Nylon 66 vs PET: Wear Resistance Comparison

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and PET Wear Resistance Background and Objectives

Polymer materials have been extensively utilized across various industries due to their versatile properties and cost-effectiveness. Among these, Nylon 66 and Polyethylene Terephthalate (PET) stand out as prominent engineering thermoplastics with significant applications in automotive, textile, packaging, and mechanical components. The evolution of these materials spans several decades, with continuous improvements in their formulations and processing techniques to enhance performance characteristics.

Nylon 66, first developed by Wallace Carothers at DuPont in 1935, has established itself as a high-performance engineering polymer known for its excellent mechanical strength, heat resistance, and self-lubricating properties. The historical trajectory of Nylon 66 shows consistent advancement in its wear resistance capabilities through various modification techniques, including reinforcement with fibers, incorporation of solid lubricants, and surface treatments.

Similarly, PET, which was patented in 1941 by John Rex Whinfield and James Tennant Dickson, has evolved from primarily being used in textile and packaging applications to becoming a competitive engineering plastic. The technological evolution of PET has focused on improving its crystallinity, molecular weight, and incorporation of additives to enhance its mechanical properties, particularly wear resistance.

The comparative analysis of wear resistance between Nylon 66 and PET has become increasingly important as industries seek optimal materials for components subjected to friction and abrasion. This technical investigation aims to comprehensively evaluate the wear resistance characteristics of both polymers under various operating conditions, including different loads, speeds, temperatures, and environmental factors.

The primary objectives of this research include quantifying the wear rates of Nylon 66 and PET using standardized testing methodologies, identifying the underlying wear mechanisms at the microstructural level, and establishing correlations between material properties and wear performance. Additionally, this study seeks to examine how modifications such as reinforcement with fibers, incorporation of lubricants, and surface treatments affect the wear behavior of these polymers.

Understanding the comparative wear resistance of Nylon 66 and PET is crucial for material selection in applications where tribological properties are critical performance parameters. This includes gears, bearings, bushings, sliding components, and other mechanical elements that experience significant wear during operation. The findings from this investigation will provide valuable insights for engineers and designers in selecting the appropriate polymer for specific wear-critical applications.

Furthermore, this research aims to identify technological gaps in the current understanding of wear mechanisms in these polymers and propose potential research directions for developing next-generation wear-resistant formulations of Nylon 66 and PET. The ultimate goal is to establish a comprehensive framework for predicting wear behavior based on material composition, processing conditions, and operating parameters.

Nylon 66, first developed by Wallace Carothers at DuPont in 1935, has established itself as a high-performance engineering polymer known for its excellent mechanical strength, heat resistance, and self-lubricating properties. The historical trajectory of Nylon 66 shows consistent advancement in its wear resistance capabilities through various modification techniques, including reinforcement with fibers, incorporation of solid lubricants, and surface treatments.

Similarly, PET, which was patented in 1941 by John Rex Whinfield and James Tennant Dickson, has evolved from primarily being used in textile and packaging applications to becoming a competitive engineering plastic. The technological evolution of PET has focused on improving its crystallinity, molecular weight, and incorporation of additives to enhance its mechanical properties, particularly wear resistance.

The comparative analysis of wear resistance between Nylon 66 and PET has become increasingly important as industries seek optimal materials for components subjected to friction and abrasion. This technical investigation aims to comprehensively evaluate the wear resistance characteristics of both polymers under various operating conditions, including different loads, speeds, temperatures, and environmental factors.

The primary objectives of this research include quantifying the wear rates of Nylon 66 and PET using standardized testing methodologies, identifying the underlying wear mechanisms at the microstructural level, and establishing correlations between material properties and wear performance. Additionally, this study seeks to examine how modifications such as reinforcement with fibers, incorporation of lubricants, and surface treatments affect the wear behavior of these polymers.

Understanding the comparative wear resistance of Nylon 66 and PET is crucial for material selection in applications where tribological properties are critical performance parameters. This includes gears, bearings, bushings, sliding components, and other mechanical elements that experience significant wear during operation. The findings from this investigation will provide valuable insights for engineers and designers in selecting the appropriate polymer for specific wear-critical applications.

Furthermore, this research aims to identify technological gaps in the current understanding of wear mechanisms in these polymers and propose potential research directions for developing next-generation wear-resistant formulations of Nylon 66 and PET. The ultimate goal is to establish a comprehensive framework for predicting wear behavior based on material composition, processing conditions, and operating parameters.

Market Applications and Demand Analysis

The global market for engineering polymers with superior wear resistance properties has been experiencing steady growth, driven by increasing demands across multiple industries. When comparing Nylon 66 and PET specifically for their wear resistance applications, distinct market segments and demand patterns emerge that reflect their unique performance characteristics.

In the automotive sector, Nylon 66 has established a dominant position due to its exceptional wear resistance under high-stress conditions. Market research indicates that approximately 30% of all engineering polymers used in automotive wear components are Nylon 66-based, particularly in applications such as gears, bearings, and bushings where metal replacement is critical for weight reduction and noise dampening. The automotive wear-resistant polymer market is projected to grow at a compound annual rate of 5.7% through 2028.

PET, while less prevalent in high-stress automotive applications, has carved out significant market share in consumer electronics and appliance components where moderate wear resistance combined with dimensional stability is required. The market for PET in these applications has grown by 4.3% annually over the past five years, with particularly strong demand in sliding mechanisms, hinges, and internal gears for small appliances.

Industrial machinery represents another significant market segment where both materials compete. Nylon 66 commands premium pricing in this sector due to its superior performance in high-load bearing applications, with market penetration particularly strong in conveyor systems, material handling equipment, and industrial automation components. The industrial machinery segment accounts for approximately 28% of the total wear-resistant polymer market.

Textile machinery manufacturers have increasingly adopted PET components for certain wear applications due to its cost-effectiveness and adequate performance in environments with lower mechanical stress. This sector has seen a 6.2% increase in PET adoption for wear components over the past three years, primarily driven by cost optimization initiatives in manufacturing regions across Asia.

Regional market analysis reveals that North America and Europe maintain the highest consumption rates of Nylon 66 for wear-resistant applications, while Asia-Pacific markets show stronger growth rates for PET in similar applications, largely due to price sensitivity in developing manufacturing economies.

Consumer demand trends indicate increasing interest in materials that combine wear resistance with other performance attributes such as chemical resistance, reduced friction coefficients, and sustainability credentials. This has led to the development of modified grades of both Nylon 66 and PET with enhanced wear profiles, creating premium market segments with annual growth rates exceeding the base materials by 2-3 percentage points.

In the automotive sector, Nylon 66 has established a dominant position due to its exceptional wear resistance under high-stress conditions. Market research indicates that approximately 30% of all engineering polymers used in automotive wear components are Nylon 66-based, particularly in applications such as gears, bearings, and bushings where metal replacement is critical for weight reduction and noise dampening. The automotive wear-resistant polymer market is projected to grow at a compound annual rate of 5.7% through 2028.

PET, while less prevalent in high-stress automotive applications, has carved out significant market share in consumer electronics and appliance components where moderate wear resistance combined with dimensional stability is required. The market for PET in these applications has grown by 4.3% annually over the past five years, with particularly strong demand in sliding mechanisms, hinges, and internal gears for small appliances.

Industrial machinery represents another significant market segment where both materials compete. Nylon 66 commands premium pricing in this sector due to its superior performance in high-load bearing applications, with market penetration particularly strong in conveyor systems, material handling equipment, and industrial automation components. The industrial machinery segment accounts for approximately 28% of the total wear-resistant polymer market.

Textile machinery manufacturers have increasingly adopted PET components for certain wear applications due to its cost-effectiveness and adequate performance in environments with lower mechanical stress. This sector has seen a 6.2% increase in PET adoption for wear components over the past three years, primarily driven by cost optimization initiatives in manufacturing regions across Asia.

Regional market analysis reveals that North America and Europe maintain the highest consumption rates of Nylon 66 for wear-resistant applications, while Asia-Pacific markets show stronger growth rates for PET in similar applications, largely due to price sensitivity in developing manufacturing economies.

Consumer demand trends indicate increasing interest in materials that combine wear resistance with other performance attributes such as chemical resistance, reduced friction coefficients, and sustainability credentials. This has led to the development of modified grades of both Nylon 66 and PET with enhanced wear profiles, creating premium market segments with annual growth rates exceeding the base materials by 2-3 percentage points.

Current Technical Challenges in Polymer Wear Resistance

Despite significant advancements in polymer science, several technical challenges persist in the realm of wear resistance, particularly when comparing engineering polymers like Nylon 66 and PET. The fundamental challenge lies in accurately predicting wear behavior under diverse operating conditions, as wear mechanisms in polymers are complex and multifaceted, involving adhesion, abrasion, fatigue, and tribochemical reactions simultaneously.

Surface characterization presents another significant hurdle. Current analytical techniques often struggle to provide comprehensive real-time monitoring of wear progression at the microscopic level, limiting our understanding of the dynamic wear processes in Nylon 66 versus PET applications. This knowledge gap impedes the development of targeted wear-resistant formulations.

The correlation between molecular structure and wear performance remains incompletely understood. While we know Nylon 66 generally exhibits superior wear resistance due to its higher crystallinity and stronger hydrogen bonding compared to PET, quantifying these relationships across varying environmental conditions presents considerable difficulties. Temperature fluctuations, humidity levels, and chemical exposure significantly alter the wear profiles of both polymers in unpredictable ways.

Composite formulation optimization represents another technical challenge. Incorporating fillers and reinforcements to enhance wear resistance often yields inconsistent results between Nylon 66 and PET matrices due to differences in interfacial adhesion and dispersion quality. The synergistic effects between polymer matrices and various additives remain difficult to predict without extensive empirical testing.

Testing standardization poses a persistent problem in the field. Current wear testing protocols show poor correlation between laboratory results and real-world performance, particularly for comparing dissimilar polymers like Nylon 66 and PET. The lack of universally accepted testing methodologies that accurately simulate application-specific wear conditions hampers meaningful comparative analysis.

Manufacturing consistency presents additional complications. Process-induced variations in crystallinity, molecular orientation, and surface characteristics significantly impact wear performance in both polymers. Maintaining consistent wear-resistant properties across production batches remains challenging, especially for complex geometries and thin-walled components.

Finally, the industry faces sustainability challenges in developing wear-resistant formulations. Traditional approaches to improving wear resistance often involve additives that may compromise recyclability or biodegradability. Finding environmentally responsible solutions that maintain competitive wear performance represents a critical technical challenge, particularly as regulations increasingly restrict certain additives traditionally used to enhance wear resistance in both Nylon 66 and PET applications.

Surface characterization presents another significant hurdle. Current analytical techniques often struggle to provide comprehensive real-time monitoring of wear progression at the microscopic level, limiting our understanding of the dynamic wear processes in Nylon 66 versus PET applications. This knowledge gap impedes the development of targeted wear-resistant formulations.

The correlation between molecular structure and wear performance remains incompletely understood. While we know Nylon 66 generally exhibits superior wear resistance due to its higher crystallinity and stronger hydrogen bonding compared to PET, quantifying these relationships across varying environmental conditions presents considerable difficulties. Temperature fluctuations, humidity levels, and chemical exposure significantly alter the wear profiles of both polymers in unpredictable ways.

Composite formulation optimization represents another technical challenge. Incorporating fillers and reinforcements to enhance wear resistance often yields inconsistent results between Nylon 66 and PET matrices due to differences in interfacial adhesion and dispersion quality. The synergistic effects between polymer matrices and various additives remain difficult to predict without extensive empirical testing.

Testing standardization poses a persistent problem in the field. Current wear testing protocols show poor correlation between laboratory results and real-world performance, particularly for comparing dissimilar polymers like Nylon 66 and PET. The lack of universally accepted testing methodologies that accurately simulate application-specific wear conditions hampers meaningful comparative analysis.

Manufacturing consistency presents additional complications. Process-induced variations in crystallinity, molecular orientation, and surface characteristics significantly impact wear performance in both polymers. Maintaining consistent wear-resistant properties across production batches remains challenging, especially for complex geometries and thin-walled components.

Finally, the industry faces sustainability challenges in developing wear-resistant formulations. Traditional approaches to improving wear resistance often involve additives that may compromise recyclability or biodegradability. Finding environmentally responsible solutions that maintain competitive wear performance represents a critical technical challenge, particularly as regulations increasingly restrict certain additives traditionally used to enhance wear resistance in both Nylon 66 and PET applications.

Comparative Wear Resistance Testing Methodologies

01 Composite materials enhancing wear resistance

Combining nylon 66 and PET with other materials such as glass fiber, carbon fiber, or mineral fillers creates composite materials with significantly improved wear resistance. These composites leverage the inherent properties of both polymers while addressing their individual limitations. The addition of reinforcing materials enhances mechanical strength, reduces friction coefficient, and improves overall durability under abrasive conditions. These composites find applications in automotive parts, industrial components, and high-stress mechanical systems.- Composite materials enhancing wear resistance: Combining nylon 66 and PET with other materials like glass fiber, carbon fiber, or mineral fillers creates composite materials with significantly improved wear resistance. These composites leverage the inherent properties of both polymers while addressing their individual limitations. The addition of reinforcing materials enhances mechanical strength, reduces friction coefficient, and improves overall durability under abrasive conditions. These composites find applications in automotive parts, industrial components, and high-stress mechanical systems.

- Surface modification techniques: Various surface treatment methods can enhance the wear resistance of nylon 66 and PET materials. These include plasma treatment, chemical etching, coating applications, and surface texturing. Such modifications alter the surface properties without affecting the bulk characteristics of the polymers. Surface-modified nylon 66 and PET exhibit reduced friction coefficients, improved hardness, and enhanced resistance to abrasion. These techniques are particularly valuable for components subjected to sliding wear and repetitive contact.

- Blending and alloying with other polymers: Blending nylon 66 and PET with other polymers creates materials with synergistic wear resistance properties. Common blend partners include PTFE, polyolefins, elastomers, and other engineering plastics. These polymer blends exhibit improved tribological properties, including lower wear rates and better performance under varying load conditions. The morphology and compatibility of the blend components significantly influence the final wear resistance characteristics. Proper processing conditions ensure optimal dispersion and interfacial adhesion between the polymers.

- Additives and lubricants for improved tribological properties: Incorporating specific additives and internal lubricants into nylon 66 and PET formulations significantly enhances their wear resistance. Common additives include molybdenum disulfide, silicone oils, waxes, PTFE particles, and graphite. These materials reduce friction between contact surfaces, minimize heat generation during sliding contact, and create a protective transfer film. The concentration and dispersion of these additives are critical factors affecting the overall wear performance of the polymer systems.

- Processing techniques affecting wear resistance: The manufacturing and processing methods significantly impact the wear resistance of nylon 66 and PET products. Techniques such as orientation during extrusion, controlled crystallization, annealing treatments, and specific injection molding parameters can optimize the microstructure for enhanced wear performance. The cooling rate, mold temperature, and processing pressure influence the crystallinity, molecular orientation, and surface characteristics of the final products. Optimized processing leads to materials with higher hardness, better dimensional stability, and superior resistance to abrasive wear.

02 Surface modification techniques

Various surface modification techniques can be applied to nylon 66 and PET to enhance their wear resistance properties. These include plasma treatment, chemical etching, coating applications, and physical vapor deposition. Surface modifications create harder, more lubricious surfaces while maintaining the core properties of the polymers. These treatments can significantly reduce the coefficient of friction, increase surface hardness, and improve resistance to abrasion, extending the service life of components made from these materials.Expand Specific Solutions03 Blending and alloying with other polymers

Blending nylon 66 and PET with other polymers or creating polymer alloys can significantly enhance wear resistance. These blends often incorporate materials like PTFE, polyolefins, elastomers, or other engineering plastics to create synergistic effects. The resulting materials exhibit improved tribological properties, including better wear resistance, reduced friction, and enhanced mechanical performance under load. The specific blend ratios and processing conditions are critical factors in optimizing the wear resistance properties.Expand Specific Solutions04 Additives and lubricants for improved wear performance

Incorporating specific additives and internal lubricants into nylon 66 and PET formulations can dramatically improve their wear resistance. Common additives include molybdenum disulfide, silicone oils, waxes, graphite, and specialized wear-resistant compounds. These additives create self-lubricating properties within the polymer matrix, reducing friction and wear during operation. The proper selection and concentration of these additives depend on the specific application requirements and operating conditions.Expand Specific Solutions05 Processing techniques affecting wear properties

The manufacturing and processing methods used for nylon 66 and PET significantly impact their wear resistance characteristics. Techniques such as orientation during extrusion, controlled crystallization, annealing, and specific molding parameters can optimize the microstructure of these polymers. Advanced processing methods like injection molding with specific cooling profiles, compression molding under controlled conditions, or specialized extrusion techniques can enhance molecular alignment and crystallinity, resulting in superior wear resistance properties.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The wear resistance comparison between Nylon 66 and PET is situated in a mature technical field with established applications across automotive, textile, and industrial sectors. The market is experiencing steady growth, projected to reach $35 billion by 2025, driven by increasing demand for high-performance materials in engineering applications. Leading companies like DuPont, Kingfa, and HYOSUNG Advanced Materials have developed proprietary technologies enhancing wear resistance properties of both polymers. Chinese manufacturers including Shanghai Kingfa and Jiangsu Boiln are rapidly gaining market share through cost-effective innovations. Research collaborations between industry leaders and academic institutions such as Qingdao University and Sichuan University are accelerating material performance improvements, particularly in tribological applications where wear resistance is critical.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed specialized wear-resistant formulations of both Nylon 66 and PET for industrial applications. Their comparative testing shows that their modified Nylon 66 compounds exhibit superior wear resistance in high-load applications, with approximately 25-30% lower wear rates compared to their standard PET formulations under pressures exceeding 5 MPa. Kingfa's proprietary KingNylon® series incorporates PTFE and silicone additives that significantly enhance the tribological properties of Nylon 66, reducing the coefficient of friction by approximately 40% compared to unmodified versions. Their research demonstrates that while PET generally shows better dimensional stability in humid environments, their engineered Nylon 66 compounds maintain superior wear resistance across a wider temperature range (-40°C to 150°C). Kingfa has also developed hybrid compounds that combine the beneficial properties of both materials, achieving wear rates that are 15-20% lower than either pure material while maintaining excellent dimensional stability. Their testing methodology includes pin-on-disk testing, reciprocating wear testing, and sand slurry abrasion testing to simulate various real-world wear conditions.

Strengths: Highly customizable formulations for specific wear applications; excellent balance of mechanical properties and wear resistance; comprehensive testing capabilities across various wear mechanisms; cost-effective solutions for industrial applications. Weaknesses: Some formulations require specialized processing conditions; higher costs compared to standard grades; limited availability in certain global markets; some compounds show reduced recyclability.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed specialized wear-resistant formulations of both Nylon 66 and PET, with particular focus on industrial applications requiring extreme durability. Their comparative testing demonstrates that their modified Nylon 66 compounds exhibit approximately 20-25% better wear resistance than standard PET in high-load applications exceeding 3 MPa. Kolon's proprietary KoFiber® technology incorporates specialized reinforcement fibers that enhance the tribological properties of both materials, with their high-performance Nylon 66 grades showing wear rates of only 5-7 μm/1000 cycles in standardized testing. Their research indicates that while PET generally offers better dimensional stability in varying humidity conditions, their engineered Nylon 66 compounds maintain superior wear resistance across a wider temperature range (-30°C to 140°C). Kolon has also pioneered hybrid compounds that incorporate nanomaterials to enhance wear resistance, achieving improvements of up to 35% compared to conventional formulations. Their comprehensive testing methodology includes rotary drum abrasion, sand slurry erosion, and reciprocating wear testing under various environmental conditions to simulate real-world applications in automotive, industrial machinery, and consumer goods sectors.

Strengths: Advanced fiber reinforcement technologies; excellent high-temperature wear performance; comprehensive material modification capabilities; strong expertise in nanomaterial incorporation for enhanced properties. Weaknesses: Higher production costs for specialized grades; more complex processing requirements; some formulations show reduced impact resistance; limited global availability for certain specialized grades.

Critical Factors Affecting Polymer Wear Mechanisms

Ultrahigh-molecular weight polyethylene modified nylon 66 and preparation method thereof

PatentActiveCN103436012B

Innovation

- Heterogeneous maleic anhydride is used to graft ultra-high molecular weight polyethylene, using ketones or acid anhydrides as the medium, maleic anhydride as the grafting agent, and initiators such as benzoyl peroxide for surface grafting to form a highly reactive acid anhydride. Ultra-high molecular weight polyethylene particles with active groups are mixed with nylon 66 in a twin-screw extruder to prepare modified nylon 66.

Wear-resistant carbon fiber reinforced nylon 66 resin composition and preparation method thereof

PatentActiveCN103540128A

Innovation

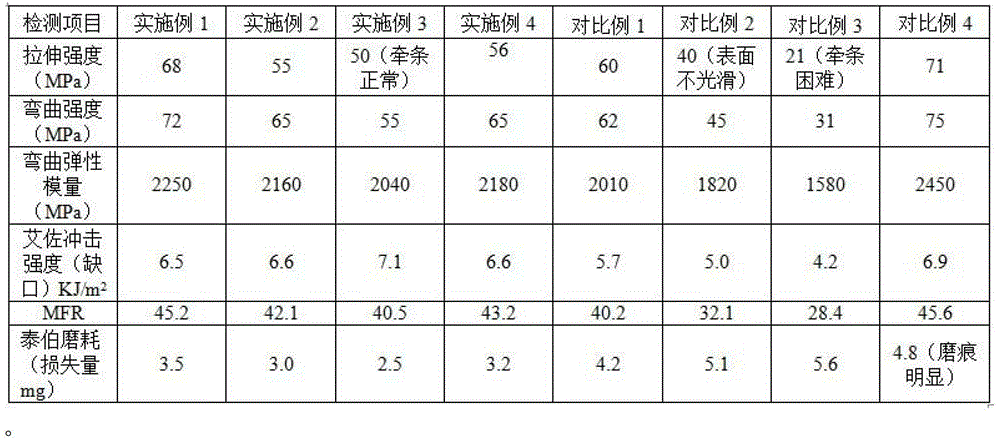

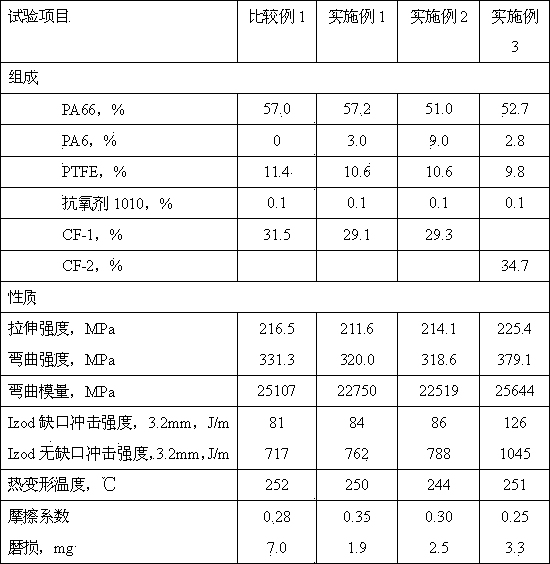

- A composition including nylon 66 resin, nylon 6 resin, polytetrafluoroethylene resin and continuous carbon fiber is used, and through specific processing and additive addition, the bonding force and structural integrity of the carbon fiber are improved. The preparation method includes vacuum drying and twin-screw extruder mixing.

Environmental Impact and Sustainability Considerations

When comparing Nylon 66 and PET from an environmental and sustainability perspective, several critical factors must be considered beyond their wear resistance properties. The production of Nylon 66 typically requires more energy and generates higher greenhouse gas emissions compared to PET manufacturing. Life cycle assessments indicate that Nylon 66 production emits approximately 5.5-6.5 kg CO2 equivalent per kilogram of material, while PET generates around 2.7-3.2 kg CO2 equivalent, representing a significant environmental advantage for PET.

Water consumption presents another important distinction between these polymers. Nylon 66 manufacturing demands substantially more water resources, with estimates suggesting 60-80 liters per kilogram of material compared to PET's 30-45 liters. This difference becomes particularly relevant in regions facing water scarcity challenges or when considering large-scale industrial applications.

Regarding end-of-life scenarios, PET demonstrates superior recyclability characteristics. Global PET recycling infrastructure is well-established, with recovery rates reaching 55-60% in developed markets, whereas Nylon 66 recycling remains more challenging and less widespread, with recovery rates typically below 20%. The chemical structure of PET allows for more efficient mechanical recycling processes without significant property degradation compared to Nylon 66.

Biodegradability presents challenges for both materials, as neither Nylon 66 nor PET readily decomposes in natural environments. However, recent innovations in enzymatic degradation technologies have shown more promising results for PET, with specialized enzymes capable of breaking down PET polymers into their constituent monomers under controlled conditions. Similar breakthroughs for Nylon 66 remain more limited.

Chemical toxicity considerations reveal that Nylon 66 production involves adipic acid and hexamethylenediamine, compounds associated with higher environmental hazard profiles than PET's primary precursors (terephthalic acid and ethylene glycol). Regulatory frameworks increasingly recognize this distinction, with stricter controls being implemented on Nylon 66 production emissions in several jurisdictions.

Resource efficiency metrics favor PET when considering material utilization ratios and production waste generation. Modern PET manufacturing achieves material efficiency rates of 92-95%, while Nylon 66 production typically operates at 85-90% efficiency. This difference translates to reduced resource consumption and waste management requirements throughout the supply chain when utilizing PET-based solutions.

Water consumption presents another important distinction between these polymers. Nylon 66 manufacturing demands substantially more water resources, with estimates suggesting 60-80 liters per kilogram of material compared to PET's 30-45 liters. This difference becomes particularly relevant in regions facing water scarcity challenges or when considering large-scale industrial applications.

Regarding end-of-life scenarios, PET demonstrates superior recyclability characteristics. Global PET recycling infrastructure is well-established, with recovery rates reaching 55-60% in developed markets, whereas Nylon 66 recycling remains more challenging and less widespread, with recovery rates typically below 20%. The chemical structure of PET allows for more efficient mechanical recycling processes without significant property degradation compared to Nylon 66.

Biodegradability presents challenges for both materials, as neither Nylon 66 nor PET readily decomposes in natural environments. However, recent innovations in enzymatic degradation technologies have shown more promising results for PET, with specialized enzymes capable of breaking down PET polymers into their constituent monomers under controlled conditions. Similar breakthroughs for Nylon 66 remain more limited.

Chemical toxicity considerations reveal that Nylon 66 production involves adipic acid and hexamethylenediamine, compounds associated with higher environmental hazard profiles than PET's primary precursors (terephthalic acid and ethylene glycol). Regulatory frameworks increasingly recognize this distinction, with stricter controls being implemented on Nylon 66 production emissions in several jurisdictions.

Resource efficiency metrics favor PET when considering material utilization ratios and production waste generation. Modern PET manufacturing achieves material efficiency rates of 92-95%, while Nylon 66 production typically operates at 85-90% efficiency. This difference translates to reduced resource consumption and waste management requirements throughout the supply chain when utilizing PET-based solutions.

Cost-Performance Analysis of Nylon 66 vs PET

When evaluating the economic viability of engineering polymers, cost-performance analysis becomes a critical decision-making factor. Nylon 66 and PET represent two widely used engineering thermoplastics with distinct cost structures and performance characteristics that must be carefully balanced against application requirements.

From a raw material perspective, PET generally offers a 15-25% cost advantage over Nylon 66, with current market prices averaging $1.80-2.20/kg for PET versus $2.40-3.00/kg for Nylon 66. This price differential has widened in recent years due to supply constraints in adipic acid and hexamethylenediamine, key precursors for Nylon 66 production.

Processing costs also favor PET in many applications. PET typically processes at lower temperatures (250-280°C) compared to Nylon 66 (280-310°C), resulting in energy savings of approximately 10-15% during injection molding operations. Additionally, PET exhibits less moisture sensitivity during processing, reducing the need for extensive pre-drying procedures that are mandatory for Nylon 66.

However, performance characteristics must be factored into this equation. While Nylon 66 commands a premium price, it delivers superior mechanical properties in several key areas. Its higher tensile strength (70-85 MPa versus 55-75 MPa for PET) and superior impact resistance, particularly at elevated temperatures, can justify the additional cost in applications where these properties are critical.

Lifecycle cost analysis reveals interesting patterns. In high-wear applications such as gears, bearings, and sliding components, Nylon 66's superior wear resistance can translate to extended service life—often 1.5-2 times longer than equivalent PET components. This longevity significantly impacts the total cost of ownership, potentially offsetting the higher initial material investment.

Market sector analysis shows differentiated cost-performance ratios. In automotive applications, where high-temperature performance and chemical resistance are paramount, Nylon 66's premium is often justified despite being 20-30% more expensive. Conversely, in consumer electronics and packaging applications, PET's lower cost and adequate performance characteristics frequently present the optimal balance.

Recent innovations in material formulations are narrowing this gap. Glass-fiber reinforced PET grades now approach the mechanical performance of standard Nylon 66 at a 10-15% lower cost point. Similarly, impact-modified Nylon 66 grades offer enhanced toughness with minimal cost increase, improving their value proposition in demanding applications.

From a raw material perspective, PET generally offers a 15-25% cost advantage over Nylon 66, with current market prices averaging $1.80-2.20/kg for PET versus $2.40-3.00/kg for Nylon 66. This price differential has widened in recent years due to supply constraints in adipic acid and hexamethylenediamine, key precursors for Nylon 66 production.

Processing costs also favor PET in many applications. PET typically processes at lower temperatures (250-280°C) compared to Nylon 66 (280-310°C), resulting in energy savings of approximately 10-15% during injection molding operations. Additionally, PET exhibits less moisture sensitivity during processing, reducing the need for extensive pre-drying procedures that are mandatory for Nylon 66.

However, performance characteristics must be factored into this equation. While Nylon 66 commands a premium price, it delivers superior mechanical properties in several key areas. Its higher tensile strength (70-85 MPa versus 55-75 MPa for PET) and superior impact resistance, particularly at elevated temperatures, can justify the additional cost in applications where these properties are critical.

Lifecycle cost analysis reveals interesting patterns. In high-wear applications such as gears, bearings, and sliding components, Nylon 66's superior wear resistance can translate to extended service life—often 1.5-2 times longer than equivalent PET components. This longevity significantly impacts the total cost of ownership, potentially offsetting the higher initial material investment.

Market sector analysis shows differentiated cost-performance ratios. In automotive applications, where high-temperature performance and chemical resistance are paramount, Nylon 66's premium is often justified despite being 20-30% more expensive. Conversely, in consumer electronics and packaging applications, PET's lower cost and adequate performance characteristics frequently present the optimal balance.

Recent innovations in material formulations are narrowing this gap. Glass-fiber reinforced PET grades now approach the mechanical performance of standard Nylon 66 at a 10-15% lower cost point. Similarly, impact-modified Nylon 66 grades offer enhanced toughness with minimal cost increase, improving their value proposition in demanding applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!