How to Measure Lithium Fluoride Thermal Expansion in Devices

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF Thermal Expansion Background and Objectives

Lithium Fluoride (LiF) has emerged as a critical material in various high-tech applications, particularly in optical and electronic devices, due to its unique physical and chemical properties. The thermal expansion characteristics of LiF have become increasingly important as devices continue to miniaturize and operate under varying temperature conditions. Understanding how LiF expands or contracts with temperature changes is essential for ensuring device reliability, performance, and longevity.

The evolution of LiF applications has seen significant growth over the past decades, transitioning from primarily optical applications to more diverse uses in semiconductor technology, radiation detection, and energy storage systems. This expansion in application scope has heightened the need for precise thermal expansion measurements, as thermal mismatch between LiF and other device materials can lead to mechanical stress, delamination, or complete device failure.

Historical approaches to measuring thermal expansion coefficients of materials like LiF have relied on conventional dilatometry, X-ray diffraction, and interferometric techniques. However, these methods often present limitations when applied to in-situ measurements within actual devices, where LiF exists as thin films or in complex multi-material structures. The technical evolution trend points toward more sophisticated, non-destructive measurement techniques capable of nanoscale resolution.

The primary objective of this technical research is to develop and validate methodologies for accurately measuring the thermal expansion of LiF specifically within functional devices. This includes establishing measurement protocols that can be implemented during both manufacturing quality control and in-field device monitoring. Secondary objectives include correlating the measured thermal expansion data with device performance metrics and developing predictive models for device reliability.

Another critical goal is to understand how the thermal expansion behavior of LiF differs when integrated into devices compared to its bulk form. This includes investigating the effects of interfaces, confinement, crystallographic orientation, and processing conditions on thermal expansion properties. Such understanding will enable more accurate device design and material selection processes.

The technical research also aims to establish standardized measurement methodologies that can be widely adopted across industries utilizing LiF components. This standardization would facilitate better comparison of data between research groups and manufacturers, ultimately accelerating innovation in LiF-based technologies.

Finally, this research seeks to explore the relationship between thermal expansion and other physical properties of LiF, such as optical transmission, mechanical strength, and electrical characteristics, to develop a comprehensive understanding of how temperature fluctuations affect overall device performance. This holistic approach will provide valuable insights for future device designs that can better accommodate or even leverage the thermal expansion properties of LiF.

The evolution of LiF applications has seen significant growth over the past decades, transitioning from primarily optical applications to more diverse uses in semiconductor technology, radiation detection, and energy storage systems. This expansion in application scope has heightened the need for precise thermal expansion measurements, as thermal mismatch between LiF and other device materials can lead to mechanical stress, delamination, or complete device failure.

Historical approaches to measuring thermal expansion coefficients of materials like LiF have relied on conventional dilatometry, X-ray diffraction, and interferometric techniques. However, these methods often present limitations when applied to in-situ measurements within actual devices, where LiF exists as thin films or in complex multi-material structures. The technical evolution trend points toward more sophisticated, non-destructive measurement techniques capable of nanoscale resolution.

The primary objective of this technical research is to develop and validate methodologies for accurately measuring the thermal expansion of LiF specifically within functional devices. This includes establishing measurement protocols that can be implemented during both manufacturing quality control and in-field device monitoring. Secondary objectives include correlating the measured thermal expansion data with device performance metrics and developing predictive models for device reliability.

Another critical goal is to understand how the thermal expansion behavior of LiF differs when integrated into devices compared to its bulk form. This includes investigating the effects of interfaces, confinement, crystallographic orientation, and processing conditions on thermal expansion properties. Such understanding will enable more accurate device design and material selection processes.

The technical research also aims to establish standardized measurement methodologies that can be widely adopted across industries utilizing LiF components. This standardization would facilitate better comparison of data between research groups and manufacturers, ultimately accelerating innovation in LiF-based technologies.

Finally, this research seeks to explore the relationship between thermal expansion and other physical properties of LiF, such as optical transmission, mechanical strength, and electrical characteristics, to develop a comprehensive understanding of how temperature fluctuations affect overall device performance. This holistic approach will provide valuable insights for future device designs that can better accommodate or even leverage the thermal expansion properties of LiF.

Market Applications for LiF Thermal Expansion Data

The accurate measurement of lithium fluoride (LiF) thermal expansion properties has significant implications across multiple industries, driving innovation and enabling advanced applications. In the semiconductor industry, LiF's thermal expansion data is crucial for designing and manufacturing high-performance microelectronics. As chip architectures continue to shrink and thermal management becomes increasingly critical, precise LiF thermal expansion coefficients help engineers develop more reliable thermal interface materials and heat dissipation solutions, ultimately extending device lifespan and improving performance under varying temperature conditions.

Optical systems represent another major market application, with LiF being widely used in specialized lenses, windows, and prisms. The space and aerospace sectors particularly benefit from this data, as equipment must withstand extreme temperature fluctuations. By incorporating accurate LiF thermal expansion measurements into optical system designs, manufacturers can ensure dimensional stability and optical performance integrity across operational temperature ranges, reducing mission-critical failures and extending equipment service life.

The energy sector, especially nuclear and fusion research facilities, represents a growing market for LiF thermal expansion data. LiF's radiation resistance properties make it valuable for various components in these environments, but its thermal behavior must be precisely understood to prevent structural failures. Accurate expansion data enables better prediction of material behavior under the combined stresses of radiation and temperature fluctuations, improving safety margins and operational reliability.

Medical device manufacturing has emerged as another significant application area. LiF components in medical imaging equipment, radiation therapy devices, and diagnostic tools must maintain precise dimensional tolerances despite temperature variations during operation. Manufacturers leverage thermal expansion data to design devices that deliver consistent performance and accuracy across different operating conditions, directly impacting patient outcomes and treatment efficacy.

The quantum computing sector represents a nascent but rapidly growing market for LiF thermal expansion data. As quantum systems often operate at extremely low temperatures with minimal thermal noise, the behavior of materials like LiF during cooling cycles and temperature transitions becomes critical. Precise thermal expansion measurements help quantum computer engineers design more stable qubit environments and reduce decoherence issues related to thermal expansion mismatches between materials.

Defense applications constitute another significant market, with LiF being utilized in various sensor systems, targeting equipment, and protective components. The extreme operating conditions of military hardware demand materials with predictable thermal behavior, making accurate expansion data essential for designing reliable defense systems that maintain operational capabilities across diverse environmental conditions.

Optical systems represent another major market application, with LiF being widely used in specialized lenses, windows, and prisms. The space and aerospace sectors particularly benefit from this data, as equipment must withstand extreme temperature fluctuations. By incorporating accurate LiF thermal expansion measurements into optical system designs, manufacturers can ensure dimensional stability and optical performance integrity across operational temperature ranges, reducing mission-critical failures and extending equipment service life.

The energy sector, especially nuclear and fusion research facilities, represents a growing market for LiF thermal expansion data. LiF's radiation resistance properties make it valuable for various components in these environments, but its thermal behavior must be precisely understood to prevent structural failures. Accurate expansion data enables better prediction of material behavior under the combined stresses of radiation and temperature fluctuations, improving safety margins and operational reliability.

Medical device manufacturing has emerged as another significant application area. LiF components in medical imaging equipment, radiation therapy devices, and diagnostic tools must maintain precise dimensional tolerances despite temperature variations during operation. Manufacturers leverage thermal expansion data to design devices that deliver consistent performance and accuracy across different operating conditions, directly impacting patient outcomes and treatment efficacy.

The quantum computing sector represents a nascent but rapidly growing market for LiF thermal expansion data. As quantum systems often operate at extremely low temperatures with minimal thermal noise, the behavior of materials like LiF during cooling cycles and temperature transitions becomes critical. Precise thermal expansion measurements help quantum computer engineers design more stable qubit environments and reduce decoherence issues related to thermal expansion mismatches between materials.

Defense applications constitute another significant market, with LiF being utilized in various sensor systems, targeting equipment, and protective components. The extreme operating conditions of military hardware demand materials with predictable thermal behavior, making accurate expansion data essential for designing reliable defense systems that maintain operational capabilities across diverse environmental conditions.

Current Measurement Techniques and Limitations

The measurement of lithium fluoride (LiF) thermal expansion in devices presents significant challenges due to the material's unique properties and the precision required for accurate data collection. Currently, several established techniques are employed in research and industrial settings, each with distinct advantages and limitations.

X-ray diffraction (XRD) represents one of the most widely used methods for measuring thermal expansion coefficients of LiF crystals. This technique allows for precise determination of lattice parameter changes as a function of temperature. However, XRD requires specialized equipment and expertise, making it less accessible for routine measurements. Additionally, when LiF is integrated into complex devices, isolating its diffraction pattern from surrounding materials becomes problematic.

Dilatometry offers another approach, directly measuring dimensional changes of materials with temperature. Conventional push-rod dilatometers can achieve resolution down to nanometers, making them suitable for bulk LiF samples. However, their application to thin films or integrated components is limited by the minimum sample size requirements and potential contact-induced measurement errors.

Optical interferometry techniques have gained prominence for thermal expansion measurements in recent years. These non-contact methods can achieve sub-nanometer resolution and are particularly valuable for thin film applications. The limitation lies in the need for optically accessible surfaces and the complexity of data interpretation when multiple materials are present in the optical path.

Capacitance dilatometry offers exceptional sensitivity for thermal expansion measurements but requires careful sample preparation and electrical contacts. This technique becomes challenging when measuring LiF in complex device architectures where establishing reliable electrical connections is difficult.

Digital image correlation (DIC) represents a newer approach that tracks surface features during thermal cycling to determine expansion coefficients. While versatile for complex geometries, DIC's resolution may be insufficient for the subtle expansion characteristics of LiF in certain applications.

A significant limitation across all current techniques is the difficulty in isolating LiF thermal expansion behavior when the material is embedded within multilayer device structures. Interface effects, mechanical constraints, and thermal gradients can all influence measurement accuracy. Furthermore, most techniques provide averaged bulk properties rather than localized expansion characteristics that may be critical for understanding device performance.

Temperature control and measurement precision represent another common challenge. Many applications require thermal expansion data across wide temperature ranges with minimal thermal gradients across samples. Achieving uniform heating/cooling while maintaining measurement stability remains technically demanding, particularly for in-situ device measurements.

X-ray diffraction (XRD) represents one of the most widely used methods for measuring thermal expansion coefficients of LiF crystals. This technique allows for precise determination of lattice parameter changes as a function of temperature. However, XRD requires specialized equipment and expertise, making it less accessible for routine measurements. Additionally, when LiF is integrated into complex devices, isolating its diffraction pattern from surrounding materials becomes problematic.

Dilatometry offers another approach, directly measuring dimensional changes of materials with temperature. Conventional push-rod dilatometers can achieve resolution down to nanometers, making them suitable for bulk LiF samples. However, their application to thin films or integrated components is limited by the minimum sample size requirements and potential contact-induced measurement errors.

Optical interferometry techniques have gained prominence for thermal expansion measurements in recent years. These non-contact methods can achieve sub-nanometer resolution and are particularly valuable for thin film applications. The limitation lies in the need for optically accessible surfaces and the complexity of data interpretation when multiple materials are present in the optical path.

Capacitance dilatometry offers exceptional sensitivity for thermal expansion measurements but requires careful sample preparation and electrical contacts. This technique becomes challenging when measuring LiF in complex device architectures where establishing reliable electrical connections is difficult.

Digital image correlation (DIC) represents a newer approach that tracks surface features during thermal cycling to determine expansion coefficients. While versatile for complex geometries, DIC's resolution may be insufficient for the subtle expansion characteristics of LiF in certain applications.

A significant limitation across all current techniques is the difficulty in isolating LiF thermal expansion behavior when the material is embedded within multilayer device structures. Interface effects, mechanical constraints, and thermal gradients can all influence measurement accuracy. Furthermore, most techniques provide averaged bulk properties rather than localized expansion characteristics that may be critical for understanding device performance.

Temperature control and measurement precision represent another common challenge. Many applications require thermal expansion data across wide temperature ranges with minimal thermal gradients across samples. Achieving uniform heating/cooling while maintaining measurement stability remains technically demanding, particularly for in-situ device measurements.

State-of-the-Art LiF Thermal Characterization Methods

01 Thermal expansion properties of lithium fluoride in optical applications

Lithium fluoride exhibits specific thermal expansion characteristics that make it valuable in optical applications. Its low thermal expansion coefficient allows for stability in temperature-varying environments, making it suitable for optical windows, lenses, and other components in high-precision optical systems. The material's thermal expansion behavior is particularly important in applications requiring dimensional stability across operating temperature ranges.- Thermal expansion properties of lithium fluoride in optical applications: Lithium fluoride exhibits specific thermal expansion characteristics that make it valuable in optical applications. Its low thermal expansion coefficient allows for stability in temperature-varying environments, making it suitable for optical windows, lenses, and other components in high-precision optical systems. The material's thermal expansion behavior can be controlled through various processing methods to optimize performance in specific optical applications.

- Lithium fluoride in battery and energy storage applications: Lithium fluoride's thermal expansion properties are significant in battery and energy storage technologies. When used in battery components, the controlled thermal expansion of lithium fluoride contributes to improved stability and safety during charging and discharging cycles. The material's behavior under temperature fluctuations affects battery performance, longevity, and thermal management systems, making it an important consideration in advanced energy storage design.

- Composite materials incorporating lithium fluoride for controlled thermal expansion: Composite materials that incorporate lithium fluoride can be engineered to have specific thermal expansion characteristics. By combining lithium fluoride with other materials in precise ratios, the overall thermal expansion coefficient of the composite can be tailored for specific applications. These composites find use in environments where dimensional stability under temperature fluctuations is critical, such as aerospace components, electronic substrates, and precision instruments.

- Manufacturing processes affecting lithium fluoride thermal expansion: Various manufacturing and processing techniques can influence the thermal expansion properties of lithium fluoride. Methods such as controlled crystallization, sintering conditions, and heat treatment protocols can modify the microstructure of lithium fluoride, thereby affecting its thermal expansion behavior. Understanding and controlling these manufacturing parameters is essential for producing lithium fluoride components with predictable and consistent thermal expansion characteristics for specific applications.

- Measurement and characterization of lithium fluoride thermal expansion: Accurate measurement and characterization of lithium fluoride's thermal expansion properties are crucial for its application in various technologies. Advanced techniques for determining thermal expansion coefficients across different temperature ranges have been developed, including dilatometry, X-ray diffraction, and interferometric methods. These measurements provide essential data for modeling and predicting the behavior of lithium fluoride in complex systems and extreme environments.

02 Lithium fluoride in battery and energy storage applications

Lithium fluoride's thermal expansion properties are significant in battery and energy storage technologies. When used in battery components, the controlled thermal expansion of lithium fluoride contributes to structural stability during charge-discharge cycles and temperature fluctuations. This characteristic helps prevent mechanical failures in battery systems and improves overall performance and longevity of energy storage devices.Expand Specific Solutions03 Composite materials incorporating lithium fluoride for thermal expansion control

Composite materials that incorporate lithium fluoride can be engineered to have specific thermal expansion characteristics. By combining lithium fluoride with other materials, the overall thermal expansion coefficient of the composite can be tailored for specific applications. These composites are particularly valuable in environments with extreme temperature variations where dimensional stability is critical to performance and safety.Expand Specific Solutions04 Manufacturing processes accounting for lithium fluoride thermal expansion

Manufacturing processes for components containing lithium fluoride must account for its thermal expansion behavior. Specialized techniques have been developed to manage dimensional changes during production, processing, and cooling. These methods include controlled heating and cooling rates, specific sintering profiles, and precision molding approaches that accommodate the material's expansion and contraction characteristics.Expand Specific Solutions05 Measurement and characterization of lithium fluoride thermal expansion

Advanced techniques for measuring and characterizing the thermal expansion properties of lithium fluoride are essential for its application in various technologies. These methods include dilatometry, X-ray diffraction at various temperatures, and interferometric techniques. Accurate measurement of thermal expansion coefficients across different temperature ranges enables better prediction of material behavior in application-specific environments.Expand Specific Solutions

Leading Research Institutions and Instrument Manufacturers

The thermal expansion measurement of lithium fluoride in devices represents a niche yet critical technological field currently in an early growth phase. The market size remains relatively modest but is expanding due to increasing applications in battery technology and optical systems. From a technical maturity perspective, the landscape shows varying degrees of advancement. Leading players include Ningde Amperex Technology Ltd. and SCHOTT AG in the commercial sector, with significant research contributions from Massachusetts Institute of Technology and the Commissariat à l'énergie atomique. Companies like Micro-Epsilon Messtechnik and Mitutoyo Corp. provide specialized measurement instrumentation, while materials expertise comes from Corning, Inc. and AGC, Inc. The competitive environment is characterized by collaboration between academic institutions and industry players, with emerging competition from Asian manufacturers focusing on lithium battery applications.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed innovative methodologies for measuring lithium fluoride thermal expansion in advanced electronic and optical devices. Their approach combines atomic force microscopy with digital image correlation techniques to achieve nanometer-scale resolution in thermal expansion measurements. MIT's technology utilizes custom-designed environmental chambers that enable precise temperature control from cryogenic to elevated temperatures while maintaining vacuum conditions necessary for accurate measurements. Their methodology incorporates machine learning algorithms to analyze expansion patterns across different crystallographic orientations, providing comprehensive characterization of LiF's anisotropic thermal behavior. MIT has also pioneered techniques for measuring interfacial effects between LiF and adjacent materials in multilayer device structures, critical for understanding stress development and potential failure mechanisms.

Strengths: Cutting-edge measurement resolution at nanoscale; sophisticated data analysis capabilities leveraging AI; comprehensive understanding of material interfaces. Weaknesses: Highly academic approach may present challenges for industrial implementation; equipment complexity requires significant expertise.

Micro-Epsilon Messtechnik GmbH & Co. KG

Technical Solution: Micro-Epsilon has developed specialized non-contact measurement systems for determining lithium fluoride thermal expansion in operational devices. Their technology utilizes confocal chromatic sensors and laser triangulation systems capable of sub-nanometer resolution measurements across a wide temperature range. The company's approach enables real-time monitoring of LiF components in situ, allowing for dynamic characterization of thermal expansion behavior under actual operating conditions. Their systems incorporate advanced temperature compensation algorithms and reference standards to ensure measurement accuracy despite environmental fluctuations. Micro-Epsilon's technology is particularly valuable for measuring LiF expansion in optical assemblies, semiconductor packages, and precision instruments where traditional contact methods might introduce measurement artifacts.

Strengths: Industry-leading non-contact measurement precision; ability to perform in-situ measurements in functioning devices; robust environmental compensation capabilities. Weaknesses: Higher implementation costs compared to conventional methods; requires specialized operator training for optimal results.

Critical Patents in Thermal Expansion Measurement

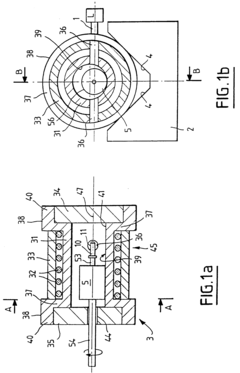

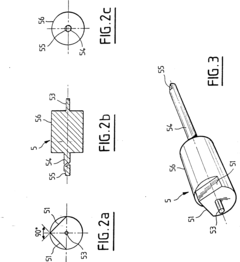

Device for measuring the thermal expansion of a sample

PatentInactiveEP0562910A1

Innovation

- A device that uses a base part with a V-shaped reference groove and a precision oven with cylindrical contours to position the sample for high-precision laser radiation measurement, minimizing heat transfer to the base and using a sample holder to prevent contact with the internal reference contour, ensuring accurate perpendicularity and avoiding defects in the measurement process.

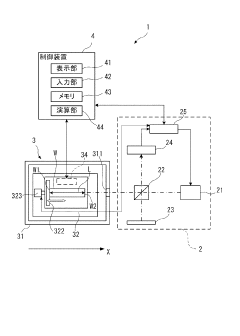

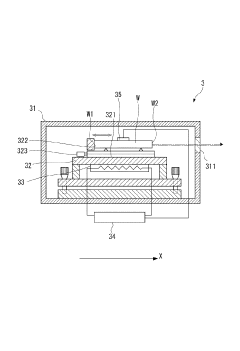

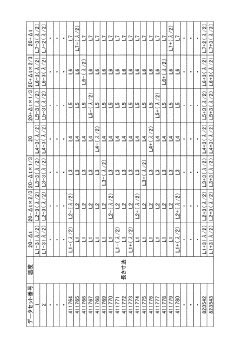

Thermal expansion coefficient measuring device and thermal expansion coefficient measurement method

PatentActiveJP2019045265A

Innovation

- A thermal expansion coefficient measuring device and method that uses a single-wavelength optical interferometer, generates multiple verification data sets by varying interference orders, and employs an evaluation index to validate data sets, ensuring accurate CTE calculations by selecting the most suitable dataset.

Temperature Control Systems for Accurate Measurements

Temperature control systems are critical components in the accurate measurement of lithium fluoride thermal expansion in devices. These systems must maintain precise and stable temperatures throughout the measurement process to ensure reliable data collection. Conventional temperature control systems typically employ PID (Proportional-Integral-Derivative) controllers that continuously adjust heating or cooling elements based on feedback from temperature sensors. However, when measuring the thermal expansion of lithium fluoride, which exhibits a relatively small coefficient of thermal expansion (approximately 37 × 10^-6 K^-1), standard systems often lack the necessary precision.

Advanced temperature control systems designed specifically for thermal expansion measurements incorporate multi-zone heating elements that create uniform temperature fields across the sample. These systems utilize platinum resistance thermometers (PRTs) or thermistors with accuracies of ±0.01°C or better, positioned strategically around the lithium fluoride sample to monitor temperature gradients. The elimination of these gradients is essential for accurate expansion measurements, as even minor variations can introduce significant measurement errors.

Recent developments in temperature control technology have introduced adaptive control algorithms that can compensate for environmental fluctuations and system nonlinearities. These algorithms continuously optimize heating and cooling parameters based on real-time performance metrics, achieving temperature stability of ±0.005°C over extended periods. Such stability is particularly important when measuring lithium fluoride's thermal expansion across different temperature ranges, as the material's expansion behavior can vary with temperature.

Vacuum or inert gas environments are often integrated into these control systems to eliminate convection effects and prevent sample contamination. This environmental control is crucial for lithium fluoride, which can react with moisture in the air at elevated temperatures. Modern systems employ double or triple-walled chambers with active thermal barriers to isolate the measurement environment from external thermal influences.

Data acquisition systems synchronized with temperature controllers provide continuous monitoring of both temperature and dimensional changes. High-resolution data logging with sampling rates of 10-100 Hz allows for the detection of transient thermal effects and ensures that expansion measurements are correlated precisely with temperature values. Advanced systems also incorporate automatic calibration routines using reference materials with well-characterized thermal expansion properties to verify system accuracy before measuring lithium fluoride samples.

For applications requiring measurements across extreme temperature ranges, specialized systems employ liquid nitrogen cooling circuits or high-temperature ceramic heating elements, extending the operational range from cryogenic temperatures to over 1000°C. These systems must maintain the same level of control precision across the entire temperature range, often requiring different sensor technologies and control strategies at different temperature regimes.

Advanced temperature control systems designed specifically for thermal expansion measurements incorporate multi-zone heating elements that create uniform temperature fields across the sample. These systems utilize platinum resistance thermometers (PRTs) or thermistors with accuracies of ±0.01°C or better, positioned strategically around the lithium fluoride sample to monitor temperature gradients. The elimination of these gradients is essential for accurate expansion measurements, as even minor variations can introduce significant measurement errors.

Recent developments in temperature control technology have introduced adaptive control algorithms that can compensate for environmental fluctuations and system nonlinearities. These algorithms continuously optimize heating and cooling parameters based on real-time performance metrics, achieving temperature stability of ±0.005°C over extended periods. Such stability is particularly important when measuring lithium fluoride's thermal expansion across different temperature ranges, as the material's expansion behavior can vary with temperature.

Vacuum or inert gas environments are often integrated into these control systems to eliminate convection effects and prevent sample contamination. This environmental control is crucial for lithium fluoride, which can react with moisture in the air at elevated temperatures. Modern systems employ double or triple-walled chambers with active thermal barriers to isolate the measurement environment from external thermal influences.

Data acquisition systems synchronized with temperature controllers provide continuous monitoring of both temperature and dimensional changes. High-resolution data logging with sampling rates of 10-100 Hz allows for the detection of transient thermal effects and ensures that expansion measurements are correlated precisely with temperature values. Advanced systems also incorporate automatic calibration routines using reference materials with well-characterized thermal expansion properties to verify system accuracy before measuring lithium fluoride samples.

For applications requiring measurements across extreme temperature ranges, specialized systems employ liquid nitrogen cooling circuits or high-temperature ceramic heating elements, extending the operational range from cryogenic temperatures to over 1000°C. These systems must maintain the same level of control precision across the entire temperature range, often requiring different sensor technologies and control strategies at different temperature regimes.

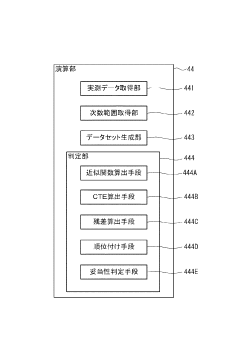

Data Processing Algorithms for Thermal Expansion Analysis

The processing of thermal expansion data for lithium fluoride in device applications requires sophisticated algorithmic approaches to ensure accuracy and reliability. Raw data collected from various measurement techniques such as X-ray diffraction, dilatometry, and interferometry must undergo several processing stages before yielding actionable insights about thermal expansion coefficients.

Signal filtering algorithms represent the first critical step in data processing, where techniques like Savitzky-Golay filtering and wavelet transforms effectively remove measurement noise while preserving the underlying thermal expansion signal characteristics. These methods are particularly valuable when dealing with the subtle dimensional changes exhibited by lithium fluoride across operational temperature ranges in electronic and optical devices.

Statistical analysis frameworks form the backbone of thermal expansion data interpretation, incorporating regression models that account for the non-linear expansion behaviors often observed in crystalline materials like lithium fluoride. Bayesian statistical methods have emerged as particularly powerful for quantifying uncertainty in thermal expansion measurements, especially important when working with the microscale dimensions typical in modern device applications.

Machine learning approaches have recently revolutionized thermal expansion data processing, with neural networks demonstrating superior capability in identifying complex patterns in multi-dimensional thermal response data. Supervised learning algorithms trained on validated lithium fluoride expansion datasets can now predict expansion behaviors under novel temperature conditions with remarkable accuracy, reducing the need for exhaustive experimental measurements.

Differential analysis techniques enable the isolation of lithium fluoride's thermal expansion from composite material systems, a critical requirement when measuring expansion in actual device configurations. These algorithms typically employ mathematical models that account for the thermal contributions of surrounding materials, substrate effects, and interface phenomena that might otherwise confound direct measurement approaches.

Real-time data processing algorithms have become increasingly important for in-situ monitoring of lithium fluoride components during device operation. These algorithms must balance computational efficiency with accuracy, often employing dimensionality reduction techniques and parallel processing architectures to deliver timely insights into thermal expansion behaviors under dynamic temperature conditions.

Calibration and error correction algorithms complete the data processing pipeline, compensating for systematic measurement errors and instrument drift. Cross-validation techniques comparing results across multiple measurement methodologies help establish confidence intervals for the derived thermal expansion coefficients, ensuring that device designers can rely on the processed data for critical engineering decisions.

Signal filtering algorithms represent the first critical step in data processing, where techniques like Savitzky-Golay filtering and wavelet transforms effectively remove measurement noise while preserving the underlying thermal expansion signal characteristics. These methods are particularly valuable when dealing with the subtle dimensional changes exhibited by lithium fluoride across operational temperature ranges in electronic and optical devices.

Statistical analysis frameworks form the backbone of thermal expansion data interpretation, incorporating regression models that account for the non-linear expansion behaviors often observed in crystalline materials like lithium fluoride. Bayesian statistical methods have emerged as particularly powerful for quantifying uncertainty in thermal expansion measurements, especially important when working with the microscale dimensions typical in modern device applications.

Machine learning approaches have recently revolutionized thermal expansion data processing, with neural networks demonstrating superior capability in identifying complex patterns in multi-dimensional thermal response data. Supervised learning algorithms trained on validated lithium fluoride expansion datasets can now predict expansion behaviors under novel temperature conditions with remarkable accuracy, reducing the need for exhaustive experimental measurements.

Differential analysis techniques enable the isolation of lithium fluoride's thermal expansion from composite material systems, a critical requirement when measuring expansion in actual device configurations. These algorithms typically employ mathematical models that account for the thermal contributions of surrounding materials, substrate effects, and interface phenomena that might otherwise confound direct measurement approaches.

Real-time data processing algorithms have become increasingly important for in-situ monitoring of lithium fluoride components during device operation. These algorithms must balance computational efficiency with accuracy, often employing dimensionality reduction techniques and parallel processing architectures to deliver timely insights into thermal expansion behaviors under dynamic temperature conditions.

Calibration and error correction algorithms complete the data processing pipeline, compensating for systematic measurement errors and instrument drift. Cross-validation techniques comparing results across multiple measurement methodologies help establish confidence intervals for the derived thermal expansion coefficients, ensuring that device designers can rely on the processed data for critical engineering decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!