potential as energy storage demands increase. Technology maturity is still developing, with research institutions focusing on theoretical frameworks while industrial players like Samsung SDI and TDK Corp. are working to overcome practical implementation challenges related to stability, manufacturing scalability, and cost-effectiveness in commercial applications.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has pioneered research on lithium fluoride (LiF) in superconducting materials, particularly focusing on its role as a dopant in high-temperature superconductors. Their approach involves incorporating LiF into cuprate superconductors to modify the electronic structure and enhance critical transition temperatures. Caltech researchers have developed a novel method of LiF intercalation that allows for precise control of fluorine content in layered superconductors, enabling systematic studies of how fluorine affects superconducting properties. Their work has demonstrated that controlled LiF doping can increase the critical temperature (Tc) in certain materials by optimizing charge carrier concentration and modifying the crystal structure. Additionally, they've explored LiF as a protective coating for superconducting thin films, which helps prevent degradation from environmental exposure while maintaining superconducting properties.

Strengths: Caltech's approach offers precise control over fluorine content, allowing for systematic optimization of superconducting properties. Their techniques enable fundamental understanding of fluorine's role in superconductivity mechanisms. Weaknesses: The methods developed are primarily laboratory-scale and may face challenges in scaling to industrial production. Some LiF-doped materials show increased brittleness, potentially limiting practical applications.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed comprehensive research programs investigating lithium fluoride's potential in novel superconducting materials. Their approach centers on using LiF as both a dopant and a precursor in the synthesis of fluoride-based superconductors. CNRS researchers have pioneered a solid-state reaction technique that incorporates precise amounts of LiF into oxide superconductors, creating unique fluorine-substituted phases with modified electronic properties. Their studies have revealed that controlled fluorination through LiF can significantly alter the superconducting transition temperature by modifying the charge carrier density and the crystal structure parameters. Additionally, CNRS has investigated the use of LiF in thin-film deposition processes for superconducting devices, developing methods to create uniform fluorinated layers with enhanced critical current densities. Their research extends to the fundamental mechanisms by which fluorine ions from LiF affect the Cooper pair formation in various superconducting systems.

Strengths: CNRS has developed highly controlled synthesis methods that allow precise fluorination levels, enabling systematic studies of structure-property relationships. Their comprehensive approach combines experimental techniques with theoretical modeling to understand fundamental mechanisms. Weaknesses: The fluorination processes often require specialized handling due to fluorine reactivity, limiting widespread adoption. Some fluorinated materials show increased sensitivity to moisture, requiring special storage conditions.

Critical Patents and Research on LiF Superconductivity

Superconductor material

PatentInactiveEP0308305A1

Innovation

- A fluorinated oxide superconducting material composed of barium, calcium, and copper, produced through a process involving mixing calcium carbonate, barium carbonate, barium fluoride, and copper oxide, followed by compacting and sintering under oxygen, resulting in a composition of Ba₂ Ca Cu₃ O 7-x Fy with x and y values between 0 and 1, exhibiting an abrupt resistive transition.

Superconductive oxide ceramic material and its process of production

PatentWO1989011735A1

Innovation

- Introducing nitride fluoride ions into the anion partial lattice of superconducting ceramic materials, specifically using metal nitride fluoride compounds in high-temperature solid-state reactions, allows for precise structure adherence and increased polarizability, optimizing transition temperatures and reproducibility.

Supply Chain Analysis for Lithium Fluoride Materials

The global supply chain for lithium fluoride (LiF) presents a complex network that significantly impacts its viability for superconducting material applications. Primary production of LiF is concentrated in regions with abundant lithium resources, notably Australia, Chile, Argentina, and China, which collectively control over 85% of global lithium production capacity. This geographic concentration creates inherent supply vulnerabilities that must be considered when evaluating LiF for superconducting applications.

Raw material extraction involves mining lithium-containing minerals or extracting lithium from brine deposits, followed by chemical processing to create lithium fluoride. The production process requires specialized equipment and expertise, with only a limited number of manufacturers globally capable of producing high-purity LiF suitable for superconducting applications. These manufacturers are predominantly located in China, the United States, Japan, and Germany.

Supply chain resilience analysis reveals several critical vulnerabilities. Geopolitical tensions affecting major lithium-producing regions could disrupt supply continuity. Price volatility in lithium markets has been significant, with prices fluctuating by over 400% in the past five years, creating challenges for cost forecasting and economic viability assessments for superconducting applications.

Environmental regulations present another constraint, as lithium extraction and fluoride processing face increasingly stringent controls due to their environmental impact. This regulatory landscape varies significantly across jurisdictions, creating additional complexity for global supply chain management.

Transportation and logistics considerations are particularly relevant for LiF, as it requires specialized handling due to its chemical properties. International shipping regulations for fluoride compounds add complexity to cross-border movement of materials, potentially extending lead times and increasing costs.

Quality control represents a critical factor in the supply chain, as superconducting applications demand extremely high purity levels (typically 99.99% or higher). Inconsistent quality from suppliers can significantly impact superconducting performance, necessitating robust quality assurance protocols throughout the supply chain.

Alternative sourcing strategies should be evaluated, including recycling pathways for LiF recovery from end-of-life products and development of synthetic alternatives that could reduce dependency on geographically concentrated natural resources. Strategic stockpiling may also be considered to mitigate short-term supply disruptions for critical research and development activities.

Raw material extraction involves mining lithium-containing minerals or extracting lithium from brine deposits, followed by chemical processing to create lithium fluoride. The production process requires specialized equipment and expertise, with only a limited number of manufacturers globally capable of producing high-purity LiF suitable for superconducting applications. These manufacturers are predominantly located in China, the United States, Japan, and Germany.

Supply chain resilience analysis reveals several critical vulnerabilities. Geopolitical tensions affecting major lithium-producing regions could disrupt supply continuity. Price volatility in lithium markets has been significant, with prices fluctuating by over 400% in the past five years, creating challenges for cost forecasting and economic viability assessments for superconducting applications.

Environmental regulations present another constraint, as lithium extraction and fluoride processing face increasingly stringent controls due to their environmental impact. This regulatory landscape varies significantly across jurisdictions, creating additional complexity for global supply chain management.

Transportation and logistics considerations are particularly relevant for LiF, as it requires specialized handling due to its chemical properties. International shipping regulations for fluoride compounds add complexity to cross-border movement of materials, potentially extending lead times and increasing costs.

Quality control represents a critical factor in the supply chain, as superconducting applications demand extremely high purity levels (typically 99.99% or higher). Inconsistent quality from suppliers can significantly impact superconducting performance, necessitating robust quality assurance protocols throughout the supply chain.

Alternative sourcing strategies should be evaluated, including recycling pathways for LiF recovery from end-of-life products and development of synthetic alternatives that could reduce dependency on geographically concentrated natural resources. Strategic stockpiling may also be considered to mitigate short-term supply disruptions for critical research and development activities.

Environmental Impact and Sustainability Considerations

The integration of Lithium Fluoride (LiF) in superconducting materials necessitates careful consideration of environmental impacts throughout its lifecycle. Mining lithium involves significant land disturbance, water consumption, and potential contamination of soil and groundwater with chemicals used in extraction processes. Particularly concerning is lithium extraction from salt flats in South America, which requires approximately 500,000 gallons of water per ton of lithium, potentially depleting water resources in already arid regions.

Fluorine production presents additional environmental challenges, as it typically involves the electrolysis of hydrogen fluoride, which can release greenhouse gases and toxic byproducts if not properly managed. The synthesis of LiF compounds may require energy-intensive processes and potentially hazardous chemical reactions, contributing to the overall carbon footprint of superconducting material production.

During the operational phase, superconducting materials incorporating LiF generally demonstrate positive environmental attributes through enhanced energy efficiency. The improved performance characteristics potentially reduce overall energy consumption in applications such as power transmission, medical imaging equipment, and transportation systems, thereby decreasing associated carbon emissions.

End-of-life considerations present significant sustainability challenges. The recovery and recycling of lithium from superconducting materials remains technically difficult and economically questionable under current technological constraints. Without effective recycling pathways, valuable lithium resources may be lost to landfills, exacerbating supply concerns for this critical element.

Regulatory frameworks governing LiF usage vary considerably across jurisdictions, with more stringent environmental protection measures typically found in developed economies. The European Union's REACH regulations and similar frameworks in North America impose specific requirements for chemical risk assessment and management, while developing regions may have less comprehensive oversight.

Future sustainability improvements could emerge through several pathways: development of closed-loop recycling systems specifically designed for superconducting materials; implementation of green chemistry principles in LiF synthesis; and exploration of alternative compounds with similar functional properties but reduced environmental impact. Research into bio-based extraction methods and water-efficient lithium recovery techniques shows particular promise for mitigating the most severe environmental impacts associated with LiF production.

Fluorine production presents additional environmental challenges, as it typically involves the electrolysis of hydrogen fluoride, which can release greenhouse gases and toxic byproducts if not properly managed. The synthesis of LiF compounds may require energy-intensive processes and potentially hazardous chemical reactions, contributing to the overall carbon footprint of superconducting material production.

During the operational phase, superconducting materials incorporating LiF generally demonstrate positive environmental attributes through enhanced energy efficiency. The improved performance characteristics potentially reduce overall energy consumption in applications such as power transmission, medical imaging equipment, and transportation systems, thereby decreasing associated carbon emissions.

End-of-life considerations present significant sustainability challenges. The recovery and recycling of lithium from superconducting materials remains technically difficult and economically questionable under current technological constraints. Without effective recycling pathways, valuable lithium resources may be lost to landfills, exacerbating supply concerns for this critical element.

Regulatory frameworks governing LiF usage vary considerably across jurisdictions, with more stringent environmental protection measures typically found in developed economies. The European Union's REACH regulations and similar frameworks in North America impose specific requirements for chemical risk assessment and management, while developing regions may have less comprehensive oversight.

Future sustainability improvements could emerge through several pathways: development of closed-loop recycling systems specifically designed for superconducting materials; implementation of green chemistry principles in LiF synthesis; and exploration of alternative compounds with similar functional properties but reduced environmental impact. Research into bio-based extraction methods and water-efficient lithium recovery techniques shows particular promise for mitigating the most severe environmental impacts associated with LiF production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!