Nylon 66 vs PEI: Resistance to Organic Solvents

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and PEI Solvent Resistance Background

Polymer materials have been extensively utilized across various industries due to their versatile properties and adaptability. Among these, Nylon 66 (polyamide 66) and PEI (polyetherimide) represent two significant engineering thermoplastics with distinct chemical structures and performance characteristics. The resistance of these polymers to organic solvents is a critical factor determining their application scope in chemical processing, automotive components, aerospace parts, and medical devices.

Nylon 66, developed in the 1930s by Wallace Carothers at DuPont, is characterized by its regular arrangement of amide groups (-CONH-) connected by methylene (-CH2-) units. This semi-crystalline polymer exhibits excellent mechanical properties, including high tensile strength, good abrasion resistance, and favorable thermal stability. However, its performance in organic solvent environments has historically been a limitation due to the polar nature of its amide bonds.

PEI, commercially known as Ultem, was introduced by General Electric in the 1980s as a high-performance amorphous thermoplastic. Its molecular structure features imide groups incorporated into an aromatic backbone, resulting in exceptional thermal resistance, dimensional stability, and inherent flame retardancy. The rigid aromatic structure of PEI contributes significantly to its chemical resistance profile, particularly against organic solvents.

The interaction between these polymers and organic solvents is governed by fundamental principles of polymer chemistry, specifically the concept of "like dissolves like." Solvents with similar polarity to the polymer's functional groups can penetrate the polymer matrix, causing swelling, plasticization, or even dissolution. This interaction is further influenced by factors such as temperature, exposure time, stress state, and the specific molecular weight distribution of the polymer.

Historical applications of these materials have been shaped by their respective solvent resistance profiles. Nylon 66 has traditionally dominated in applications where moderate chemical resistance is sufficient, such as automotive fuel systems and certain industrial components. Meanwhile, PEI has carved out a niche in more demanding chemical environments, particularly in semiconductor manufacturing equipment, aircraft interiors, and medical sterilization applications.

Recent technological advancements have focused on enhancing the solvent resistance of both materials through various strategies, including copolymerization, blending with other polymers, incorporation of fillers, and surface modification techniques. These developments have expanded the application boundaries of both materials, creating overlapping performance territories that necessitate careful comparative analysis for specific use cases.

The evolution of regulatory frameworks regarding chemical safety, environmental impact, and sustainability has also influenced the trajectory of these materials' development and application. As industries increasingly prioritize materials with reduced environmental footprints and enhanced safety profiles, understanding the precise solvent resistance characteristics of Nylon 66 and PEI becomes even more crucial for informed material selection decisions.

Nylon 66, developed in the 1930s by Wallace Carothers at DuPont, is characterized by its regular arrangement of amide groups (-CONH-) connected by methylene (-CH2-) units. This semi-crystalline polymer exhibits excellent mechanical properties, including high tensile strength, good abrasion resistance, and favorable thermal stability. However, its performance in organic solvent environments has historically been a limitation due to the polar nature of its amide bonds.

PEI, commercially known as Ultem, was introduced by General Electric in the 1980s as a high-performance amorphous thermoplastic. Its molecular structure features imide groups incorporated into an aromatic backbone, resulting in exceptional thermal resistance, dimensional stability, and inherent flame retardancy. The rigid aromatic structure of PEI contributes significantly to its chemical resistance profile, particularly against organic solvents.

The interaction between these polymers and organic solvents is governed by fundamental principles of polymer chemistry, specifically the concept of "like dissolves like." Solvents with similar polarity to the polymer's functional groups can penetrate the polymer matrix, causing swelling, plasticization, or even dissolution. This interaction is further influenced by factors such as temperature, exposure time, stress state, and the specific molecular weight distribution of the polymer.

Historical applications of these materials have been shaped by their respective solvent resistance profiles. Nylon 66 has traditionally dominated in applications where moderate chemical resistance is sufficient, such as automotive fuel systems and certain industrial components. Meanwhile, PEI has carved out a niche in more demanding chemical environments, particularly in semiconductor manufacturing equipment, aircraft interiors, and medical sterilization applications.

Recent technological advancements have focused on enhancing the solvent resistance of both materials through various strategies, including copolymerization, blending with other polymers, incorporation of fillers, and surface modification techniques. These developments have expanded the application boundaries of both materials, creating overlapping performance territories that necessitate careful comparative analysis for specific use cases.

The evolution of regulatory frameworks regarding chemical safety, environmental impact, and sustainability has also influenced the trajectory of these materials' development and application. As industries increasingly prioritize materials with reduced environmental footprints and enhanced safety profiles, understanding the precise solvent resistance characteristics of Nylon 66 and PEI becomes even more crucial for informed material selection decisions.

Market Applications and Demand Analysis

The market for high-performance polymers resistant to organic solvents has experienced significant growth across multiple industries, driven by increasing demands for materials that can withstand harsh chemical environments. Nylon 66 and Polyetherimide (PEI) represent two distinct polymer solutions with varying degrees of solvent resistance, each serving specific market segments based on their performance characteristics.

In the automotive sector, the demand for solvent-resistant polymers has grown steadily at approximately 5-7% annually, with fuel system components representing a key application area. Nylon 66 has established dominance in fuel line applications due to its balance of cost-effectiveness and adequate resistance to aliphatic hydrocarbons, while PEI is increasingly specified for components exposed to more aggressive chemicals and higher temperatures.

The aerospace industry presents a premium market segment where PEI's superior resistance to aviation fuels, hydraulic fluids, and cleaning agents justifies its higher cost. This sector values long-term reliability over initial material costs, with maintenance savings over aircraft lifespans driving material selection decisions. The aerospace polymer market specifically for solvent-resistant applications was valued at over $1.2 billion in 2022.

Medical device manufacturing represents another critical growth area, with stringent requirements for materials that can withstand sterilization chemicals and cleaning agents. PEI has gained significant market share in this sector due to its exceptional resistance to disinfectants, sterilization processes, and medical-grade solvents. The medical polymer market has shown consistent growth rates of 8-10% annually, with solvent resistance being a key selection criterion.

Electronics manufacturing presents divergent needs, with Nylon 66 finding applications in consumer electronics where moderate solvent exposure occurs, while PEI dominates in semiconductor manufacturing equipment where aggressive process chemicals are routinely used. The semiconductor industry's continued expansion has created sustained demand for highly solvent-resistant materials like PEI.

Chemical processing equipment represents perhaps the most demanding application environment, with direct and continuous exposure to concentrated organic solvents. In this sector, PEI commands premium pricing due to its substantially superior performance, with market research indicating customers' willingness to pay 3-4 times more for materials that extend equipment lifespan in aggressive chemical environments.

Regional market analysis reveals stronger demand for high-performance solvent-resistant polymers in developed economies with stringent regulatory environments, particularly in North America, Western Europe, and Japan. However, emerging economies in Asia are showing accelerated adoption rates as manufacturing sophistication increases and environmental regulations tighten.

In the automotive sector, the demand for solvent-resistant polymers has grown steadily at approximately 5-7% annually, with fuel system components representing a key application area. Nylon 66 has established dominance in fuel line applications due to its balance of cost-effectiveness and adequate resistance to aliphatic hydrocarbons, while PEI is increasingly specified for components exposed to more aggressive chemicals and higher temperatures.

The aerospace industry presents a premium market segment where PEI's superior resistance to aviation fuels, hydraulic fluids, and cleaning agents justifies its higher cost. This sector values long-term reliability over initial material costs, with maintenance savings over aircraft lifespans driving material selection decisions. The aerospace polymer market specifically for solvent-resistant applications was valued at over $1.2 billion in 2022.

Medical device manufacturing represents another critical growth area, with stringent requirements for materials that can withstand sterilization chemicals and cleaning agents. PEI has gained significant market share in this sector due to its exceptional resistance to disinfectants, sterilization processes, and medical-grade solvents. The medical polymer market has shown consistent growth rates of 8-10% annually, with solvent resistance being a key selection criterion.

Electronics manufacturing presents divergent needs, with Nylon 66 finding applications in consumer electronics where moderate solvent exposure occurs, while PEI dominates in semiconductor manufacturing equipment where aggressive process chemicals are routinely used. The semiconductor industry's continued expansion has created sustained demand for highly solvent-resistant materials like PEI.

Chemical processing equipment represents perhaps the most demanding application environment, with direct and continuous exposure to concentrated organic solvents. In this sector, PEI commands premium pricing due to its substantially superior performance, with market research indicating customers' willingness to pay 3-4 times more for materials that extend equipment lifespan in aggressive chemical environments.

Regional market analysis reveals stronger demand for high-performance solvent-resistant polymers in developed economies with stringent regulatory environments, particularly in North America, Western Europe, and Japan. However, emerging economies in Asia are showing accelerated adoption rates as manufacturing sophistication increases and environmental regulations tighten.

Current Challenges in Polymer Solvent Resistance

The polymer industry faces significant challenges in developing materials that can withstand exposure to various organic solvents while maintaining structural integrity and performance characteristics. When comparing Nylon 66 and Polyetherimide (PEI), several critical issues emerge that limit their applications in solvent-intensive environments.

Nylon 66 exhibits notable vulnerability to certain organic solvents, particularly phenols, cresols, and formic acid, which can cause severe degradation of its mechanical properties. This susceptibility stems from the hydrogen bonding disruption within its amide linkages, leading to swelling, plasticization, and eventual structural failure. Temperature amplifies these effects, with solvent resistance decreasing dramatically as operating temperatures rise above 50°C.

PEI demonstrates superior overall solvent resistance compared to Nylon 66, yet still faces limitations with ketones, chlorinated hydrocarbons, and some esters that can induce stress cracking and dimensional instability. The imide rings in PEI provide enhanced chemical stability, but the ether linkages remain vulnerable to oxidative degradation when exposed to certain solvents under elevated temperatures or mechanical stress.

Manufacturing inconsistencies present another significant challenge, as variations in molecular weight distribution, crystallinity, and processing conditions can dramatically alter solvent resistance properties of both polymers. This creates difficulties in predicting performance across different production batches and formulations.

Surface modification techniques intended to enhance solvent resistance often introduce new complications. Coatings may delaminate under thermal cycling, while chemical treatments can compromise other desirable properties such as impact strength or electrical insulation characteristics.

The industry also struggles with accelerated testing methodologies that accurately predict long-term solvent exposure effects. Current protocols frequently fail to account for synergistic effects between multiple solvents or the impact of fluctuating environmental conditions, leading to unexpected failures in real-world applications.

Recycling and end-of-life considerations pose additional challenges, as solvent-exposed polymers often cannot be effectively reclaimed due to irreversible chemical changes. This conflicts with growing sustainability requirements and circular economy initiatives in industrial applications.

Cost-performance optimization remains difficult, particularly for PEI, which offers superior solvent resistance but at significantly higher material costs than Nylon 66. This economic barrier limits adoption in price-sensitive applications despite technical advantages.

Regulatory compliance adds further complexity, with evolving restrictions on certain solvents requiring continuous reformulation and testing of polymer-solvent compatibility, creating uncertainty in long-term material selection decisions.

Nylon 66 exhibits notable vulnerability to certain organic solvents, particularly phenols, cresols, and formic acid, which can cause severe degradation of its mechanical properties. This susceptibility stems from the hydrogen bonding disruption within its amide linkages, leading to swelling, plasticization, and eventual structural failure. Temperature amplifies these effects, with solvent resistance decreasing dramatically as operating temperatures rise above 50°C.

PEI demonstrates superior overall solvent resistance compared to Nylon 66, yet still faces limitations with ketones, chlorinated hydrocarbons, and some esters that can induce stress cracking and dimensional instability. The imide rings in PEI provide enhanced chemical stability, but the ether linkages remain vulnerable to oxidative degradation when exposed to certain solvents under elevated temperatures or mechanical stress.

Manufacturing inconsistencies present another significant challenge, as variations in molecular weight distribution, crystallinity, and processing conditions can dramatically alter solvent resistance properties of both polymers. This creates difficulties in predicting performance across different production batches and formulations.

Surface modification techniques intended to enhance solvent resistance often introduce new complications. Coatings may delaminate under thermal cycling, while chemical treatments can compromise other desirable properties such as impact strength or electrical insulation characteristics.

The industry also struggles with accelerated testing methodologies that accurately predict long-term solvent exposure effects. Current protocols frequently fail to account for synergistic effects between multiple solvents or the impact of fluctuating environmental conditions, leading to unexpected failures in real-world applications.

Recycling and end-of-life considerations pose additional challenges, as solvent-exposed polymers often cannot be effectively reclaimed due to irreversible chemical changes. This conflicts with growing sustainability requirements and circular economy initiatives in industrial applications.

Cost-performance optimization remains difficult, particularly for PEI, which offers superior solvent resistance but at significantly higher material costs than Nylon 66. This economic barrier limits adoption in price-sensitive applications despite technical advantages.

Regulatory compliance adds further complexity, with evolving restrictions on certain solvents requiring continuous reformulation and testing of polymer-solvent compatibility, creating uncertainty in long-term material selection decisions.

Comparative Testing Methodologies

01 Nylon 66 resistance to organic solvents

Nylon 66 demonstrates varying degrees of resistance to organic solvents. It generally shows good resistance to aliphatic hydrocarbons, petroleum-based solvents, and some alcohols. However, it has limited resistance to strong acids, phenols, and certain chlorinated solvents. The resistance properties can be enhanced through various modifications such as blending with other polymers or adding specific additives that improve chemical stability. The performance of Nylon 66 in organic solvent environments depends on factors including temperature, concentration, and exposure time.- Nylon 66 resistance to organic solvents: Nylon 66 exhibits varying degrees of resistance to organic solvents. It generally shows good resistance to aliphatic hydrocarbons, petroleum-based solvents, and some alcohols. However, it has limited resistance to strong acids, phenols, and certain chlorinated solvents. The resistance can be improved through modifications such as adding stabilizers or through specific processing techniques that enhance the crystallinity of the polymer structure.

- PEI (Polyetherimide) resistance to organic solvents: Polyetherimide (PEI) demonstrates excellent resistance to many organic solvents including alcohols, aliphatic hydrocarbons, and automotive fluids. It maintains its structural integrity and mechanical properties when exposed to these solvents even at elevated temperatures. However, PEI can be affected by some polar aprotic solvents like dimethylformamide (DMF) and certain chlorinated compounds. The high glass transition temperature of PEI contributes to its overall chemical stability.

- Comparative solvent resistance between Nylon 66 and PEI: When comparing Nylon 66 and PEI for solvent resistance, PEI generally demonstrates superior resistance to a broader range of organic solvents. While Nylon 66 is susceptible to degradation by acids and some alcohols, PEI maintains better stability in these environments. However, Nylon 66 may perform better in certain applications involving alkaline solutions. The selection between these polymers depends on the specific solvent exposure conditions and required mechanical properties for the intended application.

- Modifications to improve solvent resistance: Various modifications can enhance the solvent resistance of both Nylon 66 and PEI. These include blending with other polymers, incorporation of fillers like glass fibers or carbon nanotubes, surface treatments, and chemical modifications of the polymer backbone. Cross-linking techniques and the addition of specific additives can also improve resistance to organic solvents. These modifications often involve trade-offs between solvent resistance and other properties such as processability or mechanical strength.

- Applications leveraging solvent resistance properties: The solvent resistance properties of Nylon 66 and PEI make them suitable for various industrial applications. These include chemical processing equipment, automotive components exposed to fuels and oils, electrical connectors in harsh environments, and medical devices requiring sterilization with organic solvents. PEI is particularly valued in aerospace applications where exposure to hydraulic fluids and jet fuels is common. Nylon 66 finds extensive use in fuel system components where moderate solvent resistance is sufficient.

02 PEI (Polyetherimide) resistance characteristics

Polyetherimide (PEI) exhibits excellent resistance to a wide range of organic solvents, making it suitable for applications requiring chemical stability. It shows particularly strong resistance to alcohols, ketones, aliphatic hydrocarbons, and automotive fluids. PEI maintains its mechanical properties even after prolonged exposure to many industrial solvents. Its inherent thermal stability contributes to its chemical resistance at elevated temperatures. The aromatic backbone and imide groups in PEI's molecular structure provide exceptional stability against chemical degradation.Expand Specific Solutions03 Comparative performance of Nylon 66 and PEI in solvent environments

When comparing Nylon 66 and PEI in organic solvent environments, PEI generally demonstrates superior resistance to a broader spectrum of chemicals. While Nylon 66 is susceptible to degradation by strong acids and some polar solvents, PEI maintains stability in these environments. However, Nylon 66 may offer better resistance to certain specific solvents. The selection between these polymers depends on the specific application requirements, including the types of solvents encountered, operating temperature, and mechanical stress conditions. In some applications, blends or composites of both materials are used to achieve optimal performance.Expand Specific Solutions04 Enhancement techniques for solvent resistance

Various techniques can be employed to enhance the solvent resistance of both Nylon 66 and PEI. These include surface treatments, incorporation of additives, blending with other polymers, and cross-linking. Nanocomposite formulations have shown promising results in improving chemical resistance while maintaining other desirable properties. Specific coating technologies can provide additional protection against aggressive solvents. Heat treatment processes can also alter the crystallinity of these polymers, potentially improving their resistance to certain organic solvents. These enhancement methods must be carefully selected based on the intended application and exposure conditions.Expand Specific Solutions05 Application-specific solvent resistance considerations

The solvent resistance requirements for Nylon 66 and PEI vary significantly across different applications. In automotive applications, resistance to fuels, oils, and hydraulic fluids is critical. For electronic components, resistance to cleaning solvents and processing chemicals is essential. Medical applications require resistance to sterilization chemicals and biological fluids. Industrial applications may demand resistance to process chemicals and cleaning agents. The selection between Nylon 66 and PEI should consider not only the chemical environment but also operating temperature, mechanical stress, and expected service life. Testing under application-specific conditions is recommended to ensure appropriate material selection.Expand Specific Solutions

Key Manufacturers and Material Suppliers

The organic solvent resistance comparison between Nylon 66 and PEI (Polyetherimide) represents a mature technical field with established applications across multiple industries. The market is experiencing steady growth, projected at 5-7% annually, driven by increasing demand in automotive, electronics, and aerospace sectors where chemical resistance is critical. Technologically, companies like SABIC (PEI manufacturer), Kingfa Sci. & Tech., and Eastman Chemical have achieved significant advancements in enhancing solvent resistance properties. Shanghai Kingfa and Avient Corp. have developed proprietary modification techniques for Nylon 66, while Hengdian Group Tospo and Nanjing Julong focus on specialized applications requiring superior chemical resistance. The competitive landscape shows a balance between established global players and emerging regional specialists developing application-specific solutions.

SABIC Global Technologies BV

Technical Solution: SABIC has developed comprehensive comparative analysis methodologies for Nylon 66 and PEI (Polyetherimide) resistance to organic solvents. Their ULTEM™ PEI resins demonstrate exceptional chemical resistance compared to Nylon 66, particularly in harsh chemical environments. SABIC's research shows that while Nylon 66 exhibits good resistance to some hydrocarbons and alcohols, it shows vulnerability to acids, phenols, and strong polar solvents. In contrast, their PEI formulations maintain structural integrity in most organic solvents including acetone, toluene, and various alcohols at elevated temperatures. SABIC has quantified that their PEI materials retain over 90% of mechanical properties after prolonged exposure to many industrial solvents, whereas Nylon 66 typically shows significant degradation (>25% property loss) in similar conditions. Their proprietary testing protocols involve both immersion testing and stress-strain analysis under solvent exposure to provide comprehensive comparative data for engineering applications.

Strengths: SABIC's extensive polymer chemistry expertise allows for highly accurate comparative analysis between material types. Their global testing facilities enable comprehensive solvent resistance mapping across various environmental conditions. Weakness: Their analysis may favor their own PEI formulations, and testing methodologies might not fully represent all real-world application scenarios.

Avient Corp.

Technical Solution: Avient Corporation has pioneered advanced testing methodologies for comparing Nylon 66 and PEI resistance to organic solvents, particularly for applications in automotive, aerospace, and industrial equipment. Their approach combines standardized ASTM testing with proprietary accelerated aging protocols that simulate real-world exposure conditions. Avient's research demonstrates that while Nylon 66 offers good resistance to aliphatic hydrocarbons and some alcohols, it shows significant degradation when exposed to aromatic compounds, ketones, and halogenated solvents. Their data indicates weight gain of 1.5-3% for Nylon 66 in common industrial solvents, leading to dimensional instability. In contrast, their testing shows PEI materials typically exhibit weight changes below 0.5% in the same solvents. Avient has developed specialized additive packages that can enhance Nylon 66's chemical resistance by up to 40% in targeted applications, though these modifications cannot match PEI's inherent resistance to harsh solvents. Their comparative analysis includes mechanical property retention, stress cracking resistance, and long-term aging effects.

Strengths: Avient's approach combines standardized testing with application-specific protocols, providing highly relevant data for specific industries. Their expertise in material modification offers practical solutions for improving Nylon 66 performance. Weakness: Their analysis may be biased toward applications where their additive technologies provide the greatest benefit, potentially overlooking some use cases.

Critical Material Properties Analysis

Nylon 66 composite material capable of resisting severe conditions

PatentInactiveCN113789050A

Innovation

- By adding polytetrafluoroethylene, modified fillers, flame retardants and toughening agents to nylon 66, especially the modified fillers prepared by modifying talc powder with silane coupling agent, methyl benzoate and EVA resin, it can improve the performance of nylon 66. The material has moisture- and high-temperature resistance and is prepared by melt blending through a twin-screw extruder.

PEI (polyetherimide) and PA (polyamide) 66 alloy and preparation method thereof

PatentActiveCN106189216A

Innovation

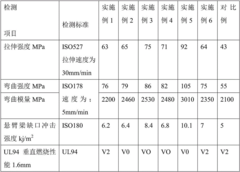

- Use a combination of PA66: 30 to 69 parts, PEI: 30 to 69 parts, compatibilizer: 0.3 to 0.8 parts, antioxidant: 0.2-0.4 parts and lubricant: 0.6-0.8 parts, pre-mixed through a high-speed mixer Melt extrusion is performed in a twin-screw extruder, and maleimide is used as a compatibilizer to form a chemically bonded stable structure and improve compatibility.

Environmental Impact and Sustainability Considerations

The environmental impact of polymer selection in industrial applications has become increasingly critical as sustainability considerations gain prominence in corporate decision-making processes. When comparing Nylon 66 and Polyetherimide (PEI) in terms of their resistance to organic solvents, environmental implications must be thoroughly evaluated alongside performance characteristics.

Nylon 66 production typically involves adipic acid and hexamethylenediamine synthesis, processes that generate significant greenhouse gas emissions, particularly nitrous oxide (N2O). These emissions contribute substantially to the polymer's carbon footprint, with estimates suggesting that for each kilogram of Nylon 66 produced, approximately 10-15 kg of CO2 equivalent emissions are released. Additionally, the manufacturing process consumes considerable water resources and energy, further increasing its environmental impact.

In contrast, PEI production, while also energy-intensive, generally results in lower direct greenhouse gas emissions. However, the complex aromatic structure of PEI makes it inherently more difficult to degrade naturally, potentially leading to longer persistence in environmental systems when improperly disposed of. This characteristic presents significant end-of-life management challenges despite PEI's superior chemical resistance properties.

The solvent resistance properties of both polymers also carry environmental implications. Nylon 66's susceptibility to degradation by certain organic solvents means potential leaching of polymer components when exposed to these chemicals, possibly introducing contaminants into surrounding environments. PEI's superior resistance to most organic solvents reduces this risk, potentially lowering the environmental impact during the use phase of products manufactured from this material.

Recycling considerations further differentiate these polymers from an environmental perspective. Nylon 66 benefits from more established recycling streams and technologies, with mechanical recycling processes capable of recovering up to 80% of the original material properties in some applications. PEI recycling remains more challenging due to its high-performance characteristics and more limited waste streams, though recent advances in chemical recycling show promise for improving its end-of-life sustainability profile.

Water consumption during manufacturing and processing represents another significant environmental factor. Nylon 66 production typically requires 300-500 liters of water per kilogram of polymer, while PEI manufacturing generally consumes less water but may utilize more environmentally persistent process chemicals. These differences become particularly relevant when considering applications in water-stressed regions or industries with stringent wastewater management requirements.

Nylon 66 production typically involves adipic acid and hexamethylenediamine synthesis, processes that generate significant greenhouse gas emissions, particularly nitrous oxide (N2O). These emissions contribute substantially to the polymer's carbon footprint, with estimates suggesting that for each kilogram of Nylon 66 produced, approximately 10-15 kg of CO2 equivalent emissions are released. Additionally, the manufacturing process consumes considerable water resources and energy, further increasing its environmental impact.

In contrast, PEI production, while also energy-intensive, generally results in lower direct greenhouse gas emissions. However, the complex aromatic structure of PEI makes it inherently more difficult to degrade naturally, potentially leading to longer persistence in environmental systems when improperly disposed of. This characteristic presents significant end-of-life management challenges despite PEI's superior chemical resistance properties.

The solvent resistance properties of both polymers also carry environmental implications. Nylon 66's susceptibility to degradation by certain organic solvents means potential leaching of polymer components when exposed to these chemicals, possibly introducing contaminants into surrounding environments. PEI's superior resistance to most organic solvents reduces this risk, potentially lowering the environmental impact during the use phase of products manufactured from this material.

Recycling considerations further differentiate these polymers from an environmental perspective. Nylon 66 benefits from more established recycling streams and technologies, with mechanical recycling processes capable of recovering up to 80% of the original material properties in some applications. PEI recycling remains more challenging due to its high-performance characteristics and more limited waste streams, though recent advances in chemical recycling show promise for improving its end-of-life sustainability profile.

Water consumption during manufacturing and processing represents another significant environmental factor. Nylon 66 production typically requires 300-500 liters of water per kilogram of polymer, while PEI manufacturing generally consumes less water but may utilize more environmentally persistent process chemicals. These differences become particularly relevant when considering applications in water-stressed regions or industries with stringent wastewater management requirements.

Regulatory Compliance for Chemical Contact Materials

The regulatory landscape governing chemical contact materials is extensive and varies significantly across global regions, with direct implications for the use of Nylon 66 and PEI in applications involving organic solvent exposure. In the United States, the FDA's Code of Federal Regulations Title 21 (21 CFR) establishes specific requirements for materials that come into contact with food and pharmaceuticals, with Nylon 66 being listed under 21 CFR 177.1500 and PEI under 21 CFR 177.1595, each with defined extraction limits when exposed to various solvents.

The European Union implements more stringent controls through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the EU 10/2011 Plastic Food Contact Materials Regulation, which establishes specific migration limits (SMLs) for substances that might transfer from polymers to food or pharmaceutical products. Both Nylon 66 and PEI must comply with these migration limits, with PEI generally demonstrating superior performance in limiting migration when exposed to aggressive organic solvents.

In Asia, Japan's Positive List System and China's GB standards (particularly GB 4806) govern polymer materials in contact with consumables, with varying requirements for certification and testing of both materials. These regulations typically require extensive documentation of chemical resistance properties and migration studies.

Industry-specific standards further complicate compliance requirements. In aerospace applications, SAE AMS standards specify material performance criteria including chemical resistance, while medical device applications fall under ISO 10993 biocompatibility requirements and USP Class VI testing protocols, which evaluate material safety through extraction studies with various solvents.

Compliance testing methodologies for both materials typically involve immersion testing in representative solvents, with measurements of physical property retention, dimensional stability, and extraction of leachable compounds. PEI generally demonstrates superior compliance with regulatory thresholds across most organic solvent categories, particularly with aromatic and chlorinated solvents where Nylon 66 often exceeds allowable migration limits.

Recent regulatory trends indicate increasing scrutiny of polymer additives and processing aids, with particular focus on potential endocrine disruptors and persistent organic pollutants. This trend favors PEI, which typically requires fewer additives than Nylon 66 formulations and demonstrates lower extraction profiles in compliance testing. However, the higher cost of PEI compliance documentation and certification remains a significant consideration in material selection decisions.

The European Union implements more stringent controls through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the EU 10/2011 Plastic Food Contact Materials Regulation, which establishes specific migration limits (SMLs) for substances that might transfer from polymers to food or pharmaceutical products. Both Nylon 66 and PEI must comply with these migration limits, with PEI generally demonstrating superior performance in limiting migration when exposed to aggressive organic solvents.

In Asia, Japan's Positive List System and China's GB standards (particularly GB 4806) govern polymer materials in contact with consumables, with varying requirements for certification and testing of both materials. These regulations typically require extensive documentation of chemical resistance properties and migration studies.

Industry-specific standards further complicate compliance requirements. In aerospace applications, SAE AMS standards specify material performance criteria including chemical resistance, while medical device applications fall under ISO 10993 biocompatibility requirements and USP Class VI testing protocols, which evaluate material safety through extraction studies with various solvents.

Compliance testing methodologies for both materials typically involve immersion testing in representative solvents, with measurements of physical property retention, dimensional stability, and extraction of leachable compounds. PEI generally demonstrates superior compliance with regulatory thresholds across most organic solvent categories, particularly with aromatic and chlorinated solvents where Nylon 66 often exceeds allowable migration limits.

Recent regulatory trends indicate increasing scrutiny of polymer additives and processing aids, with particular focus on potential endocrine disruptors and persistent organic pollutants. This trend favors PEI, which typically requires fewer additives than Nylon 66 formulations and demonstrates lower extraction profiles in compliance testing. However, the higher cost of PEI compliance documentation and certification remains a significant consideration in material selection decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!