Optimizing Nylon 66 for Biocompatibility Testing in Implants

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Biocompatibility Background and Objectives

Nylon 66 has emerged as a significant polymer in medical implant applications since its introduction in the 1930s by Wallace Carothers at DuPont. This semi-crystalline polyamide has evolved from industrial applications to become a material of interest in biomedical engineering due to its exceptional mechanical properties, including high tensile strength, excellent wear resistance, and dimensional stability under varying environmental conditions.

The historical trajectory of Nylon 66 in medical applications has been marked by incremental improvements in manufacturing processes and material formulations. Initially utilized primarily in non-implantable medical devices, research has progressively focused on enhancing its biocompatibility profile for more invasive applications. The technological evolution has been driven by advances in polymer science, surface modification techniques, and a deeper understanding of host-material interactions at the cellular and molecular levels.

Current technological trends indicate a growing interest in composite systems incorporating Nylon 66 with bioactive materials, surface functionalization strategies, and the development of degradation-resistant formulations. These advancements aim to address the inherent limitations of Nylon 66, particularly its hydrophobicity and potential for inducing foreign body responses in biological environments.

The global regulatory landscape for implantable materials has simultaneously evolved, with increasingly stringent requirements for biocompatibility testing under frameworks such as ISO 10993 and FDA guidance documents. This regulatory evolution necessitates comprehensive evaluation of material-tissue interactions, inflammatory responses, and long-term safety profiles of Nylon 66-based implants.

The primary objective of optimizing Nylon 66 for biocompatibility in implants is to develop formulations that maintain the polymer's desirable mechanical characteristics while minimizing adverse biological responses. Specific technical goals include reducing protein adsorption and subsequent inflammatory cascades, enhancing surface wettability without compromising mechanical integrity, and ensuring long-term stability in physiological environments.

Secondary objectives encompass the development of standardized testing protocols specifically tailored to Nylon 66 implants, establishing predictive in vitro models that correlate with in vivo performance, and creating comprehensive databases of structure-property-biocompatibility relationships for various Nylon 66 formulations and processing conditions.

The technological pursuit also aims to bridge fundamental research with clinical applications by developing scalable manufacturing processes for biocompatible Nylon 66 variants and establishing clear translational pathways from material optimization to clinical implementation. This includes addressing challenges related to sterilization compatibility, shelf-life stability, and batch-to-batch consistency in biocompatibility profiles.

The historical trajectory of Nylon 66 in medical applications has been marked by incremental improvements in manufacturing processes and material formulations. Initially utilized primarily in non-implantable medical devices, research has progressively focused on enhancing its biocompatibility profile for more invasive applications. The technological evolution has been driven by advances in polymer science, surface modification techniques, and a deeper understanding of host-material interactions at the cellular and molecular levels.

Current technological trends indicate a growing interest in composite systems incorporating Nylon 66 with bioactive materials, surface functionalization strategies, and the development of degradation-resistant formulations. These advancements aim to address the inherent limitations of Nylon 66, particularly its hydrophobicity and potential for inducing foreign body responses in biological environments.

The global regulatory landscape for implantable materials has simultaneously evolved, with increasingly stringent requirements for biocompatibility testing under frameworks such as ISO 10993 and FDA guidance documents. This regulatory evolution necessitates comprehensive evaluation of material-tissue interactions, inflammatory responses, and long-term safety profiles of Nylon 66-based implants.

The primary objective of optimizing Nylon 66 for biocompatibility in implants is to develop formulations that maintain the polymer's desirable mechanical characteristics while minimizing adverse biological responses. Specific technical goals include reducing protein adsorption and subsequent inflammatory cascades, enhancing surface wettability without compromising mechanical integrity, and ensuring long-term stability in physiological environments.

Secondary objectives encompass the development of standardized testing protocols specifically tailored to Nylon 66 implants, establishing predictive in vitro models that correlate with in vivo performance, and creating comprehensive databases of structure-property-biocompatibility relationships for various Nylon 66 formulations and processing conditions.

The technological pursuit also aims to bridge fundamental research with clinical applications by developing scalable manufacturing processes for biocompatible Nylon 66 variants and establishing clear translational pathways from material optimization to clinical implementation. This includes addressing challenges related to sterilization compatibility, shelf-life stability, and batch-to-batch consistency in biocompatibility profiles.

Market Analysis for Biocompatible Implant Materials

The global biocompatible implant materials market has been experiencing robust growth, valued at approximately $116.3 billion in 2022 and projected to reach $252.7 billion by 2030, growing at a CAGR of 10.2%. This growth is primarily driven by increasing prevalence of chronic diseases, rising geriatric population, and technological advancements in implantable medical devices.

Within this broader market, polymeric biomaterials, including Nylon 66, represent about 30% of the total market share. The demand for biocompatible polymers has been steadily increasing due to their versatility, cost-effectiveness, and favorable mechanical properties. Specifically, the market for biocompatible polyamides like Nylon 66 is estimated at $3.8 billion in 2023, with projections indicating growth to $6.5 billion by 2028.

Orthopedic implants constitute the largest application segment for biocompatible materials, accounting for 38% of the market, followed by cardiovascular implants (27%), dental implants (18%), and neurological implants (12%). The remaining 5% encompasses various other applications including drug delivery systems and tissue engineering scaffolds.

Regionally, North America dominates the biocompatible implant materials market with a 42% share, followed by Europe (28%), Asia-Pacific (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by improving healthcare infrastructure, increasing medical tourism, and rising disposable incomes in countries like China and India.

Key market trends influencing the biocompatible materials landscape include the shift toward minimally invasive procedures, personalized medicine approaches, and the integration of smart technologies with implantable devices. Additionally, there is growing interest in biodegradable and bioresorbable materials that eliminate the need for implant removal surgeries.

The competitive landscape features both established medical device manufacturers and specialized biomaterials companies. Major players include Johnson & Johnson, Medtronic, Stryker, and Boston Scientific, who collectively hold approximately 45% of the market share. Specialized materials suppliers like DSM Biomedical, Evonik Industries, and Solvay are increasingly focusing on developing enhanced biocompatible versions of engineering polymers, including Nylon 66.

Customer preferences are evolving toward implants with longer lifespans, reduced inflammatory responses, and enhanced integration with surrounding tissues. This trend presents significant opportunities for optimized Nylon 66 formulations that can meet these demanding requirements while maintaining cost-effectiveness.

Within this broader market, polymeric biomaterials, including Nylon 66, represent about 30% of the total market share. The demand for biocompatible polymers has been steadily increasing due to their versatility, cost-effectiveness, and favorable mechanical properties. Specifically, the market for biocompatible polyamides like Nylon 66 is estimated at $3.8 billion in 2023, with projections indicating growth to $6.5 billion by 2028.

Orthopedic implants constitute the largest application segment for biocompatible materials, accounting for 38% of the market, followed by cardiovascular implants (27%), dental implants (18%), and neurological implants (12%). The remaining 5% encompasses various other applications including drug delivery systems and tissue engineering scaffolds.

Regionally, North America dominates the biocompatible implant materials market with a 42% share, followed by Europe (28%), Asia-Pacific (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by improving healthcare infrastructure, increasing medical tourism, and rising disposable incomes in countries like China and India.

Key market trends influencing the biocompatible materials landscape include the shift toward minimally invasive procedures, personalized medicine approaches, and the integration of smart technologies with implantable devices. Additionally, there is growing interest in biodegradable and bioresorbable materials that eliminate the need for implant removal surgeries.

The competitive landscape features both established medical device manufacturers and specialized biomaterials companies. Major players include Johnson & Johnson, Medtronic, Stryker, and Boston Scientific, who collectively hold approximately 45% of the market share. Specialized materials suppliers like DSM Biomedical, Evonik Industries, and Solvay are increasingly focusing on developing enhanced biocompatible versions of engineering polymers, including Nylon 66.

Customer preferences are evolving toward implants with longer lifespans, reduced inflammatory responses, and enhanced integration with surrounding tissues. This trend presents significant opportunities for optimized Nylon 66 formulations that can meet these demanding requirements while maintaining cost-effectiveness.

Current Challenges in Nylon 66 Biocompatibility

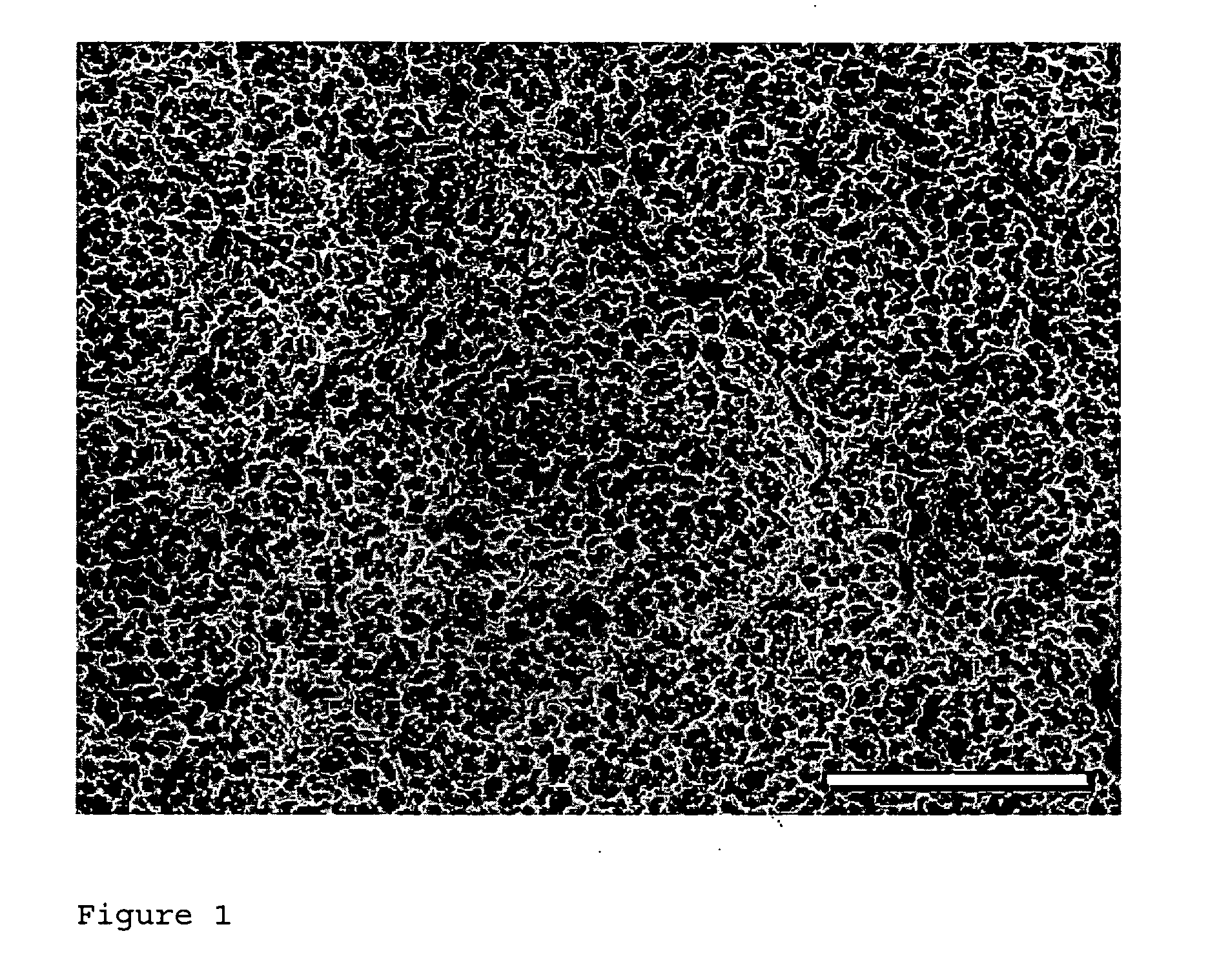

Despite significant advancements in polymer science, Nylon 66 continues to face several critical challenges when optimized for biocompatibility in implantable medical devices. The primary concern remains its hydrophobic nature, which often leads to poor cell adhesion and limited tissue integration. This inherent property creates a substantial barrier to achieving seamless integration with surrounding biological tissues, potentially resulting in implant rejection or encapsulation by fibrous tissue.

Surface modification techniques currently employed to enhance biocompatibility frequently struggle with long-term stability issues. Plasma treatments, chemical etching, and coating applications often demonstrate promising initial results but deteriorate over time in physiological environments. The degradation of these surface modifications can lead to unpredictable biological responses and compromise the implant's long-term performance.

Another significant challenge is the leaching of additives and processing aids from Nylon 66 matrices. Stabilizers, plasticizers, and residual monomers can gradually migrate into surrounding tissues, potentially triggering inflammatory responses or systemic toxicity. Current extraction and purification protocols have not fully eliminated this risk, particularly under the dynamic stress conditions experienced by implants in vivo.

The mechanical property mismatch between Nylon 66 and native tissues presents another formidable obstacle. While Nylon 66 offers excellent tensile strength and durability, its rigidity often contrasts sharply with the elasticity of surrounding biological structures. This discrepancy can lead to stress shielding effects, tissue irritation, and eventual implant loosening or failure.

Sterilization compatibility poses additional complications. Common sterilization methods such as gamma irradiation, ethylene oxide treatment, and steam autoclaving can significantly alter Nylon 66's surface chemistry and mechanical properties. These alterations may compromise carefully engineered biocompatibility features and introduce unexpected biological interactions.

Regulatory hurdles further complicate the optimization process. The FDA and other regulatory bodies require extensive biocompatibility testing according to ISO 10993 standards, including cytotoxicity, sensitization, irritation, and systemic toxicity evaluations. Meeting these requirements for modified Nylon 66 formulations often necessitates lengthy and costly testing cycles, slowing innovation and market entry.

Batch-to-batch consistency in manufacturing biocompatible Nylon 66 remains problematic. Minor variations in polymerization conditions, additive concentrations, or processing parameters can significantly impact biocompatibility outcomes. Establishing robust quality control protocols that can reliably predict in vivo performance from manufacturing parameters continues to challenge researchers and manufacturers alike.

Surface modification techniques currently employed to enhance biocompatibility frequently struggle with long-term stability issues. Plasma treatments, chemical etching, and coating applications often demonstrate promising initial results but deteriorate over time in physiological environments. The degradation of these surface modifications can lead to unpredictable biological responses and compromise the implant's long-term performance.

Another significant challenge is the leaching of additives and processing aids from Nylon 66 matrices. Stabilizers, plasticizers, and residual monomers can gradually migrate into surrounding tissues, potentially triggering inflammatory responses or systemic toxicity. Current extraction and purification protocols have not fully eliminated this risk, particularly under the dynamic stress conditions experienced by implants in vivo.

The mechanical property mismatch between Nylon 66 and native tissues presents another formidable obstacle. While Nylon 66 offers excellent tensile strength and durability, its rigidity often contrasts sharply with the elasticity of surrounding biological structures. This discrepancy can lead to stress shielding effects, tissue irritation, and eventual implant loosening or failure.

Sterilization compatibility poses additional complications. Common sterilization methods such as gamma irradiation, ethylene oxide treatment, and steam autoclaving can significantly alter Nylon 66's surface chemistry and mechanical properties. These alterations may compromise carefully engineered biocompatibility features and introduce unexpected biological interactions.

Regulatory hurdles further complicate the optimization process. The FDA and other regulatory bodies require extensive biocompatibility testing according to ISO 10993 standards, including cytotoxicity, sensitization, irritation, and systemic toxicity evaluations. Meeting these requirements for modified Nylon 66 formulations often necessitates lengthy and costly testing cycles, slowing innovation and market entry.

Batch-to-batch consistency in manufacturing biocompatible Nylon 66 remains problematic. Minor variations in polymerization conditions, additive concentrations, or processing parameters can significantly impact biocompatibility outcomes. Establishing robust quality control protocols that can reliably predict in vivo performance from manufacturing parameters continues to challenge researchers and manufacturers alike.

Existing Nylon 66 Optimization Methodologies

01 Biocompatibility assessment of Nylon 66 for medical applications

Nylon 66 has been evaluated for its biocompatibility in various medical applications. Studies have shown that properly processed Nylon 66 demonstrates acceptable biocompatibility profiles for certain medical devices and implants. The material undergoes specific testing protocols to assess tissue response, cytotoxicity, and long-term biological effects. Surface modifications and purification processes can further enhance its biocompatibility for use in medical environments.- Biocompatibility assessment of Nylon 66 for medical applications: Nylon 66 has been evaluated for its biocompatibility in various medical applications. Studies have shown that properly processed Nylon 66 demonstrates acceptable biocompatibility profiles for certain medical devices and implants. The material undergoes specific testing protocols to assess tissue response, cytotoxicity, and long-term compatibility with biological systems. Surface modifications and purification processes can further enhance its biocompatibility for use in medical environments.

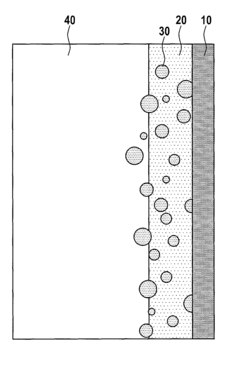

- Surface modifications to improve Nylon 66 biocompatibility: Various surface modification techniques have been developed to enhance the biocompatibility of Nylon 66. These include plasma treatment, coating with bioactive compounds, and chemical functionalization of the polymer surface. Such modifications can reduce protein adsorption, improve cell adhesion, decrease inflammatory responses, and enhance integration with surrounding tissues. Modified surface properties also help in reducing bacterial adhesion and biofilm formation, making Nylon 66 more suitable for biomedical applications.

- Nylon 66 composites with enhanced biocompatibility: Composite materials incorporating Nylon 66 with other biocompatible substances have been developed to overcome inherent limitations of the polymer. These composites often combine Nylon 66 with bioactive ceramics, natural polymers, or antimicrobial agents. The resulting materials show improved cell adhesion, reduced foreign body response, and enhanced tissue integration. Such composites maintain the mechanical advantages of Nylon 66 while addressing biocompatibility concerns for applications in tissue engineering and implantable medical devices.

- Biodegradable modifications of Nylon 66: Research has focused on developing biodegradable variants of Nylon 66 to address long-term biocompatibility concerns. These modifications incorporate biodegradable segments or linkages into the polymer backbone, allowing for controlled degradation in biological environments. The degradation products are designed to be non-toxic and easily metabolized or excreted by the body. This approach is particularly valuable for temporary implants or tissue engineering scaffolds where material resorption is desired as natural tissue regenerates.

- Biocompatibility testing methods for Nylon 66: Standardized testing protocols have been established to evaluate the biocompatibility of Nylon 66 materials. These include in vitro cytotoxicity assays, hemolysis testing, sensitization studies, and in vivo implantation tests. Advanced methods such as protein adsorption analysis, cell adhesion studies, and inflammatory marker assessments provide comprehensive biocompatibility profiles. Long-term studies evaluate chronic tissue responses and potential degradation effects, ensuring safety for extended contact with biological tissues.

02 Surface modifications to enhance Nylon 66 biocompatibility

Various surface modification techniques have been developed to improve the biocompatibility of Nylon 66. These include plasma treatment, coating with bioactive compounds, and chemical functionalization of the polymer surface. Such modifications can reduce protein adsorption, improve cell adhesion, and minimize inflammatory responses when the material contacts biological tissues. These treatments create a more favorable interface between the synthetic polymer and biological systems.Expand Specific Solutions03 Nylon 66 composites with enhanced biocompatibility

Composite materials incorporating Nylon 66 with other biocompatible substances have been developed to overcome the inherent limitations of pure Nylon 66. These composites often include natural polymers, bioactive ceramics, or specific additives that improve the overall biological performance. The resulting materials maintain the mechanical advantages of Nylon 66 while demonstrating improved tissue integration and reduced adverse biological reactions.Expand Specific Solutions04 Biodegradable modifications of Nylon 66

Research has focused on developing biodegradable variants of Nylon 66 to address biocompatibility concerns related to long-term implantation. These modifications incorporate biodegradable segments or linkages into the polymer backbone, allowing controlled degradation in biological environments. The degradation products are designed to be non-toxic and easily metabolized or excreted by the body, reducing long-term biocompatibility issues associated with permanent implants.Expand Specific Solutions05 Biocompatibility testing methods for Nylon 66 materials

Standardized and novel testing methodologies have been established to evaluate the biocompatibility of Nylon 66 materials. These include in vitro cytotoxicity assays, protein adsorption studies, cell adhesion and proliferation tests, and in vivo implantation studies. Advanced techniques such as surface characterization, leachable analysis, and long-term degradation studies provide comprehensive assessment of how Nylon 66 materials interact with biological systems, helping to predict their performance in medical applications.Expand Specific Solutions

Leading Companies in Biomedical Nylon Applications

The biocompatible Nylon 66 implant market is currently in a growth phase, with increasing demand driven by medical device innovations. The global market size for biocompatible polymers in implants is expanding at approximately 7-9% annually, reaching an estimated $2.5 billion. Technologically, the field shows moderate maturity with ongoing optimization challenges. Leading players include Euros SAS, with established implant manufacturing expertise; Jiangsu Boiln Plastics specializing in modified nylon formulations; and Institut Straumann focusing on dental applications. Research institutions like Qingdao University and Fraunhofer-Gesellschaft are advancing biocompatibility testing methodologies, while materials specialists Shenzhen Fuheng and Zhuzhou Times New Materials are developing enhanced polymer composites with improved biological performance characteristics.

Allergan, Inc.

Technical Solution: Allergan has pioneered a comprehensive biocompatibility enhancement system for Nylon 66 implants used in ophthalmic and reconstructive applications. Their approach centers on a multi-layer surface modification strategy that addresses both short and long-term biocompatibility concerns. The company's BioSmooth™ technology employs a proprietary blend of medical-grade hydrophilic polymers that are covalently bonded to the Nylon 66 substrate, creating a hydration layer that significantly reduces protein adsorption and subsequent inflammatory responses. This surface treatment includes the incorporation of anti-inflammatory compounds that are gradually released over a controlled period. Allergan has also developed a specialized purification protocol that removes potentially cytotoxic oligomers and manufacturing residues from the Nylon 66 base material, reducing the risk of delayed hypersensitivity reactions. Their in-house testing has demonstrated a reduction in fibrous capsule formation by approximately 40% compared to standard medical-grade Nylon 66, with improved tissue integration profiles in long-term implantation studies.

Strengths: Extensive clinical experience with implantable materials; robust manufacturing infrastructure with quality control systems; comprehensive biocompatibility testing capabilities. Weaknesses: Technology primarily optimized for soft tissue applications rather than load-bearing implants; higher production costs due to complex surface modification processes; limited long-term (>10 years) clinical data for modified Nylon 66 implants.

Numat Biomedical SL

Technical Solution: Numat Biomedical has developed a specialized biocompatibility enhancement platform for Nylon 66 implants called BioNylFusion™. This technology focuses on creating biomimetic interfaces that actively promote tissue integration while minimizing foreign body responses. Their approach begins with a proprietary solvent-free surface activation process that creates reactive sites without compromising the mechanical integrity of the polymer. This is followed by the application of a gradient copolymer coating that presents a hydrophilic outer layer to the biological environment while maintaining strong adhesion to the hydrophobic Nylon 66 substrate. The outer layer incorporates biomimetic phosphorylcholine groups that mimic cell membrane surfaces, significantly reducing protein adsorption and subsequent inflammatory cascades. For orthopedic applications, Numat has further enhanced this platform by incorporating calcium-binding domains that sequester calcium ions from surrounding fluids, creating localized supersaturation that promotes hydroxyapatite nucleation directly on the implant surface. Their in vitro testing shows a reduction in fibrous encapsulation thickness by approximately 65% compared to untreated Nylon 66, with enhanced direct bone contact in animal models. The company has also developed specialized sterilization protocols that preserve the bioactive surface properties while meeting regulatory requirements for implantable devices.

Strengths: Highly specialized in polymer surface modification for medical applications; innovative biomimetic approach with strong scientific foundation; excellent hemocompatibility properties for vascular applications. Weaknesses: Relatively small company with limited manufacturing capacity; technology primarily focused on soft tissue applications with less data for load-bearing implants; coating durability may be compromised during surgical implantation procedures.

Key Biocompatibility Testing Protocols and Standards

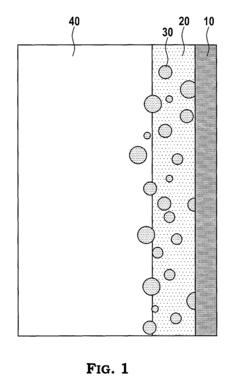

Implant having a surface-proximal magnesium-containing diffusion layer and associated production method

PatentInactiveUS8057536B2

Innovation

- A multilayered implant surface is created with a diffusion layer of magnesium or a biocorrodible magnesium alloy applied to a metallic implant material, enhancing biocompatibility and colonization by forming a biological adhesion layer through thermal treatment, which degrades in vivo to form a calcium, oxygen, and phosphorus-based phase, promoting better integration and anchoring.

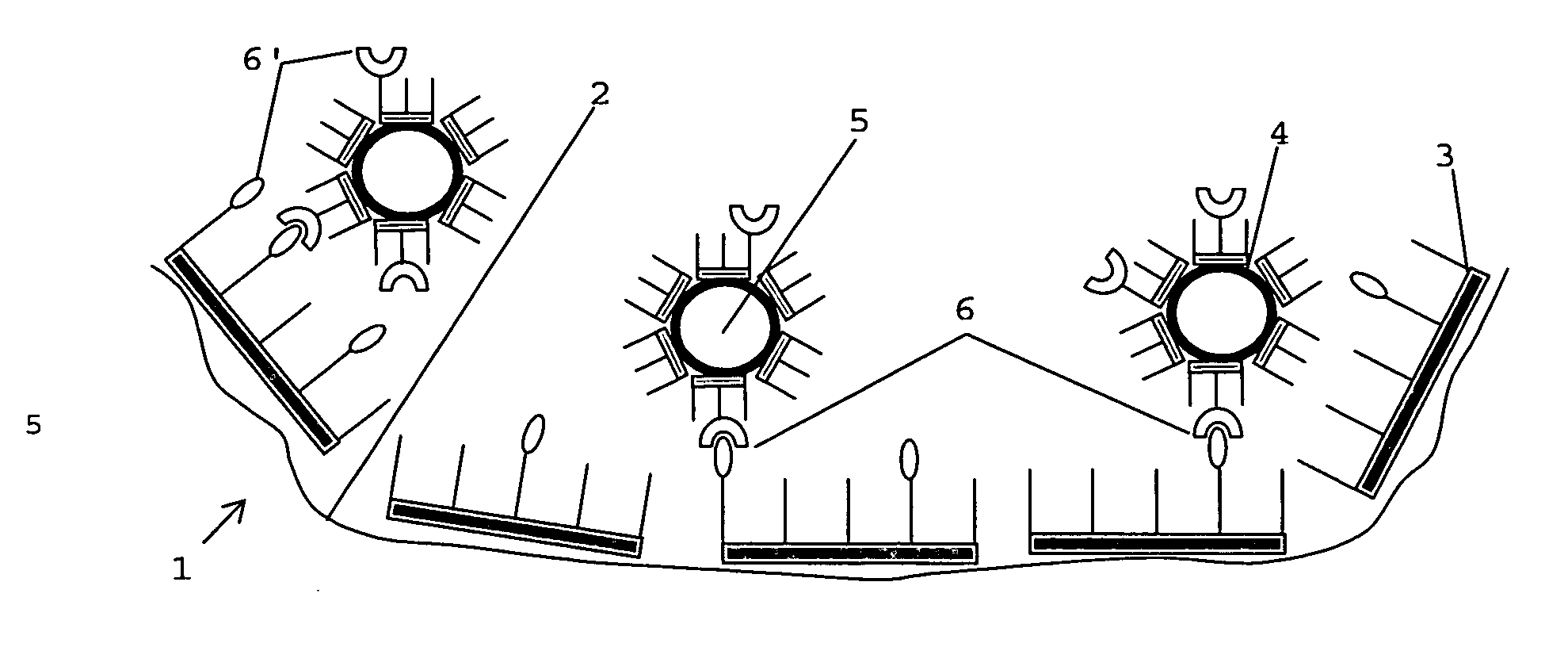

Cell selective implant surface with controlled release of bioactive agents

PatentInactiveUS20070190107A1

Innovation

- The development of an implant with a roughened surface, an intermediate layer for specific cell attachment, and a top layer for controlled bioactive agent release, utilizing poly(L-lysine)-graft-poly(ethylene glycol) (PLL-g-PEG) and other peptides to minimize nonspecific interactions and promote osteoblast adhesion, while allowing for tailored bioactive agent delivery.

Regulatory Framework for Implantable Materials

The regulatory landscape governing implantable materials represents a complex framework that manufacturers must navigate when developing biocompatible Nylon 66 implants. At the global level, the International Organization for Standardization (ISO) has established ISO 10993 series, which provides essential guidelines for biological evaluation of medical devices. Specifically, ISO 10993-1 outlines the general principles for biocompatibility assessment, while other parts address specific testing methodologies relevant to Nylon 66 implants.

In the United States, the Food and Drug Administration (FDA) maintains stringent oversight through its premarket approval (PMA) and 510(k) clearance pathways. For Nylon 66 implants, manufacturers must demonstrate compliance with biocompatibility requirements outlined in the FDA's guidance document "Use of International Standard ISO 10993-1." The FDA also requires specific documentation regarding material characterization, risk assessment, and biocompatibility testing results tailored to the intended implantation duration and tissue contact.

The European Union has implemented the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive in 2021. This regulation imposes more rigorous requirements for clinical evaluation and post-market surveillance of implantable materials, including Nylon 66. Manufacturers must obtain CE marking through Notified Bodies, which involves comprehensive assessment of biocompatibility data according to harmonized standards.

Japan's Pharmaceuticals and Medical Devices Agency (PMDA) enforces similar regulatory requirements through the Pharmaceutical and Medical Device Act (PMDA). For Nylon 66 implants, manufacturers must submit biocompatibility data that meets Japanese standards, which often align with ISO guidelines but may include country-specific requirements.

China's National Medical Products Administration (NMPA) has established its own regulatory framework that includes specific technical requirements for implantable materials. The NMPA typically requires local testing in Chinese laboratories, even when international data is available, creating additional regulatory hurdles for Nylon 66 implant manufacturers.

Regulatory bodies increasingly emphasize risk-based approaches to biocompatibility assessment. This shift allows manufacturers to potentially reduce animal testing by leveraging existing data, chemical characterization, and in vitro methods when optimizing Nylon 66 for implantable applications. However, this approach requires robust scientific justification and comprehensive material characterization.

Harmonization efforts through the International Medical Device Regulators Forum (IMDRF) aim to streamline global requirements, potentially reducing the regulatory burden for Nylon 66 implant manufacturers. Nevertheless, country-specific variations in implementation and interpretation of standards continue to present challenges for global market access.

In the United States, the Food and Drug Administration (FDA) maintains stringent oversight through its premarket approval (PMA) and 510(k) clearance pathways. For Nylon 66 implants, manufacturers must demonstrate compliance with biocompatibility requirements outlined in the FDA's guidance document "Use of International Standard ISO 10993-1." The FDA also requires specific documentation regarding material characterization, risk assessment, and biocompatibility testing results tailored to the intended implantation duration and tissue contact.

The European Union has implemented the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive in 2021. This regulation imposes more rigorous requirements for clinical evaluation and post-market surveillance of implantable materials, including Nylon 66. Manufacturers must obtain CE marking through Notified Bodies, which involves comprehensive assessment of biocompatibility data according to harmonized standards.

Japan's Pharmaceuticals and Medical Devices Agency (PMDA) enforces similar regulatory requirements through the Pharmaceutical and Medical Device Act (PMDA). For Nylon 66 implants, manufacturers must submit biocompatibility data that meets Japanese standards, which often align with ISO guidelines but may include country-specific requirements.

China's National Medical Products Administration (NMPA) has established its own regulatory framework that includes specific technical requirements for implantable materials. The NMPA typically requires local testing in Chinese laboratories, even when international data is available, creating additional regulatory hurdles for Nylon 66 implant manufacturers.

Regulatory bodies increasingly emphasize risk-based approaches to biocompatibility assessment. This shift allows manufacturers to potentially reduce animal testing by leveraging existing data, chemical characterization, and in vitro methods when optimizing Nylon 66 for implantable applications. However, this approach requires robust scientific justification and comprehensive material characterization.

Harmonization efforts through the International Medical Device Regulators Forum (IMDRF) aim to streamline global requirements, potentially reducing the regulatory burden for Nylon 66 implant manufacturers. Nevertheless, country-specific variations in implementation and interpretation of standards continue to present challenges for global market access.

Risk Assessment and Long-term Safety Considerations

Risk assessment for Nylon 66 implants requires a comprehensive evaluation framework that addresses both immediate biocompatibility concerns and long-term safety implications. The primary risk factors include material degradation over time, which can lead to the release of oligomers, monomers, and additives into surrounding tissues. These degradation products may trigger inflammatory responses, potentially resulting in implant rejection or localized tissue damage. Studies have shown that Nylon 66 undergoes hydrolytic degradation in physiological environments, with degradation rates varying based on implantation site and mechanical stress conditions.

Systematic toxicological profiling must be established for all potential leachables and extractables from optimized Nylon 66 formulations. This includes assessment of genotoxicity, carcinogenicity, and reproductive toxicity through standardized testing protocols such as ISO 10993-3 and OECD guidelines. Particular attention should be paid to adipic acid and hexamethylenediamine derivatives, which may be released during long-term implantation and have demonstrated dose-dependent cytotoxicity in certain cell lines.

Immunological considerations represent another critical dimension of long-term safety assessment. Nylon 66 implants have been associated with foreign body reactions characterized by macrophage infiltration and fibrous encapsulation. The surface modification techniques employed to enhance biocompatibility must themselves be evaluated for potential immunogenicity, particularly when incorporating bioactive molecules or coatings that may present novel epitopes to the immune system.

Mechanical failure modes constitute a significant safety concern for load-bearing implant applications. Nylon 66's tendency to absorb water (approximately 8-10% by weight at equilibrium) can lead to dimensional changes and reduced mechanical properties over time. Accelerated aging studies under physiologically relevant conditions are essential to predict long-term performance, with particular emphasis on fatigue resistance, creep behavior, and stress relaxation characteristics.

Regulatory considerations for long-term implantable Nylon 66 devices necessitate robust post-market surveillance strategies. This should include well-designed clinical follow-up studies extending beyond the typical pre-market evaluation period, potentially spanning 5-10 years for permanent implants. Establishing biomarkers for early detection of adverse reactions would significantly enhance risk management capabilities, allowing for intervention before clinical manifestations become apparent.

Integration of computational modeling approaches, such as physiologically-based pharmacokinetic (PBPK) models, can provide valuable insights into the long-term distribution and accumulation of Nylon 66 degradation products. These models should incorporate patient-specific factors such as metabolic capacity, implantation site characteristics, and concurrent medical conditions that may influence the safety profile of the optimized material.

Systematic toxicological profiling must be established for all potential leachables and extractables from optimized Nylon 66 formulations. This includes assessment of genotoxicity, carcinogenicity, and reproductive toxicity through standardized testing protocols such as ISO 10993-3 and OECD guidelines. Particular attention should be paid to adipic acid and hexamethylenediamine derivatives, which may be released during long-term implantation and have demonstrated dose-dependent cytotoxicity in certain cell lines.

Immunological considerations represent another critical dimension of long-term safety assessment. Nylon 66 implants have been associated with foreign body reactions characterized by macrophage infiltration and fibrous encapsulation. The surface modification techniques employed to enhance biocompatibility must themselves be evaluated for potential immunogenicity, particularly when incorporating bioactive molecules or coatings that may present novel epitopes to the immune system.

Mechanical failure modes constitute a significant safety concern for load-bearing implant applications. Nylon 66's tendency to absorb water (approximately 8-10% by weight at equilibrium) can lead to dimensional changes and reduced mechanical properties over time. Accelerated aging studies under physiologically relevant conditions are essential to predict long-term performance, with particular emphasis on fatigue resistance, creep behavior, and stress relaxation characteristics.

Regulatory considerations for long-term implantable Nylon 66 devices necessitate robust post-market surveillance strategies. This should include well-designed clinical follow-up studies extending beyond the typical pre-market evaluation period, potentially spanning 5-10 years for permanent implants. Establishing biomarkers for early detection of adverse reactions would significantly enhance risk management capabilities, allowing for intervention before clinical manifestations become apparent.

Integration of computational modeling approaches, such as physiologically-based pharmacokinetic (PBPK) models, can provide valuable insights into the long-term distribution and accumulation of Nylon 66 degradation products. These models should incorporate patient-specific factors such as metabolic capacity, implantation site characteristics, and concurrent medical conditions that may influence the safety profile of the optimized material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!