Optimizing Nylon 66 Hydrophobicity for Water Repellence

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Hydrophobicity Background and Objectives

Nylon 66, a synthetic polyamide, has been a cornerstone material in various industries since its invention by Wallace Carothers at DuPont in 1935. The evolution of this versatile polymer has seen significant advancements in its properties and applications over the decades. Initially valued for its strength and durability, Nylon 66 has found extensive use in textiles, automotive components, and industrial applications. However, its inherent hydrophilic nature, attributed to the amide groups in its molecular structure, has limited its performance in water-repellent applications.

The technological trajectory of Nylon 66 has been marked by continuous efforts to enhance its properties, with hydrophobicity becoming increasingly important in recent years. This focus on water repellence has been driven by emerging applications in outdoor gear, protective clothing, and advanced technical textiles where resistance to moisture is critical for performance and longevity.

Current research indicates a growing demand for hydrophobic Nylon 66 materials across multiple sectors, including sportswear, medical textiles, and electronic device protection. The global market for water-repellent textiles alone is projected to reach $5.9 billion by 2025, with modified polyamides playing a significant role in this expansion.

The primary technical objective of optimizing Nylon 66 hydrophobicity is to achieve a contact angle greater than 150° while maintaining the material's inherent mechanical properties and processability. This would classify the material as superhydrophobic, enabling applications where extreme water repellence is required. Secondary objectives include developing treatments that are environmentally sustainable, cost-effective, and durable under various conditions including mechanical stress and exposure to chemicals.

Recent technological trends point toward multi-disciplinary approaches combining surface modification techniques, nanotechnology, and biomimetic strategies inspired by naturally water-repellent surfaces like lotus leaves. The integration of these approaches represents a promising direction for achieving unprecedented levels of hydrophobicity in Nylon 66.

The evolution of this technology is also being shaped by regulatory pressures, particularly regarding the phase-out of perfluorinated compounds traditionally used for water repellence. This has accelerated research into alternative, more sustainable methods for enhancing hydrophobicity, creating both challenges and opportunities for innovation in this field.

As we look toward future developments, the optimization of Nylon 66 hydrophobicity stands at the intersection of polymer science, surface engineering, and sustainable chemistry, with potential breakthroughs poised to transform multiple industries and create new application possibilities for this established material.

The technological trajectory of Nylon 66 has been marked by continuous efforts to enhance its properties, with hydrophobicity becoming increasingly important in recent years. This focus on water repellence has been driven by emerging applications in outdoor gear, protective clothing, and advanced technical textiles where resistance to moisture is critical for performance and longevity.

Current research indicates a growing demand for hydrophobic Nylon 66 materials across multiple sectors, including sportswear, medical textiles, and electronic device protection. The global market for water-repellent textiles alone is projected to reach $5.9 billion by 2025, with modified polyamides playing a significant role in this expansion.

The primary technical objective of optimizing Nylon 66 hydrophobicity is to achieve a contact angle greater than 150° while maintaining the material's inherent mechanical properties and processability. This would classify the material as superhydrophobic, enabling applications where extreme water repellence is required. Secondary objectives include developing treatments that are environmentally sustainable, cost-effective, and durable under various conditions including mechanical stress and exposure to chemicals.

Recent technological trends point toward multi-disciplinary approaches combining surface modification techniques, nanotechnology, and biomimetic strategies inspired by naturally water-repellent surfaces like lotus leaves. The integration of these approaches represents a promising direction for achieving unprecedented levels of hydrophobicity in Nylon 66.

The evolution of this technology is also being shaped by regulatory pressures, particularly regarding the phase-out of perfluorinated compounds traditionally used for water repellence. This has accelerated research into alternative, more sustainable methods for enhancing hydrophobicity, creating both challenges and opportunities for innovation in this field.

As we look toward future developments, the optimization of Nylon 66 hydrophobicity stands at the intersection of polymer science, surface engineering, and sustainable chemistry, with potential breakthroughs poised to transform multiple industries and create new application possibilities for this established material.

Market Analysis for Water-Repellent Nylon Applications

The global market for water-repellent textiles has been experiencing significant growth, with the nylon segment showing particularly strong potential. Current market valuations place the water-repellent textile sector at approximately 7.5 billion USD in 2023, with projections indicating a compound annual growth rate of 6.2% through 2030. Within this broader market, nylon-based water-repellent materials account for roughly 18% of the total market share, demonstrating the material's importance in this application space.

Consumer demand for water-repellent nylon products spans multiple sectors, with outdoor apparel representing the largest market segment at 42% of total applications. Technical textiles follow at 27%, while automotive and aerospace applications constitute 15% and 10% respectively. The remaining 6% is distributed across various niche applications including medical textiles and protective equipment.

Regional analysis reveals that North America and Europe currently dominate the market for high-performance water-repellent nylon products, collectively accounting for 65% of global consumption. However, the Asia-Pacific region is demonstrating the most rapid growth rate at 8.7% annually, driven primarily by expanding manufacturing capabilities in China and increasing consumer demand in developing economies.

Industry surveys indicate that consumer preferences are shifting toward more environmentally sustainable water-repellent solutions, with 73% of respondents expressing concern about traditional fluorocarbon-based treatments. This trend presents both a challenge and an opportunity for optimized Nylon 66 hydrophobic treatments, as manufacturers must balance performance requirements with environmental considerations.

Price sensitivity analysis shows that consumers are willing to pay a premium of 15-20% for enhanced water repellency in premium outdoor and technical applications, while mass-market applications demonstrate more elastic price sensitivity with acceptable premiums limited to 5-8%. This bifurcation in the market suggests potential for tiered product strategies based on hydrophobicity performance levels.

Competitive landscape assessment reveals increasing competition from alternative materials, particularly advanced polyester formulations and emerging bio-based polymers. These competing materials have captured approximately 12% of market share from traditional nylon applications over the past five years, highlighting the need for continued innovation in Nylon 66 hydrophobic treatments to maintain market position.

Market forecasting models predict that demand for water-repellent Nylon 66 will continue to grow at rates exceeding GDP growth in most developed economies, with particular strength in technical applications requiring durability combined with water repellence. The highest growth potential exists in breathable waterproof membranes, where optimized Nylon 66 could address current performance gaps in the market.

Consumer demand for water-repellent nylon products spans multiple sectors, with outdoor apparel representing the largest market segment at 42% of total applications. Technical textiles follow at 27%, while automotive and aerospace applications constitute 15% and 10% respectively. The remaining 6% is distributed across various niche applications including medical textiles and protective equipment.

Regional analysis reveals that North America and Europe currently dominate the market for high-performance water-repellent nylon products, collectively accounting for 65% of global consumption. However, the Asia-Pacific region is demonstrating the most rapid growth rate at 8.7% annually, driven primarily by expanding manufacturing capabilities in China and increasing consumer demand in developing economies.

Industry surveys indicate that consumer preferences are shifting toward more environmentally sustainable water-repellent solutions, with 73% of respondents expressing concern about traditional fluorocarbon-based treatments. This trend presents both a challenge and an opportunity for optimized Nylon 66 hydrophobic treatments, as manufacturers must balance performance requirements with environmental considerations.

Price sensitivity analysis shows that consumers are willing to pay a premium of 15-20% for enhanced water repellency in premium outdoor and technical applications, while mass-market applications demonstrate more elastic price sensitivity with acceptable premiums limited to 5-8%. This bifurcation in the market suggests potential for tiered product strategies based on hydrophobicity performance levels.

Competitive landscape assessment reveals increasing competition from alternative materials, particularly advanced polyester formulations and emerging bio-based polymers. These competing materials have captured approximately 12% of market share from traditional nylon applications over the past five years, highlighting the need for continued innovation in Nylon 66 hydrophobic treatments to maintain market position.

Market forecasting models predict that demand for water-repellent Nylon 66 will continue to grow at rates exceeding GDP growth in most developed economies, with particular strength in technical applications requiring durability combined with water repellence. The highest growth potential exists in breathable waterproof membranes, where optimized Nylon 66 could address current performance gaps in the market.

Current Hydrophobic Treatment Technologies and Limitations

Current hydrophobic treatment technologies for Nylon 66 can be broadly categorized into several approaches, each with distinct mechanisms and limitations. Surface coating methods represent the most widely adopted technique, where fluoropolymers such as polytetrafluoroethylene (PTFE) and perfluoroalkyl compounds are applied to create low surface energy barriers. While these treatments achieve water contact angles of 110-120°, they suffer from poor durability under mechanical abrasion and washing cycles, typically degrading after 15-20 wash cycles.

Chemical modification techniques involve grafting hydrophobic functional groups directly onto the Nylon 66 polymer chains. Silane coupling agents and long-chain alkyl groups are commonly employed to reduce surface energy. These methods provide better durability than coatings but often require harsh chemical conditions that can compromise the mechanical properties of the base material, reducing tensile strength by up to 15% in some cases.

Plasma treatment represents an environmentally friendly alternative that modifies only the outermost surface layer without affecting bulk properties. By introducing CF₃ and CF₂ groups through plasma polymerization, water contact angles of up to 130° can be achieved. However, the specialized equipment required makes this approach cost-prohibitive for large-scale production, with treatment costs approximately 3-5 times higher than conventional methods.

Nanoparticle incorporation techniques involve embedding hydrophobic nanoparticles such as silica, zinc oxide, or titanium dioxide into the Nylon 66 matrix. This creates hierarchical surface roughness that enhances hydrophobicity through the Cassie-Baxter wetting state. While effective at achieving contact angles of 135-145°, these treatments often suffer from nanoparticle leaching during use, raising both environmental and performance concerns over time.

Sol-gel processing methods create durable silica-based networks on Nylon 66 surfaces with hydrophobic functional groups. These treatments offer good chemical resistance but typically require high curing temperatures (>150°C) that can distort or damage Nylon 66 fibers and finished products.

A significant limitation across all current technologies is the trade-off between hydrophobicity and other essential textile properties. Highly effective water-repellent treatments often compromise breathability, reducing moisture vapor transmission rates by 30-50%. Additionally, most current treatments rely on environmentally problematic fluorinated compounds, which face increasing regulatory restrictions worldwide due to their persistence and bioaccumulation potential.

Chemical modification techniques involve grafting hydrophobic functional groups directly onto the Nylon 66 polymer chains. Silane coupling agents and long-chain alkyl groups are commonly employed to reduce surface energy. These methods provide better durability than coatings but often require harsh chemical conditions that can compromise the mechanical properties of the base material, reducing tensile strength by up to 15% in some cases.

Plasma treatment represents an environmentally friendly alternative that modifies only the outermost surface layer without affecting bulk properties. By introducing CF₃ and CF₂ groups through plasma polymerization, water contact angles of up to 130° can be achieved. However, the specialized equipment required makes this approach cost-prohibitive for large-scale production, with treatment costs approximately 3-5 times higher than conventional methods.

Nanoparticle incorporation techniques involve embedding hydrophobic nanoparticles such as silica, zinc oxide, or titanium dioxide into the Nylon 66 matrix. This creates hierarchical surface roughness that enhances hydrophobicity through the Cassie-Baxter wetting state. While effective at achieving contact angles of 135-145°, these treatments often suffer from nanoparticle leaching during use, raising both environmental and performance concerns over time.

Sol-gel processing methods create durable silica-based networks on Nylon 66 surfaces with hydrophobic functional groups. These treatments offer good chemical resistance but typically require high curing temperatures (>150°C) that can distort or damage Nylon 66 fibers and finished products.

A significant limitation across all current technologies is the trade-off between hydrophobicity and other essential textile properties. Highly effective water-repellent treatments often compromise breathability, reducing moisture vapor transmission rates by 30-50%. Additionally, most current treatments rely on environmentally problematic fluorinated compounds, which face increasing regulatory restrictions worldwide due to their persistence and bioaccumulation potential.

Existing Methods for Enhancing Nylon 66 Water Repellence

01 Surface modification techniques for enhancing hydrophobicity of Nylon 66

Various surface modification techniques can be applied to enhance the hydrophobicity of Nylon 66. These include plasma treatment, chemical grafting, and coating with hydrophobic agents. These methods alter the surface properties of Nylon 66 without affecting its bulk mechanical properties, resulting in increased water repellency and improved performance in applications requiring hydrophobic characteristics.- Surface modification techniques for enhancing hydrophobicity of Nylon 66: Various surface modification techniques can be applied to enhance the hydrophobicity of Nylon 66. These include plasma treatment, chemical grafting, and coating with hydrophobic agents. These modifications alter the surface properties of Nylon 66 without affecting its bulk mechanical properties, resulting in improved water repellency and reduced moisture absorption. The modified Nylon 66 exhibits higher contact angles with water and better resistance to wetting.

- Incorporation of hydrophobic additives in Nylon 66 formulations: Hydrophobic additives can be incorporated into Nylon 66 during processing to enhance its water resistance. These additives include fluoropolymers, silicones, waxes, and certain organic compounds that reduce the material's affinity for water. By blending these additives with Nylon 66, the resulting composite material exhibits significantly improved hydrophobicity, reduced water absorption, and enhanced dimensional stability in humid environments.

- Copolymerization and blending strategies for hydrophobic Nylon 66: Copolymerization of Nylon 66 with hydrophobic monomers or blending with other hydrophobic polymers can significantly alter its water absorption properties. These approaches introduce hydrophobic segments into the polymer structure, disrupting hydrogen bonding sites and reducing the material's interaction with water molecules. The resulting modified Nylon 66 materials show decreased equilibrium moisture content and improved dimensional stability under varying humidity conditions.

- Nanocomposite approaches for enhancing Nylon 66 hydrophobicity: Incorporating nanomaterials such as nanoclays, carbon nanotubes, graphene, or metal oxide nanoparticles into Nylon 66 can enhance its hydrophobicity. These nanofillers create tortuous paths for water molecules, reducing water diffusion through the polymer matrix. Additionally, some nanoparticles with inherent hydrophobic properties can transfer these characteristics to the Nylon 66 matrix, resulting in composite materials with improved water resistance and reduced moisture sensitivity.

- Heat treatment and crystallinity control for hydrophobicity enhancement: Heat treatment processes and crystallinity control methods can be employed to enhance the hydrophobicity of Nylon 66. Increasing the crystallinity of Nylon 66 through annealing, controlled cooling, or nucleating agents reduces the amorphous regions that are prone to water absorption. The higher crystalline content results in decreased water uptake and improved dimensional stability. These physical modification techniques alter the microstructure of Nylon 66 to minimize its interaction with water molecules.

02 Incorporation of hydrophobic additives in Nylon 66 formulations

Hydrophobic additives can be incorporated into Nylon 66 during processing to enhance its water-repellent properties. These additives include fluoropolymers, silicones, waxes, and certain organic compounds that migrate to the surface during processing. The incorporation of these additives results in a more hydrophobic material suitable for applications in moisture-sensitive environments.Expand Specific Solutions03 Nylon 66 blends with hydrophobic polymers

Blending Nylon 66 with inherently hydrophobic polymers can significantly improve its water resistance. Common blend partners include polyolefins, fluoropolymers, and silicone-based materials. These blends combine the mechanical strength of Nylon 66 with the hydrophobic nature of the partner polymer, resulting in materials with balanced properties suitable for various applications requiring water resistance.Expand Specific Solutions04 Chemical modification of Nylon 66 polymer structure

The hydrophobicity of Nylon 66 can be enhanced through chemical modification of its polymer structure. This includes end-capping of hydrophilic groups, introduction of hydrophobic side chains, and copolymerization with hydrophobic monomers. These modifications reduce the number of hydrophilic amide groups exposed at the surface or introduce hydrophobic moieties that shield the hydrophilic groups from water interaction.Expand Specific Solutions05 Nanocomposite approaches for hydrophobic Nylon 66

Incorporating nanomaterials into Nylon 66 can enhance its hydrophobicity. Nanofillers such as modified clay, silica nanoparticles, carbon nanotubes, and graphene can be used to create nanocomposites with improved water resistance. These nanofillers can create micro-roughness on the surface, which combined with the inherent low surface energy of the additives, leads to enhanced hydrophobicity following the Cassie-Baxter model.Expand Specific Solutions

Leading Companies in Hydrophobic Textile Technologies

The hydrophobic optimization of Nylon 66 for water repellence is currently in a growth phase, with the market expanding due to increasing demand in automotive, textile, and consumer goods sectors. Major players like Kingfa Sci. & Tech., HYOSUNG Corp., and Toray Industries are leading innovation through advanced surface modification techniques and composite formulations. Chinese companies, including CGN Juner New Materials and Shanghai Kingfa, are rapidly gaining market share by leveraging research partnerships with institutions like Zhejiang University of Technology and Qingdao University. The technology is approaching maturity in traditional applications but continues to evolve with new nanomaterial approaches and environmentally friendly formulations, creating opportunities for specialized players like Jiangxi Xiancai Nanofibers Technology.

Shanghai Kingfa Sci. & Tech. Dvpt. Co., Ltd.

Technical Solution: Shanghai Kingfa has developed a comprehensive approach to enhancing Nylon 66 hydrophobicity through their "HydroShield" technology platform. Their solution involves a two-step modification process: first, a bulk modification of the polymer matrix by incorporating hydrophobic nanoparticles during the compounding stage, and second, a surface treatment using silane coupling agents that create covalent bonds with the nylon substrate. The company has pioneered the use of modified silica nanoparticles with long-chain alkyl groups that significantly increase the water contact angle while maintaining the mechanical properties of the base polymer. Their research has demonstrated that controlling the dispersion of these nanoparticles is critical for achieving uniform hydrophobicity. Kingfa has also developed specialized additives that migrate to the surface during processing, creating a self-organizing hydrophobic layer that continuously renews itself when the surface is abraded. This technology enables water contact angles exceeding 135° while maintaining excellent mechanical properties and thermal stability inherent to Nylon 66.

Strengths: Excellent integration with existing manufacturing processes; maintains mechanical properties of base polymer; self-healing hydrophobic properties that regenerate after surface abrasion; cost-effective compared to post-treatment methods. Weaknesses: Lower maximum contact angles compared to some surface treatment methods; potential for additive migration in certain applications; performance may degrade under extreme temperature conditions.

The Iowa State University Research Foundation, Inc.

Technical Solution: The Iowa State University Research Foundation has developed an innovative biomimetic approach to enhancing Nylon 66 hydrophobicity. Their technology draws inspiration from natural water-repellent surfaces like lotus leaves and butterfly wings, implementing a hierarchical surface structure on Nylon 66 substrates. The process involves a controlled etching technique that creates micro-scale roughness, followed by the application of a nano-scale coating of modified silica particles. These particles are functionalized with long-chain hydrophobic groups that chemically bond to the nylon surface. The research team has pioneered a green chemistry approach, using environmentally friendly reagents derived from renewable resources instead of traditional fluorinated compounds. Their method employs plant-based fatty acids modified to react with the amide groups in Nylon 66, creating a durable hydrophobic layer. The foundation's research has demonstrated that this dual-scale roughness combined with their bio-based surface chemistry can achieve water contact angles exceeding 145° while maintaining the mechanical integrity and breathability of the base material. Additionally, they've developed a UV-curable formulation that enables rapid processing suitable for industrial applications.

Strengths: Environmentally sustainable approach using bio-based chemicals; maintains breathability of the fabric; excellent durability with minimal performance loss after 30+ wash cycles; compatible with existing textile finishing equipment. Weaknesses: Currently more expensive than conventional treatments; requires precise control of surface etching parameters; slightly lower performance in oil repellency compared to fluorinated alternatives.

Key Patents in Nylon Hydrophobic Surface Treatments

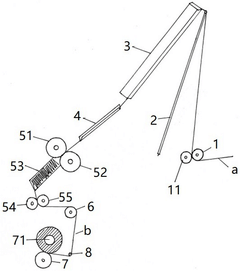

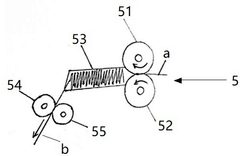

Processing device and processing technology of chinlon 66 water-repellent fiber

PatentPendingCN118668346A

Innovation

- A stuffed deformation box is used to replace the stacked disk false twister. The water-repellent nylon 66POY is processed through compressed air and high-temperature cross-linking and curing to optimize the silk path and give the fiber elasticity and fluffiness. The biphenyl gas phase heating and crimping roller mechanism are used to ensure the temperature. Uniform and shape-stable, combined with oiling and winding devices to improve the fiber's water-repellent effect and mechanical properties.

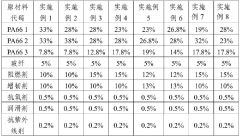

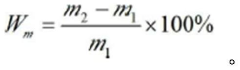

High-strength low-water-absorption nylon 66 composite material as well as preparation method and application thereof

PatentPendingCN117165073A

Innovation

- It is formulated with PA66, glass fiber, flame retardants, tougheners, antioxidants, lubricants and anti-UV agents in specific proportions, and is melted and molded through a twin-screw extruder to improve the uniformity of polymer molecular chain distribution and material density. , reduce water absorption, and meet the flame retardant requirements of UL94-V0.

Environmental Impact of Hydrophobic Treatments

The enhancement of Nylon 66 hydrophobicity through various treatments raises significant environmental concerns that must be addressed in any comprehensive technical assessment. Traditional hydrophobic treatments often involve fluorinated compounds, particularly perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), which have been identified as persistent organic pollutants with bioaccumulative properties. These substances remain in the environment for extended periods, potentially contaminating water sources and entering food chains.

Recent regulatory frameworks, including the Stockholm Convention and REACH regulations, have increasingly restricted the use of long-chain perfluorinated compounds due to their environmental persistence and potential health impacts. This regulatory landscape has accelerated the search for more environmentally benign alternatives for hydrophobic treatments of Nylon 66.

Water consumption represents another critical environmental consideration in hydrophobic treatment processes. Conventional methods often require substantial water usage during application and curing phases, contributing to industrial water footprints. Additionally, wastewater from these processes may contain chemical residues requiring specialized treatment before discharge, further increasing the environmental burden.

Energy requirements for hydrophobic treatments vary significantly across different methodologies. Thermal curing processes, commonly employed for certain hydrophobic finishes on Nylon 66, demand considerable energy inputs, contributing to carbon emissions. Plasma treatments, while offering environmental advantages in terms of chemical usage, typically require substantial electrical energy.

Life cycle assessment (LCA) studies comparing various hydrophobic treatment technologies for polymers like Nylon 66 indicate that newer silicone-based and bio-inspired treatments generally demonstrate reduced environmental impacts compared to fluorinated alternatives. However, these assessments must consider not only the immediate application process but also end-of-life scenarios.

The durability of hydrophobic treatments directly influences their environmental footprint. Treatments requiring frequent reapplication generate more waste and resource consumption over the product lifecycle. Research indicates that optimizing treatment durability through cross-linking mechanisms or deeper penetration into the Nylon 66 structure can significantly reduce long-term environmental impacts despite potentially higher initial resource investments.

Biodegradability presents a particular challenge for hydrophobic treatments. While Nylon 66 itself has limited biodegradability, certain hydrophobic treatments can further impede natural breakdown processes. Emerging bio-based hydrophobic compounds derived from plant waxes and proteins offer promising alternatives with improved end-of-life environmental profiles, though their performance characteristics often still lag behind synthetic options.

Recent regulatory frameworks, including the Stockholm Convention and REACH regulations, have increasingly restricted the use of long-chain perfluorinated compounds due to their environmental persistence and potential health impacts. This regulatory landscape has accelerated the search for more environmentally benign alternatives for hydrophobic treatments of Nylon 66.

Water consumption represents another critical environmental consideration in hydrophobic treatment processes. Conventional methods often require substantial water usage during application and curing phases, contributing to industrial water footprints. Additionally, wastewater from these processes may contain chemical residues requiring specialized treatment before discharge, further increasing the environmental burden.

Energy requirements for hydrophobic treatments vary significantly across different methodologies. Thermal curing processes, commonly employed for certain hydrophobic finishes on Nylon 66, demand considerable energy inputs, contributing to carbon emissions. Plasma treatments, while offering environmental advantages in terms of chemical usage, typically require substantial electrical energy.

Life cycle assessment (LCA) studies comparing various hydrophobic treatment technologies for polymers like Nylon 66 indicate that newer silicone-based and bio-inspired treatments generally demonstrate reduced environmental impacts compared to fluorinated alternatives. However, these assessments must consider not only the immediate application process but also end-of-life scenarios.

The durability of hydrophobic treatments directly influences their environmental footprint. Treatments requiring frequent reapplication generate more waste and resource consumption over the product lifecycle. Research indicates that optimizing treatment durability through cross-linking mechanisms or deeper penetration into the Nylon 66 structure can significantly reduce long-term environmental impacts despite potentially higher initial resource investments.

Biodegradability presents a particular challenge for hydrophobic treatments. While Nylon 66 itself has limited biodegradability, certain hydrophobic treatments can further impede natural breakdown processes. Emerging bio-based hydrophobic compounds derived from plant waxes and proteins offer promising alternatives with improved end-of-life environmental profiles, though their performance characteristics often still lag behind synthetic options.

Durability Testing Standards for Water-Repellent Textiles

The evaluation of water-repellent textiles, particularly those made from hydrophobic Nylon 66, requires standardized testing protocols to ensure consistent performance assessment across different products and applications. These durability testing standards are crucial for manufacturers, researchers, and end-users to understand the longevity and effectiveness of water-repellent treatments under various conditions.

The American Association of Textile Chemists and Colorists (AATCC) has established several key testing methods that have become industry standards. AATCC Test Method 22 (Spray Test) evaluates the initial water repellency by spraying water onto the fabric surface and assessing the wetting pattern. For Nylon 66 applications, this test provides baseline hydrophobicity measurements before durability testing begins.

AATCC Test Method 35 measures the water resistance after multiple launderings, which is particularly relevant for consumer textiles made from hydrophobic Nylon 66. The standard typically requires testing after 5, 10, 20, and 50 wash cycles to demonstrate long-term performance. Similarly, ISO 6330 provides international standards for domestic washing and drying procedures used in these durability assessments.

For outdoor applications, weathering resistance standards are essential. AATCC Test Method 169 evaluates weather resistance using xenon arc light exposure, while ASTM G154 uses fluorescent UV lamps to simulate outdoor exposure conditions. These tests are critical for Nylon 66 products intended for exterior use, as UV degradation can significantly impact hydrophobic treatments.

Abrasion resistance testing follows standards such as ASTM D4966 (Martindale method) or ISO 12947, which measure how well the water-repellent finish withstands physical wear. For Nylon 66 fabrics, these tests typically require maintaining a minimum water repellency rating after specified cycles of abrasion.

Chemical resistance standards include AATCC Test Method 118 for oil repellency and AATCC Test Method 193 for resistance to aqueous liquids. These are particularly important for evaluating the comprehensive performance of hydrophobic Nylon 66 in environments where exposure to various chemicals is expected.

Industry-specific standards also exist, such as OEKO-TEX Standard 100 for consumer safety and ASTM F1670/F1671 for medical protective clothing. These standards incorporate water repellency requirements alongside other performance criteria relevant to particular applications of hydrophobic Nylon 66.

Emerging standards are beginning to address environmental concerns, including tests for biodegradability of water-repellent finishes and assessments of PFAS-free alternatives for Nylon 66 treatments. The Sustainable Apparel Coalition's Higg Index now includes metrics for evaluating the environmental impact of water-repellent technologies throughout their lifecycle.

The American Association of Textile Chemists and Colorists (AATCC) has established several key testing methods that have become industry standards. AATCC Test Method 22 (Spray Test) evaluates the initial water repellency by spraying water onto the fabric surface and assessing the wetting pattern. For Nylon 66 applications, this test provides baseline hydrophobicity measurements before durability testing begins.

AATCC Test Method 35 measures the water resistance after multiple launderings, which is particularly relevant for consumer textiles made from hydrophobic Nylon 66. The standard typically requires testing after 5, 10, 20, and 50 wash cycles to demonstrate long-term performance. Similarly, ISO 6330 provides international standards for domestic washing and drying procedures used in these durability assessments.

For outdoor applications, weathering resistance standards are essential. AATCC Test Method 169 evaluates weather resistance using xenon arc light exposure, while ASTM G154 uses fluorescent UV lamps to simulate outdoor exposure conditions. These tests are critical for Nylon 66 products intended for exterior use, as UV degradation can significantly impact hydrophobic treatments.

Abrasion resistance testing follows standards such as ASTM D4966 (Martindale method) or ISO 12947, which measure how well the water-repellent finish withstands physical wear. For Nylon 66 fabrics, these tests typically require maintaining a minimum water repellency rating after specified cycles of abrasion.

Chemical resistance standards include AATCC Test Method 118 for oil repellency and AATCC Test Method 193 for resistance to aqueous liquids. These are particularly important for evaluating the comprehensive performance of hydrophobic Nylon 66 in environments where exposure to various chemicals is expected.

Industry-specific standards also exist, such as OEKO-TEX Standard 100 for consumer safety and ASTM F1670/F1671 for medical protective clothing. These standards incorporate water repellency requirements alongside other performance criteria relevant to particular applications of hydrophobic Nylon 66.

Emerging standards are beginning to address environmental concerns, including tests for biodegradability of water-repellent finishes and assessments of PFAS-free alternatives for Nylon 66 treatments. The Sustainable Apparel Coalition's Higg Index now includes metrics for evaluating the environmental impact of water-repellent technologies throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!