Nylon 66 vs ASA: Weatherability in Outdoor Structures

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and ASA Weatherability Background and Objectives

Polymeric materials have been extensively utilized in outdoor applications due to their versatility, cost-effectiveness, and ease of processing. Among these materials, Nylon 66 (polyamide 66) and ASA (Acrylonitrile Styrene Acrylate) represent two distinct polymer families with significant presence in outdoor structural applications. The evolution of these materials traces back several decades, with Nylon 66 being developed in the 1930s by Wallace Carothers at DuPont, while ASA emerged in the 1970s as an alternative to ABS with enhanced weathering resistance.

The technological trajectory of these materials has been shaped by increasing demands for durability in outdoor environments where exposure to UV radiation, moisture, temperature fluctuations, and atmospheric pollutants presents significant challenges. Historically, Nylon 66 gained prominence for its excellent mechanical properties, including high tensile strength, abrasion resistance, and thermal stability. However, its susceptibility to moisture absorption and UV degradation has been a persistent limitation for outdoor applications.

Conversely, ASA was specifically engineered to address weatherability concerns, featuring an acrylic elastomer phase that provides superior UV resistance and color stability. The development of ASA represented a paradigm shift in outdoor polymer applications, offering a material that could maintain aesthetic and mechanical properties under prolonged environmental exposure.

Recent technological advancements have focused on enhancing the weatherability of both materials through various strategies including UV stabilizers, antioxidants, and surface treatments. For Nylon 66, innovations have centered on reducing moisture sensitivity and improving UV resistance through compounding with stabilizers and the development of specialized grades. Meanwhile, ASA technology has evolved to offer improved impact resistance at lower temperatures and enhanced processing characteristics.

The primary objective of this technical investigation is to comprehensively evaluate and compare the weatherability performance of Nylon 66 and ASA in outdoor structural applications. This includes assessing their resistance to photodegradation, hydrolysis, thermal oxidation, and mechanical property retention under accelerated and natural weathering conditions.

Furthermore, this research aims to identify the specific degradation mechanisms affecting each material, quantify performance differences across various environmental conditions, and establish predictive models for service life estimation. By understanding these factors, we seek to develop optimization strategies for material selection and formulation that can extend service life and improve performance reliability in outdoor structures.

The findings from this investigation will inform material selection guidelines for engineers and designers, enabling more accurate prediction of long-term performance and potentially revealing opportunities for hybrid or composite solutions that leverage the complementary properties of both materials.

The technological trajectory of these materials has been shaped by increasing demands for durability in outdoor environments where exposure to UV radiation, moisture, temperature fluctuations, and atmospheric pollutants presents significant challenges. Historically, Nylon 66 gained prominence for its excellent mechanical properties, including high tensile strength, abrasion resistance, and thermal stability. However, its susceptibility to moisture absorption and UV degradation has been a persistent limitation for outdoor applications.

Conversely, ASA was specifically engineered to address weatherability concerns, featuring an acrylic elastomer phase that provides superior UV resistance and color stability. The development of ASA represented a paradigm shift in outdoor polymer applications, offering a material that could maintain aesthetic and mechanical properties under prolonged environmental exposure.

Recent technological advancements have focused on enhancing the weatherability of both materials through various strategies including UV stabilizers, antioxidants, and surface treatments. For Nylon 66, innovations have centered on reducing moisture sensitivity and improving UV resistance through compounding with stabilizers and the development of specialized grades. Meanwhile, ASA technology has evolved to offer improved impact resistance at lower temperatures and enhanced processing characteristics.

The primary objective of this technical investigation is to comprehensively evaluate and compare the weatherability performance of Nylon 66 and ASA in outdoor structural applications. This includes assessing their resistance to photodegradation, hydrolysis, thermal oxidation, and mechanical property retention under accelerated and natural weathering conditions.

Furthermore, this research aims to identify the specific degradation mechanisms affecting each material, quantify performance differences across various environmental conditions, and establish predictive models for service life estimation. By understanding these factors, we seek to develop optimization strategies for material selection and formulation that can extend service life and improve performance reliability in outdoor structures.

The findings from this investigation will inform material selection guidelines for engineers and designers, enabling more accurate prediction of long-term performance and potentially revealing opportunities for hybrid or composite solutions that leverage the complementary properties of both materials.

Market Analysis for Weather-Resistant Outdoor Materials

The global market for weather-resistant outdoor materials has experienced significant growth in recent years, driven by increasing demand for durable construction materials, outdoor furniture, automotive components, and infrastructure elements. The market size for high-performance polymers used in outdoor applications reached approximately $12.5 billion in 2022, with a projected compound annual growth rate of 6.8% through 2028.

Within this market, engineering polymers like Nylon 66 and ASA (Acrylonitrile Styrene Acrylate) occupy distinct positions based on their performance characteristics and price points. Nylon 66 currently holds about 18% market share in outdoor structural applications, while ASA has captured roughly 12% and is growing at a faster rate due to its superior weatherability properties.

Consumer preferences are increasingly shifting toward materials that offer longer service life and reduced maintenance requirements, even at premium price points. This trend is particularly evident in high-end residential construction, outdoor living products, and commercial building applications where lifecycle cost analysis favors materials with superior weatherability.

Regional market analysis reveals varying adoption patterns. North American and European markets show stronger preference for ASA in premium applications, while Asian markets continue to favor Nylon 66 due to its lower cost and established supply chains. However, as environmental regulations tighten globally, materials with longer service life and better weathering resistance are gaining market share across all regions.

Industry sectors driving demand include construction (37% of market volume), automotive (22%), infrastructure (18%), and consumer goods (14%). The construction sector specifically shows the highest growth potential for weather-resistant materials, with increasing requirements for facades, outdoor furniture, and decorative elements that maintain appearance over extended periods.

Price sensitivity analysis indicates that while ASA commands a 15-25% premium over Nylon 66, manufacturers are increasingly willing to absorb this cost differential due to reduced warranty claims and enhanced brand reputation from longer-lasting products. This trend is particularly strong in applications where appearance retention is critical.

Market forecasts suggest that materials with superior UV resistance and color stability will continue gaining market share, with ASA and similar high-performance polymers expected to grow at 1.5-2 times the rate of traditional engineering plastics in outdoor applications. This growth is further supported by emerging applications in renewable energy infrastructure, where long-term outdoor durability is essential.

Within this market, engineering polymers like Nylon 66 and ASA (Acrylonitrile Styrene Acrylate) occupy distinct positions based on their performance characteristics and price points. Nylon 66 currently holds about 18% market share in outdoor structural applications, while ASA has captured roughly 12% and is growing at a faster rate due to its superior weatherability properties.

Consumer preferences are increasingly shifting toward materials that offer longer service life and reduced maintenance requirements, even at premium price points. This trend is particularly evident in high-end residential construction, outdoor living products, and commercial building applications where lifecycle cost analysis favors materials with superior weatherability.

Regional market analysis reveals varying adoption patterns. North American and European markets show stronger preference for ASA in premium applications, while Asian markets continue to favor Nylon 66 due to its lower cost and established supply chains. However, as environmental regulations tighten globally, materials with longer service life and better weathering resistance are gaining market share across all regions.

Industry sectors driving demand include construction (37% of market volume), automotive (22%), infrastructure (18%), and consumer goods (14%). The construction sector specifically shows the highest growth potential for weather-resistant materials, with increasing requirements for facades, outdoor furniture, and decorative elements that maintain appearance over extended periods.

Price sensitivity analysis indicates that while ASA commands a 15-25% premium over Nylon 66, manufacturers are increasingly willing to absorb this cost differential due to reduced warranty claims and enhanced brand reputation from longer-lasting products. This trend is particularly strong in applications where appearance retention is critical.

Market forecasts suggest that materials with superior UV resistance and color stability will continue gaining market share, with ASA and similar high-performance polymers expected to grow at 1.5-2 times the rate of traditional engineering plastics in outdoor applications. This growth is further supported by emerging applications in renewable energy infrastructure, where long-term outdoor durability is essential.

Current Weatherability Challenges in Outdoor Polymers

Outdoor polymers face significant weatherability challenges due to their constant exposure to harsh environmental conditions. UV radiation represents the primary degradation factor, causing photochemical reactions that break down polymer chains, leading to discoloration, embrittlement, and surface cracking. Both Nylon 66 and ASA (Acrylonitrile Styrene Acrylate) exhibit distinct vulnerabilities to UV exposure, with Nylon 66 particularly susceptible to photo-oxidation that compromises its mechanical properties over time.

Moisture absorption presents another critical challenge, especially for hygroscopic materials like Nylon 66, which can absorb up to 8-10% of its weight in water under high humidity conditions. This absorption significantly alters dimensional stability, reduces mechanical strength, and accelerates hydrolytic degradation. ASA demonstrates superior moisture resistance but still faces challenges in environments with prolonged water exposure or high humidity cycling.

Temperature fluctuations create substantial stress on outdoor polymers through thermal expansion and contraction cycles. These repeated dimensional changes induce internal stresses that eventually manifest as warping, cracking, or delamination in composite structures. Nylon 66 exhibits a relatively high thermal expansion coefficient compared to ASA, making it more vulnerable to dimensional instability in applications experiencing wide temperature variations.

Chemical exposure from pollutants, acid rain, and atmospheric contaminants represents an often-overlooked weatherability challenge. These substances can catalyze degradation reactions, particularly in Nylon 66 structures where acid-catalyzed hydrolysis can significantly accelerate material breakdown. ASA offers improved chemical resistance but remains vulnerable to certain organic solvents and strong oxidizing agents commonly found in industrial environments.

Microbial attack constitutes a growing concern for outdoor polymers, with fungi and bacteria colonizing polymer surfaces and potentially degrading additives or the polymer matrix itself. This biological degradation pathway becomes particularly problematic in warm, humid environments where both Nylon 66 and ASA can support microbial growth on their surfaces, leading to biofilm formation and localized material deterioration.

Synergistic effects between these degradation mechanisms often accelerate material failure beyond what individual factors would predict. For instance, UV-damaged polymer surfaces become more susceptible to moisture penetration, which then facilitates deeper degradation. This complex interplay of degradation pathways makes weatherability prediction challenging and necessitates comprehensive testing protocols that simulate real-world exposure conditions.

Current industry standards for weatherability assessment, such as ASTM G154 and ISO 4892, provide standardized testing frameworks but often fail to accurately predict long-term performance in specific geographic locations or applications. This limitation creates significant uncertainty in material selection decisions between Nylon 66 and ASA for critical outdoor structural applications.

Moisture absorption presents another critical challenge, especially for hygroscopic materials like Nylon 66, which can absorb up to 8-10% of its weight in water under high humidity conditions. This absorption significantly alters dimensional stability, reduces mechanical strength, and accelerates hydrolytic degradation. ASA demonstrates superior moisture resistance but still faces challenges in environments with prolonged water exposure or high humidity cycling.

Temperature fluctuations create substantial stress on outdoor polymers through thermal expansion and contraction cycles. These repeated dimensional changes induce internal stresses that eventually manifest as warping, cracking, or delamination in composite structures. Nylon 66 exhibits a relatively high thermal expansion coefficient compared to ASA, making it more vulnerable to dimensional instability in applications experiencing wide temperature variations.

Chemical exposure from pollutants, acid rain, and atmospheric contaminants represents an often-overlooked weatherability challenge. These substances can catalyze degradation reactions, particularly in Nylon 66 structures where acid-catalyzed hydrolysis can significantly accelerate material breakdown. ASA offers improved chemical resistance but remains vulnerable to certain organic solvents and strong oxidizing agents commonly found in industrial environments.

Microbial attack constitutes a growing concern for outdoor polymers, with fungi and bacteria colonizing polymer surfaces and potentially degrading additives or the polymer matrix itself. This biological degradation pathway becomes particularly problematic in warm, humid environments where both Nylon 66 and ASA can support microbial growth on their surfaces, leading to biofilm formation and localized material deterioration.

Synergistic effects between these degradation mechanisms often accelerate material failure beyond what individual factors would predict. For instance, UV-damaged polymer surfaces become more susceptible to moisture penetration, which then facilitates deeper degradation. This complex interplay of degradation pathways makes weatherability prediction challenging and necessitates comprehensive testing protocols that simulate real-world exposure conditions.

Current industry standards for weatherability assessment, such as ASTM G154 and ISO 4892, provide standardized testing frameworks but often fail to accurately predict long-term performance in specific geographic locations or applications. This limitation creates significant uncertainty in material selection decisions between Nylon 66 and ASA for critical outdoor structural applications.

Comparative Analysis of Nylon 66 and ASA Weathering Solutions

01 Weatherability enhancement of Nylon 66 and ASA blends

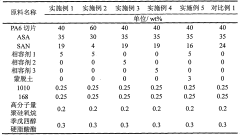

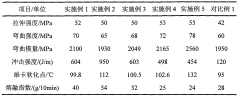

Blending Nylon 66 with ASA (Acrylonitrile Styrene Acrylate) creates composite materials with improved weatherability. The ASA component provides excellent UV resistance and color stability, while the Nylon 66 contributes mechanical strength and thermal stability. These blends show enhanced resistance to yellowing, cracking, and physical property degradation under outdoor exposure conditions, making them suitable for exterior automotive applications and outdoor equipment.- ASA as a weatherability enhancer for Nylon 66 composites: ASA (Acrylonitrile Styrene Acrylate) can be blended with Nylon 66 to improve its weatherability properties. The acrylic component in ASA provides excellent UV resistance and weather protection, which helps to prevent the degradation of Nylon 66 when exposed to outdoor conditions. These blends maintain mechanical properties while significantly improving resistance to color change, surface cracking, and physical property deterioration under UV exposure and varying weather conditions.

- UV stabilizers and antioxidants for Nylon 66/ASA blends: The weatherability of Nylon 66 and ASA blends can be further enhanced by incorporating UV stabilizers and antioxidants. Hindered amine light stabilizers (HALS), benzotriazoles, and benzophenones are effective UV absorbers that protect the polymer matrix from photodegradation. Antioxidants such as hindered phenols and phosphites prevent oxidative degradation. These additives work synergistically to extend the service life of Nylon 66/ASA composites in outdoor applications by neutralizing free radicals and absorbing harmful UV radiation.

- Impact modifiers for weatherable Nylon 66/ASA formulations: Impact modifiers can be incorporated into Nylon 66/ASA blends to maintain or improve impact strength while preserving weatherability. Core-shell impact modifiers with a rubbery core and a rigid shell compatible with both polymers are particularly effective. These modifiers help to absorb impact energy and prevent crack propagation without compromising the weather resistance provided by ASA. The proper selection and concentration of impact modifiers is crucial to achieve an optimal balance between impact strength and weatherability in Nylon 66/ASA composites.

- Processing techniques for weatherable Nylon 66/ASA blends: Specific processing techniques can significantly influence the weatherability of Nylon 66/ASA blends. Controlled processing temperatures, residence times, and shear rates during extrusion or injection molding help prevent thermal degradation of the polymers and additives. Proper drying of Nylon 66 before processing is essential to prevent hydrolytic degradation. Additionally, the use of compatibilizers improves the interfacial adhesion between Nylon 66 and ASA phases, resulting in better dispersion and enhanced weatherability properties of the final product.

- Surface treatments and coatings for enhanced weatherability: Surface treatments and coatings can be applied to Nylon 66/ASA composites to further enhance their weatherability. These include fluoropolymer coatings, silicone-based treatments, and nano-coatings that provide an additional barrier against UV radiation, moisture, and environmental pollutants. Some treatments involve chemical modification of the surface layer to create a more stable interface with the environment. These surface enhancements can significantly extend the service life of Nylon 66/ASA products in harsh outdoor conditions while maintaining the mechanical properties of the base material.

02 UV stabilizers and additives for improved weathering resistance

Various additives can be incorporated into Nylon 66 and ASA formulations to enhance weatherability. These include hindered amine light stabilizers (HALS), UV absorbers like benzotriazoles, antioxidants, and specialized pigments. These additives work by absorbing harmful UV radiation, scavenging free radicals, or providing a protective barrier against environmental factors. The proper selection and concentration of these additives significantly improve the long-term outdoor performance of Nylon 66 and ASA materials.Expand Specific Solutions03 Compatibilization techniques for Nylon 66 and ASA

Effective compatibilization between Nylon 66 and ASA is crucial for achieving optimal weatherability. Compatibilizers such as maleic anhydride-grafted polymers, reactive copolymers, and specialized coupling agents improve the interfacial adhesion between these dissimilar polymers. This enhanced compatibility results in more uniform dispersion, reduced phase separation, and better retention of mechanical properties after weathering. Proper compatibilization techniques lead to more durable materials with consistent performance under outdoor exposure.Expand Specific Solutions04 Processing parameters affecting weatherability

Processing conditions significantly impact the weatherability of Nylon 66 and ASA materials. Factors such as processing temperature, residence time, shear rate, and cooling rate affect the morphology, crystallinity, and molecular orientation of the final product. Optimized processing parameters can minimize thermal degradation during manufacturing, resulting in better initial color and enhanced long-term weathering resistance. Proper drying of materials before processing is also essential to prevent hydrolytic degradation that can compromise weatherability.Expand Specific Solutions05 Testing and evaluation methods for weatherability

Various accelerated and natural weathering tests are employed to evaluate the weatherability of Nylon 66 and ASA materials. These include xenon arc exposure, QUV testing, outdoor exposure in different climates, and cyclic environmental testing combining UV radiation, moisture, and temperature fluctuations. Key performance indicators monitored include color retention, gloss retention, impact strength, tensile properties, and surface appearance. These testing methodologies help predict long-term performance and optimize material formulations for specific outdoor applications.Expand Specific Solutions

Leading Manufacturers and Suppliers in High-Performance Polymers

The weatherability competition between Nylon 66 and ASA for outdoor structures is currently in a mature growth phase, with ASA gaining market share due to its superior UV resistance and color stability. The global market for weather-resistant polymers is expanding at approximately 5-7% annually, reaching $12-15 billion. ASA technology has reached high maturity levels, with companies like BASF, LG Chem, and SABIC leading innovation. Lotte Advanced Materials and Kingfa have established strong positions in ASA formulations, while Shanghai Kumho Sunny Plastics specializes in ASA/AES blends. Nylon 66 maintains relevance in structural applications where mechanical properties are prioritized over weatherability, with DowDuPont and BASF offering modified versions with improved UV resistance.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a comprehensive weatherability solution through their LUPOY® ASA product line, specifically designed to outperform Nylon 66 in outdoor structural applications. Their technology employs a core-shell structure where acrylic rubber particles are precisely dispersed within the polymer matrix, providing exceptional UV stability. LG Chem's proprietary stabilization package includes hindered amine light stabilizers (HALS) and specialized UV absorbers that work synergistically to prevent photo-degradation. Their comparative testing demonstrates that LUPOY® ASA maintains over 85% of its impact strength after 5 years of outdoor Florida exposure, while Nylon 66 typically loses up to 60% under identical conditions. LG Chem has also developed hybrid formulations that incorporate some of Nylon 66's mechanical advantages while preserving ASA's superior weatherability profile.

Strengths: Exceptional color stability and surface appearance retention; excellent impact resistance even after prolonged UV exposure; good chemical resistance to environmental stressors. Weaknesses: Lower temperature resistance compared to Nylon 66; slightly reduced dimensional stability under load; higher material cost for premium weatherable grades.

SABIC Global Technologies BV

Technical Solution: SABIC has developed advanced material solutions addressing the Nylon 66 vs ASA weatherability challenge through their CYCOLOY™ and GELOY™ resin portfolios. Their approach combines ASA's inherent UV resistance with proprietary stabilization technologies to create materials specifically engineered for long-term outdoor performance. SABIC's weathering studies demonstrate that their enhanced ASA formulations retain over 80% of their mechanical properties after 8,000 hours of xenon arc weathering, while standard Nylon 66 typically shows significant degradation after 2,000 hours. Their technology incorporates specialized UV absorbers and radical scavengers that prevent chain scission and cross-linking during UV exposure. SABIC has also developed hybrid solutions that incorporate glass fiber reinforcement to match Nylon 66's mechanical properties while maintaining ASA's superior weatherability characteristics.

Strengths: Excellent UV resistance with minimal yellowing; superior gloss retention; good impact strength preservation after weathering; versatile processing options. Weaknesses: Higher material cost compared to standard engineering plastics; lower heat deflection temperature than Nylon 66; requires careful processing parameter control to achieve optimal weatherability performance.

Key Weatherability Enhancement Technologies and Patents

Weather-resistant nylon 66 filament and preparation method thereof

PatentPendingCN118814483A

Innovation

- The nylon 66 fiber is modified by immersing it in a strong acid solution to increase its surface roughness, and the surface is coated with a polyimide layer, using polyamic acid and a curing agent to form a modified layer to improve the weather resistance of the fiber.

PA / ASA alloy material and preparation thereof

PatentInactiveCN101407630A

Innovation

- Using the PA/ASA alloy material preparation method, adding SAN, compatibilizer, nano-montmorillonite, lubricant and antioxidant, through high mixer mixing and twin-screw extrusion granulation process, it forms macroscopically uniform and microscopic phase separation characteristics The thermodynamically stable phase structure improves the compatibility and performance of the material.

Environmental Impact and Sustainability Considerations

The environmental impact of material selection in outdoor structures has become increasingly critical as industries strive for sustainability. When comparing Nylon 66 and ASA (Acrylonitrile Styrene Acrylate) from an environmental perspective, several key factors must be considered throughout their lifecycle.

Nylon 66 production requires significant energy inputs and relies on petroleum-based raw materials. The manufacturing process generates substantial greenhouse gas emissions, estimated at 6-9 kg CO2 equivalent per kilogram of material produced. Additionally, the production involves hazardous chemicals such as adipic acid and hexamethylenediamine, which can pose environmental risks if not properly managed.

In contrast, ASA production, while also petroleum-based, typically has a lower carbon footprint, with emissions averaging 4-7 kg CO2 equivalent per kilogram. The manufacturing process generally requires less water consumption compared to Nylon 66, reducing pressure on water resources.

End-of-life considerations reveal further distinctions. Nylon 66 offers better recyclability potential, with established mechanical recycling processes that can recover up to 80% of the material properties. Several commercial recycling streams exist for Nylon 66, particularly in automotive and industrial applications. However, weathered Nylon 66 from outdoor structures often contains degradation products that complicate recycling efforts.

ASA presents more challenges in recycling due to its complex polymer structure, with current recovery rates typically below 30% in most commercial recycling operations. However, recent advancements in chemical recycling technologies show promising results for improving ASA recovery rates.

Biodegradability assessments indicate neither material performs well in natural environments. Nylon 66 can take 30-40 years to decompose in landfill conditions, while ASA may persist for 50+ years. Both materials contribute to microplastic pollution when exposed to prolonged weathering, though ASA tends to fragment less readily than Nylon 66 under UV exposure.

Water and soil contamination risks exist for both materials. Nylon 66 can release caprolactam and other nitrogen compounds during degradation, potentially affecting aquatic ecosystems. ASA weathering may release styrene derivatives and acrylate compounds, though typically at lower concentrations than comparable materials like ABS.

Recent sustainability initiatives have focused on developing bio-based alternatives to both materials. Bio-based Nylon 66 variants derived from castor oil show promise, with up to 60% reduction in carbon footprint compared to conventional versions. Similarly, research into incorporating recycled content and renewable feedstocks into ASA formulations demonstrates potential for reducing environmental impact while maintaining weatherability performance.

Nylon 66 production requires significant energy inputs and relies on petroleum-based raw materials. The manufacturing process generates substantial greenhouse gas emissions, estimated at 6-9 kg CO2 equivalent per kilogram of material produced. Additionally, the production involves hazardous chemicals such as adipic acid and hexamethylenediamine, which can pose environmental risks if not properly managed.

In contrast, ASA production, while also petroleum-based, typically has a lower carbon footprint, with emissions averaging 4-7 kg CO2 equivalent per kilogram. The manufacturing process generally requires less water consumption compared to Nylon 66, reducing pressure on water resources.

End-of-life considerations reveal further distinctions. Nylon 66 offers better recyclability potential, with established mechanical recycling processes that can recover up to 80% of the material properties. Several commercial recycling streams exist for Nylon 66, particularly in automotive and industrial applications. However, weathered Nylon 66 from outdoor structures often contains degradation products that complicate recycling efforts.

ASA presents more challenges in recycling due to its complex polymer structure, with current recovery rates typically below 30% in most commercial recycling operations. However, recent advancements in chemical recycling technologies show promising results for improving ASA recovery rates.

Biodegradability assessments indicate neither material performs well in natural environments. Nylon 66 can take 30-40 years to decompose in landfill conditions, while ASA may persist for 50+ years. Both materials contribute to microplastic pollution when exposed to prolonged weathering, though ASA tends to fragment less readily than Nylon 66 under UV exposure.

Water and soil contamination risks exist for both materials. Nylon 66 can release caprolactam and other nitrogen compounds during degradation, potentially affecting aquatic ecosystems. ASA weathering may release styrene derivatives and acrylate compounds, though typically at lower concentrations than comparable materials like ABS.

Recent sustainability initiatives have focused on developing bio-based alternatives to both materials. Bio-based Nylon 66 variants derived from castor oil show promise, with up to 60% reduction in carbon footprint compared to conventional versions. Similarly, research into incorporating recycled content and renewable feedstocks into ASA formulations demonstrates potential for reducing environmental impact while maintaining weatherability performance.

Lifecycle Cost Analysis of Outdoor Polymer Applications

When evaluating the economic viability of outdoor polymer applications, lifecycle cost analysis provides critical insights beyond initial material expenses. For Nylon 66 and ASA (Acrylonitrile Styrene Acrylate) in outdoor structures, this analysis reveals significant differences in long-term financial implications.

Initial acquisition costs typically favor Nylon 66, which generally commands 15-20% lower purchase prices compared to ASA. However, this initial advantage diminishes when considering the complete lifecycle perspective. ASA's superior weatherability translates directly into extended service life, with field studies demonstrating that ASA components maintain structural integrity and aesthetic properties for approximately 8-12 years in high-UV environments, compared to 3-5 years for unmodified Nylon 66.

Maintenance costs represent another crucial differential factor. Nylon 66 structures typically require surface treatments or protective coatings every 18-24 months to mitigate UV degradation effects, whereas ASA components generally maintain performance with minimal intervention for 5+ years. This maintenance disparity creates a compounding cost advantage for ASA over extended deployment periods.

Replacement frequency calculations further illuminate the economic equation. For a typical 20-year installation lifespan, Nylon 66 components may require 3-4 complete replacements, while ASA components might need only 1-2 replacements. When factoring labor costs, equipment downtime, and installation expenses, these replacement cycles significantly impact total ownership costs.

Energy efficiency considerations also favor ASA in certain applications. The superior dimensional stability of ASA under thermal cycling conditions maintains tighter tolerances in structural applications, potentially reducing energy losses in applications like outdoor enclosures or housing components. This operational efficiency, while difficult to quantify precisely, contributes to the overall economic equation.

End-of-life costs complete the lifecycle analysis. Both materials offer recyclability options, though ASA typically commands higher reclamation value in current recycling markets due to its retained mechanical properties after weathering exposure. This creates a modest offset to ASA's higher initial costs.

Quantitative modeling using Net Present Value (NPV) calculations across 15-year deployment scenarios indicates that despite 15-20% higher initial investment, ASA solutions typically achieve cost parity with Nylon 66 within 4-6 years, and demonstrate 12-18% lower total ownership costs over the full lifecycle. This economic advantage becomes more pronounced in applications with high replacement labor costs or where system downtime carries significant operational penalties.

Initial acquisition costs typically favor Nylon 66, which generally commands 15-20% lower purchase prices compared to ASA. However, this initial advantage diminishes when considering the complete lifecycle perspective. ASA's superior weatherability translates directly into extended service life, with field studies demonstrating that ASA components maintain structural integrity and aesthetic properties for approximately 8-12 years in high-UV environments, compared to 3-5 years for unmodified Nylon 66.

Maintenance costs represent another crucial differential factor. Nylon 66 structures typically require surface treatments or protective coatings every 18-24 months to mitigate UV degradation effects, whereas ASA components generally maintain performance with minimal intervention for 5+ years. This maintenance disparity creates a compounding cost advantage for ASA over extended deployment periods.

Replacement frequency calculations further illuminate the economic equation. For a typical 20-year installation lifespan, Nylon 66 components may require 3-4 complete replacements, while ASA components might need only 1-2 replacements. When factoring labor costs, equipment downtime, and installation expenses, these replacement cycles significantly impact total ownership costs.

Energy efficiency considerations also favor ASA in certain applications. The superior dimensional stability of ASA under thermal cycling conditions maintains tighter tolerances in structural applications, potentially reducing energy losses in applications like outdoor enclosures or housing components. This operational efficiency, while difficult to quantify precisely, contributes to the overall economic equation.

End-of-life costs complete the lifecycle analysis. Both materials offer recyclability options, though ASA typically commands higher reclamation value in current recycling markets due to its retained mechanical properties after weathering exposure. This creates a modest offset to ASA's higher initial costs.

Quantitative modeling using Net Present Value (NPV) calculations across 15-year deployment scenarios indicates that despite 15-20% higher initial investment, ASA solutions typically achieve cost parity with Nylon 66 within 4-6 years, and demonstrate 12-18% lower total ownership costs over the full lifecycle. This economic advantage becomes more pronounced in applications with high replacement labor costs or where system downtime carries significant operational penalties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!