Nylon 66 vs PMMA: Impact Strength for Transparent Objects

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Polymers Evolution and Objectives

Transparent polymers have evolved significantly over the past century, transforming from rudimentary materials with limited optical clarity to sophisticated engineering plastics with exceptional transparency and mechanical properties. The journey began in the early 20th century with celluloid and cellulose acetate, which offered basic transparency but suffered from yellowing and poor durability. The 1930s marked a pivotal moment with the development of polymethyl methacrylate (PMMA), commercially known as acrylic or Plexiglas, which revolutionized transparent materials with its exceptional optical clarity.

The 1950s witnessed the emergence of polycarbonate, offering superior impact resistance while maintaining good transparency. Concurrently, engineering polymers like Nylon 66, though primarily valued for mechanical properties, began to be explored for applications requiring both strength and varying degrees of transparency. The subsequent decades saw continuous refinement in polymer chemistry, processing techniques, and additive technologies, enabling manufacturers to enhance the balance between transparency and mechanical performance.

Recent advancements have focused on developing transparent polymers with tailored impact strength profiles. This evolution has been driven by increasing demands from industries such as automotive, aerospace, medical devices, and consumer electronics, where transparent components must withstand significant mechanical stress while maintaining optical clarity. The comparison between Nylon 66 and PMMA represents a critical intersection in this evolution, as these materials embody different approaches to achieving transparency and impact resistance.

The primary objective of current research is to understand the fundamental relationship between molecular structure, processing conditions, and the resulting optical and mechanical properties. Specifically, researchers aim to identify how the semi-crystalline nature of Nylon 66 affects its potential for transparency compared to the amorphous structure of PMMA, and how these structural differences influence impact resistance under various conditions.

Additional goals include developing enhanced formulations or composites that combine the superior impact strength of engineering polymers like Nylon 66 with the exceptional transparency of optical polymers like PMMA. This includes exploring novel additives, reinforcement strategies, and processing techniques that can minimize light scattering while maximizing energy absorption during impact events.

The ultimate aim is to establish design guidelines and material selection criteria for transparent components based on specific impact requirements, enabling engineers to make informed decisions when balancing optical clarity against mechanical performance. This research has significant implications for safety-critical applications where both visibility and impact protection are essential, such as protective eyewear, vehicle windshields, aircraft windows, and medical face shields.

The 1950s witnessed the emergence of polycarbonate, offering superior impact resistance while maintaining good transparency. Concurrently, engineering polymers like Nylon 66, though primarily valued for mechanical properties, began to be explored for applications requiring both strength and varying degrees of transparency. The subsequent decades saw continuous refinement in polymer chemistry, processing techniques, and additive technologies, enabling manufacturers to enhance the balance between transparency and mechanical performance.

Recent advancements have focused on developing transparent polymers with tailored impact strength profiles. This evolution has been driven by increasing demands from industries such as automotive, aerospace, medical devices, and consumer electronics, where transparent components must withstand significant mechanical stress while maintaining optical clarity. The comparison between Nylon 66 and PMMA represents a critical intersection in this evolution, as these materials embody different approaches to achieving transparency and impact resistance.

The primary objective of current research is to understand the fundamental relationship between molecular structure, processing conditions, and the resulting optical and mechanical properties. Specifically, researchers aim to identify how the semi-crystalline nature of Nylon 66 affects its potential for transparency compared to the amorphous structure of PMMA, and how these structural differences influence impact resistance under various conditions.

Additional goals include developing enhanced formulations or composites that combine the superior impact strength of engineering polymers like Nylon 66 with the exceptional transparency of optical polymers like PMMA. This includes exploring novel additives, reinforcement strategies, and processing techniques that can minimize light scattering while maximizing energy absorption during impact events.

The ultimate aim is to establish design guidelines and material selection criteria for transparent components based on specific impact requirements, enabling engineers to make informed decisions when balancing optical clarity against mechanical performance. This research has significant implications for safety-critical applications where both visibility and impact protection are essential, such as protective eyewear, vehicle windshields, aircraft windows, and medical face shields.

Market Analysis for High-Impact Transparent Materials

The transparent materials market for high-impact applications has been experiencing significant growth, driven by increasing demand across automotive, electronics, medical devices, and consumer goods sectors. The global market for high-impact transparent polymers reached approximately $7.2 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028, potentially reaching $10.7 billion by the end of the forecast period.

Within this market, Nylon 66 and PMMA (Polymethyl Methacrylate) represent two distinct material solutions with different value propositions. PMMA currently dominates the transparent materials segment with roughly 38% market share due to its exceptional optical clarity (92% light transmission) and moderate impact resistance. The PMMA market alone was valued at $3.9 billion in 2022, with applications requiring both transparency and impact resistance accounting for approximately 45% of this value.

Nylon 66, traditionally known for its mechanical strength rather than transparency, has been gaining traction in modified transparent formulations. The market for transparent polyamides, including modified Nylon 66, has grown at 8.3% annually over the past five years, outpacing the broader transparent polymers market. This growth is primarily driven by applications requiring higher temperature resistance and superior impact strength compared to PMMA.

Regional analysis reveals that Asia-Pacific represents the largest market for high-impact transparent materials (41% of global demand), followed by North America (28%) and Europe (24%). China and India are experiencing the fastest growth rates at 9.2% and 8.7% respectively, driven by rapid industrialization and increasing domestic consumption of electronic devices and automotive components.

End-user segmentation shows automotive applications leading demand (32%), followed by electronics (27%), medical devices (18%), and consumer goods (14%). The automotive sector's shift toward lightweight materials for improved fuel efficiency and the growing integration of displays and sensors has particularly benefited high-impact transparent materials.

Price sensitivity analysis indicates that while PMMA maintains a competitive advantage with average prices of $2.80-$3.50 per kilogram, specialized transparent Nylon 66 formulations command premium pricing of $6.50-$9.00 per kilogram due to their enhanced performance characteristics. This price differential has created distinct market segments, with PMMA dominating cost-sensitive applications and modified Nylon 66 capturing high-performance niches.

Market forecasts suggest that materials combining transparency with enhanced impact resistance will see accelerated adoption, with a projected compound annual growth rate of 7.5% through 2028, outpacing the broader transparent materials market. This trend is particularly evident in applications requiring both optical clarity and resistance to mechanical stress or impact.

Within this market, Nylon 66 and PMMA (Polymethyl Methacrylate) represent two distinct material solutions with different value propositions. PMMA currently dominates the transparent materials segment with roughly 38% market share due to its exceptional optical clarity (92% light transmission) and moderate impact resistance. The PMMA market alone was valued at $3.9 billion in 2022, with applications requiring both transparency and impact resistance accounting for approximately 45% of this value.

Nylon 66, traditionally known for its mechanical strength rather than transparency, has been gaining traction in modified transparent formulations. The market for transparent polyamides, including modified Nylon 66, has grown at 8.3% annually over the past five years, outpacing the broader transparent polymers market. This growth is primarily driven by applications requiring higher temperature resistance and superior impact strength compared to PMMA.

Regional analysis reveals that Asia-Pacific represents the largest market for high-impact transparent materials (41% of global demand), followed by North America (28%) and Europe (24%). China and India are experiencing the fastest growth rates at 9.2% and 8.7% respectively, driven by rapid industrialization and increasing domestic consumption of electronic devices and automotive components.

End-user segmentation shows automotive applications leading demand (32%), followed by electronics (27%), medical devices (18%), and consumer goods (14%). The automotive sector's shift toward lightweight materials for improved fuel efficiency and the growing integration of displays and sensors has particularly benefited high-impact transparent materials.

Price sensitivity analysis indicates that while PMMA maintains a competitive advantage with average prices of $2.80-$3.50 per kilogram, specialized transparent Nylon 66 formulations command premium pricing of $6.50-$9.00 per kilogram due to their enhanced performance characteristics. This price differential has created distinct market segments, with PMMA dominating cost-sensitive applications and modified Nylon 66 capturing high-performance niches.

Market forecasts suggest that materials combining transparency with enhanced impact resistance will see accelerated adoption, with a projected compound annual growth rate of 7.5% through 2028, outpacing the broader transparent materials market. This trend is particularly evident in applications requiring both optical clarity and resistance to mechanical stress or impact.

Technical Comparison of Nylon 66 and PMMA Properties

Nylon 66 and PMMA (Polymethyl Methacrylate) represent two distinct polymer families with significant differences in their mechanical, optical, and thermal properties. When considering transparent applications requiring impact resistance, these differences become particularly relevant for material selection decisions.

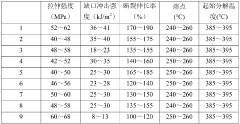

Nylon 66, a semi-crystalline polyamide, exhibits excellent mechanical strength, abrasion resistance, and fatigue resistance. Its impact strength typically ranges from 53-160 J/m (notched Izod), making it considerably tougher than many other engineering plastics. However, in its natural state, Nylon 66 is translucent to opaque due to its crystalline structure, which significantly limits its application in transparent products without substantial modification.

PMMA, commonly known as acrylic or by trade names like Plexiglas and Lucite, is an amorphous thermoplastic with outstanding optical clarity, with light transmission rates of approximately 92%. Its impact strength is moderate, typically measuring 16-32 J/m (notched Izod), which is significantly lower than Nylon 66. However, PMMA's naturally transparent nature makes it the preferred choice for optical applications despite its lower impact resistance.

The tensile strength of Nylon 66 (70-85 MPa) exceeds that of PMMA (48-76 MPa), further highlighting Nylon 66's superior mechanical properties. Similarly, Nylon 66 demonstrates better heat resistance with a heat deflection temperature of approximately 75-80°C compared to PMMA's 65-105°C (depending on grade).

Water absorption represents another critical difference, with Nylon 66 absorbing 1.0-1.5% moisture at equilibrium, which can affect dimensional stability and mechanical properties. PMMA, conversely, absorbs only about 0.3-0.4% moisture, maintaining more consistent properties in humid environments.

For UV resistance, PMMA naturally outperforms Nylon 66, showing excellent weatherability and UV stability without additives. Nylon 66 typically requires UV stabilizers to prevent yellowing and degradation when exposed to sunlight.

Processing characteristics also differ significantly. PMMA can be easily thermoformed, cast, or injection molded with excellent surface finish and dimensional accuracy. Nylon 66 requires higher processing temperatures (260-290°C vs. PMMA's 210-250°C) and presents challenges in achieving optical clarity during processing.

Cost considerations favor Nylon 66 for structural applications, while PMMA may be more economical for optical applications when considering the additional processing required to achieve transparency in Nylon 66.

When specifically evaluating impact strength for transparent objects, modified grades of both materials exist. Impact-modified PMMA can achieve impact strengths of 53-80 J/m, while transparent Nylon formulations typically sacrifice some impact performance to achieve clarity.

Nylon 66, a semi-crystalline polyamide, exhibits excellent mechanical strength, abrasion resistance, and fatigue resistance. Its impact strength typically ranges from 53-160 J/m (notched Izod), making it considerably tougher than many other engineering plastics. However, in its natural state, Nylon 66 is translucent to opaque due to its crystalline structure, which significantly limits its application in transparent products without substantial modification.

PMMA, commonly known as acrylic or by trade names like Plexiglas and Lucite, is an amorphous thermoplastic with outstanding optical clarity, with light transmission rates of approximately 92%. Its impact strength is moderate, typically measuring 16-32 J/m (notched Izod), which is significantly lower than Nylon 66. However, PMMA's naturally transparent nature makes it the preferred choice for optical applications despite its lower impact resistance.

The tensile strength of Nylon 66 (70-85 MPa) exceeds that of PMMA (48-76 MPa), further highlighting Nylon 66's superior mechanical properties. Similarly, Nylon 66 demonstrates better heat resistance with a heat deflection temperature of approximately 75-80°C compared to PMMA's 65-105°C (depending on grade).

Water absorption represents another critical difference, with Nylon 66 absorbing 1.0-1.5% moisture at equilibrium, which can affect dimensional stability and mechanical properties. PMMA, conversely, absorbs only about 0.3-0.4% moisture, maintaining more consistent properties in humid environments.

For UV resistance, PMMA naturally outperforms Nylon 66, showing excellent weatherability and UV stability without additives. Nylon 66 typically requires UV stabilizers to prevent yellowing and degradation when exposed to sunlight.

Processing characteristics also differ significantly. PMMA can be easily thermoformed, cast, or injection molded with excellent surface finish and dimensional accuracy. Nylon 66 requires higher processing temperatures (260-290°C vs. PMMA's 210-250°C) and presents challenges in achieving optical clarity during processing.

Cost considerations favor Nylon 66 for structural applications, while PMMA may be more economical for optical applications when considering the additional processing required to achieve transparency in Nylon 66.

When specifically evaluating impact strength for transparent objects, modified grades of both materials exist. Impact-modified PMMA can achieve impact strengths of 53-80 J/m, while transparent Nylon formulations typically sacrifice some impact performance to achieve clarity.

Current Engineering Solutions for Transparent Impact Resistance

01 Blending Nylon 66 with PMMA for improved impact strength

Combining Nylon 66 with PMMA creates polymer blends with enhanced impact resistance properties. The proper ratio of these polymers can significantly improve impact strength while maintaining other desirable mechanical properties. Various compatibilizers may be used to ensure good interfacial adhesion between the two polymers, resulting in a more uniform blend with superior impact performance.- Blending Nylon 66 with PMMA for improved impact strength: Combining Nylon 66 with PMMA creates polymer blends with enhanced impact resistance properties. The proper ratio of these polymers can significantly improve impact strength while maintaining other desirable mechanical properties. Various compatibilizers may be used to ensure good interfacial adhesion between the two polymers, resulting in a more uniform blend with superior impact performance.

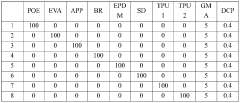

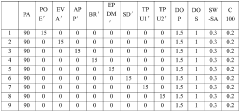

- Impact modifiers for Nylon 66/PMMA composites: Specific impact modifiers can be incorporated into Nylon 66/PMMA blends to further enhance impact strength. These modifiers include elastomeric compounds, core-shell particles, and functionalized rubbers that can absorb impact energy and prevent crack propagation. The proper selection and concentration of impact modifiers can significantly improve the toughness of these polymer systems without substantially compromising other mechanical properties.

- Processing techniques affecting impact strength: The processing methods used for Nylon 66/PMMA blends significantly influence the final impact strength properties. Techniques such as reactive extrusion, specific temperature profiles during molding, and controlled cooling rates can optimize the morphology of the blend. Advanced processing methods can improve the dispersion of components and enhance interfacial adhesion, resulting in materials with superior impact resistance.

- Nanofillers for reinforcing Nylon 66/PMMA systems: Incorporating nanofillers into Nylon 66/PMMA blends can significantly enhance impact strength. Materials such as nanoclay, carbon nanotubes, graphene, and nanosilica can create reinforced polymer nanocomposites with improved mechanical properties. These nanofillers can act as stress concentrators and energy dissipation points, effectively increasing the impact resistance of the composite material while maintaining or improving other mechanical properties.

- Surface treatments and modifications for enhanced impact properties: Surface treatments and chemical modifications of either Nylon 66 or PMMA can improve compatibility and impact strength in blended systems. Techniques such as grafting, functionalization with reactive groups, and surface activation can enhance interfacial adhesion between the polymers. These modifications create stronger interactions at the polymer interfaces, resulting in more efficient stress transfer and improved impact resistance in the final composite material.

02 Impact modifiers for Nylon 66/PMMA composites

Specific impact modifiers can be incorporated into Nylon 66/PMMA blends to further enhance impact strength. These modifiers include elastomeric compounds, core-shell particles, and functionalized rubbers that can absorb impact energy and prevent crack propagation. The proper selection and concentration of impact modifiers can significantly improve the toughness of these polymer systems without compromising other mechanical properties.Expand Specific Solutions03 Processing techniques to enhance impact properties

Various processing techniques can be employed to optimize the impact strength of Nylon 66/PMMA materials. These include specific extrusion parameters, injection molding conditions, annealing processes, and cooling rates that affect the crystallinity and morphology of the polymer blend. Proper processing can lead to improved molecular orientation and interfacial adhesion between components, resulting in enhanced impact resistance.Expand Specific Solutions04 Reinforcement materials for improved impact strength

The addition of reinforcement materials such as glass fibers, carbon fibers, or mineral fillers to Nylon 66/PMMA blends can significantly enhance impact strength. These reinforcements create a three-dimensional network within the polymer matrix that helps distribute impact forces. Surface-treated reinforcements with coupling agents ensure better adhesion to the polymer matrix, further improving impact resistance properties.Expand Specific Solutions05 Nanocomposite formulations for enhanced impact performance

Incorporating nanomaterials such as nanoclay, carbon nanotubes, or graphene into Nylon 66/PMMA blends can dramatically improve impact strength at low loading levels. These nanofillers create unique morphological structures that effectively dissipate impact energy. The high surface area of nanomaterials allows for better interaction with the polymer matrix, resulting in superior mechanical properties including enhanced impact resistance.Expand Specific Solutions

Leading Manufacturers in High-Performance Transparent Materials

The transparent materials market for impact-resistant applications is currently in a growth phase, with an estimated global market size exceeding $7 billion. The competition between Nylon 66 and PMMA (polymethyl methacrylate) represents a key technological battleground where impact strength meets transparency requirements. Industry leaders ROEHM GMBH dominates the PMMA sector with their Plexiglas® products, while BASF and Mitsubishi Gas Chemical lead in Nylon 66 innovations. The technology maturity differs significantly - PMMA is well-established with excellent optical properties but moderate impact resistance, while modified Nylon 66 is emerging as a viable alternative offering superior impact strength with improving transparency. Companies like Kingfa, Toyobo, and Arkema are actively developing hybrid solutions that combine the advantages of both materials, indicating a trend toward specialized composite formulations for high-performance applications.

ROEHM GMBH

Technical Solution: ROEHM GMBH is a global leader in PMMA (polymethyl methacrylate) production, marketing their products under the PLEXIGLAS® brand. Their technical approach focuses on enhancing PMMA's impact resistance through molecular weight optimization and rubber modification. Their IMPACT modified PMMA grades incorporate elastomeric particles within the polymer matrix, creating a two-phase system that effectively absorbs and dissipates impact energy. This technology allows the material to maintain up to 92% light transmission while significantly improving impact resistance. ROEHM has developed proprietary processing techniques that ensure uniform distribution of impact modifiers throughout the polymer, preventing optical distortion. Their latest generation of impact-modified PMMA achieves Charpy impact strengths of 15-20 kJ/m², substantially higher than standard PMMA (2-3 kJ/m²), while maintaining transparency above 89%.

Strengths: Superior optical clarity (92% light transmission) combined with improved impact resistance; excellent weatherability and UV resistance; precise control of impact modifier distribution maintains optical quality. Weaknesses: Still generally lower impact strength than modified Nylon 66; higher cost than standard PMMA; impact modification reduces heat resistance compared to standard PMMA.

BASF Corp.

Technical Solution: BASF has developed advanced Nylon 66 formulations under their Ultramid® brand specifically addressing transparency and impact strength challenges. Their proprietary technology involves controlling crystallization behavior through precise thermal processing and nucleating agents to achieve semi-transparent to transparent Nylon 66 variants. BASF's approach includes incorporating nano-scale impact modifiers and specialized compatibilizers that maintain optical clarity while enhancing impact resistance. Their Ultramid® Vision line achieves light transmission of 85-90% in thin sections with Charpy notched impact strength values of 12-15 kJ/m² at room temperature. BASF has also pioneered hybrid materials combining Nylon 66 with amorphous polymers to balance transparency and mechanical properties. Their technology includes special processing aids that improve mold filling and prevent yellowing during processing, maintaining optical quality while preserving the superior chemical resistance and thermal stability inherent to Nylon 66.

Strengths: Excellent balance of transparency and mechanical properties; superior chemical resistance compared to PMMA; better heat resistance and dimensional stability than PMMA; maintains mechanical properties across wider temperature range. Weaknesses: Transparency still not equal to PMMA (maximum 90% vs. 92%+ for PMMA); moisture sensitivity can affect optical properties over time; higher processing temperatures required compared to PMMA.

Key Patents in Transparent Polymer Impact Enhancement

Polymethyl methacrylate based moulding materials having improved impact strength

PatentInactiveEP0606636A1

Innovation

- A molding composition comprising 5 to 95% by weight of polymethyl methacrylate, 0 to 20% by weight of a C₁-C₂₀ alkyl ester of acrylic acid, and 95 to 5% by weight of a multistage graft copolymer, combined with 0.01 to 5% by weight of a polysiloxane, where the polysiloxane is specifically formulated to enhance notched impact strength while maintaining high light transmittance and low yellowness.

Nylon composite material capable of tolerating alpine region impact, and preparation method thereof

PatentActiveCN109880360A

Innovation

- A composite material composed of nylon, modified toughening agent, cold-resistant plasticizer and heat stabilizer is mixed in a high-speed mixer and melt-blended using a twin-screw extruder to prepare a composite material with improved High temperature resistant nylon composite material with high impact strength and toughness.

Manufacturing Process Optimization for Transparent Polymers

Manufacturing Process Optimization for Transparent Polymers

The manufacturing processes for transparent polymers like Nylon 66 and PMMA require careful optimization to achieve optimal impact strength while maintaining transparency. For Nylon 66, which is naturally semi-crystalline and typically opaque, specialized processing techniques are essential to enhance transparency while preserving mechanical properties.

Injection molding parameters significantly influence the final properties of both materials. For PMMA, lower injection speeds and moderate mold temperatures (70-90°C) typically yield the best combination of optical clarity and impact resistance. Nylon 66 requires higher processing temperatures (270-290°C) and rapid cooling strategies to minimize crystallization that would otherwise reduce transparency.

Moisture control represents a critical factor in processing both polymers, though for different reasons. Nylon 66 is highly hygroscopic and requires thorough drying (typically at 80°C for 4-6 hours) before processing to prevent hydrolytic degradation that compromises both transparency and impact strength. PMMA, while less moisture-sensitive, still benefits from pre-drying to avoid surface defects that can create stress concentration points.

Annealing processes can significantly enhance the impact strength of both materials. For PMMA, controlled cooling after molding reduces internal stresses that might otherwise create fracture initiation points. Nylon 66 benefits from specialized annealing protocols that balance crystallinity reduction (for transparency) with molecular orientation (for impact strength).

Additives management presents another optimization opportunity. Impact modifiers can be incorporated into both polymers, though they must be carefully selected to maintain transparency. For PMMA, core-shell rubber particles at 2-5% concentration can increase impact strength by 200-300% with minimal effect on transparency. For Nylon 66, specialized transparent impact modifiers based on functionalized elastomers have shown promising results when precisely dispersed.

Mold design also plays a crucial role in optimizing transparent polymer properties. Gates should be positioned to minimize weld lines, which create weak points particularly vulnerable to impact. Wall thickness uniformity is essential to prevent internal stress concentrations, with optimal thickness ranging from 2-4mm for both materials to balance transparency with impact resistance.

Advanced techniques like gas-assisted injection molding can further enhance the impact strength of transparent parts by creating more uniform internal structures and reducing sink marks that might otherwise serve as stress concentrators. Similarly, multi-component molding allows for strategic reinforcement of high-stress areas while maintaining transparency in visible sections.

The manufacturing processes for transparent polymers like Nylon 66 and PMMA require careful optimization to achieve optimal impact strength while maintaining transparency. For Nylon 66, which is naturally semi-crystalline and typically opaque, specialized processing techniques are essential to enhance transparency while preserving mechanical properties.

Injection molding parameters significantly influence the final properties of both materials. For PMMA, lower injection speeds and moderate mold temperatures (70-90°C) typically yield the best combination of optical clarity and impact resistance. Nylon 66 requires higher processing temperatures (270-290°C) and rapid cooling strategies to minimize crystallization that would otherwise reduce transparency.

Moisture control represents a critical factor in processing both polymers, though for different reasons. Nylon 66 is highly hygroscopic and requires thorough drying (typically at 80°C for 4-6 hours) before processing to prevent hydrolytic degradation that compromises both transparency and impact strength. PMMA, while less moisture-sensitive, still benefits from pre-drying to avoid surface defects that can create stress concentration points.

Annealing processes can significantly enhance the impact strength of both materials. For PMMA, controlled cooling after molding reduces internal stresses that might otherwise create fracture initiation points. Nylon 66 benefits from specialized annealing protocols that balance crystallinity reduction (for transparency) with molecular orientation (for impact strength).

Additives management presents another optimization opportunity. Impact modifiers can be incorporated into both polymers, though they must be carefully selected to maintain transparency. For PMMA, core-shell rubber particles at 2-5% concentration can increase impact strength by 200-300% with minimal effect on transparency. For Nylon 66, specialized transparent impact modifiers based on functionalized elastomers have shown promising results when precisely dispersed.

Mold design also plays a crucial role in optimizing transparent polymer properties. Gates should be positioned to minimize weld lines, which create weak points particularly vulnerable to impact. Wall thickness uniformity is essential to prevent internal stress concentrations, with optimal thickness ranging from 2-4mm for both materials to balance transparency with impact resistance.

Advanced techniques like gas-assisted injection molding can further enhance the impact strength of transparent parts by creating more uniform internal structures and reducing sink marks that might otherwise serve as stress concentrators. Similarly, multi-component molding allows for strategic reinforcement of high-stress areas while maintaining transparency in visible sections.

Sustainability Aspects of Nylon 66 and PMMA Production

The production processes of both Nylon 66 and PMMA present distinct environmental challenges and sustainability considerations that manufacturers must address. Nylon 66 production typically involves the polymerization of hexamethylenediamine and adipic acid, processes that generate significant greenhouse gas emissions, particularly nitrous oxide (N2O). Recent industry data indicates that for every kilogram of Nylon 66 produced, approximately 5-7 kg of CO2 equivalent emissions are generated, positioning it as a material with a substantial carbon footprint.

In contrast, PMMA production, based on the polymerization of methyl methacrylate, generally exhibits a lower environmental impact with approximately 3-4 kg of CO2 equivalent emissions per kilogram of material. However, PMMA production involves the use of petroleum-derived feedstocks and potentially hazardous chemicals such as acetone cyanohydrin, raising concerns about resource depletion and chemical safety.

Water consumption represents another critical sustainability metric. Nylon 66 manufacturing requires significant water volumes for cooling and washing processes, with estimates suggesting 200-300 liters per kilogram of product. PMMA production demonstrates more favorable water efficiency, typically consuming 100-150 liters per kilogram, representing a notable advantage in regions facing water scarcity challenges.

End-of-life considerations further differentiate these materials. Nylon 66 offers established mechanical recycling pathways, with approximately 20% of post-industrial waste currently being recycled globally. Chemical recycling technologies for Nylon 66 are advancing rapidly, potentially enabling closed-loop systems. PMMA demonstrates superior recyclability characteristics, with up to 80% recovery rates through depolymerization processes that yield monomer suitable for virgin-quality material production.

Recent innovations in both material systems are addressing sustainability concerns. Bio-based precursors for Nylon 66, derived from renewable resources rather than petroleum, have emerged in commercial applications, reducing fossil resource dependence. Similarly, bio-based PMMA variants utilizing sugarcane-derived feedstocks have entered commercial production, offering carbon footprint reductions of 20-30% compared to conventional counterparts.

Energy consumption during manufacturing presents additional sustainability considerations. Nylon 66 production typically requires 80-100 MJ/kg, while PMMA manufacturing consumes approximately 70-90 MJ/kg. Both industries are implementing energy efficiency measures, with leading manufacturers reporting 15-25% energy reductions through process optimizations and renewable energy integration over the past decade.

In contrast, PMMA production, based on the polymerization of methyl methacrylate, generally exhibits a lower environmental impact with approximately 3-4 kg of CO2 equivalent emissions per kilogram of material. However, PMMA production involves the use of petroleum-derived feedstocks and potentially hazardous chemicals such as acetone cyanohydrin, raising concerns about resource depletion and chemical safety.

Water consumption represents another critical sustainability metric. Nylon 66 manufacturing requires significant water volumes for cooling and washing processes, with estimates suggesting 200-300 liters per kilogram of product. PMMA production demonstrates more favorable water efficiency, typically consuming 100-150 liters per kilogram, representing a notable advantage in regions facing water scarcity challenges.

End-of-life considerations further differentiate these materials. Nylon 66 offers established mechanical recycling pathways, with approximately 20% of post-industrial waste currently being recycled globally. Chemical recycling technologies for Nylon 66 are advancing rapidly, potentially enabling closed-loop systems. PMMA demonstrates superior recyclability characteristics, with up to 80% recovery rates through depolymerization processes that yield monomer suitable for virgin-quality material production.

Recent innovations in both material systems are addressing sustainability concerns. Bio-based precursors for Nylon 66, derived from renewable resources rather than petroleum, have emerged in commercial applications, reducing fossil resource dependence. Similarly, bio-based PMMA variants utilizing sugarcane-derived feedstocks have entered commercial production, offering carbon footprint reductions of 20-30% compared to conventional counterparts.

Energy consumption during manufacturing presents additional sustainability considerations. Nylon 66 production typically requires 80-100 MJ/kg, while PMMA manufacturing consumes approximately 70-90 MJ/kg. Both industries are implementing energy efficiency measures, with leading manufacturers reporting 15-25% energy reductions through process optimizations and renewable energy integration over the past decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!