Compare: Lithium Fluoride vs. Lithium Ion in Energy Storage

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF vs Li-ion Energy Storage Background and Objectives

Energy storage technologies have evolved significantly over the past decades, with lithium-based systems emerging as dominant solutions for various applications. Lithium-ion (Li-ion) batteries have revolutionized portable electronics, electric vehicles, and grid-scale storage since their commercial introduction in the early 1990s. Meanwhile, lithium fluoride (LiF) represents an alternative approach to energy storage that has gained increasing attention in recent years for its theoretical advantages in energy density and safety.

The historical development of Li-ion technology began with pioneering work by M.S. Whittingham, John Goodenough, and Akira Yoshino in the 1970s and 1980s, leading to the first commercial cells by Sony in 1991. Since then, continuous improvements in electrode materials, electrolytes, and manufacturing processes have driven steady performance gains of approximately 5-8% annually in energy density while reducing costs by over 90% in the past decade.

Lithium fluoride-based storage systems represent a different technological approach, with roots in conversion reaction chemistry rather than the intercalation mechanisms of traditional Li-ion batteries. Research into LiF for energy storage applications accelerated in the 2010s as scientists sought alternatives to overcome the theoretical energy density limitations of conventional Li-ion systems.

The fundamental difference between these technologies lies in their energy storage mechanisms. Li-ion batteries store energy through the reversible movement of lithium ions between layered electrode materials, while LiF-based systems typically utilize conversion reactions involving the breaking and forming of chemical bonds with lithium fluoride. This distinction creates significant differences in theoretical energy density, cycle life, safety characteristics, and manufacturing requirements.

Current market dynamics heavily favor Li-ion technology, which has reached manufacturing maturity with global production capacity exceeding 500 GWh annually. However, increasing demands for higher energy density, improved safety, and reduced dependence on critical materials like cobalt and nickel are driving exploration of alternative chemistries, including LiF-based approaches.

The primary objective of this technical assessment is to comprehensively compare lithium fluoride and lithium-ion technologies for energy storage applications across multiple dimensions: theoretical and practical energy densities, cycle life and degradation mechanisms, safety characteristics, raw material requirements, manufacturing scalability, and economic viability. Additionally, this report aims to identify potential application spaces where each technology might hold competitive advantages and outline the technological hurdles that must be overcome for broader commercial adoption.

This analysis will provide strategic insights to guide research priorities, partnership opportunities, and long-term technology roadmapping in the rapidly evolving energy storage landscape.

The historical development of Li-ion technology began with pioneering work by M.S. Whittingham, John Goodenough, and Akira Yoshino in the 1970s and 1980s, leading to the first commercial cells by Sony in 1991. Since then, continuous improvements in electrode materials, electrolytes, and manufacturing processes have driven steady performance gains of approximately 5-8% annually in energy density while reducing costs by over 90% in the past decade.

Lithium fluoride-based storage systems represent a different technological approach, with roots in conversion reaction chemistry rather than the intercalation mechanisms of traditional Li-ion batteries. Research into LiF for energy storage applications accelerated in the 2010s as scientists sought alternatives to overcome the theoretical energy density limitations of conventional Li-ion systems.

The fundamental difference between these technologies lies in their energy storage mechanisms. Li-ion batteries store energy through the reversible movement of lithium ions between layered electrode materials, while LiF-based systems typically utilize conversion reactions involving the breaking and forming of chemical bonds with lithium fluoride. This distinction creates significant differences in theoretical energy density, cycle life, safety characteristics, and manufacturing requirements.

Current market dynamics heavily favor Li-ion technology, which has reached manufacturing maturity with global production capacity exceeding 500 GWh annually. However, increasing demands for higher energy density, improved safety, and reduced dependence on critical materials like cobalt and nickel are driving exploration of alternative chemistries, including LiF-based approaches.

The primary objective of this technical assessment is to comprehensively compare lithium fluoride and lithium-ion technologies for energy storage applications across multiple dimensions: theoretical and practical energy densities, cycle life and degradation mechanisms, safety characteristics, raw material requirements, manufacturing scalability, and economic viability. Additionally, this report aims to identify potential application spaces where each technology might hold competitive advantages and outline the technological hurdles that must be overcome for broader commercial adoption.

This analysis will provide strategic insights to guide research priorities, partnership opportunities, and long-term technology roadmapping in the rapidly evolving energy storage landscape.

Market Analysis of Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the need for reliable grid stabilization solutions. The market value reached $180 billion in 2022 and is projected to grow at a CAGR of 12.3% through 2030, highlighting the significant economic potential of advanced energy storage technologies.

Lithium-ion batteries currently dominate the commercial energy storage landscape, accounting for approximately 70% of newly installed capacity worldwide. Their widespread adoption stems from continuous improvements in energy density, which has increased by roughly 5-8% annually over the past decade, alongside declining costs that have fallen by over 85% since 2010.

In contrast, lithium fluoride-based storage solutions represent an emerging technology segment with distinct market positioning. While currently occupying less than 2% of the commercial market share, lithium fluoride technologies have demonstrated superior theoretical energy density capabilities in laboratory settings, potentially offering up to 2-3 times the energy storage capacity of conventional lithium-ion systems.

Market segmentation reveals divergent adoption patterns across sectors. Lithium-ion batteries have established strong footholds in consumer electronics (43% market share), electric vehicles (38%), and grid-scale applications (19%). Lithium fluoride technologies are primarily gaining traction in specialized high-performance applications where energy density and thermal stability outweigh cost considerations.

Regional analysis indicates Asia-Pacific leads lithium-ion manufacturing with 75% of global production capacity, while North America and Europe are making strategic investments in next-generation technologies including lithium fluoride research. China alone controls approximately 80% of the lithium-ion supply chain, creating significant market concentration risks.

Consumer demand patterns show increasing preference for storage solutions with enhanced safety profiles, longer cycle life, and improved sustainability metrics. Lithium fluoride systems score favorably in safety assessments due to their inherent thermal stability, addressing a key concern in the lithium-ion market where thermal runaway incidents have impacted consumer confidence.

Investment trends reveal growing venture capital interest in advanced lithium chemistries, with funding for lithium fluoride research increasing by 45% in 2022 compared to the previous year. Major energy companies are diversifying their technology portfolios through strategic acquisitions and research partnerships focused on next-generation storage solutions.

Lithium-ion batteries currently dominate the commercial energy storage landscape, accounting for approximately 70% of newly installed capacity worldwide. Their widespread adoption stems from continuous improvements in energy density, which has increased by roughly 5-8% annually over the past decade, alongside declining costs that have fallen by over 85% since 2010.

In contrast, lithium fluoride-based storage solutions represent an emerging technology segment with distinct market positioning. While currently occupying less than 2% of the commercial market share, lithium fluoride technologies have demonstrated superior theoretical energy density capabilities in laboratory settings, potentially offering up to 2-3 times the energy storage capacity of conventional lithium-ion systems.

Market segmentation reveals divergent adoption patterns across sectors. Lithium-ion batteries have established strong footholds in consumer electronics (43% market share), electric vehicles (38%), and grid-scale applications (19%). Lithium fluoride technologies are primarily gaining traction in specialized high-performance applications where energy density and thermal stability outweigh cost considerations.

Regional analysis indicates Asia-Pacific leads lithium-ion manufacturing with 75% of global production capacity, while North America and Europe are making strategic investments in next-generation technologies including lithium fluoride research. China alone controls approximately 80% of the lithium-ion supply chain, creating significant market concentration risks.

Consumer demand patterns show increasing preference for storage solutions with enhanced safety profiles, longer cycle life, and improved sustainability metrics. Lithium fluoride systems score favorably in safety assessments due to their inherent thermal stability, addressing a key concern in the lithium-ion market where thermal runaway incidents have impacted consumer confidence.

Investment trends reveal growing venture capital interest in advanced lithium chemistries, with funding for lithium fluoride research increasing by 45% in 2022 compared to the previous year. Major energy companies are diversifying their technology portfolios through strategic acquisitions and research partnerships focused on next-generation storage solutions.

Technical Status and Challenges in Lithium-based Storage

Lithium-based energy storage technologies have witnessed significant advancements globally, with lithium-ion batteries dominating the commercial market while lithium fluoride-based systems remain primarily in research stages. Currently, lithium-ion technology has reached maturity with energy densities ranging from 100-265 Wh/kg for commercial applications, whereas lithium fluoride-based storage systems are still emerging with theoretical energy densities exceeding 1,000 Wh/kg, though practical implementations remain limited.

The geographical distribution of lithium-based storage technology development shows concentration in East Asia (particularly Japan, South Korea, and China), North America, and Europe. China has emerged as the dominant player in lithium-ion manufacturing, controlling approximately 75% of global production capacity, while advanced research on lithium fluoride systems is primarily conducted in research institutions across the United States and Europe.

Despite their commercial success, lithium-ion technologies face several critical challenges. These include safety concerns related to thermal runaway and flammability, limited energy density plateauing around 300 Wh/kg for next-generation designs, resource constraints for critical materials like cobalt and nickel, and significant environmental impacts from mining and manufacturing processes. Additionally, lithium-ion batteries suffer from capacity degradation over time, typically losing 20-30% capacity after 1,000 cycles.

Lithium fluoride-based storage systems encounter different technical hurdles. The primary challenges include poor ionic conductivity at room temperature, requiring operation at elevated temperatures (>150°C) for practical performance. Interface stability issues between electrodes and electrolytes lead to high internal resistance and poor cycle life. Manufacturing complexities arise from handling highly reactive fluoride compounds, and there are significant gaps in fundamental understanding of reaction mechanisms and kinetics in fluoride-ion transport.

Both technologies face shared challenges in scaling production while maintaining quality control, though lithium-ion benefits from decades of manufacturing optimization while lithium fluoride systems lack established industrial processes. The cost structure differs substantially, with lithium-ion batteries achieving $100-150/kWh at pack level, while lithium fluoride systems remain prohibitively expensive for commercial applications due to specialized materials and processing requirements.

Recent research breakthroughs in solid-state electrolytes and nanostructured electrode materials show promise for addressing conductivity issues in lithium fluoride systems, while advanced battery management systems and silicon/graphene composites are extending the capabilities of conventional lithium-ion technologies. The technical convergence of these approaches may yield hybrid systems that leverage advantages from both storage paradigms.

The geographical distribution of lithium-based storage technology development shows concentration in East Asia (particularly Japan, South Korea, and China), North America, and Europe. China has emerged as the dominant player in lithium-ion manufacturing, controlling approximately 75% of global production capacity, while advanced research on lithium fluoride systems is primarily conducted in research institutions across the United States and Europe.

Despite their commercial success, lithium-ion technologies face several critical challenges. These include safety concerns related to thermal runaway and flammability, limited energy density plateauing around 300 Wh/kg for next-generation designs, resource constraints for critical materials like cobalt and nickel, and significant environmental impacts from mining and manufacturing processes. Additionally, lithium-ion batteries suffer from capacity degradation over time, typically losing 20-30% capacity after 1,000 cycles.

Lithium fluoride-based storage systems encounter different technical hurdles. The primary challenges include poor ionic conductivity at room temperature, requiring operation at elevated temperatures (>150°C) for practical performance. Interface stability issues between electrodes and electrolytes lead to high internal resistance and poor cycle life. Manufacturing complexities arise from handling highly reactive fluoride compounds, and there are significant gaps in fundamental understanding of reaction mechanisms and kinetics in fluoride-ion transport.

Both technologies face shared challenges in scaling production while maintaining quality control, though lithium-ion benefits from decades of manufacturing optimization while lithium fluoride systems lack established industrial processes. The cost structure differs substantially, with lithium-ion batteries achieving $100-150/kWh at pack level, while lithium fluoride systems remain prohibitively expensive for commercial applications due to specialized materials and processing requirements.

Recent research breakthroughs in solid-state electrolytes and nanostructured electrode materials show promise for addressing conductivity issues in lithium fluoride systems, while advanced battery management systems and silicon/graphene composites are extending the capabilities of conventional lithium-ion technologies. The technical convergence of these approaches may yield hybrid systems that leverage advantages from both storage paradigms.

Current Technical Solutions for Lithium-based Storage

01 Lithium fluoride as solid electrolyte in lithium-ion batteries

Lithium fluoride (LiF) can be used as a solid electrolyte material in lithium-ion batteries, offering improved safety and stability compared to liquid electrolytes. The incorporation of LiF in the electrolyte system enhances ionic conductivity and forms a stable solid-electrolyte interphase (SEI) layer, which protects the electrode surface and prevents capacity degradation during cycling. This technology contributes to higher energy storage capacity and longer battery life.- Lithium fluoride as solid electrolyte in lithium-ion batteries: Lithium fluoride (LiF) can be used as a solid electrolyte material in lithium-ion batteries, offering improved safety and stability compared to liquid electrolytes. The incorporation of LiF in solid-state batteries helps to enhance ionic conductivity while maintaining structural integrity during charging and discharging cycles. This technology enables higher energy density storage while reducing the risk of leakage and thermal runaway issues associated with conventional liquid electrolyte systems.

- Lithium fluoride coatings for cathode materials: Applying lithium fluoride coatings on cathode materials can significantly improve the energy storage capacity and cycling stability of lithium-ion batteries. These coatings act as protective layers that prevent unwanted side reactions between the cathode and electrolyte, reducing capacity fade over time. The LiF coating technology enables higher voltage operation and improved rate capability, resulting in batteries with enhanced energy density and longer service life.

- Advanced lithium-ion electrode compositions with fluoride additives: Incorporating fluoride-based additives into lithium-ion electrode compositions can enhance energy storage capacity through improved electrochemical stability. These additives modify the solid-electrolyte interphase (SEI) formation, leading to more efficient lithium-ion transport and reduced impedance. The optimized electrode compositions with fluoride components enable higher capacity retention during cycling and better performance under extreme temperature conditions, addressing key limitations in conventional lithium-ion technology.

- Lithium-fluoride-based conversion cathodes: Conversion cathodes based on lithium fluoride compounds represent an emerging technology for high-energy-density storage systems. These materials undergo conversion reactions rather than intercalation, potentially storing multiple electrons per active metal center and thus achieving theoretical capacities far exceeding conventional lithium-ion cathodes. While facing challenges with voltage hysteresis and cycling stability, research advances in nanostructuring and composite formation are improving the practical viability of these high-capacity storage systems.

- Hybrid energy storage systems combining lithium-ion and lithium fluoride technologies: Hybrid energy storage systems that integrate conventional lithium-ion technology with lithium fluoride components offer optimized performance across multiple parameters. These systems leverage the high energy density of lithium fluoride-based components while maintaining the power capability and reliability of traditional lithium-ion cells. The hybrid approach enables customizable energy storage solutions that can be tailored for specific applications, from high-energy to high-power requirements, while potentially extending overall system lifetime and improving safety characteristics.

02 Lithium fluoride coatings for cathode materials

Applying lithium fluoride coatings on cathode materials can significantly improve the electrochemical performance of lithium-ion batteries. These coatings act as protective layers that prevent unwanted side reactions between the cathode and electrolyte, reducing capacity fade during cycling. The LiF coating also enhances lithium-ion diffusion at the electrode-electrolyte interface, leading to improved rate capability and higher energy storage capacity of the battery system.Expand Specific Solutions03 Composite electrode materials incorporating lithium fluoride

Composite electrode materials that incorporate lithium fluoride show enhanced energy storage capacity for lithium-ion batteries. These composites typically combine LiF with other active materials to create synergistic effects that improve electrochemical performance. The presence of LiF in the composite structure helps maintain electrode integrity during charge-discharge cycles, prevents volume expansion issues, and facilitates faster lithium-ion transport, resulting in batteries with higher capacity and improved cycle life.Expand Specific Solutions04 Advanced lithium-ion cell designs with enhanced energy density

Advanced lithium-ion cell designs incorporate innovative architectures and material combinations to achieve higher energy storage capacities. These designs often feature optimized electrode structures, novel separator technologies, and improved current collectors. By carefully engineering the cell components and their interfaces, these advanced designs enable more efficient utilization of active materials, reduced internal resistance, and better thermal management, all contributing to significantly higher energy densities compared to conventional lithium-ion batteries.Expand Specific Solutions05 Lithium-ion battery systems with integrated thermal management

Lithium-ion battery systems with integrated thermal management technologies offer improved energy storage capacity by maintaining optimal operating temperatures. These systems incorporate cooling channels, phase change materials, or other thermal regulation mechanisms to prevent capacity loss due to temperature fluctuations. Effective thermal management prevents degradation mechanisms that occur at high temperatures, extends battery lifetime, and allows for higher charging and discharging rates without compromising the energy storage capacity of the battery system.Expand Specific Solutions

Key Industry Players in Energy Storage Market

The energy storage market is witnessing a technological transition between traditional Lithium Fluoride (LiF) and Lithium-Ion technologies, with the latter currently dominating commercial applications. While LiF offers theoretical advantages in energy density and safety, it remains at an early research stage, with companies like CATL, EVE Energy, and Enevate leading development efforts. Lithium-Ion technology has reached commercial maturity, with major players including Robert Bosch, Honda, Toyota, and Subaru investing heavily in manufacturing infrastructure. Research institutions like California Institute of Technology and Rutgers University are exploring next-generation LiF technologies, while companies like Honeycomb Battery are developing hybrid approaches. The market is expected to grow significantly as automotive and grid storage applications expand, with technological competition intensifying between established Li-Ion manufacturers and emerging LiF innovators.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology Ltd.) has developed advanced lithium-ion battery technologies with high energy density (up to 300 Wh/kg) and long cycle life (over 3,000 cycles). Their cell-to-pack technology eliminates traditional module components, increasing energy density by 10-15%. For lithium fluoride applications, CATL has pioneered solid-state battery research incorporating lithium fluoride as a key component in their protective coating layers to enhance interface stability between electrodes and electrolytes. Their lithium fluoride-based solid electrolyte interphase (SEI) technology significantly reduces dendrite formation and improves battery safety. CATL has also explored lithium fluoride conversion cathodes that theoretically offer energy densities exceeding 1000 Wh/kg, though commercialization remains in research phase.

Strengths: Industry-leading manufacturing scale enables cost-effective production; extensive R&D capabilities with over 5,000 patents in battery technology; established supply chain relationships. Weaknesses: Lithium fluoride battery technology still in early development stage with significant commercialization challenges; higher production costs compared to conventional lithium-ion; requires specialized manufacturing processes not yet optimized for mass production.

Penn State Research Foundation

Technical Solution: Penn State has conducted pioneering research comparing lithium fluoride and lithium-ion technologies for energy storage applications. Their lithium-ion research has focused on high-voltage spinel cathodes achieving energy densities of 220-250 Wh/kg with enhanced thermal stability. For lithium fluoride applications, Penn State has developed innovative nanostructured conversion electrodes where lithium fluoride serves as both an active material and a stabilizing agent. Their research demonstrates that lithium fluoride conversion reactions can theoretically store 2-3 times more lithium per unit volume than conventional intercalation mechanisms. Penn State's advanced in-situ characterization techniques have revealed that controlling the nanoscale architecture of lithium fluoride domains is critical for achieving reversible conversion reactions. Their solid-state battery research incorporates lithium fluoride in composite electrolytes, achieving ionic conductivities approaching 10^-4 S/cm at room temperature while maintaining excellent electrochemical stability windows exceeding 4.5V. Penn State has also pioneered the use of lithium fluoride as a protective coating material for high-voltage cathodes, demonstrating significant improvements in cycle life and capacity retention.

Strengths: World-class battery characterization facilities; interdisciplinary research approach combining materials science, chemistry and engineering; strong industry partnerships for technology validation; comprehensive understanding of interfacial phenomena in battery systems. Weaknesses: Lithium fluoride conversion reactions still face significant kinetic limitations; manufacturing scalability remains unproven; higher production costs compared to conventional lithium-ion; requires further development to address voltage hysteresis issues.

Core Patents and Research in LiF and Li-ion Technologies

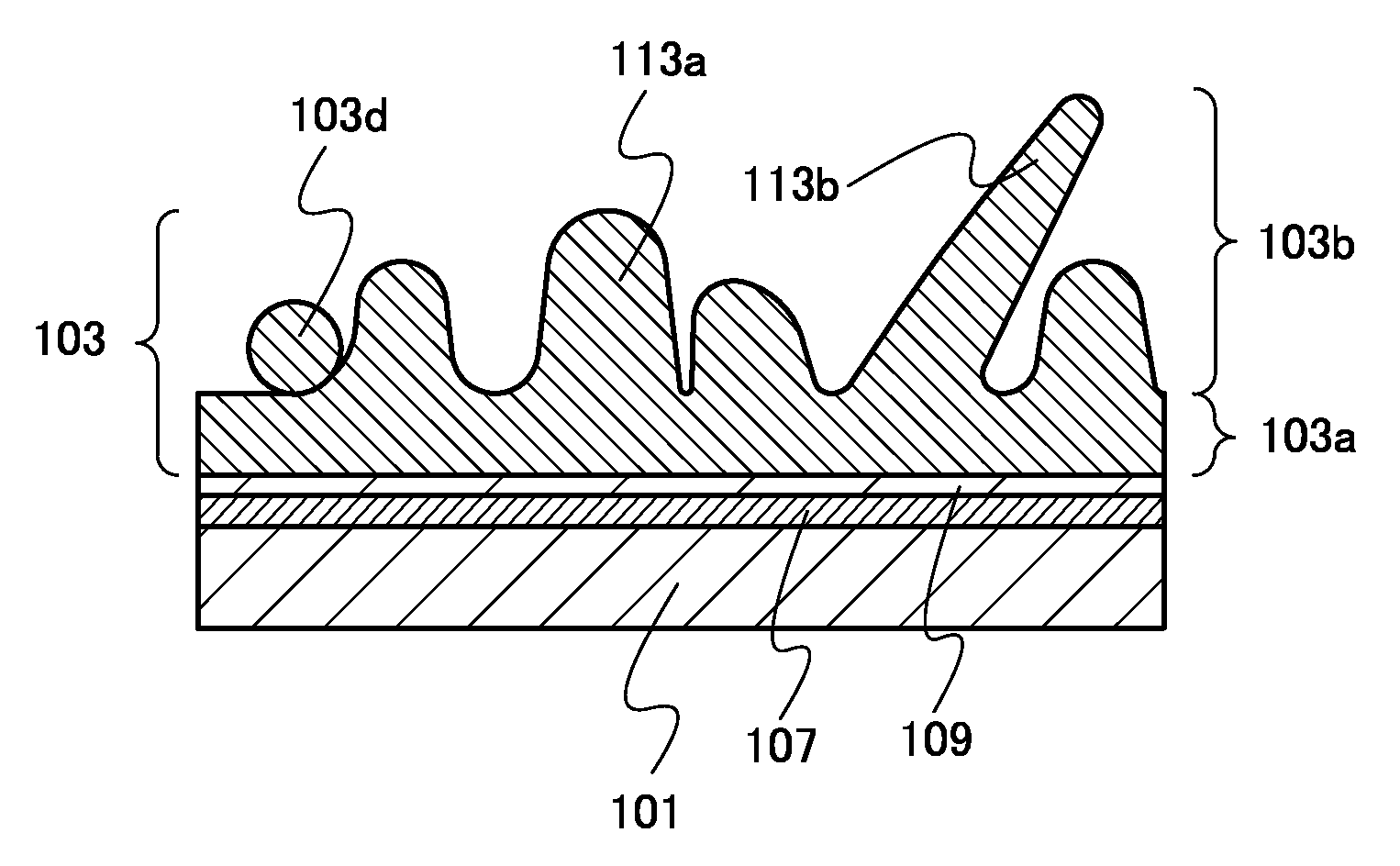

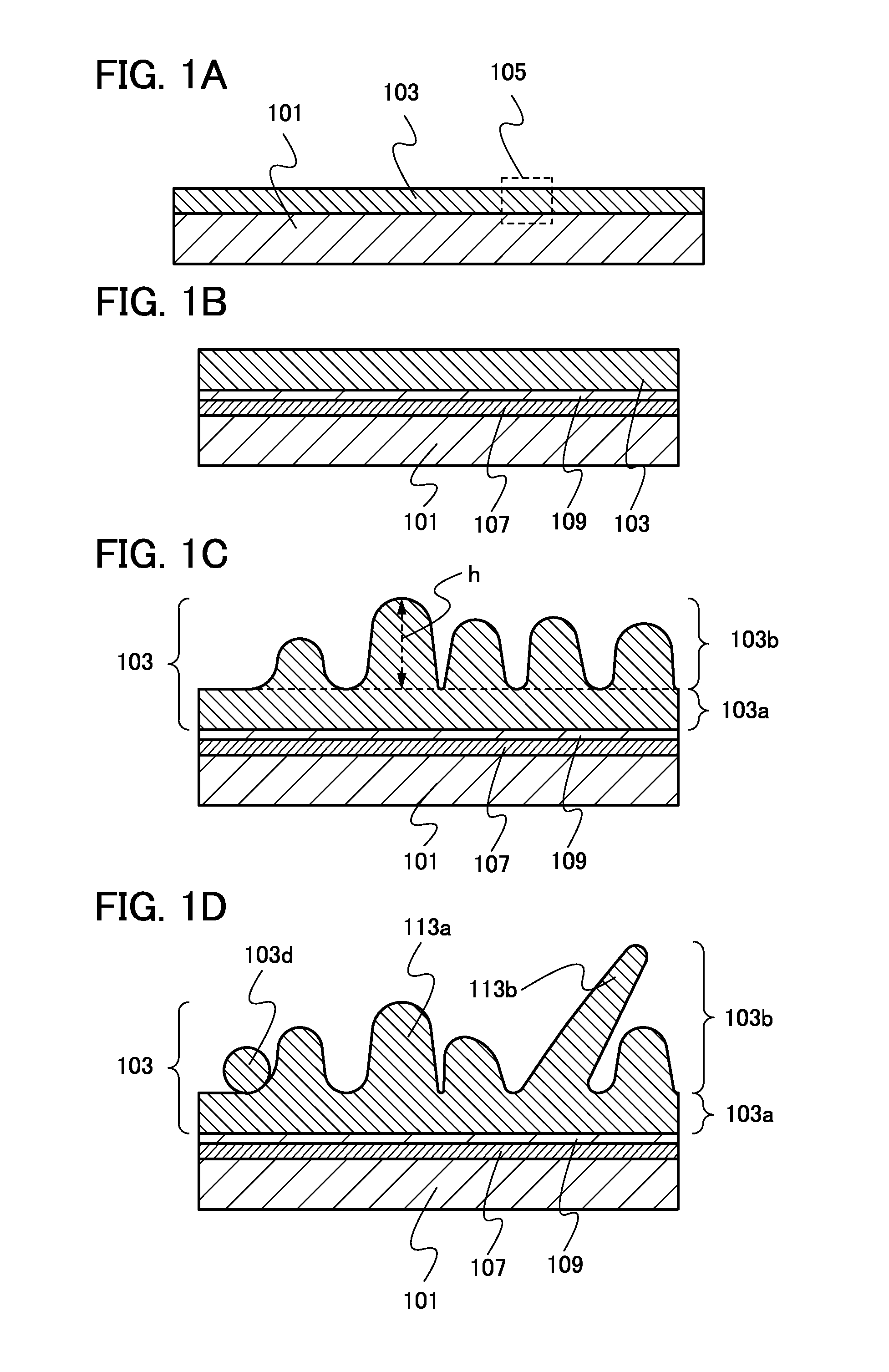

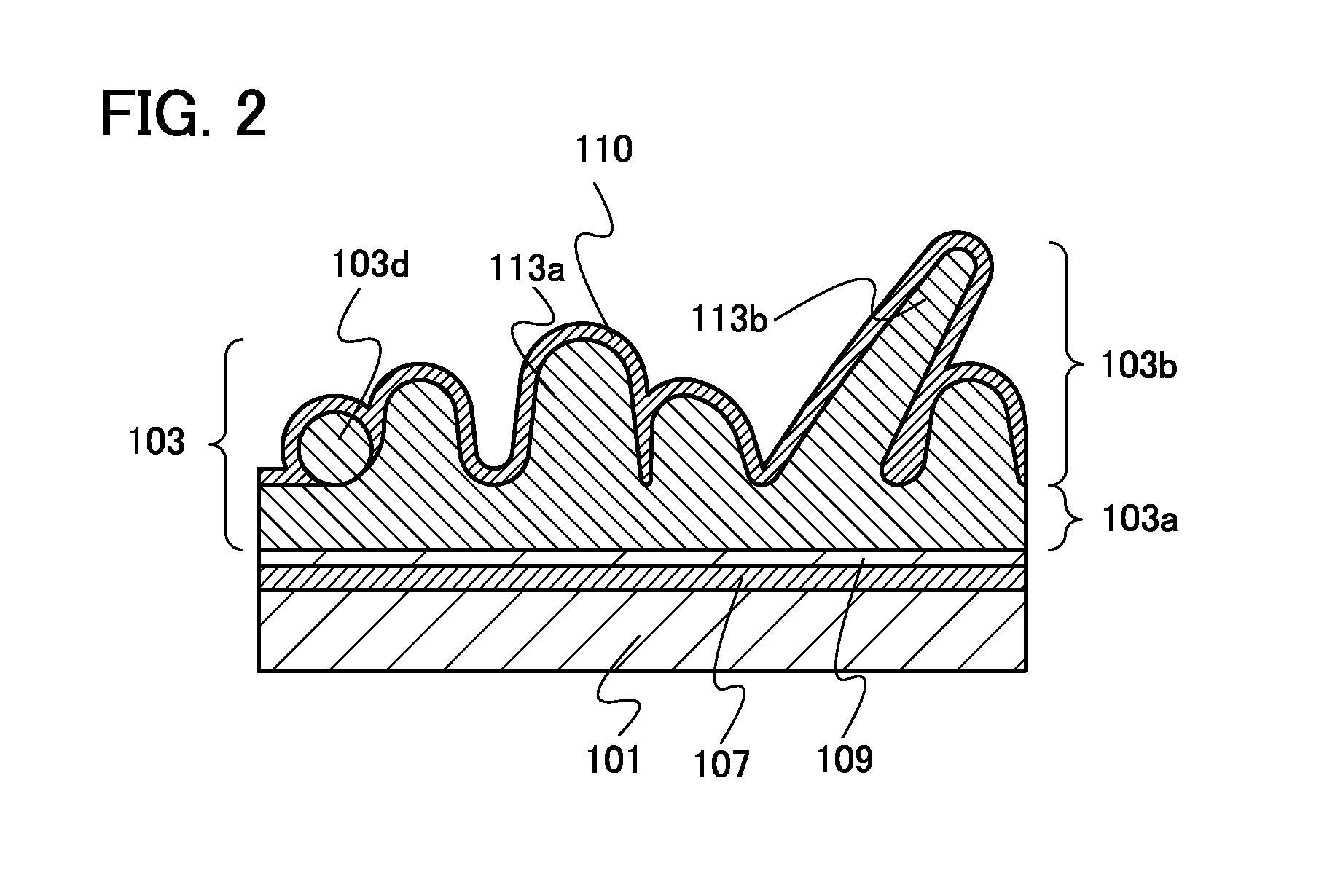

Energy storage device and method for manufacturing the same

PatentInactiveUS20120003535A1

Innovation

- Introducing lithium into a silicon layer through various methods such as applying a lithium solution or particles followed by heat treatment, ensuring a higher lithium concentration in the superficial portion of the negative electrode active material to enhance conductivity and reduce internal resistance.

Liquid-type room-temperature fluoride ion batteries

PatentWO2020118118A1

Innovation

- The development of fluoride ion batteries with a rare-earth or alkaline earth metal anode having a solid electrolyte interphase layer and a transition metal cathode with shell structures, utilizing a liquid fluoride electrolyte to prevent metal dissolution and enhance charge/discharge efficiency.

Environmental Impact and Sustainability Assessment

The environmental footprint of energy storage technologies has become increasingly critical as the world transitions toward sustainable energy systems. When comparing lithium fluoride (LiF) and lithium-ion batteries, their environmental impacts differ significantly across the entire lifecycle.

Lithium-ion batteries present substantial environmental challenges during raw material extraction. The mining of lithium, cobalt, and nickel causes habitat destruction, water pollution, and soil contamination. These processes are energy-intensive and often occur in ecologically sensitive regions. In contrast, lithium fluoride technology requires fewer rare earth elements and toxic metals, potentially reducing the environmental burden associated with resource extraction.

Manufacturing processes for conventional lithium-ion batteries involve energy-intensive production steps and toxic chemicals that generate significant carbon emissions. The production of lithium fluoride-based storage systems generally requires less complex manufacturing processes and fewer hazardous materials, resulting in a potentially lower carbon footprint during production.

Operational sustainability metrics favor lithium fluoride technology in several aspects. LiF-based systems typically demonstrate longer cycle life and greater thermal stability than conventional lithium-ion batteries, reducing replacement frequency and associated environmental impacts. Additionally, lithium fluoride storage systems operate efficiently across wider temperature ranges without requiring energy-intensive cooling systems that increase operational carbon footprints.

End-of-life management presents distinct challenges for both technologies. Current lithium-ion recycling infrastructure remains inadequate, with less than 5% of lithium-ion batteries effectively recycled globally. The complex mixture of materials in lithium-ion batteries complicates recycling processes. Lithium fluoride systems potentially offer simpler material separation and recovery, though dedicated recycling infrastructure would need development as the technology scales.

Water consumption patterns differ significantly between these technologies. Lithium extraction for conventional batteries requires approximately 500,000 gallons of water per ton of lithium, primarily in water-stressed regions. Lithium fluoride production generally requires less water intensity, presenting an advantage in regions facing water scarcity challenges.

Carbon footprint analysis reveals that lithium-ion batteries generate approximately 73-200 kg CO2-equivalent per kWh of storage capacity throughout their lifecycle. Preliminary assessments suggest lithium fluoride technologies could reduce this impact by 30-40% through simplified material requirements and manufacturing processes, though more comprehensive lifecycle assessments are needed as the technology matures.

Resource circularity potential appears more promising for lithium fluoride systems due to their simpler chemical composition and fewer component materials, potentially enabling more efficient material recovery and reuse in second-life applications.

Lithium-ion batteries present substantial environmental challenges during raw material extraction. The mining of lithium, cobalt, and nickel causes habitat destruction, water pollution, and soil contamination. These processes are energy-intensive and often occur in ecologically sensitive regions. In contrast, lithium fluoride technology requires fewer rare earth elements and toxic metals, potentially reducing the environmental burden associated with resource extraction.

Manufacturing processes for conventional lithium-ion batteries involve energy-intensive production steps and toxic chemicals that generate significant carbon emissions. The production of lithium fluoride-based storage systems generally requires less complex manufacturing processes and fewer hazardous materials, resulting in a potentially lower carbon footprint during production.

Operational sustainability metrics favor lithium fluoride technology in several aspects. LiF-based systems typically demonstrate longer cycle life and greater thermal stability than conventional lithium-ion batteries, reducing replacement frequency and associated environmental impacts. Additionally, lithium fluoride storage systems operate efficiently across wider temperature ranges without requiring energy-intensive cooling systems that increase operational carbon footprints.

End-of-life management presents distinct challenges for both technologies. Current lithium-ion recycling infrastructure remains inadequate, with less than 5% of lithium-ion batteries effectively recycled globally. The complex mixture of materials in lithium-ion batteries complicates recycling processes. Lithium fluoride systems potentially offer simpler material separation and recovery, though dedicated recycling infrastructure would need development as the technology scales.

Water consumption patterns differ significantly between these technologies. Lithium extraction for conventional batteries requires approximately 500,000 gallons of water per ton of lithium, primarily in water-stressed regions. Lithium fluoride production generally requires less water intensity, presenting an advantage in regions facing water scarcity challenges.

Carbon footprint analysis reveals that lithium-ion batteries generate approximately 73-200 kg CO2-equivalent per kWh of storage capacity throughout their lifecycle. Preliminary assessments suggest lithium fluoride technologies could reduce this impact by 30-40% through simplified material requirements and manufacturing processes, though more comprehensive lifecycle assessments are needed as the technology matures.

Resource circularity potential appears more promising for lithium fluoride systems due to their simpler chemical composition and fewer component materials, potentially enabling more efficient material recovery and reuse in second-life applications.

Cost-Performance Analysis and Commercial Viability

The cost-performance ratio of energy storage technologies is a critical factor in determining their commercial viability. Lithium-ion batteries currently dominate the market with production costs ranging from $137-$250/kWh, having decreased significantly from over $1,000/kWh a decade ago due to manufacturing scale economies and technological improvements. In contrast, lithium fluoride-based solid-state batteries remain at the early development stage with estimated production costs between $400-$800/kWh, reflecting their complex manufacturing processes and limited production scale.

Performance metrics reveal distinct advantages for each technology. Lithium-ion batteries offer energy densities of 100-265 Wh/kg, cycle lives of 500-2,000 cycles, and charging efficiencies of 85-95%. Lithium fluoride-based systems demonstrate theoretical energy densities of 300-500 Wh/kg, potential cycle lives exceeding 3,000 cycles, and charging efficiencies of 90-98%, though these figures remain largely theoretical pending further development.

The commercial landscape shows lithium-ion technology has achieved market maturity with global production capacity exceeding 500 GWh annually and widespread adoption across consumer electronics, electric vehicles, and grid storage applications. Major manufacturers have established supply chains and continue to invest in production expansion, with projections indicating costs could fall below $100/kWh by 2025.

Lithium fluoride technology faces significant commercialization barriers despite its promising performance characteristics. These include manufacturing scalability challenges, material stability issues, and interface engineering complexities. Current commercial applications remain limited to specialized research projects and pilot demonstrations, with market-ready products likely 5-10 years away.

Return on investment calculations indicate lithium-ion systems typically achieve payback periods of 3-7 years depending on application and usage patterns. Lithium fluoride systems, while potentially offering longer operational lifespans that could improve lifetime economics, currently face prohibitive initial costs that extend theoretical payback periods to 8-15 years, beyond what most commercial entities consider viable.

Market adoption forecasts suggest lithium-ion technology will maintain dominance through 2030, with lithium fluoride potentially capturing niche high-performance applications by mid-decade before broader commercial viability emerges. The tipping point for widespread lithium fluoride adoption depends on manufacturing breakthroughs that could dramatically reduce production costs while maintaining performance advantages.

Performance metrics reveal distinct advantages for each technology. Lithium-ion batteries offer energy densities of 100-265 Wh/kg, cycle lives of 500-2,000 cycles, and charging efficiencies of 85-95%. Lithium fluoride-based systems demonstrate theoretical energy densities of 300-500 Wh/kg, potential cycle lives exceeding 3,000 cycles, and charging efficiencies of 90-98%, though these figures remain largely theoretical pending further development.

The commercial landscape shows lithium-ion technology has achieved market maturity with global production capacity exceeding 500 GWh annually and widespread adoption across consumer electronics, electric vehicles, and grid storage applications. Major manufacturers have established supply chains and continue to invest in production expansion, with projections indicating costs could fall below $100/kWh by 2025.

Lithium fluoride technology faces significant commercialization barriers despite its promising performance characteristics. These include manufacturing scalability challenges, material stability issues, and interface engineering complexities. Current commercial applications remain limited to specialized research projects and pilot demonstrations, with market-ready products likely 5-10 years away.

Return on investment calculations indicate lithium-ion systems typically achieve payback periods of 3-7 years depending on application and usage patterns. Lithium fluoride systems, while potentially offering longer operational lifespans that could improve lifetime economics, currently face prohibitive initial costs that extend theoretical payback periods to 8-15 years, beyond what most commercial entities consider viable.

Market adoption forecasts suggest lithium-ion technology will maintain dominance through 2030, with lithium fluoride potentially capturing niche high-performance applications by mid-decade before broader commercial viability emerges. The tipping point for widespread lithium fluoride adoption depends on manufacturing breakthroughs that could dramatically reduce production costs while maintaining performance advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!