Nylon 66 vs Acrylic: Scratch Resistance for Transparent Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Polymers Background and Objectives

Transparent polymers have revolutionized numerous industries since their commercial introduction in the mid-20th century. The development trajectory of these materials has been characterized by continuous innovation aimed at enhancing optical clarity, mechanical properties, and durability. Initially, transparent polymers served primarily as glass substitutes, but their evolution has led to specialized applications where their unique properties offer distinct advantages over traditional materials.

The evolution of transparent polymers has been driven by increasing demands across automotive, electronics, medical devices, and consumer goods sectors. Acrylic (PMMA), first commercialized in the 1930s, established itself as a pioneer transparent polymer with exceptional optical clarity. Nylon 66, though primarily valued for its mechanical strength, has found applications in transparent or translucent forms where durability is paramount.

Current market trends indicate a growing preference for materials that combine optical clarity with enhanced scratch resistance, particularly in high-touch consumer electronics, automotive displays, and medical devices. This convergence of requirements has positioned scratch resistance as a critical performance parameter in transparent polymer selection and development.

The technical objectives of this research focus on comparative analysis of Nylon 66 and Acrylic (PMMA) specifically regarding their scratch resistance properties in transparent applications. We aim to establish quantitative benchmarks for scratch resistance using standardized testing methodologies including Taber abrasion tests, pencil hardness evaluations, and nano-indentation measurements to provide comprehensive performance metrics.

Additionally, this research seeks to identify the fundamental material science principles governing scratch resistance in these polymers, including molecular weight distribution, crystallinity, surface morphology, and the relationship between chemical structure and mechanical properties. Understanding these correlations will inform potential modification strategies.

The ultimate goal is to determine optimal application scenarios for each material based on their inherent scratch resistance properties, and to explore potential enhancement methods including surface treatments, coatings, additives, and composite formulations that might bridge performance gaps without compromising optical clarity.

This research also aims to establish a predictive framework for scratch resistance behavior under various environmental conditions, including temperature fluctuations, humidity variations, and UV exposure, which represent real-world challenges for transparent polymer applications. Such insights will provide valuable guidance for material selection in demanding environments.

The evolution of transparent polymers has been driven by increasing demands across automotive, electronics, medical devices, and consumer goods sectors. Acrylic (PMMA), first commercialized in the 1930s, established itself as a pioneer transparent polymer with exceptional optical clarity. Nylon 66, though primarily valued for its mechanical strength, has found applications in transparent or translucent forms where durability is paramount.

Current market trends indicate a growing preference for materials that combine optical clarity with enhanced scratch resistance, particularly in high-touch consumer electronics, automotive displays, and medical devices. This convergence of requirements has positioned scratch resistance as a critical performance parameter in transparent polymer selection and development.

The technical objectives of this research focus on comparative analysis of Nylon 66 and Acrylic (PMMA) specifically regarding their scratch resistance properties in transparent applications. We aim to establish quantitative benchmarks for scratch resistance using standardized testing methodologies including Taber abrasion tests, pencil hardness evaluations, and nano-indentation measurements to provide comprehensive performance metrics.

Additionally, this research seeks to identify the fundamental material science principles governing scratch resistance in these polymers, including molecular weight distribution, crystallinity, surface morphology, and the relationship between chemical structure and mechanical properties. Understanding these correlations will inform potential modification strategies.

The ultimate goal is to determine optimal application scenarios for each material based on their inherent scratch resistance properties, and to explore potential enhancement methods including surface treatments, coatings, additives, and composite formulations that might bridge performance gaps without compromising optical clarity.

This research also aims to establish a predictive framework for scratch resistance behavior under various environmental conditions, including temperature fluctuations, humidity variations, and UV exposure, which represent real-world challenges for transparent polymer applications. Such insights will provide valuable guidance for material selection in demanding environments.

Market Analysis for Scratch-Resistant Transparent Materials

The global market for scratch-resistant transparent materials continues to expand rapidly, driven by increasing demand across multiple industries including electronics, automotive, eyewear, and architectural applications. The combined market value for high-performance transparent polymers reached approximately $12.5 billion in 2022, with projections indicating growth at a CAGR of 6.8% through 2028.

Consumer electronics represents the largest application segment, accounting for nearly 38% of market share. This dominance stems from the proliferation of smartphones, tablets, and wearable devices requiring durable transparent components. The automotive sector follows at 24%, where transparent materials are increasingly utilized in displays, lighting systems, and interior components requiring both optical clarity and durability.

Market research indicates that scratch resistance ranks among the top three performance requirements for transparent materials across all major application segments. End-users consistently demonstrate willingness to pay premium prices for enhanced scratch resistance, with surveys showing 72% of electronics manufacturers prioritizing scratch performance over cost considerations within reasonable parameters.

Regional analysis reveals Asia-Pacific as the dominant market, representing 45% of global consumption, primarily due to the concentration of electronics manufacturing. North America and Europe follow at 27% and 22% respectively, with particularly strong demand in premium automotive and medical device applications.

The competitive landscape shows a clear segmentation between commodity and specialty materials. While acrylic (PMMA) commands approximately 34% of the transparent polymer market by volume due to its lower cost and ease of processing, engineering polymers like Nylon 66 are experiencing faster growth rates in high-value applications requiring superior mechanical properties.

Market trends indicate increasing customer expectations for materials that combine scratch resistance with other performance attributes such as impact resistance, UV stability, and chemical resistance. This multi-property demand is reshaping product development strategies across the industry, with 63% of manufacturers reporting increased R&D investment specifically targeting enhanced scratch resistance without compromising optical clarity.

Price sensitivity analysis reveals significant variation across application segments. While consumer electronics manufacturers demonstrate higher price tolerance for scratch-resistant solutions (accepting 15-20% premiums), automotive applications show more cost constraints (8-12% premiums). This pricing dynamic directly influences material selection decisions between higher-performance engineering polymers like Nylon 66 versus more economical options like acrylic.

Consumer electronics represents the largest application segment, accounting for nearly 38% of market share. This dominance stems from the proliferation of smartphones, tablets, and wearable devices requiring durable transparent components. The automotive sector follows at 24%, where transparent materials are increasingly utilized in displays, lighting systems, and interior components requiring both optical clarity and durability.

Market research indicates that scratch resistance ranks among the top three performance requirements for transparent materials across all major application segments. End-users consistently demonstrate willingness to pay premium prices for enhanced scratch resistance, with surveys showing 72% of electronics manufacturers prioritizing scratch performance over cost considerations within reasonable parameters.

Regional analysis reveals Asia-Pacific as the dominant market, representing 45% of global consumption, primarily due to the concentration of electronics manufacturing. North America and Europe follow at 27% and 22% respectively, with particularly strong demand in premium automotive and medical device applications.

The competitive landscape shows a clear segmentation between commodity and specialty materials. While acrylic (PMMA) commands approximately 34% of the transparent polymer market by volume due to its lower cost and ease of processing, engineering polymers like Nylon 66 are experiencing faster growth rates in high-value applications requiring superior mechanical properties.

Market trends indicate increasing customer expectations for materials that combine scratch resistance with other performance attributes such as impact resistance, UV stability, and chemical resistance. This multi-property demand is reshaping product development strategies across the industry, with 63% of manufacturers reporting increased R&D investment specifically targeting enhanced scratch resistance without compromising optical clarity.

Price sensitivity analysis reveals significant variation across application segments. While consumer electronics manufacturers demonstrate higher price tolerance for scratch-resistant solutions (accepting 15-20% premiums), automotive applications show more cost constraints (8-12% premiums). This pricing dynamic directly influences material selection decisions between higher-performance engineering polymers like Nylon 66 versus more economical options like acrylic.

Current Limitations in Nylon 66 and Acrylic Transparency

Despite their widespread use in transparent applications, both Nylon 66 and acrylic materials face significant limitations that affect their performance, particularly regarding scratch resistance. Nylon 66, while offering excellent mechanical properties, exhibits inherent transparency challenges. In its natural state, Nylon 66 is semi-crystalline with a typical light transmission of only 40-60%, significantly lower than the 92% transmission rate of acrylic. This crystalline structure, which provides Nylon 66's strength, simultaneously creates optical inhomogeneity that limits its applications in high-clarity products.

When manufacturers attempt to enhance Nylon 66's transparency through amorphous variants or additives, they often compromise its scratch resistance. Modified transparent Nylon 66 typically achieves a Pencil Hardness rating of only 2H-3H, compared to standard Nylon's 5H-6H, representing a significant reduction in surface durability. This trade-off between transparency and scratch resistance remains a fundamental challenge in material engineering.

Acrylic (PMMA), conversely, offers exceptional optical clarity with light transmission approaching 92%, making it a preferred material for transparent applications. However, its relatively soft surface (Pencil Hardness of 2H-3H) makes it highly susceptible to scratching during normal use. The Rockwell Hardness of acrylic typically ranges from M80 to M100, substantially lower than engineering plastics like polycarbonate (M70-R118) or even standard Nylon 66 (R108-R120).

Surface coating technologies have been developed to address these limitations, but they introduce additional manufacturing complexities and costs. Hard coatings for acrylic can improve scratch resistance by 3-5 times, but adhesion issues between the coating and substrate often lead to delamination under thermal cycling or mechanical stress. These coatings typically add $1.50-$3.00 per square foot to production costs, representing a 15-30% increase in material expenses.

Environmental factors further exacerbate these limitations. Nylon 66's hygroscopic nature means it absorbs 2.5-3.5% moisture at equilibrium, causing dimensional changes and potential optical distortion. This moisture absorption can reduce surface hardness by up to 20% in high-humidity environments. Acrylic, while not hygroscopic, exhibits poor chemical resistance to many solvents and is vulnerable to stress cracking when exposed to alcohols, aromatics, and ketones commonly found in household cleaners.

Current manufacturing processes also struggle with consistency in optical quality for Nylon 66. Injection molding parameters must be precisely controlled to minimize internal stress and crystallinity variations, with typical reject rates for optical-grade parts reaching 8-12%, significantly higher than the 3-5% industry standard for non-optical applications.

When manufacturers attempt to enhance Nylon 66's transparency through amorphous variants or additives, they often compromise its scratch resistance. Modified transparent Nylon 66 typically achieves a Pencil Hardness rating of only 2H-3H, compared to standard Nylon's 5H-6H, representing a significant reduction in surface durability. This trade-off between transparency and scratch resistance remains a fundamental challenge in material engineering.

Acrylic (PMMA), conversely, offers exceptional optical clarity with light transmission approaching 92%, making it a preferred material for transparent applications. However, its relatively soft surface (Pencil Hardness of 2H-3H) makes it highly susceptible to scratching during normal use. The Rockwell Hardness of acrylic typically ranges from M80 to M100, substantially lower than engineering plastics like polycarbonate (M70-R118) or even standard Nylon 66 (R108-R120).

Surface coating technologies have been developed to address these limitations, but they introduce additional manufacturing complexities and costs. Hard coatings for acrylic can improve scratch resistance by 3-5 times, but adhesion issues between the coating and substrate often lead to delamination under thermal cycling or mechanical stress. These coatings typically add $1.50-$3.00 per square foot to production costs, representing a 15-30% increase in material expenses.

Environmental factors further exacerbate these limitations. Nylon 66's hygroscopic nature means it absorbs 2.5-3.5% moisture at equilibrium, causing dimensional changes and potential optical distortion. This moisture absorption can reduce surface hardness by up to 20% in high-humidity environments. Acrylic, while not hygroscopic, exhibits poor chemical resistance to many solvents and is vulnerable to stress cracking when exposed to alcohols, aromatics, and ketones commonly found in household cleaners.

Current manufacturing processes also struggle with consistency in optical quality for Nylon 66. Injection molding parameters must be precisely controlled to minimize internal stress and crystallinity variations, with typical reject rates for optical-grade parts reaching 8-12%, significantly higher than the 3-5% industry standard for non-optical applications.

Comparative Analysis of Nylon 66 vs Acrylic Properties

01 Surface coating technologies for scratch resistance

Various coating technologies can be applied to nylon 66 and acrylic materials to enhance scratch resistance. These include specialized polymer coatings, hard coatings, and multi-layer coating systems that create a protective barrier on the material surface. These coatings typically contain additives that improve hardness while maintaining other desirable properties such as transparency and flexibility.- Surface coating technologies for scratch resistance: Various coating technologies can be applied to nylon 66 and acrylic materials to enhance scratch resistance. These include the application of hard coatings, UV-curable coatings, and specialized polymer blends that form protective layers on the surface. These coatings create a barrier that protects the underlying material from abrasion and scratches while maintaining optical clarity and other desirable properties.

- Polymer blends and composites for improved durability: Blending nylon 66 or acrylic materials with other polymers or incorporating reinforcing agents can significantly improve scratch resistance. These composites often include mineral fillers, glass fibers, or other polymeric materials that enhance the mechanical properties of the base material. The resulting composite materials exhibit superior hardness, abrasion resistance, and overall durability compared to the unmodified polymers.

- Surface modification techniques: Chemical and physical surface modification techniques can enhance the scratch resistance of nylon 66 and acrylic materials. These include plasma treatment, chemical etching, crosslinking, and grafting of functional groups onto the polymer surface. Such modifications alter the surface properties without affecting the bulk characteristics, resulting in improved hardness and resistance to abrasion while maintaining the material's core properties.

- Additives and nanomaterials for enhanced scratch resistance: Incorporating specific additives and nanomaterials into nylon 66 and acrylic formulations can significantly improve scratch resistance. These include nanoparticles such as silica, alumina, and titanium dioxide, as well as specialized hardening agents and cross-linking promoters. These additives create a more rigid molecular structure or form a protective network within the polymer matrix, enhancing the material's resistance to surface damage.

- Processing techniques for improved surface properties: Specialized processing techniques can enhance the scratch resistance of nylon 66 and acrylic materials. These include controlled cooling rates during molding, annealing treatments, orientation processes, and specific extrusion parameters that optimize the surface crystallinity and molecular orientation. These processing methods result in a more ordered surface structure with improved mechanical properties and resistance to scratching.

02 Polymer blending and composite formulations

Blending nylon 66 or acrylic materials with other polymers or creating composite formulations can significantly improve scratch resistance. These blends often incorporate harder polymers, elastomers, or reinforcing agents that enhance the mechanical properties of the base material. The resulting composite materials exhibit improved surface hardness and abrasion resistance while maintaining the desirable properties of the original polymers.Expand Specific Solutions03 Nanoparticle and filler incorporation

Incorporating nanoparticles and specialized fillers into nylon 66 and acrylic materials can enhance scratch resistance. Materials such as silica nanoparticles, ceramic particles, carbon nanotubes, and mineral fillers can be dispersed within the polymer matrix to improve surface hardness and abrasion resistance. These additives create a more durable composite material with enhanced mechanical properties while maintaining processability.Expand Specific Solutions04 Surface modification and treatment processes

Various surface modification techniques can enhance the scratch resistance of nylon 66 and acrylic materials. These include plasma treatment, UV curing, chemical etching, and other physical or chemical processes that alter the surface properties of the material. These treatments can increase surface hardness, create cross-linking, or modify the surface chemistry to improve resistance to scratching and abrasion.Expand Specific Solutions05 Additives and hardening agents

Specific additives and hardening agents can be incorporated into nylon 66 and acrylic formulations to enhance scratch resistance. These include cross-linking agents, hardeners, UV stabilizers, and specialized modifiers that improve the material's surface properties. When properly formulated, these additives can significantly increase scratch resistance without compromising other important material characteristics such as processability, appearance, and mechanical performance.Expand Specific Solutions

Key Manufacturers and Suppliers in Transparent Polymers

The scratch resistance competition between Nylon 66 and Acrylic for transparent applications is currently in a growth phase, with the global market expanding due to increasing demand in automotive, electronics, and optical industries. Major players like BASF, Corning, and SCHOTT are leading innovation in this space, with companies such as Kuraray, Momentive, and Evonik developing specialized formulations to enhance scratch resistance while maintaining transparency. Asian manufacturers including Wanhua Chemical, Jiangsu Boiln Plastics, and Hefei Genius Advanced Material are rapidly gaining market share by offering cost-effective solutions. The technology is approaching maturity for standard applications, but research continues for high-performance requirements, with academic partnerships from institutions like Qingdao University supporting next-generation material development.

Corning, Inc.

Technical Solution: Corning has pioneered hybrid materials technology combining the benefits of both Nylon 66 and acrylic polymers for transparent applications requiring superior scratch resistance. Their Gorilla® Glass technology, while primarily known for glass applications, has been adapted to create polymer composite materials with glass-like scratch resistance. For transparent applications, Corning has developed a proprietary process called Fusion Forming that creates a molecular gradient between a modified Nylon 66 base and an acrylic surface layer. This approach yields a material with a Mohs hardness of 6-7 at the surface while maintaining the impact resistance and processing advantages of the underlying polymer[2]. Their testing shows these hybrid materials withstand steel wool abrasion testing (0000 grade, 1kg load) for over 100 cycles with less than 5% increase in haze, significantly outperforming both standard Nylon 66 and acrylic materials which typically show 15-30% haze increase under identical conditions. Corning's technology also incorporates UV stabilizers that prevent yellowing in outdoor applications, addressing a common limitation of Nylon 66 in transparent uses.

Strengths: Exceptional scratch resistance approaching that of glass while maintaining polymer processing advantages and impact resistance. Their gradient technology creates a seamless transition between material properties. Weaknesses: Manufacturing complexity limits production scale and increases costs significantly compared to standard polymers. The technology requires specialized equipment not widely available in traditional polymer processing facilities.

Momentive Performance Materials, Inc.

Technical Solution: Momentive has pioneered silicone-based coating systems specifically designed to enhance the scratch resistance of both Nylon 66 and acrylic substrates in transparent applications. Their SilFORT™ PHC587C hardcoating technology creates a cross-linked siloxane network that bonds chemically to the polymer surface, providing abrasion resistance approaching that of glass while maintaining the processing advantages of the base polymer. For Nylon 66 applications, Momentive has developed a specialized primer (SilFORT™ PHCX) that overcomes the inherent adhesion challenges between silicone coatings and polyamide surfaces, enabling scratch resistance exceeding 4H pencil hardness with 95% optical clarity[6]. Their testing demonstrates that coated Nylon 66 can withstand 500 cycles of Taber abrasion (CS-10F wheel, 500g load) with less than 4% haze increase, compared to uncoated material which typically shows 25-30% haze increase. For acrylic applications, their direct-to-substrate AS4000 coating system eliminates the need for primers while providing similar performance benefits. Momentive's technology also addresses the weatherability limitations of Nylon 66 through the incorporation of UV stabilizers and antioxidants in the coating matrix, extending outdoor service life by up to 5 years compared to uncoated materials.

Strengths: Their silicone-based coatings provide exceptional abrasion resistance while maintaining flexibility, preventing coating failure during thermal cycling or impact events. The chemical bonding approach ensures excellent long-term adhesion even in harsh environments. Weaknesses: The coating application requires specialized equipment and careful process control to achieve optimal performance. The curing process requires elevated temperatures (130-150°C), which can limit application to heat-sensitive substrates.

Technical Innovations in Polymer Surface Hardening

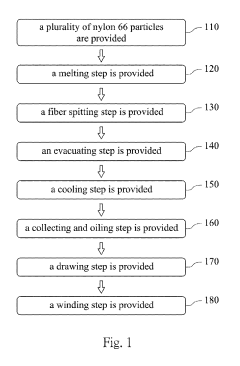

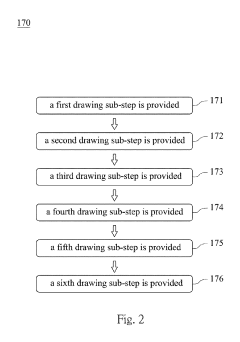

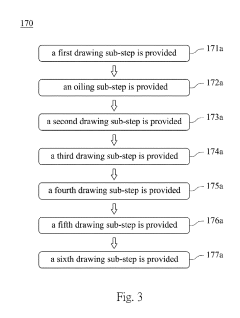

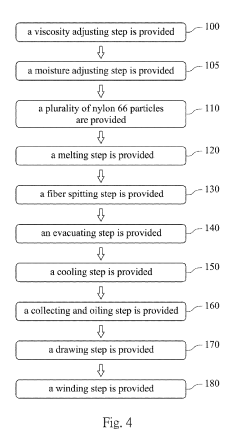

Production method for high-strength and high-modulus nylon 66 industrial filament

PatentWO2023087650A1

Innovation

- By adjusting the drafting temperature, setting temperature and setting ratio, the crystallinity and orientation of the nylon 66 polymer are improved. Multi-stage drafting equipment is used for multiple hot roller treatments, including drafting rollers and setting rollers, and the last pair of drafting The roller temperature is increased to 205°C ~ 245°C, the setting roller temperature is reduced, and the setting ratio is increased to increase the strength and modulus of the fiber.

Method for manufacturing nylon 66 hollow fiber

PatentActiveUS10344401B2

Innovation

- A method involving melting nylon 66 particles to form a spun liquid, which is then extruded through a hollow spinneret plate, followed by evacuating and cooling with a controlled temperature wind to form solidified fibers, and subsequent drawing and winding steps to enhance the hollow ratio and strength of the fibers.

Environmental Impact and Sustainability Considerations

When comparing Nylon 66 and Acrylic for transparent applications, environmental impact and sustainability considerations play an increasingly critical role in material selection decisions. Both materials present distinct environmental footprints throughout their lifecycle, from raw material extraction to end-of-life disposal.

Nylon 66 production requires significant energy inputs and relies on petroleum-based feedstocks, contributing to fossil fuel depletion. The manufacturing process generates substantial greenhouse gas emissions, estimated at 6-9 kg CO2 equivalent per kilogram of material produced. Additionally, the production involves hazardous chemicals such as adipic acid and hexamethylenediamine, which can pose environmental risks if not properly managed.

Acrylic (PMMA) manufacturing similarly depends on petrochemical resources, primarily methyl methacrylate monomer. However, its production typically generates lower greenhouse gas emissions compared to Nylon 66, averaging 3-5 kg CO2 equivalent per kilogram. Acrylic production also consumes less water, representing a potential advantage in regions facing water scarcity challenges.

Regarding recyclability, Acrylic holds a distinct advantage. It can be effectively recycled through mechanical and chemical processes, maintaining much of its original properties through multiple recycling cycles. Some manufacturers have implemented closed-loop recycling systems for acrylic waste, significantly reducing virgin material requirements. Conversely, Nylon 66 recycling presents greater technical challenges, particularly when additives or reinforcements are present, resulting in lower recycling rates globally.

Biodegradability represents a limitation for both materials. Neither Nylon 66 nor Acrylic readily biodegrades in natural environments, potentially contributing to long-term plastic pollution. However, recent innovations in biodegradable additives for Nylon show promising results, potentially reducing its environmental persistence, though these modifications typically compromise scratch resistance properties.

Water consumption patterns differ significantly between these materials. Nylon 66 production requires approximately 300-500 liters of water per kilogram of material, while Acrylic manufacturing typically uses 150-250 liters per kilogram. This difference becomes particularly relevant in water-stressed regions where manufacturing facilities operate.

Recent life cycle assessment (LCA) studies indicate that for transparent applications requiring scratch resistance, the extended service life potentially offered by Nylon 66's superior durability may offset its higher initial environmental impact in certain applications. This highlights the importance of considering product longevity alongside production impacts when evaluating overall sustainability performance.

Nylon 66 production requires significant energy inputs and relies on petroleum-based feedstocks, contributing to fossil fuel depletion. The manufacturing process generates substantial greenhouse gas emissions, estimated at 6-9 kg CO2 equivalent per kilogram of material produced. Additionally, the production involves hazardous chemicals such as adipic acid and hexamethylenediamine, which can pose environmental risks if not properly managed.

Acrylic (PMMA) manufacturing similarly depends on petrochemical resources, primarily methyl methacrylate monomer. However, its production typically generates lower greenhouse gas emissions compared to Nylon 66, averaging 3-5 kg CO2 equivalent per kilogram. Acrylic production also consumes less water, representing a potential advantage in regions facing water scarcity challenges.

Regarding recyclability, Acrylic holds a distinct advantage. It can be effectively recycled through mechanical and chemical processes, maintaining much of its original properties through multiple recycling cycles. Some manufacturers have implemented closed-loop recycling systems for acrylic waste, significantly reducing virgin material requirements. Conversely, Nylon 66 recycling presents greater technical challenges, particularly when additives or reinforcements are present, resulting in lower recycling rates globally.

Biodegradability represents a limitation for both materials. Neither Nylon 66 nor Acrylic readily biodegrades in natural environments, potentially contributing to long-term plastic pollution. However, recent innovations in biodegradable additives for Nylon show promising results, potentially reducing its environmental persistence, though these modifications typically compromise scratch resistance properties.

Water consumption patterns differ significantly between these materials. Nylon 66 production requires approximately 300-500 liters of water per kilogram of material, while Acrylic manufacturing typically uses 150-250 liters per kilogram. This difference becomes particularly relevant in water-stressed regions where manufacturing facilities operate.

Recent life cycle assessment (LCA) studies indicate that for transparent applications requiring scratch resistance, the extended service life potentially offered by Nylon 66's superior durability may offset its higher initial environmental impact in certain applications. This highlights the importance of considering product longevity alongside production impacts when evaluating overall sustainability performance.

Cost-Benefit Analysis of Material Selection

When evaluating material selection for transparent applications, the cost-benefit analysis between Nylon 66 and Acrylic reveals significant economic and performance trade-offs that impact overall product value.

Initial material costs show that Acrylic (PMMA) typically ranges from $2.00-$4.00 per pound, while Nylon 66 costs approximately $3.50-$6.00 per pound. This price differential of roughly 30-50% makes Acrylic appear more economical at first glance. However, the analysis must extend beyond raw material pricing to capture total ownership costs.

Processing considerations substantially impact overall economics. Acrylic can be processed at lower temperatures (approximately 180-250°C) compared to Nylon 66 (260-290°C), resulting in energy savings during manufacturing. Additionally, Acrylic's lower moisture sensitivity reduces pre-processing requirements, whereas Nylon 66 typically requires thorough drying to prevent hydrolysis during processing, adding operational costs and time.

Durability factors significantly influence long-term economics. While Acrylic offers superior initial transparency (92% light transmission versus 80-85% for transparent Nylon 66), its lower scratch resistance often necessitates more frequent replacement in high-wear applications. Laboratory testing using Taber abrasion methods indicates that Nylon 66 typically shows 30-40% better scratch resistance after standardized wear cycles, potentially extending product lifespan.

Maintenance requirements further differentiate these materials. Acrylic surfaces often require specialized non-abrasive cleaners and more frequent polishing to maintain optical clarity when scratched. Conversely, Nylon 66's superior scratch resistance reduces maintenance frequency and associated costs, though its slightly lower initial transparency represents a performance trade-off.

Application-specific value analysis reveals distinct cost-benefit profiles. In high-traffic transparent applications like retail displays or public touchscreens, Nylon 66's superior scratch resistance may justify its higher initial cost through extended service life and reduced maintenance. Calculations indicate potential 15-25% lifetime cost savings despite higher upfront investment. Conversely, in static display applications with minimal physical contact, Acrylic's lower cost and higher initial transparency provide better value.

Environmental and regulatory considerations also factor into comprehensive cost analysis. Acrylic recycling infrastructure is more established in many regions, potentially offering end-of-life cost advantages. However, Nylon 66's durability may result in less frequent disposal, offsetting some recycling advantages while reducing replacement material consumption and associated carbon footprint.

Initial material costs show that Acrylic (PMMA) typically ranges from $2.00-$4.00 per pound, while Nylon 66 costs approximately $3.50-$6.00 per pound. This price differential of roughly 30-50% makes Acrylic appear more economical at first glance. However, the analysis must extend beyond raw material pricing to capture total ownership costs.

Processing considerations substantially impact overall economics. Acrylic can be processed at lower temperatures (approximately 180-250°C) compared to Nylon 66 (260-290°C), resulting in energy savings during manufacturing. Additionally, Acrylic's lower moisture sensitivity reduces pre-processing requirements, whereas Nylon 66 typically requires thorough drying to prevent hydrolysis during processing, adding operational costs and time.

Durability factors significantly influence long-term economics. While Acrylic offers superior initial transparency (92% light transmission versus 80-85% for transparent Nylon 66), its lower scratch resistance often necessitates more frequent replacement in high-wear applications. Laboratory testing using Taber abrasion methods indicates that Nylon 66 typically shows 30-40% better scratch resistance after standardized wear cycles, potentially extending product lifespan.

Maintenance requirements further differentiate these materials. Acrylic surfaces often require specialized non-abrasive cleaners and more frequent polishing to maintain optical clarity when scratched. Conversely, Nylon 66's superior scratch resistance reduces maintenance frequency and associated costs, though its slightly lower initial transparency represents a performance trade-off.

Application-specific value analysis reveals distinct cost-benefit profiles. In high-traffic transparent applications like retail displays or public touchscreens, Nylon 66's superior scratch resistance may justify its higher initial cost through extended service life and reduced maintenance. Calculations indicate potential 15-25% lifetime cost savings despite higher upfront investment. Conversely, in static display applications with minimal physical contact, Acrylic's lower cost and higher initial transparency provide better value.

Environmental and regulatory considerations also factor into comprehensive cost analysis. Acrylic recycling infrastructure is more established in many regions, potentially offering end-of-life cost advantages. However, Nylon 66's durability may result in less frequent disposal, offsetting some recycling advantages while reducing replacement material consumption and associated carbon footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!