Reducing Nylon 66 Water Absorption for Better Performance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Hydrophilicity Background and Objectives

Nylon 66, discovered in the 1930s by Wallace Carothers at DuPont, has evolved into one of the most versatile engineering thermoplastics in modern industry. Its unique combination of mechanical strength, thermal stability, and chemical resistance has positioned it as a critical material in automotive, electrical, and consumer goods manufacturing. However, despite its numerous advantages, Nylon 66 exhibits significant hydrophilic properties, absorbing moisture from the surrounding environment at rates up to 2.5-3% by weight under standard conditions.

This hydrophilicity stems from the polymer's chemical structure, specifically the amide groups (-CONH-) that form hydrogen bonds with water molecules. The historical development of Nylon 66 technology has seen incremental improvements in moisture resistance, yet water absorption remains a persistent challenge that compromises dimensional stability, mechanical properties, and electrical insulation characteristics in high-humidity environments.

The technical evolution trajectory shows increasing focus on this limitation, with research intensifying in the past decade as applications in precision engineering and electronics demand greater performance consistency across varying environmental conditions. Recent market trends indicate growing demand for moisture-resistant polyamides, particularly in automotive electronics, aerospace components, and precision mechanical parts where dimensional stability is paramount.

The primary objective of this research is to develop innovative approaches to significantly reduce water absorption in Nylon 66 while maintaining or enhancing its desirable mechanical and thermal properties. Specifically, we aim to achieve a reduction of at least 50% in moisture uptake compared to standard Nylon 66 formulations, without compromising tensile strength, impact resistance, or processing characteristics.

Secondary objectives include understanding the fundamental mechanisms of water-polymer interaction in polyamides, establishing quantitative structure-property relationships between chemical modifications and hydrophobicity, and developing scalable manufacturing processes for modified Nylon 66 with enhanced moisture resistance.

This research aligns with broader industry trends toward high-performance engineering plastics that maintain consistent properties across varying environmental conditions. The technological trajectory suggests multiple potential approaches, including chemical modification of the polymer backbone, incorporation of hydrophobic additives, surface treatments, and development of novel composite structures combining Nylon 66 with inherently hydrophobic materials.

Success in this endeavor would represent a significant advancement in polyamide technology, potentially opening new application domains where current moisture sensitivity limitations have restricted Nylon 66 adoption despite its otherwise excellent property profile.

This hydrophilicity stems from the polymer's chemical structure, specifically the amide groups (-CONH-) that form hydrogen bonds with water molecules. The historical development of Nylon 66 technology has seen incremental improvements in moisture resistance, yet water absorption remains a persistent challenge that compromises dimensional stability, mechanical properties, and electrical insulation characteristics in high-humidity environments.

The technical evolution trajectory shows increasing focus on this limitation, with research intensifying in the past decade as applications in precision engineering and electronics demand greater performance consistency across varying environmental conditions. Recent market trends indicate growing demand for moisture-resistant polyamides, particularly in automotive electronics, aerospace components, and precision mechanical parts where dimensional stability is paramount.

The primary objective of this research is to develop innovative approaches to significantly reduce water absorption in Nylon 66 while maintaining or enhancing its desirable mechanical and thermal properties. Specifically, we aim to achieve a reduction of at least 50% in moisture uptake compared to standard Nylon 66 formulations, without compromising tensile strength, impact resistance, or processing characteristics.

Secondary objectives include understanding the fundamental mechanisms of water-polymer interaction in polyamides, establishing quantitative structure-property relationships between chemical modifications and hydrophobicity, and developing scalable manufacturing processes for modified Nylon 66 with enhanced moisture resistance.

This research aligns with broader industry trends toward high-performance engineering plastics that maintain consistent properties across varying environmental conditions. The technological trajectory suggests multiple potential approaches, including chemical modification of the polymer backbone, incorporation of hydrophobic additives, surface treatments, and development of novel composite structures combining Nylon 66 with inherently hydrophobic materials.

Success in this endeavor would represent a significant advancement in polyamide technology, potentially opening new application domains where current moisture sensitivity limitations have restricted Nylon 66 adoption despite its otherwise excellent property profile.

Market Analysis for Low Water Absorption Polyamides

The global market for low water absorption polyamides has been experiencing significant growth, driven primarily by increasing demand from automotive, electrical and electronics, and industrial sectors. The market size for specialty polyamides with enhanced water resistance properties was valued at approximately 2.3 billion USD in 2022 and is projected to reach 3.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.2%.

The automotive industry remains the largest consumer of low water absorption polyamides, accounting for roughly 42% of the total market share. This dominance is attributed to the growing trend of metal replacement with lightweight engineering plastics to improve fuel efficiency and reduce emissions. Particularly, under-the-hood components that require dimensional stability in humid environments are driving the demand for moisture-resistant nylon variants.

Electrical and electronics applications constitute the second-largest market segment at 28%, with the demand primarily coming from connectors, switches, and housings that require excellent electrical insulation properties even in humid conditions. The increasing miniaturization of electronic devices further necessitates materials with minimal dimensional changes due to moisture absorption.

Regionally, Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea's robust manufacturing sectors. North America and Europe follow with 27% and 23% market shares respectively, with significant demand coming from premium automotive and aerospace applications.

Consumer preferences are increasingly shifting toward materials that offer consistent performance across varying environmental conditions. This trend is particularly evident in the growing demand for polyamides in outdoor applications and in regions with high humidity levels. Market research indicates that customers are willing to pay a premium of 15-20% for polyamides with water absorption rates below 1.5% compared to standard nylon grades.

The competitive landscape shows that specialty chemical companies focusing on modified polyamides are gaining market share against traditional nylon producers. Companies offering comprehensive solutions that address both water absorption and other performance parameters like heat resistance and mechanical strength are particularly successful in capturing market value.

Future market growth is expected to be driven by emerging applications in 3D printing, medical devices, and sustainable products. The demand for bio-based low water absorption polyamides is projected to grow at twice the rate of petroleum-based counterparts, reflecting the broader industry shift toward sustainability.

The automotive industry remains the largest consumer of low water absorption polyamides, accounting for roughly 42% of the total market share. This dominance is attributed to the growing trend of metal replacement with lightweight engineering plastics to improve fuel efficiency and reduce emissions. Particularly, under-the-hood components that require dimensional stability in humid environments are driving the demand for moisture-resistant nylon variants.

Electrical and electronics applications constitute the second-largest market segment at 28%, with the demand primarily coming from connectors, switches, and housings that require excellent electrical insulation properties even in humid conditions. The increasing miniaturization of electronic devices further necessitates materials with minimal dimensional changes due to moisture absorption.

Regionally, Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea's robust manufacturing sectors. North America and Europe follow with 27% and 23% market shares respectively, with significant demand coming from premium automotive and aerospace applications.

Consumer preferences are increasingly shifting toward materials that offer consistent performance across varying environmental conditions. This trend is particularly evident in the growing demand for polyamides in outdoor applications and in regions with high humidity levels. Market research indicates that customers are willing to pay a premium of 15-20% for polyamides with water absorption rates below 1.5% compared to standard nylon grades.

The competitive landscape shows that specialty chemical companies focusing on modified polyamides are gaining market share against traditional nylon producers. Companies offering comprehensive solutions that address both water absorption and other performance parameters like heat resistance and mechanical strength are particularly successful in capturing market value.

Future market growth is expected to be driven by emerging applications in 3D printing, medical devices, and sustainable products. The demand for bio-based low water absorption polyamides is projected to grow at twice the rate of petroleum-based counterparts, reflecting the broader industry shift toward sustainability.

Current Challenges in Nylon 66 Moisture Resistance

Nylon 66 inherently exhibits high water absorption characteristics due to its chemical structure containing amide groups, which form hydrogen bonds with water molecules. This hydrophilic nature presents significant challenges for applications requiring dimensional stability, mechanical strength, and electrical insulation properties. Current testing shows that standard Nylon 66 can absorb 2.5-3.0% moisture at equilibrium under standard conditions (23°C, 50% relative humidity), with this percentage increasing to 8-10% when fully saturated in water.

The primary challenge lies in the molecular structure of Nylon 66, where the polar amide groups (-CONH-) create strong affinity for water molecules. When moisture is absorbed, it acts as a plasticizer, reducing the glass transition temperature by approximately 40-50°C, which dramatically impacts mechanical properties. Tensile strength can decrease by 30-40%, while impact resistance may increase but at the expense of modulus and dimensional stability.

Manufacturing processes further complicate moisture management in Nylon 66. During injection molding, inadequate drying can lead to hydrolytic degradation at processing temperatures, reducing molecular weight and compromising mechanical properties. Post-processing moisture absorption creates significant quality control challenges, as parts may continue to absorb moisture and change dimensions even after production.

Environmental factors present additional obstacles, as performance characteristics vary widely depending on humidity conditions. This variability makes design specifications particularly challenging, requiring engineers to account for worst-case scenarios or implement costly environmental controls. In automotive applications, temperature cycling combined with moisture exposure accelerates aging and potential failure mechanisms.

Current surface treatments like fluorination provide only temporary barriers against moisture, typically degrading over time through mechanical abrasion or chemical exposure. Bulk modification approaches using hydrophobic additives often create processing complications and may negatively impact other desirable properties of the polymer.

Recycling and sustainability present emerging challenges, as moisture-resistant additives or treatments may complicate recycling processes or introduce environmental concerns. The industry faces increasing pressure to develop solutions that maintain recyclability while improving moisture resistance.

Cost-effectiveness remains a significant hurdle, as many existing solutions that effectively reduce water absorption (such as specialty copolymers or extensive compounding) substantially increase material costs, limiting widespread adoption. The ideal solution must balance performance improvements against economic viability for mass production applications.

The primary challenge lies in the molecular structure of Nylon 66, where the polar amide groups (-CONH-) create strong affinity for water molecules. When moisture is absorbed, it acts as a plasticizer, reducing the glass transition temperature by approximately 40-50°C, which dramatically impacts mechanical properties. Tensile strength can decrease by 30-40%, while impact resistance may increase but at the expense of modulus and dimensional stability.

Manufacturing processes further complicate moisture management in Nylon 66. During injection molding, inadequate drying can lead to hydrolytic degradation at processing temperatures, reducing molecular weight and compromising mechanical properties. Post-processing moisture absorption creates significant quality control challenges, as parts may continue to absorb moisture and change dimensions even after production.

Environmental factors present additional obstacles, as performance characteristics vary widely depending on humidity conditions. This variability makes design specifications particularly challenging, requiring engineers to account for worst-case scenarios or implement costly environmental controls. In automotive applications, temperature cycling combined with moisture exposure accelerates aging and potential failure mechanisms.

Current surface treatments like fluorination provide only temporary barriers against moisture, typically degrading over time through mechanical abrasion or chemical exposure. Bulk modification approaches using hydrophobic additives often create processing complications and may negatively impact other desirable properties of the polymer.

Recycling and sustainability present emerging challenges, as moisture-resistant additives or treatments may complicate recycling processes or introduce environmental concerns. The industry faces increasing pressure to develop solutions that maintain recyclability while improving moisture resistance.

Cost-effectiveness remains a significant hurdle, as many existing solutions that effectively reduce water absorption (such as specialty copolymers or extensive compounding) substantially increase material costs, limiting widespread adoption. The ideal solution must balance performance improvements against economic viability for mass production applications.

Existing Water Absorption Reduction Methods for Nylon 66

01 Methods to reduce water absorption in Nylon 66

Various techniques can be employed to reduce the water absorption properties of Nylon 66, which naturally tends to absorb moisture. These methods include adding hydrophobic additives, surface treatments, and creating composite materials. By incorporating water-repellent compounds or applying specialized coatings, the hygroscopic nature of Nylon 66 can be significantly reduced, making it more suitable for applications where moisture sensitivity is a concern.- Methods to reduce water absorption in Nylon 66: Various methods can be employed to reduce the water absorption properties of Nylon 66, which naturally tends to absorb moisture. These methods include adding hydrophobic additives, surface treatments, and creating composite materials. By incorporating water-repellent components or modifying the polymer structure, the hygroscopic nature of Nylon 66 can be significantly reduced, making it more suitable for applications requiring dimensional stability and consistent mechanical properties in humid environments.

- Impact of water absorption on mechanical properties of Nylon 66: Water absorption in Nylon 66 significantly affects its mechanical properties. As Nylon 66 absorbs moisture, it undergoes plasticization, which typically reduces tensile strength and modulus while increasing elongation and impact resistance. The glass transition temperature decreases with increasing moisture content, affecting the material's thermal behavior. Understanding these relationships is crucial for predicting performance in various humidity conditions and designing components that maintain required mechanical properties throughout their service life.

- Nylon 66 composites with improved water resistance: Composite materials based on Nylon 66 can be engineered to have improved water resistance compared to the neat polymer. By incorporating fillers such as glass fibers, carbon fibers, mineral particles, or nanomaterials, the water absorption rate and equilibrium content can be reduced. These composites maintain better dimensional stability and mechanical properties in humid environments, making them suitable for applications where exposure to moisture is unavoidable but performance stability is required.

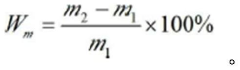

- Testing and measurement methods for water absorption in Nylon 66: Various standardized and experimental methods are used to measure and characterize water absorption in Nylon 66. These include gravimetric analysis, dimensional change measurements, and spectroscopic techniques. Testing protocols typically involve conditioning samples under controlled temperature and humidity, followed by periodic measurements to determine absorption rates and equilibrium content. These methods are essential for quality control, material development, and predicting long-term performance of Nylon 66 components in various environmental conditions.

- Applications considering Nylon 66 water absorption characteristics: The water absorption characteristics of Nylon 66 must be carefully considered in various applications. In automotive and electrical components, dimensional changes due to moisture uptake can affect fit and function. For outdoor applications, moisture-induced property changes may impact long-term durability. Engineers often design with the equilibrium moisture content in mind, sometimes pre-conditioning parts or selecting modified grades with lower absorption rates. In some cases, the hygroscopic nature of Nylon 66 is beneficial, such as in applications requiring comfort or noise damping properties.

02 Impact of water absorption on mechanical properties

Water absorption in Nylon 66 significantly affects its mechanical properties. As Nylon 66 absorbs moisture, it undergoes plasticization, which typically reduces tensile strength and modulus while increasing elongation and impact resistance. The dimensional stability is also compromised as the material swells with moisture uptake. Understanding these property changes is crucial for designing components that will be exposed to humid environments during their service life.Expand Specific Solutions03 Measurement and testing of water absorption

Specific methods and standards exist for measuring and testing water absorption in Nylon 66. These include immersion tests under controlled temperature and humidity conditions, followed by precise weight measurements to determine absorption percentages. Advanced analytical techniques such as moisture analyzers and spectroscopic methods can also be employed to evaluate moisture content and distribution within the polymer matrix. These testing protocols are essential for quality control and material specification compliance.Expand Specific Solutions04 Additives and fillers to control water absorption

Various additives and fillers can be incorporated into Nylon 66 to control its water absorption characteristics. Glass fibers, mineral fillers, and nanomaterials can reduce overall water uptake by decreasing the available polymer volume for water interaction. Chemical modifiers such as silanes, fluoropolymers, and certain organic compounds can enhance the hydrophobicity of the material. These additives not only affect moisture resistance but also influence processing parameters and final product properties.Expand Specific Solutions05 Applications considering water absorption characteristics

The water absorption properties of Nylon 66 must be carefully considered for specific applications. In automotive and electrical components, dimensional stability and electrical insulation properties can be compromised by moisture uptake. For outdoor applications, UV stabilizers are often combined with moisture-resistant additives to enhance durability. In some cases, the controlled water absorption can be beneficial, such as in applications requiring self-lubricating properties or improved impact resistance. Proper material selection and design considerations can mitigate potential issues related to water absorption.Expand Specific Solutions

Leading Companies in Moisture-Resistant Polyamide Materials

The water absorption reduction in Nylon 66 market is currently in a growth phase, with increasing demand driven by performance requirements across automotive, electronics, and consumer goods sectors. The global market size for modified Nylon 66 is expanding at approximately 5-7% annually, reaching multi-billion dollar valuation. Technologically, the field shows moderate maturity with ongoing innovation. Key players include established chemical giants like LyondellBasell and Toray Industries providing commercial solutions, while companies such as Kingfa Sci. & Tech. and HYOSUNG Corp. lead in specialized formulations. Academic institutions including Beijing University of Chemical Technology and Donghua University contribute fundamental research, while regional manufacturers like Jiangsu Boiln Plastics and CGN Juner New Materials focus on application-specific developments, creating a competitive landscape balancing innovation and commercialization.

LyondellBasell Advanced Polymers, Inc.

Technical Solution: LyondellBasell has developed a comprehensive approach to reducing water absorption in Nylon 66 through their proprietary "HydroShield" technology. This multi-faceted solution combines polymer blending, compatibilization, and surface modification techniques. Their process incorporates specially formulated polyolefin-based modifiers that are reactively compounded with Nylon 66, creating a semi-interpenetrating network that physically blocks water pathways while maintaining thermal stability. The company has also developed specialized nucleating agents that promote controlled crystallization, further reducing amorphous regions where water molecules typically accumulate. Industrial testing shows their modified Nylon 66 grades exhibit 30-45% lower water absorption rates compared to standard grades, with minimal impact on processing parameters. LyondellBasell has successfully implemented this technology in moisture-sensitive applications including electrical connectors and precision mechanical components.

Strengths: Established commercial-scale production capabilities; comprehensive technical support infrastructure; formulations tailored for specific end-use requirements. Weaknesses: Some formulations show slightly reduced mechanical properties at elevated temperatures; higher cost compared to standard Nylon 66; potential compatibility issues with certain additives.

Toray Industries, Inc.

Technical Solution: Toray has developed a proprietary technology called "NANOALLOY" for Nylon 66 that creates nano-scale polymer alloys with controlled structure. This technology significantly reduces water absorption by creating hydrophobic domains within the polymer matrix while maintaining the mechanical properties of Nylon 66. Their approach involves blending specially modified fluoropolymers with Nylon 66 and using compatibilizers to ensure proper dispersion. The resulting material shows approximately 40% reduction in water absorption compared to standard Nylon 66 while maintaining over 90% of its mechanical strength. Toray has also implemented surface modification techniques using plasma treatment to create hydrophobic barriers on Nylon 66 components, further enhancing moisture resistance in critical applications.

Strengths: Industry-leading polymer science expertise with established manufacturing infrastructure; comprehensive approach combining bulk and surface modifications; maintains mechanical properties while reducing water absorption. Weaknesses: Higher production costs compared to standard Nylon 66; requires specialized equipment for processing; some solutions may have regulatory limitations in certain applications.

Key Technologies in Hydrophobic Nylon 66 Modifications

High-strength low-water-absorption nylon 66 composite material as well as preparation method and application thereof

PatentPendingCN117165073A

Innovation

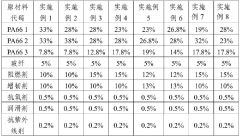

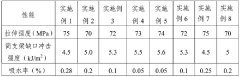

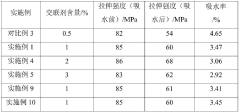

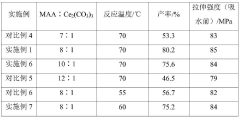

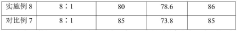

- It is formulated with PA66, glass fiber, flame retardants, tougheners, antioxidants, lubricants and anti-UV agents in specific proportions, and is melted and molded through a twin-screw extruder to improve the uniformity of polymer molecular chain distribution and material density. , reduce water absorption, and meet the flame retardant requirements of UL94-V0.

Preparation method of low-water-absorption nylon 66

PatentPendingCN117487348A

Innovation

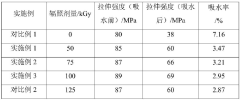

- Cerium methacrylate is used as a cross-linking agent, and a cross-linked network structure is formed on the surface of nylon 66 through electron beam irradiation technology to reduce water absorption and improve mechanical properties.

Environmental Impact of Nylon 66 Modification Processes

The environmental implications of Nylon 66 modification processes aimed at reducing water absorption warrant careful consideration. Traditional methods to enhance Nylon 66's hydrophobicity often involve chemical treatments that may introduce harmful substances into the environment. Surface modification techniques utilizing fluorinated compounds, while effective at reducing water absorption, raise significant ecological concerns due to their persistence in the environment and potential bioaccumulation properties.

Chemical crosslinking agents employed to reduce water absorption frequently contain formaldehyde or isocyanates, which pose risks to both human health and ecosystems when released during manufacturing or disposal phases. The production of these modification agents typically requires energy-intensive processes and petroleum-based raw materials, contributing to carbon emissions and resource depletion.

Blending Nylon 66 with hydrophobic polymers presents a more environmentally favorable approach compared to chemical treatments. However, the resulting composite materials may complicate recycling efforts, as the heterogeneous composition can render conventional recycling methods ineffective, potentially increasing landfill waste.

Nanotechnology-based solutions, while promising for performance enhancement, introduce uncertainties regarding nanoparticle fate in the environment. The potential for nanoparticle leaching during product use or disposal remains inadequately understood, with emerging research suggesting possible ecotoxicological impacts on aquatic organisms.

Life cycle assessments of modified Nylon 66 products reveal complex trade-offs. While improved water resistance extends product lifespan and reduces replacement frequency, the additional processing steps and materials often increase the initial environmental footprint. This creates a challenging balance between immediate manufacturing impacts and long-term sustainability benefits.

Recent regulatory developments worldwide are increasingly restricting certain modification chemicals, particularly those containing perfluorinated compounds. This regulatory landscape is driving innovation toward greener alternatives, including bio-based modification agents derived from renewable resources and environmentally benign processing methods.

Water consumption during modification processes presents another environmental consideration, as many treatment methods require substantial water for processing and subsequent effluent treatment. Closed-loop systems and water recycling technologies are being developed to mitigate these impacts, though implementation remains limited in commercial settings.

Chemical crosslinking agents employed to reduce water absorption frequently contain formaldehyde or isocyanates, which pose risks to both human health and ecosystems when released during manufacturing or disposal phases. The production of these modification agents typically requires energy-intensive processes and petroleum-based raw materials, contributing to carbon emissions and resource depletion.

Blending Nylon 66 with hydrophobic polymers presents a more environmentally favorable approach compared to chemical treatments. However, the resulting composite materials may complicate recycling efforts, as the heterogeneous composition can render conventional recycling methods ineffective, potentially increasing landfill waste.

Nanotechnology-based solutions, while promising for performance enhancement, introduce uncertainties regarding nanoparticle fate in the environment. The potential for nanoparticle leaching during product use or disposal remains inadequately understood, with emerging research suggesting possible ecotoxicological impacts on aquatic organisms.

Life cycle assessments of modified Nylon 66 products reveal complex trade-offs. While improved water resistance extends product lifespan and reduces replacement frequency, the additional processing steps and materials often increase the initial environmental footprint. This creates a challenging balance between immediate manufacturing impacts and long-term sustainability benefits.

Recent regulatory developments worldwide are increasingly restricting certain modification chemicals, particularly those containing perfluorinated compounds. This regulatory landscape is driving innovation toward greener alternatives, including bio-based modification agents derived from renewable resources and environmentally benign processing methods.

Water consumption during modification processes presents another environmental consideration, as many treatment methods require substantial water for processing and subsequent effluent treatment. Closed-loop systems and water recycling technologies are being developed to mitigate these impacts, though implementation remains limited in commercial settings.

Performance Testing Standards for Modified Polyamides

Standardized testing protocols are essential for evaluating the performance of modified polyamides, particularly when assessing improvements in water absorption resistance. The most widely recognized standard for measuring water absorption in polyamides is ASTM D570, which provides detailed procedures for determining the rate and amount of water absorbed by plastic materials when immersed. For Nylon 66 specifically, this test typically involves conditioning samples at 50% relative humidity, followed by immersion in distilled water at 23°C for 24 hours or until equilibrium is reached.

ISO 62 represents another critical international standard that outlines methods for determining water absorption properties in plastics. This standard offers multiple procedures, including immersion in water at different temperatures and exposure to humid environments, making it particularly valuable for evaluating modified Nylon 66 formulations under various conditions that simulate real-world applications.

Beyond water absorption, comprehensive performance evaluation requires testing mechanical properties before and after moisture exposure. ASTM D638 for tensile properties and ASTM D790 for flexural properties are commonly employed to quantify how water absorption affects the structural integrity of modified polyamides. These tests provide critical data on strength retention and dimensional stability under humid conditions.

For applications requiring long-term performance assessment, accelerated aging tests following ASTM D3045 protocols help predict the durability of moisture-resistant Nylon 66 formulations. These tests typically expose materials to elevated temperatures and humidity levels to simulate years of service in condensed timeframes.

Thermal analysis standards, including ASTM E1356 for glass transition temperature determination and ASTM D3418 for melting point analysis, are essential for understanding how moisture-resistant modifications affect the thermal behavior of Nylon 66. These properties often correlate with moisture resistance and overall performance stability.

Industry-specific standards supplement these general protocols. For automotive applications, SAE J2192 outlines weathering requirements, while medical device standards like ISO 10993 series address biocompatibility concerns for moisture-resistant polyamides in healthcare settings. Electronics applications typically reference IEC 60068-2-78 for humidity resistance testing of components made from modified polyamides.

Emerging standards are beginning to address sustainability aspects of modified polyamides, including ISO 14040 for life cycle assessment and ASTM D6866 for bio-based content verification, reflecting growing industry interest in environmentally responsible polymer modifications that maintain or enhance moisture resistance properties.

ISO 62 represents another critical international standard that outlines methods for determining water absorption properties in plastics. This standard offers multiple procedures, including immersion in water at different temperatures and exposure to humid environments, making it particularly valuable for evaluating modified Nylon 66 formulations under various conditions that simulate real-world applications.

Beyond water absorption, comprehensive performance evaluation requires testing mechanical properties before and after moisture exposure. ASTM D638 for tensile properties and ASTM D790 for flexural properties are commonly employed to quantify how water absorption affects the structural integrity of modified polyamides. These tests provide critical data on strength retention and dimensional stability under humid conditions.

For applications requiring long-term performance assessment, accelerated aging tests following ASTM D3045 protocols help predict the durability of moisture-resistant Nylon 66 formulations. These tests typically expose materials to elevated temperatures and humidity levels to simulate years of service in condensed timeframes.

Thermal analysis standards, including ASTM E1356 for glass transition temperature determination and ASTM D3418 for melting point analysis, are essential for understanding how moisture-resistant modifications affect the thermal behavior of Nylon 66. These properties often correlate with moisture resistance and overall performance stability.

Industry-specific standards supplement these general protocols. For automotive applications, SAE J2192 outlines weathering requirements, while medical device standards like ISO 10993 series address biocompatibility concerns for moisture-resistant polyamides in healthcare settings. Electronics applications typically reference IEC 60068-2-78 for humidity resistance testing of components made from modified polyamides.

Emerging standards are beginning to address sustainability aspects of modified polyamides, including ISO 14040 for life cycle assessment and ASTM D6866 for bio-based content verification, reflecting growing industry interest in environmentally responsible polymer modifications that maintain or enhance moisture resistance properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!