Optimize Nylon 66 Molding Techniques for Precision Parts

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Molding Evolution and Precision Goals

Nylon 66 has evolved significantly since its discovery in the 1930s by Wallace Carothers at DuPont. Initially developed as a fiber material, its application expanded to engineering plastics in the 1950s when injection molding techniques advanced sufficiently to process this semi-crystalline polymer. The evolution of Nylon 66 molding technology has been characterized by progressive improvements in material formulations, processing equipment, and manufacturing methodologies to enhance dimensional stability and mechanical properties.

Early molding techniques faced significant challenges with moisture sensitivity, inconsistent crystallization, and warpage issues that limited precision applications. The 1970s-1980s marked a turning point with the introduction of improved drying systems, more precise temperature control mechanisms, and the development of glass-fiber reinforced grades that substantially enhanced dimensional stability and mechanical strength.

The current technological trajectory is focused on achieving unprecedented levels of precision for components with complex geometries and tight tolerances. Modern precision requirements often demand dimensional accuracies of ±0.025mm or better, particularly in automotive, aerospace, and medical device applications where component reliability is critical. These industries increasingly require Nylon 66 parts that combine excellent mechanical properties with precise dimensional control.

Key technological goals in optimizing Nylon 66 molding for precision parts include minimizing post-molding dimensional changes through crystallization control, reducing internal stresses, and enhancing mold surface replication. Advanced process monitoring and control systems are being developed to maintain consistent melt viscosity and pressure profiles throughout the injection cycle, which is essential for achieving repeatable precision.

Material science advancements are equally important, with research focused on developing Nylon 66 compounds with improved flow characteristics at lower processing temperatures, reduced moisture sensitivity, and more uniform crystallization behavior. These improvements aim to minimize part-to-part variations and enhance overall dimensional stability.

The integration of simulation technologies represents another critical development path, enabling more accurate prediction of material behavior during molding and subsequent cooling. Computational fluid dynamics and finite element analysis tools are increasingly sophisticated in modeling the complex rheological properties of Nylon 66 under various processing conditions.

Industry 4.0 principles are being applied to precision Nylon 66 molding through the implementation of sensor networks, real-time data analytics, and machine learning algorithms that can detect and correct process deviations before they impact part quality. This technological convergence is creating new possibilities for achieving precision that was previously unattainable with conventional molding approaches.

Early molding techniques faced significant challenges with moisture sensitivity, inconsistent crystallization, and warpage issues that limited precision applications. The 1970s-1980s marked a turning point with the introduction of improved drying systems, more precise temperature control mechanisms, and the development of glass-fiber reinforced grades that substantially enhanced dimensional stability and mechanical strength.

The current technological trajectory is focused on achieving unprecedented levels of precision for components with complex geometries and tight tolerances. Modern precision requirements often demand dimensional accuracies of ±0.025mm or better, particularly in automotive, aerospace, and medical device applications where component reliability is critical. These industries increasingly require Nylon 66 parts that combine excellent mechanical properties with precise dimensional control.

Key technological goals in optimizing Nylon 66 molding for precision parts include minimizing post-molding dimensional changes through crystallization control, reducing internal stresses, and enhancing mold surface replication. Advanced process monitoring and control systems are being developed to maintain consistent melt viscosity and pressure profiles throughout the injection cycle, which is essential for achieving repeatable precision.

Material science advancements are equally important, with research focused on developing Nylon 66 compounds with improved flow characteristics at lower processing temperatures, reduced moisture sensitivity, and more uniform crystallization behavior. These improvements aim to minimize part-to-part variations and enhance overall dimensional stability.

The integration of simulation technologies represents another critical development path, enabling more accurate prediction of material behavior during molding and subsequent cooling. Computational fluid dynamics and finite element analysis tools are increasingly sophisticated in modeling the complex rheological properties of Nylon 66 under various processing conditions.

Industry 4.0 principles are being applied to precision Nylon 66 molding through the implementation of sensor networks, real-time data analytics, and machine learning algorithms that can detect and correct process deviations before they impact part quality. This technological convergence is creating new possibilities for achieving precision that was previously unattainable with conventional molding approaches.

Market Demand for High-Precision Nylon 66 Components

The global market for high-precision Nylon 66 components has experienced significant growth over the past decade, driven primarily by increasing demands from automotive, aerospace, electronics, and medical device industries. These sectors require components with exceptional dimensional stability, mechanical strength, and resistance to thermal and chemical stressors.

In the automotive industry, the shift toward lightweight vehicles for improved fuel efficiency has accelerated the adoption of high-performance polymers like Nylon 66. Precision components such as gear systems, bearings, and under-hood components represent a substantial market segment, valued at approximately $3.2 billion in 2022, with projected annual growth rates of 6.8% through 2028.

The aerospace sector presents another robust demand center, particularly for precision components in non-structural applications where weight reduction is critical. The industry's stringent quality requirements and certification processes have created a premium market segment for suppliers capable of delivering consistently high-precision Nylon 66 parts with near-zero defect rates.

Electronics manufacturers increasingly rely on precision-molded Nylon 66 components for connectors, housings, and structural elements in consumer and industrial devices. This market segment has shown remarkable resilience even during supply chain disruptions, with demand growing at 7.3% annually since 2019.

Medical device manufacturing represents the fastest-growing application area, with demand for biocompatible, sterilization-resistant precision components increasing by 9.2% annually. Surgical instruments, diagnostic equipment, and implantable device components require exceptional dimensional precision and surface quality that only optimized molding techniques can deliver.

Market research indicates that customers across these industries are willing to pay premium prices for components that demonstrate superior dimensional accuracy, consistency between production batches, and reduced need for secondary finishing operations. A survey of procurement specialists revealed that 78% prioritize precision and quality over unit cost when sourcing critical Nylon 66 components.

Regional analysis shows Asia-Pacific as the fastest-growing market for high-precision Nylon 66 components, driven by expanding manufacturing bases in China, India, and Southeast Asia. However, North America and Europe maintain leadership in high-value applications requiring the most stringent quality standards and complex geometries.

Industry forecasts suggest that the global market for high-precision engineering polymers, including Nylon 66, will reach $17.5 billion by 2027, with precision-molded components accounting for approximately 42% of this value. This growth trajectory creates significant opportunities for manufacturers who can optimize their molding techniques to meet increasingly demanding specifications.

In the automotive industry, the shift toward lightweight vehicles for improved fuel efficiency has accelerated the adoption of high-performance polymers like Nylon 66. Precision components such as gear systems, bearings, and under-hood components represent a substantial market segment, valued at approximately $3.2 billion in 2022, with projected annual growth rates of 6.8% through 2028.

The aerospace sector presents another robust demand center, particularly for precision components in non-structural applications where weight reduction is critical. The industry's stringent quality requirements and certification processes have created a premium market segment for suppliers capable of delivering consistently high-precision Nylon 66 parts with near-zero defect rates.

Electronics manufacturers increasingly rely on precision-molded Nylon 66 components for connectors, housings, and structural elements in consumer and industrial devices. This market segment has shown remarkable resilience even during supply chain disruptions, with demand growing at 7.3% annually since 2019.

Medical device manufacturing represents the fastest-growing application area, with demand for biocompatible, sterilization-resistant precision components increasing by 9.2% annually. Surgical instruments, diagnostic equipment, and implantable device components require exceptional dimensional precision and surface quality that only optimized molding techniques can deliver.

Market research indicates that customers across these industries are willing to pay premium prices for components that demonstrate superior dimensional accuracy, consistency between production batches, and reduced need for secondary finishing operations. A survey of procurement specialists revealed that 78% prioritize precision and quality over unit cost when sourcing critical Nylon 66 components.

Regional analysis shows Asia-Pacific as the fastest-growing market for high-precision Nylon 66 components, driven by expanding manufacturing bases in China, India, and Southeast Asia. However, North America and Europe maintain leadership in high-value applications requiring the most stringent quality standards and complex geometries.

Industry forecasts suggest that the global market for high-precision engineering polymers, including Nylon 66, will reach $17.5 billion by 2027, with precision-molded components accounting for approximately 42% of this value. This growth trajectory creates significant opportunities for manufacturers who can optimize their molding techniques to meet increasingly demanding specifications.

Technical Challenges in Precision Nylon 66 Molding

Nylon 66 molding for precision parts faces significant technical challenges that require comprehensive understanding and innovative solutions. The primary challenge lies in the material's hygroscopic nature, which causes it to absorb moisture from the atmosphere. This moisture absorption can lead to hydrolysis during processing, resulting in reduced molecular weight and compromised mechanical properties. Even small amounts of moisture can cause surface defects, dimensional instability, and reduced part strength.

Temperature control presents another critical challenge in precision molding. Nylon 66 has a narrow processing window, requiring precise temperature management throughout the entire molding cycle. Insufficient heating leads to poor flow and incomplete filling, while excessive temperatures can cause material degradation, yellowing, and reduced mechanical properties. The high melting point (approximately 260°C) necessitates specialized equipment and careful process design.

Dimensional stability issues are particularly problematic for precision applications. Nylon 66 exhibits significant shrinkage (1.5-2%) during cooling, which varies depending on wall thickness, fiber orientation, and processing conditions. This non-uniform shrinkage often results in warpage, especially in complex geometries with varying wall thicknesses. Post-molding dimensional changes due to moisture absorption further complicate achieving tight tolerances.

Gate and runner design presents unique challenges for precision Nylon 66 parts. Improper gate placement can lead to jetting, weld lines, and air traps that compromise both aesthetics and structural integrity. The high viscosity of Nylon 66 requires careful runner sizing to ensure balanced filling while minimizing material waste and cycle time.

Fiber reinforcement, while beneficial for enhancing mechanical properties, introduces additional complexities. Fiber orientation significantly impacts part strength, dimensional stability, and appearance. Controlling fiber orientation during molding requires sophisticated flow analysis and mold design. Fiber breakage during processing can reduce reinforcement effectiveness and create inconsistent material properties throughout the part.

Mold design challenges are amplified when working with Nylon 66. The material's abrasiveness accelerates mold wear, particularly in high-precision applications requiring tight tolerances. Proper venting is critical to prevent trapped gases that create burn marks or incomplete filling. Additionally, the high processing temperatures necessitate effective cooling systems to maintain cycle efficiency while ensuring dimensional stability.

Advanced process control systems are essential but challenging to implement effectively. Achieving consistent part quality requires sophisticated monitoring of multiple parameters including pressure, temperature, and flow rate throughout the molding cycle. Integrating these controls with predictive maintenance systems represents a significant technical hurdle for many manufacturers.

Temperature control presents another critical challenge in precision molding. Nylon 66 has a narrow processing window, requiring precise temperature management throughout the entire molding cycle. Insufficient heating leads to poor flow and incomplete filling, while excessive temperatures can cause material degradation, yellowing, and reduced mechanical properties. The high melting point (approximately 260°C) necessitates specialized equipment and careful process design.

Dimensional stability issues are particularly problematic for precision applications. Nylon 66 exhibits significant shrinkage (1.5-2%) during cooling, which varies depending on wall thickness, fiber orientation, and processing conditions. This non-uniform shrinkage often results in warpage, especially in complex geometries with varying wall thicknesses. Post-molding dimensional changes due to moisture absorption further complicate achieving tight tolerances.

Gate and runner design presents unique challenges for precision Nylon 66 parts. Improper gate placement can lead to jetting, weld lines, and air traps that compromise both aesthetics and structural integrity. The high viscosity of Nylon 66 requires careful runner sizing to ensure balanced filling while minimizing material waste and cycle time.

Fiber reinforcement, while beneficial for enhancing mechanical properties, introduces additional complexities. Fiber orientation significantly impacts part strength, dimensional stability, and appearance. Controlling fiber orientation during molding requires sophisticated flow analysis and mold design. Fiber breakage during processing can reduce reinforcement effectiveness and create inconsistent material properties throughout the part.

Mold design challenges are amplified when working with Nylon 66. The material's abrasiveness accelerates mold wear, particularly in high-precision applications requiring tight tolerances. Proper venting is critical to prevent trapped gases that create burn marks or incomplete filling. Additionally, the high processing temperatures necessitate effective cooling systems to maintain cycle efficiency while ensuring dimensional stability.

Advanced process control systems are essential but challenging to implement effectively. Achieving consistent part quality requires sophisticated monitoring of multiple parameters including pressure, temperature, and flow rate throughout the molding cycle. Integrating these controls with predictive maintenance systems represents a significant technical hurdle for many manufacturers.

Current Precision Molding Techniques for Nylon 66

01 Precision injection molding techniques for Nylon 66

Advanced injection molding techniques specifically designed for Nylon 66 to achieve high precision components. These techniques involve optimized processing parameters such as temperature control, pressure settings, and cooling rates to minimize warpage and dimensional variations. The methods enable the production of complex geometries with tight tolerances required for engineering applications.- Precision injection molding techniques for Nylon 66: Advanced injection molding techniques specifically designed for Nylon 66 to achieve high precision components. These techniques involve optimized injection parameters including pressure control, temperature management, and cooling rate regulation to minimize warpage and dimensional variations. The methods enable the production of complex geometries with tight tolerances required for engineering applications.

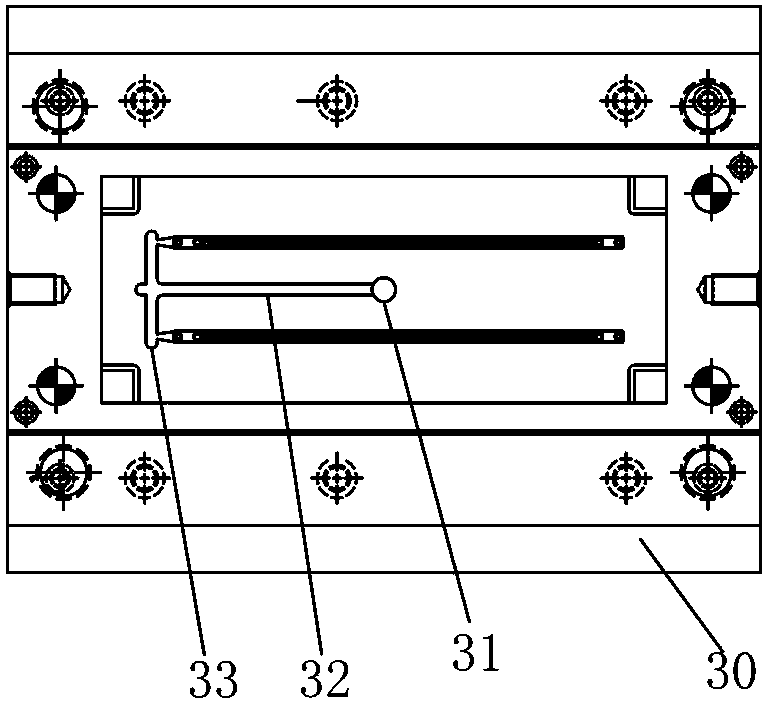

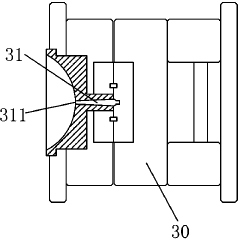

- Mold design optimization for Nylon 66 precision parts: Specialized mold designs that accommodate the unique crystallization and shrinkage characteristics of Nylon 66. These designs incorporate precise gating systems, optimized runner layouts, and advanced venting mechanisms to ensure complete cavity filling without defects. Features like conformal cooling channels and precision parting line designs help achieve dimensional stability and surface quality in the final molded parts.

- Material formulation and additives for enhanced moldability: Specialized Nylon 66 formulations with additives that improve flow characteristics and dimensional stability during molding. These formulations may include nucleating agents to control crystallization, processing aids to enhance flow, and reinforcing materials like glass fibers or minerals to reduce warpage. The modified materials enable more precise molding while maintaining or enhancing the mechanical properties of the final parts.

- Post-molding treatments for dimensional accuracy: Various post-processing techniques applied to Nylon 66 molded parts to enhance dimensional precision. These include controlled annealing processes to relieve internal stresses, precision machining operations to achieve critical dimensions, and conditioning treatments to stabilize the material against moisture absorption. These treatments help overcome the inherent challenges of Nylon 66's hygroscopic nature and crystallization behavior.

- Advanced process monitoring and control systems: Implementation of sophisticated monitoring and control technologies to ensure precision in Nylon 66 molding processes. These systems utilize sensors to track critical parameters like cavity pressure, melt temperature, and cooling rates in real-time. Adaptive control algorithms make automatic adjustments to process parameters to maintain consistency across production runs, while data analytics help identify optimization opportunities for enhanced precision.

02 Mold design optimization for Nylon 66 precision parts

Specialized mold designs that accommodate the unique properties of Nylon 66 during the molding process. These designs incorporate features such as optimized gate locations, runner systems, and venting to ensure complete filling and minimal defects. Advanced cooling channel configurations help maintain uniform temperature distribution throughout the mold, resulting in improved dimensional stability and surface finish of the final parts.Expand Specific Solutions03 Material formulation and additives for enhanced moldability

Specific formulations of Nylon 66 with additives that improve flow characteristics and processing windows during molding. These formulations may include nucleating agents, flow modifiers, and reinforcing materials such as glass fibers or minerals. The modified compositions enable better mold filling, reduced cycle times, and enhanced mechanical properties while maintaining dimensional precision in the final molded parts.Expand Specific Solutions04 Post-molding treatments for precision enhancement

Various post-processing techniques applied to Nylon 66 molded parts to improve dimensional accuracy and surface quality. These treatments include annealing processes to relieve internal stresses, precision machining operations, and surface treatments to enhance functional properties. The combination of these post-molding operations helps achieve tighter tolerances and better performance in high-precision applications.Expand Specific Solutions05 Advanced monitoring and control systems for precision molding

Implementation of sophisticated monitoring and control technologies in the Nylon 66 molding process to ensure consistent precision. These systems utilize sensors, real-time data analysis, and feedback control mechanisms to maintain optimal processing conditions throughout the production cycle. Machine learning algorithms and predictive models help anticipate and compensate for variations in material properties and processing conditions, resulting in higher yields of precision parts.Expand Specific Solutions

Key Patents in Advanced Nylon 66 Molding

Injection moulding method of long glass fiber reinforced nylon 66 materials

PatentActiveCN104004354A

Innovation

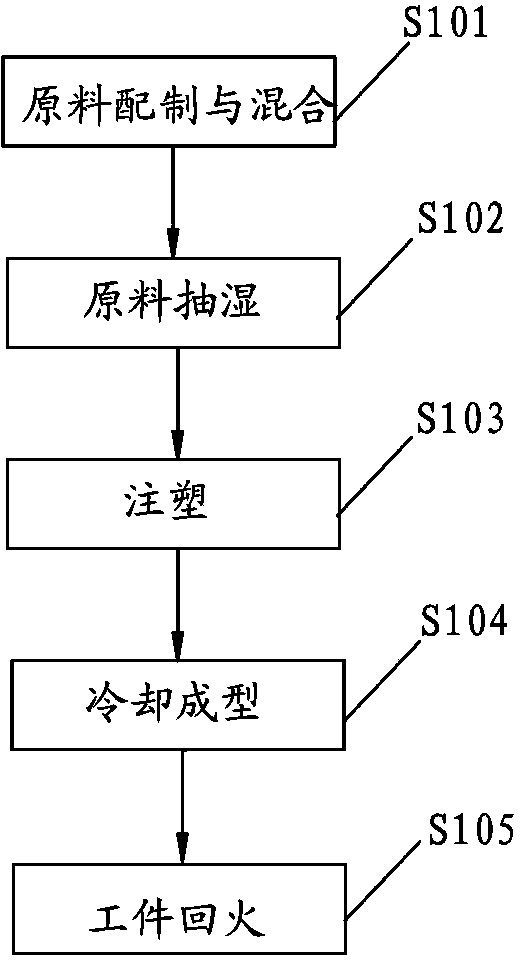

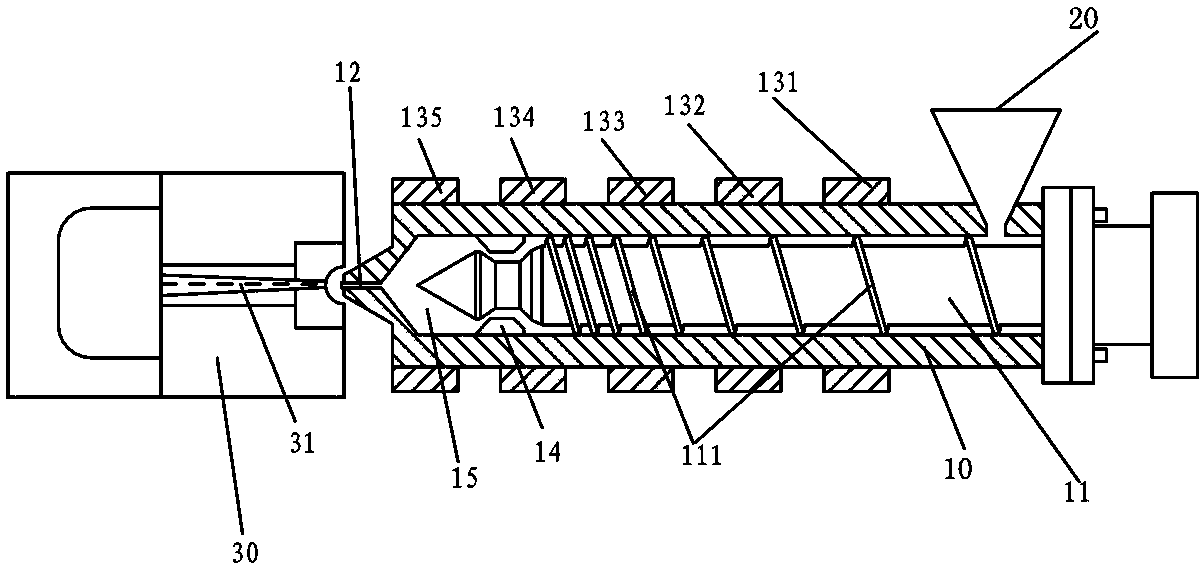

- It adopts raw material preparation and mixing, dehumidification, injection molding, cooling molding and tempering processes. The specific steps include mechanical mixing and mixing of long glass fiber and nylon 66 matrix in a ratio of 1:1, dehumidification and segmented heating and melting in the injection molding machine. , through slow one-stage injection molding and water absorption and tempering after cooling, the injection molding equipment and mold structure are optimized to reduce the shearing effect of long glass fibers.

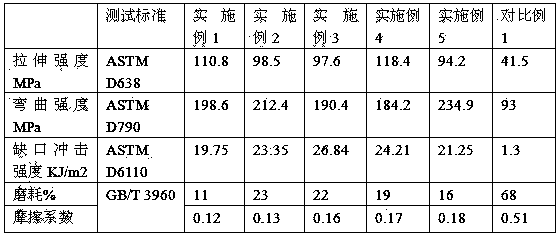

Wear-resistant and high-temperature-resistant nylon composite material and preparation method thereof

PatentActiveCN104046017A

Innovation

- Nylon 66 is premixed with a wear-resistant agent, and antioxidants and lubricants are added. Melt extrusion granulation is performed through a twin-screw extruder to adjust the viscosity and dispersion of the composition, improve wear resistance, and solve problems during processing. clogging and breakage problems.

Material Science Advancements for Enhanced Properties

Recent advancements in material science have significantly expanded the possibilities for enhancing Nylon 66 properties, directly impacting precision molding capabilities. The development of nano-composite technologies has enabled the incorporation of nanoscale fillers such as clay, carbon nanotubes, and graphene into Nylon 66 matrices. These additives create substantial improvements in mechanical strength, thermal stability, and dimensional accuracy—critical factors for precision molded components.

Crystallization control technologies represent another breakthrough area, with new nucleating agents specifically designed for polyamides that promote uniform crystallization patterns. This advancement reduces internal stresses and warpage in molded parts, while simultaneously accelerating production cycles through faster crystallization kinetics. The controlled crystalline structure results in more predictable shrinkage behavior, essential for maintaining tight tolerances in precision applications.

Polymer chain modification techniques have evolved to allow tailored molecular weight distributions and end-group functionalization of Nylon 66. These modifications create materials with enhanced flow characteristics during molding while maintaining excellent mechanical properties in the finished part. The ability to engineer the polymer at the molecular level has opened new possibilities for complex geometries with thin walls and intricate features previously unachievable with standard grades.

Surface modification technologies have also progressed significantly, with treatments that can be applied either to the raw material or during the molding process. These treatments alter the surface energy, improve mold release properties, and enhance the bonding capabilities of Nylon 66 parts. Advanced coupling agents now enable stronger interfaces between the polymer matrix and reinforcing fibers, resulting in composite materials with superior mechanical performance and dimensional stability.

Moisture management innovations address one of Nylon 66's traditional challenges—its hygroscopic nature. New drying technologies, moisture-resistant grades, and in-process moisture control systems have been developed to minimize the impact of humidity on molding parameters and final part dimensions. These advancements have expanded the application range of Nylon 66 in precision environments where dimensional stability is paramount.

Thermal stabilization additives have been refined to extend the upper temperature limits of Nylon 66 while maintaining its processability. These additives prevent degradation during processing and enhance long-term heat resistance, allowing precision parts to function reliably in more demanding thermal environments. The improved thermal performance opens new application possibilities in automotive, electronics, and industrial sectors where operating temperatures continue to increase.

Crystallization control technologies represent another breakthrough area, with new nucleating agents specifically designed for polyamides that promote uniform crystallization patterns. This advancement reduces internal stresses and warpage in molded parts, while simultaneously accelerating production cycles through faster crystallization kinetics. The controlled crystalline structure results in more predictable shrinkage behavior, essential for maintaining tight tolerances in precision applications.

Polymer chain modification techniques have evolved to allow tailored molecular weight distributions and end-group functionalization of Nylon 66. These modifications create materials with enhanced flow characteristics during molding while maintaining excellent mechanical properties in the finished part. The ability to engineer the polymer at the molecular level has opened new possibilities for complex geometries with thin walls and intricate features previously unachievable with standard grades.

Surface modification technologies have also progressed significantly, with treatments that can be applied either to the raw material or during the molding process. These treatments alter the surface energy, improve mold release properties, and enhance the bonding capabilities of Nylon 66 parts. Advanced coupling agents now enable stronger interfaces between the polymer matrix and reinforcing fibers, resulting in composite materials with superior mechanical performance and dimensional stability.

Moisture management innovations address one of Nylon 66's traditional challenges—its hygroscopic nature. New drying technologies, moisture-resistant grades, and in-process moisture control systems have been developed to minimize the impact of humidity on molding parameters and final part dimensions. These advancements have expanded the application range of Nylon 66 in precision environments where dimensional stability is paramount.

Thermal stabilization additives have been refined to extend the upper temperature limits of Nylon 66 while maintaining its processability. These additives prevent degradation during processing and enhance long-term heat resistance, allowing precision parts to function reliably in more demanding thermal environments. The improved thermal performance opens new application possibilities in automotive, electronics, and industrial sectors where operating temperatures continue to increase.

Sustainability Considerations in Nylon 66 Manufacturing

The environmental impact of Nylon 66 manufacturing has become increasingly significant as industries face mounting pressure to adopt sustainable practices. Traditional Nylon 66 production processes are energy-intensive, consuming approximately 138 MJ/kg of energy and generating substantial greenhouse gas emissions. The molding phase alone accounts for 30-40% of the total carbon footprint in precision parts manufacturing, highlighting the urgent need for sustainability improvements.

Water usage presents another critical concern, with conventional Nylon 66 production requiring 500-1000 liters per kilogram of material. Closed-loop water systems have demonstrated potential to reduce this consumption by up to 70%, while simultaneously minimizing chemical discharge into local watersheds. Leading manufacturers have begun implementing these systems alongside advanced filtration technologies to recover and reuse process water.

Material efficiency strategies offer substantial sustainability benefits for Nylon 66 molding operations. Techniques such as hot runner systems can reduce material waste by 15-25% compared to traditional cold runner systems. Additionally, the integration of in-line recycling capabilities allows for immediate reprocessing of sprues and runners, achieving material utilization rates exceeding 95% in optimized production environments.

Renewable energy integration represents a transformative opportunity for Nylon 66 manufacturing facilities. Solar and wind power installations at production sites have demonstrated potential to offset 30-50% of energy requirements for molding operations. Several industry leaders have committed to 100% renewable energy targets by 2030, with interim milestones driving continuous improvement in carbon intensity metrics.

Bio-based alternatives to traditional petroleum-derived Nylon 66 are emerging as viable options for certain applications. These materials, derived partially from renewable resources such as castor oil, can reduce fossil fuel dependency by 20-40%. While current bio-based options may exhibit slightly different processing parameters, ongoing research is rapidly closing performance gaps for precision molding applications.

End-of-life considerations have gained prominence in sustainable Nylon 66 manufacturing strategies. Chemical recycling technologies capable of breaking down Nylon 66 into its monomer components achieve recycling efficiencies of 85-90%, significantly outperforming mechanical recycling methods. Design for disassembly principles further enhance recyclability by facilitating the separation of Nylon 66 components from multi-material assemblies.

Regulatory compliance increasingly shapes sustainability initiatives in Nylon 66 manufacturing. The implementation of ISO 14001 environmental management systems provides a structured framework for continuous improvement, while emerging extended producer responsibility regulations in key markets are driving manufacturers to develop comprehensive product lifecycle management approaches.

Water usage presents another critical concern, with conventional Nylon 66 production requiring 500-1000 liters per kilogram of material. Closed-loop water systems have demonstrated potential to reduce this consumption by up to 70%, while simultaneously minimizing chemical discharge into local watersheds. Leading manufacturers have begun implementing these systems alongside advanced filtration technologies to recover and reuse process water.

Material efficiency strategies offer substantial sustainability benefits for Nylon 66 molding operations. Techniques such as hot runner systems can reduce material waste by 15-25% compared to traditional cold runner systems. Additionally, the integration of in-line recycling capabilities allows for immediate reprocessing of sprues and runners, achieving material utilization rates exceeding 95% in optimized production environments.

Renewable energy integration represents a transformative opportunity for Nylon 66 manufacturing facilities. Solar and wind power installations at production sites have demonstrated potential to offset 30-50% of energy requirements for molding operations. Several industry leaders have committed to 100% renewable energy targets by 2030, with interim milestones driving continuous improvement in carbon intensity metrics.

Bio-based alternatives to traditional petroleum-derived Nylon 66 are emerging as viable options for certain applications. These materials, derived partially from renewable resources such as castor oil, can reduce fossil fuel dependency by 20-40%. While current bio-based options may exhibit slightly different processing parameters, ongoing research is rapidly closing performance gaps for precision molding applications.

End-of-life considerations have gained prominence in sustainable Nylon 66 manufacturing strategies. Chemical recycling technologies capable of breaking down Nylon 66 into its monomer components achieve recycling efficiencies of 85-90%, significantly outperforming mechanical recycling methods. Design for disassembly principles further enhance recyclability by facilitating the separation of Nylon 66 components from multi-material assemblies.

Regulatory compliance increasingly shapes sustainability initiatives in Nylon 66 manufacturing. The implementation of ISO 14001 environmental management systems provides a structured framework for continuous improvement, while emerging extended producer responsibility regulations in key markets are driving manufacturers to develop comprehensive product lifecycle management approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!