Nylon 66 vs TPA: Corrosion Resistance in Chemical Environments

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and TPA Corrosion Resistance Background

The evolution of engineering polymers has significantly impacted various industries, with Nylon 66 and Thermoplastic Polyamide (TPA) emerging as critical materials for applications requiring chemical resistance. Nylon 66, first developed by Wallace Carothers at DuPont in 1935, represents one of the earliest synthetic polymers with commercial success. Its molecular structure, characterized by amide linkages formed between hexamethylenediamine and adipic acid, provides a unique combination of mechanical strength and moderate chemical resistance.

TPA, a more recent development in polymer science, encompasses a family of materials that maintain the basic polyamide structure while incorporating various modifications to enhance specific properties. These modifications often target improved resistance to hydrolysis and chemical attack, addressing some of the inherent limitations of traditional nylons.

The chemical resistance properties of these materials stem from their molecular architecture. Nylon 66 features a semi-crystalline structure with strong hydrogen bonding between polymer chains, contributing to its mechanical properties but also creating vulnerability to certain chemical environments. The amide groups (-CONH-) in the polymer backbone are particularly susceptible to attack by acids and certain oxidizing agents.

Historical applications of these materials reveal their evolving role in chemical environments. Initially, Nylon 66 found limited use in chemical processing equipment due to its vulnerability to acids and certain solvents. However, engineering advancements led to modified formulations with improved resistance profiles, expanding its application range.

The technological trajectory has shown consistent efforts to enhance the chemical resistance of polyamides. Early modifications included the addition of stabilizers and the development of copolymers. More recent innovations have focused on molecular architecture modifications, such as aromatic ring incorporation and cross-linking techniques, particularly evident in modern TPA formulations.

Industry standards for chemical resistance have evolved alongside these materials. The ASTM D543 test method for evaluating resistance of plastics to chemical reagents has become a benchmark for comparing materials like Nylon 66 and TPA. Similarly, ISO 175 provides standardized methods for determining the effects of liquid chemicals on polymeric materials.

The fundamental challenge in polyamide chemical resistance lies in balancing molecular mobility, crystallinity, and functional group accessibility. Higher crystallinity typically improves chemical resistance but may compromise other mechanical properties. This balance represents the core technical challenge that continues to drive innovation in this field.

TPA, a more recent development in polymer science, encompasses a family of materials that maintain the basic polyamide structure while incorporating various modifications to enhance specific properties. These modifications often target improved resistance to hydrolysis and chemical attack, addressing some of the inherent limitations of traditional nylons.

The chemical resistance properties of these materials stem from their molecular architecture. Nylon 66 features a semi-crystalline structure with strong hydrogen bonding between polymer chains, contributing to its mechanical properties but also creating vulnerability to certain chemical environments. The amide groups (-CONH-) in the polymer backbone are particularly susceptible to attack by acids and certain oxidizing agents.

Historical applications of these materials reveal their evolving role in chemical environments. Initially, Nylon 66 found limited use in chemical processing equipment due to its vulnerability to acids and certain solvents. However, engineering advancements led to modified formulations with improved resistance profiles, expanding its application range.

The technological trajectory has shown consistent efforts to enhance the chemical resistance of polyamides. Early modifications included the addition of stabilizers and the development of copolymers. More recent innovations have focused on molecular architecture modifications, such as aromatic ring incorporation and cross-linking techniques, particularly evident in modern TPA formulations.

Industry standards for chemical resistance have evolved alongside these materials. The ASTM D543 test method for evaluating resistance of plastics to chemical reagents has become a benchmark for comparing materials like Nylon 66 and TPA. Similarly, ISO 175 provides standardized methods for determining the effects of liquid chemicals on polymeric materials.

The fundamental challenge in polyamide chemical resistance lies in balancing molecular mobility, crystallinity, and functional group accessibility. Higher crystallinity typically improves chemical resistance but may compromise other mechanical properties. This balance represents the core technical challenge that continues to drive innovation in this field.

Market Demand for Chemical-Resistant Polymers

The global market for chemical-resistant polymers has witnessed substantial growth over the past decade, driven primarily by increasing industrial applications requiring materials that can withstand harsh chemical environments. The combined market value for specialized chemical-resistant polymers reached approximately $32 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Within this expanding market, both Nylon 66 and Thermoplastic Polyamide (TPA) have established significant presence due to their superior chemical resistance properties compared to conventional polymers. The automotive industry represents the largest consumer segment, accounting for 34% of the total demand, followed by industrial equipment manufacturing at 28% and chemical processing equipment at 22%.

End-users across these industries consistently report increasing requirements for polymers that can withstand exposure to acids, bases, hydrocarbons, and various solvents while maintaining structural integrity. A recent industry survey revealed that 76% of manufacturing engineers consider chemical resistance as a "critical" or "very important" factor when selecting materials for components exposed to chemical environments.

The market demand is further segmented by specific performance requirements. Applications requiring resistance to strong acids and oxidizing agents represent 41% of the market, while resistance to petroleum-based products and organic solvents accounts for 37%. The remaining market share is distributed among specialized applications requiring resistance to bases, salts, and other chemical compounds.

Regional analysis indicates that Asia-Pacific dominates the market with a 42% share, driven by rapid industrialization in China and India. North America follows with 28%, while Europe accounts for 23% of the global demand. The remaining 7% is distributed across other regions, with the Middle East showing the fastest growth rate at 9.2% annually.

Price sensitivity varies significantly across application segments. High-performance applications in aerospace and medical devices demonstrate low price elasticity, with customers willing to pay premium prices for superior chemical resistance. In contrast, mass-market applications in consumer goods and general industrial components show higher price sensitivity, creating market opportunities for cost-effective solutions that maintain adequate chemical resistance properties.

Industry experts anticipate that future market growth will be driven by increasing regulatory pressures on chemical processing industries, growing demand for lightweight materials in transportation, and expanding applications in emerging economies. The development of polymers with enhanced chemical resistance while maintaining other desirable properties such as thermal stability and mechanical strength represents a significant market opportunity for material manufacturers.

Within this expanding market, both Nylon 66 and Thermoplastic Polyamide (TPA) have established significant presence due to their superior chemical resistance properties compared to conventional polymers. The automotive industry represents the largest consumer segment, accounting for 34% of the total demand, followed by industrial equipment manufacturing at 28% and chemical processing equipment at 22%.

End-users across these industries consistently report increasing requirements for polymers that can withstand exposure to acids, bases, hydrocarbons, and various solvents while maintaining structural integrity. A recent industry survey revealed that 76% of manufacturing engineers consider chemical resistance as a "critical" or "very important" factor when selecting materials for components exposed to chemical environments.

The market demand is further segmented by specific performance requirements. Applications requiring resistance to strong acids and oxidizing agents represent 41% of the market, while resistance to petroleum-based products and organic solvents accounts for 37%. The remaining market share is distributed among specialized applications requiring resistance to bases, salts, and other chemical compounds.

Regional analysis indicates that Asia-Pacific dominates the market with a 42% share, driven by rapid industrialization in China and India. North America follows with 28%, while Europe accounts for 23% of the global demand. The remaining 7% is distributed across other regions, with the Middle East showing the fastest growth rate at 9.2% annually.

Price sensitivity varies significantly across application segments. High-performance applications in aerospace and medical devices demonstrate low price elasticity, with customers willing to pay premium prices for superior chemical resistance. In contrast, mass-market applications in consumer goods and general industrial components show higher price sensitivity, creating market opportunities for cost-effective solutions that maintain adequate chemical resistance properties.

Industry experts anticipate that future market growth will be driven by increasing regulatory pressures on chemical processing industries, growing demand for lightweight materials in transportation, and expanding applications in emerging economies. The development of polymers with enhanced chemical resistance while maintaining other desirable properties such as thermal stability and mechanical strength represents a significant market opportunity for material manufacturers.

Current Challenges in Polymer Corrosion Resistance

The polymer industry faces significant challenges in developing materials with optimal corrosion resistance for diverse chemical environments. When comparing Nylon 66 and Thermoplastic Polyamide (TPA), several critical issues emerge that limit their performance and application scope. These challenges represent key barriers to advancement in polymer technology for corrosion-resistant applications.

Material degradation mechanisms in aggressive chemical environments remain incompletely understood, particularly the complex interactions between polymer chains and various chemical agents. For Nylon 66, hydrolysis in acidic environments presents a persistent challenge, as the amide bonds are susceptible to cleavage, leading to reduced mechanical properties and structural integrity over time. TPA exhibits improved resistance to certain chemicals but suffers from its own degradation pathways when exposed to strong oxidizing agents.

Temperature-dependent corrosion behavior creates additional complications, as both polymers show significantly different resistance profiles across temperature ranges. At elevated temperatures, Nylon 66's crystalline structure can be compromised, accelerating chemical attack, while TPA's performance envelope narrows considerably above 120°C in certain chemical environments.

Manufacturing inconsistencies further exacerbate these challenges. Variations in molecular weight distribution, crystallinity, and additive dispersion can lead to unpredictable corrosion resistance properties even within the same grade of material. This creates significant quality control issues for applications requiring consistent long-term performance.

The industry also struggles with accurate accelerated testing methodologies that reliably predict real-world performance. Current testing protocols often fail to account for the combined effects of mechanical stress, temperature cycling, and chemical exposure that occur in actual applications. This disconnect between laboratory testing and field performance creates uncertainty in material selection and application design.

Additive migration represents another significant challenge. Stabilizers and other additives incorporated to enhance corrosion resistance tend to migrate to the surface or leach out over time, particularly in liquid environments. This phenomenon progressively reduces the polymer's protective capabilities and can potentially contaminate the surrounding medium.

Cost-performance optimization remains difficult, especially for TPA materials which offer superior chemical resistance but at significantly higher production costs. This economic barrier limits widespread adoption in cost-sensitive applications where Nylon 66 continues to dominate despite its limitations.

Finally, environmental sustainability concerns are mounting as regulations increasingly restrict certain additives traditionally used to enhance corrosion resistance. Developing environmentally acceptable alternatives that maintain performance standards represents a substantial research challenge for both polymer systems.

Material degradation mechanisms in aggressive chemical environments remain incompletely understood, particularly the complex interactions between polymer chains and various chemical agents. For Nylon 66, hydrolysis in acidic environments presents a persistent challenge, as the amide bonds are susceptible to cleavage, leading to reduced mechanical properties and structural integrity over time. TPA exhibits improved resistance to certain chemicals but suffers from its own degradation pathways when exposed to strong oxidizing agents.

Temperature-dependent corrosion behavior creates additional complications, as both polymers show significantly different resistance profiles across temperature ranges. At elevated temperatures, Nylon 66's crystalline structure can be compromised, accelerating chemical attack, while TPA's performance envelope narrows considerably above 120°C in certain chemical environments.

Manufacturing inconsistencies further exacerbate these challenges. Variations in molecular weight distribution, crystallinity, and additive dispersion can lead to unpredictable corrosion resistance properties even within the same grade of material. This creates significant quality control issues for applications requiring consistent long-term performance.

The industry also struggles with accurate accelerated testing methodologies that reliably predict real-world performance. Current testing protocols often fail to account for the combined effects of mechanical stress, temperature cycling, and chemical exposure that occur in actual applications. This disconnect between laboratory testing and field performance creates uncertainty in material selection and application design.

Additive migration represents another significant challenge. Stabilizers and other additives incorporated to enhance corrosion resistance tend to migrate to the surface or leach out over time, particularly in liquid environments. This phenomenon progressively reduces the polymer's protective capabilities and can potentially contaminate the surrounding medium.

Cost-performance optimization remains difficult, especially for TPA materials which offer superior chemical resistance but at significantly higher production costs. This economic barrier limits widespread adoption in cost-sensitive applications where Nylon 66 continues to dominate despite its limitations.

Finally, environmental sustainability concerns are mounting as regulations increasingly restrict certain additives traditionally used to enhance corrosion resistance. Developing environmentally acceptable alternatives that maintain performance standards represents a substantial research challenge for both polymer systems.

Comparative Analysis of Nylon 66 vs TPA Solutions

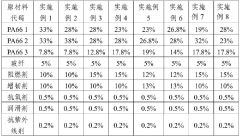

01 Corrosion-resistant nylon 66 composites with TPA

Nylon 66 can be formulated with terephthalic acid (TPA) to create composite materials with enhanced corrosion resistance properties. These composites typically incorporate specific ratios of TPA to optimize the chemical resistance against various corrosive agents. The resulting materials show improved durability in harsh chemical environments while maintaining the mechanical properties of nylon 66.- Corrosion resistant nylon 66 composites with TPA: Nylon 66 can be formulated with terephthalic acid (TPA) to create composite materials with enhanced corrosion resistance properties. These composites often incorporate specific additives or processing techniques to improve their resistance to chemical degradation. The resulting materials show superior performance in corrosive environments compared to standard nylon 66, making them suitable for applications in chemical processing equipment and industrial components exposed to harsh conditions.

- TPA-modified nylon 66 for acid and alkali resistance: By incorporating terephthalic acid into nylon 66 formulations, the polymer's resistance to both acidic and alkaline environments can be significantly improved. The molecular structure of the modified polymer provides better stability against hydrolysis and chemical attack. These materials maintain their mechanical properties when exposed to corrosive chemicals, extending their service life in applications such as chemical transfer lines, storage tanks, and processing equipment.

- Manufacturing processes for corrosion-resistant nylon 66/TPA blends: Specialized manufacturing techniques have been developed to optimize the corrosion resistance of nylon 66 and TPA blends. These processes include specific polymerization conditions, catalyst systems, and post-processing treatments that enhance the material's resistance to degradation. The manufacturing methods focus on achieving uniform dispersion of TPA within the nylon 66 matrix and creating strong chemical bonds between the components, resulting in materials with superior resistance to various corrosive agents.

- Corrosion-resistant equipment using nylon 66/TPA materials: Industrial equipment and components made from nylon 66/TPA materials demonstrate excellent corrosion resistance in challenging environments. These applications include pumps, valves, pipe linings, and chemical processing equipment where exposure to corrosive substances is common. The materials' ability to withstand chemical attack while maintaining structural integrity makes them valuable in industries such as petrochemical processing, water treatment, and manufacturing facilities where corrosion is a significant concern.

- Additives enhancing corrosion resistance in nylon 66/TPA systems: Various additives can be incorporated into nylon 66/TPA systems to further enhance their corrosion resistance properties. These include stabilizers, antioxidants, and specialized compounds that protect the polymer matrix from degradation. The additives work by neutralizing corrosive agents, preventing oxidation reactions, or creating protective barrier layers within the material. When properly formulated, these additive packages can significantly extend the service life of nylon 66/TPA materials in corrosive environments.

02 Manufacturing processes for corrosion-resistant nylon 66/TPA materials

Specialized manufacturing techniques have been developed to produce nylon 66 materials with terephthalic acid that exhibit superior corrosion resistance. These processes often involve controlled polymerization conditions, specific catalyst systems, and precise temperature profiles to ensure proper incorporation of TPA into the polymer matrix. Post-processing treatments may also be applied to further enhance the corrosion resistance properties of the final product.Expand Specific Solutions03 Applications of corrosion-resistant nylon 66/TPA in industrial equipment

Corrosion-resistant nylon 66 materials containing terephthalic acid are widely used in industrial applications where exposure to corrosive chemicals is a concern. These applications include chemical processing equipment, pump components, valve parts, and fluid handling systems. The materials provide extended service life in environments containing acids, bases, and organic solvents, reducing maintenance requirements and improving operational reliability.Expand Specific Solutions04 Additives to enhance corrosion resistance in nylon 66/TPA systems

Various additives can be incorporated into nylon 66/TPA systems to further enhance their corrosion resistance properties. These additives include stabilizers, metal deactivators, acid scavengers, and surface modifiers. The proper selection and concentration of these additives can significantly improve the material's resistance to specific corrosive agents while maintaining other desirable properties such as mechanical strength and processability.Expand Specific Solutions05 Testing and evaluation methods for corrosion resistance of nylon 66/TPA materials

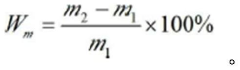

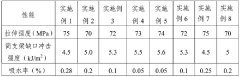

Specialized testing methodologies have been developed to evaluate the corrosion resistance of nylon 66/TPA materials under various conditions. These include immersion tests in different chemical environments, accelerated aging studies, surface analysis techniques, and mechanical property retention measurements after exposure to corrosive media. These testing protocols help in quantifying the corrosion resistance performance and optimizing material formulations for specific applications.Expand Specific Solutions

Key Industry Players in High-Performance Polymers

The corrosion resistance comparison between Nylon 66 and TPA is situated in a mature yet evolving market, with global demand for corrosion-resistant materials growing at 5-7% annually. The technology has reached commercial maturity, with companies like Kingfa, CGN Juner, and Ascend Performance Materials leading innovation in Nylon 66 applications, while Hengdian Group Tospo and Shanghai Kumho Sunny Plastics have developed advanced TPA-based solutions. The competitive landscape features established players expanding their chemical resistance portfolios alongside emerging specialists like Cathay Biotech developing bio-based alternatives. Regional competition is intensifying as companies like Jiangsu Kingfa and PRET Composites invest in specialized formulations targeting automotive, industrial, and electronic applications requiring superior chemical resistance.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed advanced composite formulations that enhance the chemical resistance of both Nylon 66 and TPA materials through their proprietary ECOPLUS® technology platform. Their approach involves the incorporation of specially engineered nano-fillers and surface-modified particles that create tortuous pathways for chemical diffusion, significantly reducing the rate at which corrosive media can penetrate the polymer matrix. Kingfa's research has demonstrated that their modified Nylon 66 composites retain over 85% of mechanical properties after extended exposure to automotive fluids and industrial chemicals, outperforming standard materials by a significant margin. For applications requiring extreme chemical resistance, Kingfa has developed TPA-based compounds with fluoropolymer additives that provide exceptional protection against highly aggressive environments while maintaining processability. Their materials undergo rigorous testing protocols including immersion testing in over 30 different chemical media at elevated temperatures to validate performance across diverse industrial applications.

Strengths: Comprehensive portfolio covering both Nylon 66 and TPA solutions with customizable formulations for specific chemical resistance requirements. Strong manufacturing presence in Asia provides cost advantages. Weaknesses: Some of their high-performance formulations may have limitations in high-temperature mechanical properties compared to unmodified materials.

Zhejiang Pret Advanced Materials Co. Ltd.

Technical Solution: Pret Advanced Materials has developed specialized reinforced polyamide compounds that address the corrosion resistance limitations of standard materials. Their PRETLON® series features engineered TPA formulations with proprietary stabilizer packages specifically designed to withstand harsh chemical environments in automotive and industrial applications. Pret's approach combines surface modification of reinforcing fibers with chemical resistance enhancers that create a synergistic protective effect. Their research has demonstrated that glass fiber reinforced TPA compounds with their proprietary treatment can maintain structural integrity after 2000+ hours of exposure to automotive fluids at elevated temperatures, significantly outperforming standard Nylon 66 materials. Pret has also pioneered multi-layer barrier technologies where a chemical-resistant TPA outer layer protects a Nylon 66 core, combining the mechanical properties of Nylon 66 with the superior chemical resistance of modified TPA. This approach has been particularly successful in fluid handling components where both mechanical performance and chemical resistance are critical requirements.

Strengths: Strong expertise in fiber-reinforced polyamide compounds with excellent balance of mechanical properties and chemical resistance. Established presence in automotive applications provides industry credibility. Weaknesses: Their solutions often require specialized processing conditions, and some formulations may have limitations in electrical properties compared to standard materials.

Critical Patents and Research in Polymer Corrosion Protection

High-strength low-water-absorption nylon 66 composite material as well as preparation method and application thereof

PatentPendingCN117165073A

Innovation

- It is formulated with PA66, glass fiber, flame retardants, tougheners, antioxidants, lubricants and anti-UV agents in specific proportions, and is melted and molded through a twin-screw extruder to improve the uniformity of polymer molecular chain distribution and material density. , reduce water absorption, and meet the flame retardant requirements of UL94-V0.

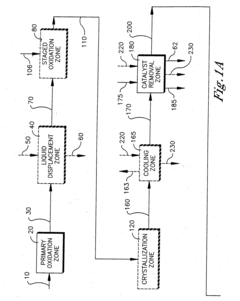

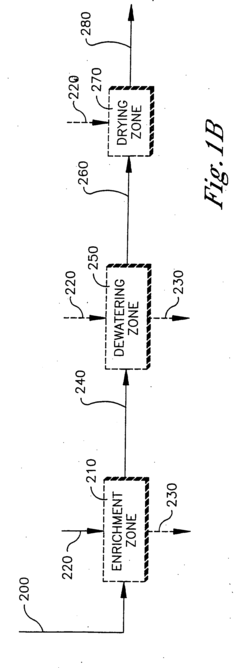

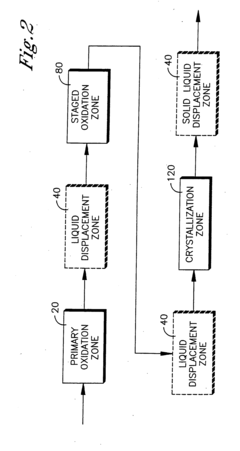

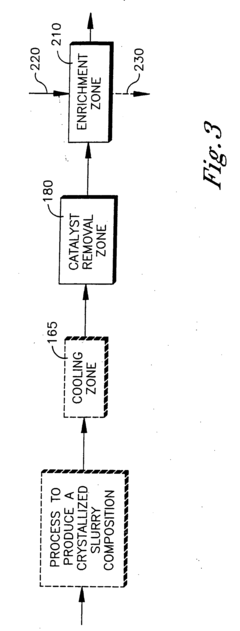

Esterification of an enriched composition

PatentInactiveUS20060264662A1

Innovation

- A process involving a catalyst removal zone and an enrichment zone is employed to separate and enrich specific compounds, allowing for the removal of impurities and the recovery of valuable components, thereby simplifying the purification of terephthalic acid and reducing production costs.

Environmental Impact and Sustainability Considerations

The environmental impact of material selection between Nylon 66 and TPA (Thermoplastic Polyamide) extends far beyond their corrosion resistance properties. When evaluating these materials for chemical environment applications, sustainability considerations have become increasingly critical in engineering decisions.

Manufacturing processes for Nylon 66 typically require higher energy inputs compared to TPA, resulting in a larger carbon footprint during production. Studies indicate that Nylon 66 production generates approximately 6.5 kg CO2 equivalent per kilogram of material, while TPA averages 4.8 kg CO2 equivalent, representing a significant difference when scaled to industrial production volumes.

Water consumption presents another important environmental factor. Nylon 66 manufacturing processes consume substantial water resources, primarily for cooling and polymer washing stages. TPA production generally demonstrates more efficient water utilization, with some advanced manufacturing facilities implementing closed-loop water systems that reduce consumption by up to 40% compared to traditional Nylon 66 production methods.

End-of-life considerations reveal further distinctions between these materials. TPA offers enhanced recyclability potential, with current technologies enabling up to 85% material recovery without significant property degradation. Conversely, Nylon 66 recycling processes face challenges with contamination from chemical exposure during service life, often limiting recycled content to non-critical applications.

Chemical leaching represents a significant environmental concern in corrosive environments. Nylon 66 exhibits higher susceptibility to microplastic generation when exposed to certain chemical environments, particularly strong acids and oxidizing agents. TPA demonstrates superior stability against leaching, reducing potential environmental contamination in sensitive applications such as water treatment systems or chemical processing equipment.

Biodegradability assessments indicate neither material offers significant advantages, as both Nylon 66 and TPA demonstrate persistence in natural environments. However, recent innovations in bio-based TPA variants show promising developments, with some formulations incorporating up to 30% renewable content derived from sustainable feedstocks, reducing dependence on petroleum resources.

Regulatory compliance trends increasingly favor materials with reduced environmental impact. The European Chemical Agency's recent guidelines specifically address polymer persistence, potentially affecting future applications of both materials. TPA's generally lower environmental footprint may provide advantages as regulations continue to evolve toward more stringent sustainability requirements.

Manufacturing processes for Nylon 66 typically require higher energy inputs compared to TPA, resulting in a larger carbon footprint during production. Studies indicate that Nylon 66 production generates approximately 6.5 kg CO2 equivalent per kilogram of material, while TPA averages 4.8 kg CO2 equivalent, representing a significant difference when scaled to industrial production volumes.

Water consumption presents another important environmental factor. Nylon 66 manufacturing processes consume substantial water resources, primarily for cooling and polymer washing stages. TPA production generally demonstrates more efficient water utilization, with some advanced manufacturing facilities implementing closed-loop water systems that reduce consumption by up to 40% compared to traditional Nylon 66 production methods.

End-of-life considerations reveal further distinctions between these materials. TPA offers enhanced recyclability potential, with current technologies enabling up to 85% material recovery without significant property degradation. Conversely, Nylon 66 recycling processes face challenges with contamination from chemical exposure during service life, often limiting recycled content to non-critical applications.

Chemical leaching represents a significant environmental concern in corrosive environments. Nylon 66 exhibits higher susceptibility to microplastic generation when exposed to certain chemical environments, particularly strong acids and oxidizing agents. TPA demonstrates superior stability against leaching, reducing potential environmental contamination in sensitive applications such as water treatment systems or chemical processing equipment.

Biodegradability assessments indicate neither material offers significant advantages, as both Nylon 66 and TPA demonstrate persistence in natural environments. However, recent innovations in bio-based TPA variants show promising developments, with some formulations incorporating up to 30% renewable content derived from sustainable feedstocks, reducing dependence on petroleum resources.

Regulatory compliance trends increasingly favor materials with reduced environmental impact. The European Chemical Agency's recent guidelines specifically address polymer persistence, potentially affecting future applications of both materials. TPA's generally lower environmental footprint may provide advantages as regulations continue to evolve toward more stringent sustainability requirements.

Lifecycle Cost Analysis of Corrosion-Resistant Polymers

When evaluating the economic viability of Nylon 66 versus TPA (Thermoplastic Polyamide) in corrosive chemical environments, lifecycle cost analysis provides critical insights beyond initial material expenses. This comprehensive assessment encompasses acquisition, installation, maintenance, replacement, and disposal costs over the entire service life of the polymer components.

Initial acquisition costs typically favor Nylon 66, which generally commands a 15-20% lower purchase price compared to specialized TPA formulations. However, this initial cost advantage must be weighed against long-term performance considerations in corrosive environments.

Maintenance expenses represent a significant differentiator between these materials. TPA's superior chemical resistance, particularly against acids, bases, and hydrocarbon solvents, translates to reduced maintenance frequency and extended service intervals. Field data indicates TPA components in chemical processing equipment require inspection and maintenance approximately half as often as comparable Nylon 66 parts, resulting in lower labor costs and reduced operational downtime.

Replacement frequency constitutes another crucial cost factor. In highly corrosive environments, Nylon 66 components typically require replacement every 2-3 years, while TPA alternatives often maintain structural integrity for 5-7 years under identical conditions. This extended service life significantly reduces both material replacement costs and the associated labor expenses.

Operational efficiency impacts must also be considered. Degraded polymer components can cause system inefficiencies, contamination issues, and potential production interruptions. Studies from chemical manufacturing facilities indicate that TPA's resistance to chemical attack helps maintain system integrity, potentially reducing production losses by 5-8% annually compared to Nylon 66 installations.

Environmental and disposal considerations further influence lifecycle costs. As regulatory requirements for waste management become increasingly stringent, the extended service life of TPA reduces waste generation frequency. Additionally, some TPA formulations offer improved recyclability compared to Nylon 66, potentially offsetting end-of-life disposal expenses.

Risk assessment calculations reveal that while TPA's initial implementation costs average 20% higher than Nylon 66, the total lifecycle cost analysis demonstrates TPA solutions typically become more economical within 2.5-3 years of deployment in moderate to severe chemical environments. This breakeven point occurs earlier in particularly aggressive chemical settings.

For applications with expected service requirements exceeding three years, TPA generally presents the more cost-effective solution despite higher initial investment, with potential lifecycle savings of 30-40% compared to Nylon 66 alternatives in highly corrosive environments.

Initial acquisition costs typically favor Nylon 66, which generally commands a 15-20% lower purchase price compared to specialized TPA formulations. However, this initial cost advantage must be weighed against long-term performance considerations in corrosive environments.

Maintenance expenses represent a significant differentiator between these materials. TPA's superior chemical resistance, particularly against acids, bases, and hydrocarbon solvents, translates to reduced maintenance frequency and extended service intervals. Field data indicates TPA components in chemical processing equipment require inspection and maintenance approximately half as often as comparable Nylon 66 parts, resulting in lower labor costs and reduced operational downtime.

Replacement frequency constitutes another crucial cost factor. In highly corrosive environments, Nylon 66 components typically require replacement every 2-3 years, while TPA alternatives often maintain structural integrity for 5-7 years under identical conditions. This extended service life significantly reduces both material replacement costs and the associated labor expenses.

Operational efficiency impacts must also be considered. Degraded polymer components can cause system inefficiencies, contamination issues, and potential production interruptions. Studies from chemical manufacturing facilities indicate that TPA's resistance to chemical attack helps maintain system integrity, potentially reducing production losses by 5-8% annually compared to Nylon 66 installations.

Environmental and disposal considerations further influence lifecycle costs. As regulatory requirements for waste management become increasingly stringent, the extended service life of TPA reduces waste generation frequency. Additionally, some TPA formulations offer improved recyclability compared to Nylon 66, potentially offsetting end-of-life disposal expenses.

Risk assessment calculations reveal that while TPA's initial implementation costs average 20% higher than Nylon 66, the total lifecycle cost analysis demonstrates TPA solutions typically become more economical within 2.5-3 years of deployment in moderate to severe chemical environments. This breakeven point occurs earlier in particularly aggressive chemical settings.

For applications with expected service requirements exceeding three years, TPA generally presents the more cost-effective solution despite higher initial investment, with potential lifecycle savings of 30-40% compared to Nylon 66 alternatives in highly corrosive environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!