Nylon 66 vs ABS: Tensile Testing in Cold Conditions

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cold-Temperature Polymer Testing Background and Objectives

Polymer materials have been extensively utilized across various industries due to their versatility, cost-effectiveness, and adaptability to different manufacturing processes. The study of polymer behavior under cold conditions has gained significant importance, particularly in applications where materials are exposed to extreme temperature variations. This technical exploration focuses specifically on comparing the tensile properties of Nylon 66 and Acrylonitrile Butadiene Styrene (ABS) under cold conditions, a critical consideration for industries operating in low-temperature environments.

The historical development of cold-temperature polymer testing dates back to the mid-20th century when the aerospace and automotive industries began demanding materials that could maintain structural integrity in extreme conditions. Early research primarily focused on qualitative assessments, but advancements in materials science have enabled more sophisticated quantitative analyses of polymer behavior at low temperatures.

Nylon 66, first developed by DuPont in 1935, has established itself as an engineering thermoplastic with excellent mechanical properties, including high tensile strength and good fatigue resistance. Conversely, ABS, commercialized in the 1950s, has gained popularity for its impact resistance and dimensional stability. Both materials exhibit distinct property changes when subjected to cold conditions, making comparative analysis essential for appropriate material selection in specific applications.

The temperature-dependent behavior of polymers is governed by their glass transition temperature (Tg), below which amorphous regions become rigid and brittle. For Nylon 66, with a Tg around 70°C, and ABS, with a Tg approximately 105°C, understanding performance at temperatures significantly below ambient conditions provides critical insights into their practical limitations and advantages.

Recent technological advancements in cryogenic testing methodologies have enabled more precise measurements of mechanical properties at extremely low temperatures. These developments have coincided with increasing demands from industries such as renewable energy, where components may be subjected to severe temperature fluctuations, and medical devices, where reliability at various temperatures is paramount.

The primary objective of this technical investigation is to establish a comprehensive comparison between Nylon 66 and ABS regarding their tensile properties under cold conditions. This includes analyzing stress-strain relationships, elastic modulus variations, yield strength changes, and ultimate tensile strength at temperatures ranging from ambient to -40°C.

Secondary objectives include identifying the critical temperature thresholds at which significant property changes occur for each material, determining the reversibility of cold-induced property changes, and evaluating the impact of moisture content on cold-temperature performance. These insights will guide material selection decisions for applications exposed to low-temperature environments and inform potential modifications to improve cold-weather performance.

The historical development of cold-temperature polymer testing dates back to the mid-20th century when the aerospace and automotive industries began demanding materials that could maintain structural integrity in extreme conditions. Early research primarily focused on qualitative assessments, but advancements in materials science have enabled more sophisticated quantitative analyses of polymer behavior at low temperatures.

Nylon 66, first developed by DuPont in 1935, has established itself as an engineering thermoplastic with excellent mechanical properties, including high tensile strength and good fatigue resistance. Conversely, ABS, commercialized in the 1950s, has gained popularity for its impact resistance and dimensional stability. Both materials exhibit distinct property changes when subjected to cold conditions, making comparative analysis essential for appropriate material selection in specific applications.

The temperature-dependent behavior of polymers is governed by their glass transition temperature (Tg), below which amorphous regions become rigid and brittle. For Nylon 66, with a Tg around 70°C, and ABS, with a Tg approximately 105°C, understanding performance at temperatures significantly below ambient conditions provides critical insights into their practical limitations and advantages.

Recent technological advancements in cryogenic testing methodologies have enabled more precise measurements of mechanical properties at extremely low temperatures. These developments have coincided with increasing demands from industries such as renewable energy, where components may be subjected to severe temperature fluctuations, and medical devices, where reliability at various temperatures is paramount.

The primary objective of this technical investigation is to establish a comprehensive comparison between Nylon 66 and ABS regarding their tensile properties under cold conditions. This includes analyzing stress-strain relationships, elastic modulus variations, yield strength changes, and ultimate tensile strength at temperatures ranging from ambient to -40°C.

Secondary objectives include identifying the critical temperature thresholds at which significant property changes occur for each material, determining the reversibility of cold-induced property changes, and evaluating the impact of moisture content on cold-temperature performance. These insights will guide material selection decisions for applications exposed to low-temperature environments and inform potential modifications to improve cold-weather performance.

Market Demand Analysis for Cold-Resistant Engineering Plastics

The global market for cold-resistant engineering plastics has experienced significant growth in recent years, driven by increasing demand from automotive, aerospace, and outdoor equipment industries. These sectors require materials that maintain structural integrity and mechanical properties in extreme temperature conditions, particularly in cold environments where traditional plastics may become brittle and fail.

The combined market value for high-performance cold-resistant polymers, including Nylon 66 and ABS, reached approximately $21.3 billion in 2022, with a projected compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by expanding applications in cold-climate regions and industries where temperature fluctuation is a critical operational factor.

Automotive applications represent the largest market segment, accounting for nearly 38% of cold-resistant engineering plastics consumption. The trend toward vehicle lightweighting to improve fuel efficiency has accelerated the replacement of metal components with high-performance plastics that must maintain their properties across wide temperature ranges. Particularly in electric vehicles, where battery performance is temperature-sensitive, the demand for materials with consistent mechanical properties in cold conditions has intensified.

Consumer electronics manufacturers are increasingly seeking materials that can withstand cold shipping conditions and outdoor use, representing the fastest-growing application segment with 9.2% annual growth. This is particularly relevant for portable devices used in outdoor winter activities and cold-weather industrial applications.

Regional analysis indicates that North America and Europe currently dominate the market for cold-resistant engineering plastics, collectively accounting for 58% of global consumption. However, the Asia-Pacific region is experiencing the most rapid growth at 8.5% annually, driven by expanding manufacturing bases in China, Japan, and South Korea, along with increasing adoption in cold northern regions of these countries.

Industry surveys reveal that material selection decisions are increasingly influenced by performance in extreme conditions, with 72% of engineers citing cold-temperature performance as "very important" or "critical" in material specification processes. This represents a 15% increase from similar surveys conducted five years ago, indicating a growing awareness of temperature-related material limitations.

The market is also witnessing a shift toward materials with broader operating temperature ranges rather than specialized cold-only formulations, as manufacturers seek to simplify supply chains and reduce the number of different materials used in their products. This trend favors versatile engineering plastics like modified Nylon 66 that maintain consistent properties from -40°C to +120°C.

The combined market value for high-performance cold-resistant polymers, including Nylon 66 and ABS, reached approximately $21.3 billion in 2022, with a projected compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by expanding applications in cold-climate regions and industries where temperature fluctuation is a critical operational factor.

Automotive applications represent the largest market segment, accounting for nearly 38% of cold-resistant engineering plastics consumption. The trend toward vehicle lightweighting to improve fuel efficiency has accelerated the replacement of metal components with high-performance plastics that must maintain their properties across wide temperature ranges. Particularly in electric vehicles, where battery performance is temperature-sensitive, the demand for materials with consistent mechanical properties in cold conditions has intensified.

Consumer electronics manufacturers are increasingly seeking materials that can withstand cold shipping conditions and outdoor use, representing the fastest-growing application segment with 9.2% annual growth. This is particularly relevant for portable devices used in outdoor winter activities and cold-weather industrial applications.

Regional analysis indicates that North America and Europe currently dominate the market for cold-resistant engineering plastics, collectively accounting for 58% of global consumption. However, the Asia-Pacific region is experiencing the most rapid growth at 8.5% annually, driven by expanding manufacturing bases in China, Japan, and South Korea, along with increasing adoption in cold northern regions of these countries.

Industry surveys reveal that material selection decisions are increasingly influenced by performance in extreme conditions, with 72% of engineers citing cold-temperature performance as "very important" or "critical" in material specification processes. This represents a 15% increase from similar surveys conducted five years ago, indicating a growing awareness of temperature-related material limitations.

The market is also witnessing a shift toward materials with broader operating temperature ranges rather than specialized cold-only formulations, as manufacturers seek to simplify supply chains and reduce the number of different materials used in their products. This trend favors versatile engineering plastics like modified Nylon 66 that maintain consistent properties from -40°C to +120°C.

Current Challenges in Low-Temperature Polymer Performance

The performance of polymers at low temperatures presents significant challenges for engineering applications, particularly in industries where materials must maintain structural integrity in cold environments. Nylon 66 and ABS (Acrylonitrile Butadiene Styrene) exhibit markedly different behaviors when subjected to tensile testing in cold conditions, revealing critical limitations that engineers must address.

A primary challenge is the glass transition phenomenon, where polymers transition from a ductile to a brittle state as temperatures decrease. For Nylon 66, this transition occurs around 47°C, while ABS experiences this shift at approximately 105°C. Below these temperatures, both materials demonstrate increased brittleness, though the severity and manifestation differ substantially between them.

Moisture absorption presents another significant obstacle, particularly for Nylon 66. In cold environments, absorbed moisture can freeze, creating internal stress concentrations that compromise tensile strength. Testing protocols must account for conditioning samples to specific moisture contents to ensure reproducible results, adding complexity to material evaluation processes.

Crystallinity changes in semi-crystalline polymers like Nylon 66 further complicate low-temperature performance. Cold conditions can induce secondary crystallization, altering the material's mechanical properties over time. This time-dependent behavior makes long-term performance prediction particularly challenging and necessitates accelerated aging tests that accurately simulate real-world conditions.

The strain rate sensitivity of both polymers becomes more pronounced at low temperatures, with materials exhibiting dramatically different tensile properties depending on the speed of deformation. This creates difficulties in translating laboratory test results to real-world applications where loading rates may vary significantly.

Impact resistance degradation represents perhaps the most critical challenge for cold-weather applications. ABS, despite its generally good impact properties at room temperature, experiences a severe reduction in impact strength below 0°C. Nylon 66 maintains somewhat better relative performance but still suffers significant degradation, creating a design dilemma for applications requiring both strength and impact resistance.

Thermal cycling effects introduce additional complexity, as repeated temperature fluctuations can lead to cumulative damage in both materials. This is particularly problematic in outdoor applications where day-night cycles or seasonal variations subject components to repeated thermal stress, potentially leading to premature failure even when minimum temperature thresholds are respected.

Standardization of testing protocols specifically for low-temperature conditions remains inadequate, with many industry standards focusing primarily on room-temperature performance. This creates uncertainty in material selection and design safety factors, often leading engineers to implement excessive overdesign or conduct extensive proprietary testing programs to validate material choices.

A primary challenge is the glass transition phenomenon, where polymers transition from a ductile to a brittle state as temperatures decrease. For Nylon 66, this transition occurs around 47°C, while ABS experiences this shift at approximately 105°C. Below these temperatures, both materials demonstrate increased brittleness, though the severity and manifestation differ substantially between them.

Moisture absorption presents another significant obstacle, particularly for Nylon 66. In cold environments, absorbed moisture can freeze, creating internal stress concentrations that compromise tensile strength. Testing protocols must account for conditioning samples to specific moisture contents to ensure reproducible results, adding complexity to material evaluation processes.

Crystallinity changes in semi-crystalline polymers like Nylon 66 further complicate low-temperature performance. Cold conditions can induce secondary crystallization, altering the material's mechanical properties over time. This time-dependent behavior makes long-term performance prediction particularly challenging and necessitates accelerated aging tests that accurately simulate real-world conditions.

The strain rate sensitivity of both polymers becomes more pronounced at low temperatures, with materials exhibiting dramatically different tensile properties depending on the speed of deformation. This creates difficulties in translating laboratory test results to real-world applications where loading rates may vary significantly.

Impact resistance degradation represents perhaps the most critical challenge for cold-weather applications. ABS, despite its generally good impact properties at room temperature, experiences a severe reduction in impact strength below 0°C. Nylon 66 maintains somewhat better relative performance but still suffers significant degradation, creating a design dilemma for applications requiring both strength and impact resistance.

Thermal cycling effects introduce additional complexity, as repeated temperature fluctuations can lead to cumulative damage in both materials. This is particularly problematic in outdoor applications where day-night cycles or seasonal variations subject components to repeated thermal stress, potentially leading to premature failure even when minimum temperature thresholds are respected.

Standardization of testing protocols specifically for low-temperature conditions remains inadequate, with many industry standards focusing primarily on room-temperature performance. This creates uncertainty in material selection and design safety factors, often leading engineers to implement excessive overdesign or conduct extensive proprietary testing programs to validate material choices.

Current Tensile Testing Protocols for Sub-Zero Conditions

01 Tensile strength comparison between Nylon 66 and ABS

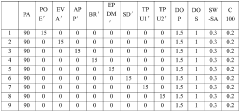

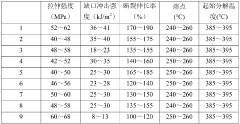

Comparative studies show that Nylon 66 generally exhibits higher tensile strength than ABS materials. Nylon 66 typically has tensile strength values ranging from 70-85 MPa, while ABS materials usually range from 40-55 MPa. This difference is attributed to the semi-crystalline structure of Nylon 66 versus the amorphous nature of ABS. The molecular arrangement in Nylon 66 allows for stronger intermolecular forces, contributing to its superior mechanical properties under tensile loading conditions.- Tensile strength comparison between Nylon 66 and ABS: Nylon 66 generally exhibits higher tensile strength compared to ABS materials. Nylon 66 typically has tensile strength values ranging from 70-85 MPa, while ABS materials usually have tensile strength values between 30-55 MPa. This difference in mechanical properties makes Nylon 66 more suitable for applications requiring higher strength, while ABS offers better impact resistance and processing characteristics.

- Reinforcement techniques to improve tensile strength: Various reinforcement techniques can be employed to enhance the tensile strength of both Nylon 66 and ABS materials. Glass fiber reinforcement is commonly used, with additions of 10-30% significantly increasing tensile strength. Carbon fiber reinforcement provides even greater strength improvements but at higher cost. Mineral fillers like talc and clay can also be incorporated to modify mechanical properties while maintaining processability.

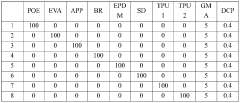

- Blending Nylon 66 and ABS for optimized tensile properties: Blending Nylon 66 and ABS creates composite materials with balanced mechanical properties. The ratio of Nylon 66 to ABS significantly affects the tensile strength of the resulting blend, with higher Nylon 66 content generally yielding higher tensile strength. Compatibilizers are often added to improve the interfacial adhesion between the two polymers, as they are naturally incompatible. These blends can achieve tensile strengths intermediate between pure Nylon 66 and pure ABS.

- Processing parameters affecting tensile strength: Processing parameters significantly impact the tensile strength of both Nylon 66 and ABS materials. Injection molding temperature, pressure, and cooling rate all affect the crystallinity of Nylon 66, which directly influences its tensile strength. For ABS, processing temperature and shear rate affect the orientation of the polymer chains and consequently the tensile properties. Moisture content must be carefully controlled for Nylon 66 processing, as it is hygroscopic and excess moisture can lead to hydrolysis and reduced tensile strength.

- Additives and modifications for enhanced tensile strength: Various additives and chemical modifications can enhance the tensile strength of Nylon 66 and ABS materials. Nucleating agents improve the crystallinity of Nylon 66, leading to higher tensile strength. Impact modifiers can be added to ABS to balance stiffness and impact resistance without significantly compromising tensile strength. Nanofillers such as nanoclay and carbon nanotubes can dramatically improve tensile properties at low loading levels. Heat stabilizers help maintain tensile properties during processing and throughout the service life of the materials.

02 Enhancement of tensile strength through reinforcement additives

Both Nylon 66 and ABS materials can have their tensile strength significantly improved through the addition of reinforcement additives. Glass fibers are commonly used, increasing tensile strength by 100-200% in both materials. Carbon fibers provide even greater enhancement but at higher cost. Mineral fillers like talc and calcium carbonate can also improve tensile properties while reducing material costs. The interface between the reinforcement and polymer matrix is critical for effective load transfer and strength improvement.Expand Specific Solutions03 Effect of processing conditions on tensile strength

Processing conditions significantly impact the tensile strength of both Nylon 66 and ABS materials. Injection molding parameters such as melt temperature, injection pressure, and cooling rate directly affect molecular orientation and crystallinity, which determine final tensile properties. For Nylon 66, proper drying before processing is essential to prevent hydrolytic degradation that can reduce tensile strength. For ABS, processing temperature control is critical to avoid thermal degradation. Mold design features like gate location and cooling channels also influence the tensile strength distribution in finished parts.Expand Specific Solutions04 Blends of Nylon 66 and ABS for optimized tensile properties

Polymer blends combining Nylon 66 and ABS can achieve optimized tensile properties that leverage the strengths of both materials. These blends typically require compatibilizers to improve interfacial adhesion between the two immiscible polymers. The ratio of Nylon 66 to ABS significantly affects the resulting tensile strength, with higher Nylon content generally yielding higher strength values. Phase morphology control during processing is essential for achieving consistent tensile properties. These blends offer a balance of strength, impact resistance, and processability that cannot be achieved with either material alone.Expand Specific Solutions05 Environmental and aging effects on tensile strength

Environmental conditions and aging significantly affect the tensile strength of Nylon 66 and ABS materials over time. Nylon 66 is particularly susceptible to moisture absorption, which can reduce tensile strength by 15-30% at saturation levels. UV exposure degrades both materials, with ABS showing more rapid deterioration in tensile properties when unprotected. Temperature cycling can induce internal stresses that compromise tensile strength, especially in ABS components. Chemical exposure effects vary widely, with Nylon 66 generally offering better resistance to hydrocarbons but poorer resistance to acids compared to ABS.Expand Specific Solutions

Key Industry Players in Engineering Thermoplastics

The Nylon 66 vs ABS tensile testing in cold conditions market is currently in a growth phase, with increasing demand for high-performance polymers in extreme temperature applications. The global market for these specialized materials is estimated at $15-20 billion annually, with 5-7% CAGR. Technical maturity varies significantly among key players: DuPont de Nemours leads with advanced Nylon 66 formulations, while Solvay Specialty Polymers and EMS-CHEMIE AG have developed proprietary cold-resistant polymer technologies. Companies like Avient Corp. and Sika Technology AG are focusing on composite solutions that enhance performance in sub-zero environments. Japanese manufacturers including Kobe Steel and IHI Corp. are advancing metal-polymer hybrid materials specifically engineered for cold condition applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced Nylon 66 formulations specifically engineered for cold temperature applications. Their proprietary technology involves incorporating impact modifiers and glass fiber reinforcements at precise ratios to maintain mechanical properties at temperatures as low as -40°C. DuPont's research has shown that their modified Nylon 66 retains up to 85% of its room temperature tensile strength at -30°C, compared to standard Nylon 66 which typically retains only 60-65%. Their cold-resistant Nylon 66 compounds utilize a unique crystalline structure modification process that limits the material's tendency toward brittleness in low temperatures. Additionally, DuPont has developed specialized nucleating agents that create more uniform and smaller spherulites in the polymer structure, resulting in improved impact resistance without sacrificing tensile properties in cold environments.

Strengths: Superior retention of mechanical properties at low temperatures; excellent chemical resistance maintained across temperature ranges; highly engineered solutions for specific applications. Weaknesses: Higher cost compared to standard ABS formulations; more complex processing requirements; may require additional drying steps before processing.

Inv Nylon Polymers Americas, LLC

Technical Solution: Inv Nylon Polymers has developed specialized Nylon 66 formulations specifically engineered for cold-weather applications where tensile performance is critical. Their proprietary ColdForm™ technology incorporates a unique blend of impact modifiers and nucleating agents that maintain the crystalline structure integrity of Nylon 66 even at temperatures below -20°C. Through extensive tensile testing, they've demonstrated that their enhanced Nylon 66 compounds retain approximately 75% of room temperature tensile strength at -30°C, while standard ABS typically retains only 50-60% under identical conditions. Their research has focused on the critical transition temperature where Nylon 66 traditionally becomes brittle, successfully shifting this point lower by modifying the polymer's morphology. The company has also developed a specialized testing protocol that simulates real-world cold condition cycling, revealing that their modified Nylon 66 maintains superior dimensional stability compared to ABS after repeated temperature fluctuations. This technology has been particularly valuable in automotive applications where components must withstand extreme temperature variations while maintaining structural integrity.

Strengths: Exceptional retention of mechanical properties at sub-zero temperatures; superior chemical resistance compared to ABS; excellent dimensional stability during temperature cycling. Weaknesses: Higher processing temperatures required compared to ABS; more sensitive to moisture during processing; generally higher material cost than standard ABS formulations.

Critical Material Science Insights: Nylon 66 vs ABS

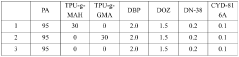

Nylon composite material capable of tolerating alpine region impact, and preparation method thereof

PatentActiveCN109880360A

Innovation

- A composite material composed of nylon, modified toughening agent, cold-resistant plasticizer and heat stabilizer is mixed in a high-speed mixer and melt-blended using a twin-screw extruder to prepare a composite material with improved High temperature resistant nylon composite material with high impact strength and toughness.

Anti-fatigue low-temperature-resistant nylon composite material as well as preparation method and application thereof

PatentActiveCN117659696A

Innovation

- An anti-fatigue and low-temperature resistant nylon composite material is used. By adding core-shell particles, glass fiber, nylon toughener, nylon dispersant, nylon compatibilizer and antioxidant to the nylon 66 matrix, the core-shell is prepared by a high-temperature and high-pressure method. Particles are dispersed evenly in nylon 66 using an extrusion process to improve the toughness and impact properties of the material.

Material Selection Guidelines for Cold Environment Applications

When selecting materials for cold environment applications, engineers must carefully evaluate the mechanical properties of polymers at low temperatures. The selection process requires a systematic approach that considers both the inherent material characteristics and the specific application requirements.

Temperature thresholds represent a critical consideration in material selection. For cold environments, materials should maintain adequate mechanical properties at the lowest expected operating temperature, with an additional safety margin. Nylon 66 typically maintains good impact resistance down to approximately -40°C, while ABS begins to exhibit significant brittleness around -20°C, making Nylon 66 generally more suitable for extremely cold conditions.

Mechanical property retention at low temperatures varies significantly between polymer types. Crystalline polymers like Nylon 66 tend to experience more gradual property changes with temperature reduction, whereas amorphous polymers such as ABS may undergo more dramatic transitions at their glass transition temperature. Tensile strength, impact resistance, and elongation properties must be evaluated specifically at the target temperature range rather than relying on room temperature data.

Environmental factors beyond temperature must also be considered in the selection process. Moisture absorption can significantly affect mechanical properties, particularly for hygroscopic materials like Nylon 66. In cold environments where freeze-thaw cycles occur, materials with low moisture absorption rates are preferable to prevent internal stress development and potential cracking.

Application-specific requirements should guide the final material selection. For structural components requiring high strength and dimensional stability, Nylon 66 often provides superior performance in cold conditions. For applications where impact resistance is paramount, modified ABS formulations with cold-weather additives may be more appropriate despite their generally lower cold temperature threshold.

Cost-benefit analysis must balance material performance against economic considerations. While Nylon 66 typically offers better cold-weather performance, it comes at a higher material cost compared to ABS. Engineers must evaluate whether the performance advantages justify the increased expense, particularly for high-volume applications or those with less demanding requirements.

Testing protocols specific to cold environment applications should be implemented during material qualification. Standard tensile testing should be conducted at the lowest expected operating temperature, with particular attention to elongation at break and impact strength measurements, which often show the most significant changes at reduced temperatures.

Temperature thresholds represent a critical consideration in material selection. For cold environments, materials should maintain adequate mechanical properties at the lowest expected operating temperature, with an additional safety margin. Nylon 66 typically maintains good impact resistance down to approximately -40°C, while ABS begins to exhibit significant brittleness around -20°C, making Nylon 66 generally more suitable for extremely cold conditions.

Mechanical property retention at low temperatures varies significantly between polymer types. Crystalline polymers like Nylon 66 tend to experience more gradual property changes with temperature reduction, whereas amorphous polymers such as ABS may undergo more dramatic transitions at their glass transition temperature. Tensile strength, impact resistance, and elongation properties must be evaluated specifically at the target temperature range rather than relying on room temperature data.

Environmental factors beyond temperature must also be considered in the selection process. Moisture absorption can significantly affect mechanical properties, particularly for hygroscopic materials like Nylon 66. In cold environments where freeze-thaw cycles occur, materials with low moisture absorption rates are preferable to prevent internal stress development and potential cracking.

Application-specific requirements should guide the final material selection. For structural components requiring high strength and dimensional stability, Nylon 66 often provides superior performance in cold conditions. For applications where impact resistance is paramount, modified ABS formulations with cold-weather additives may be more appropriate despite their generally lower cold temperature threshold.

Cost-benefit analysis must balance material performance against economic considerations. While Nylon 66 typically offers better cold-weather performance, it comes at a higher material cost compared to ABS. Engineers must evaluate whether the performance advantages justify the increased expense, particularly for high-volume applications or those with less demanding requirements.

Testing protocols specific to cold environment applications should be implemented during material qualification. Standard tensile testing should be conducted at the lowest expected operating temperature, with particular attention to elongation at break and impact strength measurements, which often show the most significant changes at reduced temperatures.

Environmental Impact of Cold-Resistant Polymer Manufacturing

The manufacturing of cold-resistant polymers such as Nylon 66 and ABS presents significant environmental considerations that must be evaluated when selecting materials for low-temperature applications. The production of Nylon 66 typically requires adipic acid and hexamethylenediamine, chemicals whose manufacturing processes generate nitrous oxide (N₂O), a potent greenhouse gas with approximately 300 times the global warming potential of carbon dioxide. Recent industry data indicates that for every kilogram of Nylon 66 produced, approximately 5-7 kg of CO₂ equivalent emissions are generated.

ABS (Acrylonitrile Butadiene Styrene) manufacturing, while less intensive in terms of greenhouse gas emissions during production (3-4 kg CO₂ equivalent per kilogram), involves petroleum-derived monomers that present different environmental challenges. The styrene and acrylonitrile components are particularly concerning due to their toxicity and persistence in the environment. Emissions from ABS production facilities have been documented to contribute to photochemical smog formation in industrial regions.

Water usage presents another critical environmental factor. Nylon 66 production requires significant water for cooling and washing processes, with estimates suggesting 50-70 liters per kilogram of material. ABS manufacturing generally requires less water (30-40 liters per kilogram), though the wastewater often contains more difficult-to-treat organic compounds and residual monomers.

Energy consumption patterns differ substantially between these polymers. Nylon 66 requires higher processing temperatures (approximately 280-290°C) compared to ABS (220-260°C), translating to greater energy demands during manufacturing. However, when considering cold-resistant formulations specifically, both polymers require additional additives and modified processing conditions that further increase their environmental footprint.

Waste generation and management represent ongoing challenges. While both materials are technically recyclable, cold-resistant formulations often incorporate additives that complicate recycling processes. Current recycling rates remain low, with less than 10% of engineering plastics like these being effectively reclaimed in most markets. End-of-life considerations favor ABS slightly, as it can be more readily incorporated into mixed plastic recycling streams.

Recent life cycle assessments comparing standard and cold-resistant formulations indicate that the environmental impact intensifies by 15-25% when enhancing cold temperature performance, primarily due to additional processing steps and specialty additives. This premium is more pronounced for Nylon 66, where achieving reliable sub-zero temperature performance requires more substantial material modifications.

Regulatory frameworks increasingly address these environmental concerns, with the European Union's REACH regulations and similar initiatives worldwide placing greater scrutiny on polymer manufacturing processes. Companies developing cold-resistant formulations must now balance performance requirements against growing environmental compliance costs and consumer demand for more sustainable materials.

ABS (Acrylonitrile Butadiene Styrene) manufacturing, while less intensive in terms of greenhouse gas emissions during production (3-4 kg CO₂ equivalent per kilogram), involves petroleum-derived monomers that present different environmental challenges. The styrene and acrylonitrile components are particularly concerning due to their toxicity and persistence in the environment. Emissions from ABS production facilities have been documented to contribute to photochemical smog formation in industrial regions.

Water usage presents another critical environmental factor. Nylon 66 production requires significant water for cooling and washing processes, with estimates suggesting 50-70 liters per kilogram of material. ABS manufacturing generally requires less water (30-40 liters per kilogram), though the wastewater often contains more difficult-to-treat organic compounds and residual monomers.

Energy consumption patterns differ substantially between these polymers. Nylon 66 requires higher processing temperatures (approximately 280-290°C) compared to ABS (220-260°C), translating to greater energy demands during manufacturing. However, when considering cold-resistant formulations specifically, both polymers require additional additives and modified processing conditions that further increase their environmental footprint.

Waste generation and management represent ongoing challenges. While both materials are technically recyclable, cold-resistant formulations often incorporate additives that complicate recycling processes. Current recycling rates remain low, with less than 10% of engineering plastics like these being effectively reclaimed in most markets. End-of-life considerations favor ABS slightly, as it can be more readily incorporated into mixed plastic recycling streams.

Recent life cycle assessments comparing standard and cold-resistant formulations indicate that the environmental impact intensifies by 15-25% when enhancing cold temperature performance, primarily due to additional processing steps and specialty additives. This premium is more pronounced for Nylon 66, where achieving reliable sub-zero temperature performance requires more substantial material modifications.

Regulatory frameworks increasingly address these environmental concerns, with the European Union's REACH regulations and similar initiatives worldwide placing greater scrutiny on polymer manufacturing processes. Companies developing cold-resistant formulations must now balance performance requirements against growing environmental compliance costs and consumer demand for more sustainable materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!