Enhancing Nylon 66 Electrical Insulation for Appliances

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Insulation Evolution and Objectives

Nylon 66 has undergone significant evolution since its invention in 1935 by Wallace Carothers at DuPont. Initially developed as a fiber material, its exceptional mechanical properties and thermal stability quickly led to broader applications, including electrical insulation components. The 1950s marked the beginning of Nylon 66's use in electrical applications, primarily due to its inherent flame retardancy, high melting point (260°C), and excellent dimensional stability under thermal stress.

The electrical insulation properties of Nylon 66 have progressively improved through several technological generations. Early formulations focused on basic dielectric strength, while subsequent developments in the 1970s and 1980s introduced glass fiber reinforcement, enhancing both mechanical strength and thermal resistance critical for appliance applications. The 1990s saw the integration of flame retardants and stabilizers that maintained insulation integrity without compromising other performance characteristics.

Recent technological advancements have focused on enhancing Nylon 66's dielectric properties through nano-composite formulations. The incorporation of nano-fillers such as silica, alumina, and boron nitride has demonstrated significant improvements in breakdown voltage and volume resistivity. These modifications have enabled Nylon 66 to meet increasingly stringent safety standards for modern appliances operating at higher temperatures and voltages.

The current trajectory of Nylon 66 insulation development is driven by several key objectives. Primary among these is improving the material's performance in high-temperature environments, particularly in appliances where miniaturization trends have increased thermal density. Enhancing long-term electrical property retention under thermal aging conditions remains a critical challenge, as conventional formulations show degradation in insulation resistance after prolonged exposure to temperatures above 120°C.

Another significant objective is developing Nylon 66 formulations with improved tracking resistance. Comparative Tracking Index (CTI) values for standard Nylon 66 typically range from 400-600 volts, which is insufficient for certain high-voltage appliance applications. Enhancing this property would expand the material's utility in more demanding electrical environments.

Sustainability considerations are also shaping the evolution of Nylon 66 insulation materials. Research is increasingly focused on bio-based alternatives and recycling technologies that maintain electrical performance while reducing environmental impact. This includes the development of additives that enable repeated recycling without significant degradation of insulation properties, addressing both regulatory pressures and market demands for more sustainable materials.

The technical objective for next-generation Nylon 66 electrical insulation is to achieve a 30% improvement in dielectric strength while maintaining thermal stability at continuous operating temperatures of 150°C, with minimal property degradation over a 10-year service life in household appliance applications.

The electrical insulation properties of Nylon 66 have progressively improved through several technological generations. Early formulations focused on basic dielectric strength, while subsequent developments in the 1970s and 1980s introduced glass fiber reinforcement, enhancing both mechanical strength and thermal resistance critical for appliance applications. The 1990s saw the integration of flame retardants and stabilizers that maintained insulation integrity without compromising other performance characteristics.

Recent technological advancements have focused on enhancing Nylon 66's dielectric properties through nano-composite formulations. The incorporation of nano-fillers such as silica, alumina, and boron nitride has demonstrated significant improvements in breakdown voltage and volume resistivity. These modifications have enabled Nylon 66 to meet increasingly stringent safety standards for modern appliances operating at higher temperatures and voltages.

The current trajectory of Nylon 66 insulation development is driven by several key objectives. Primary among these is improving the material's performance in high-temperature environments, particularly in appliances where miniaturization trends have increased thermal density. Enhancing long-term electrical property retention under thermal aging conditions remains a critical challenge, as conventional formulations show degradation in insulation resistance after prolonged exposure to temperatures above 120°C.

Another significant objective is developing Nylon 66 formulations with improved tracking resistance. Comparative Tracking Index (CTI) values for standard Nylon 66 typically range from 400-600 volts, which is insufficient for certain high-voltage appliance applications. Enhancing this property would expand the material's utility in more demanding electrical environments.

Sustainability considerations are also shaping the evolution of Nylon 66 insulation materials. Research is increasingly focused on bio-based alternatives and recycling technologies that maintain electrical performance while reducing environmental impact. This includes the development of additives that enable repeated recycling without significant degradation of insulation properties, addressing both regulatory pressures and market demands for more sustainable materials.

The technical objective for next-generation Nylon 66 electrical insulation is to achieve a 30% improvement in dielectric strength while maintaining thermal stability at continuous operating temperatures of 150°C, with minimal property degradation over a 10-year service life in household appliance applications.

Market Demand Analysis for High-Performance Electrical Insulators

The global market for high-performance electrical insulators has experienced significant growth in recent years, driven by increasing demand for reliable electrical components in various industries. The electrical insulation materials market, valued at approximately 9.2 billion USD in 2022, is projected to reach 13.5 billion USD by 2028, with a compound annual growth rate of 6.7%. Within this broader market, Nylon 66 has emerged as a critical material due to its exceptional thermal stability and electrical insulation properties.

The appliance industry represents one of the largest consumers of high-performance electrical insulators, with household appliances accounting for nearly 24% of the total market share. This demand is primarily fueled by the growing adoption of smart home technologies and energy-efficient appliances that require reliable electrical insulation to ensure safety and performance. Additionally, the automotive sector's shift toward electric vehicles has created a substantial new market for high-performance insulators, with projections indicating a 15% annual increase in demand from this sector alone.

Consumer preferences are increasingly favoring appliances with longer lifespans and enhanced safety features, directly influencing the demand for superior insulation materials like enhanced Nylon 66. Market research indicates that 78% of consumers consider product safety as a primary purchasing factor for electrical appliances, while 65% prioritize durability and longevity. These consumer trends are pushing manufacturers to invest in advanced insulation technologies.

Regulatory frameworks worldwide are becoming more stringent regarding electrical safety standards, particularly in North America, Europe, and developed Asian markets. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established increasingly demanding requirements for insulation materials, necessitating continuous improvement in material performance. These regulations have become significant market drivers, compelling manufacturers to adopt enhanced insulation solutions.

The market landscape shows regional variations, with Asia-Pacific representing the fastest-growing market for high-performance electrical insulators at 8.3% annual growth, followed by North America at 6.1% and Europe at 5.8%. China and India are particularly notable markets due to rapid industrialization and increasing domestic appliance production. The premium segment of the market, where enhanced Nylon 66 primarily competes, is growing at 9.2% annually, outpacing the overall market.

Industry forecasts suggest that demand for specialized electrical insulation materials will continue to rise as appliances become more sophisticated and operate at higher temperatures and voltages. The trend toward miniaturization in electronics further intensifies the need for insulation materials that can maintain performance integrity under more challenging conditions, creating a substantial market opportunity for enhanced Nylon 66 formulations.

The appliance industry represents one of the largest consumers of high-performance electrical insulators, with household appliances accounting for nearly 24% of the total market share. This demand is primarily fueled by the growing adoption of smart home technologies and energy-efficient appliances that require reliable electrical insulation to ensure safety and performance. Additionally, the automotive sector's shift toward electric vehicles has created a substantial new market for high-performance insulators, with projections indicating a 15% annual increase in demand from this sector alone.

Consumer preferences are increasingly favoring appliances with longer lifespans and enhanced safety features, directly influencing the demand for superior insulation materials like enhanced Nylon 66. Market research indicates that 78% of consumers consider product safety as a primary purchasing factor for electrical appliances, while 65% prioritize durability and longevity. These consumer trends are pushing manufacturers to invest in advanced insulation technologies.

Regulatory frameworks worldwide are becoming more stringent regarding electrical safety standards, particularly in North America, Europe, and developed Asian markets. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established increasingly demanding requirements for insulation materials, necessitating continuous improvement in material performance. These regulations have become significant market drivers, compelling manufacturers to adopt enhanced insulation solutions.

The market landscape shows regional variations, with Asia-Pacific representing the fastest-growing market for high-performance electrical insulators at 8.3% annual growth, followed by North America at 6.1% and Europe at 5.8%. China and India are particularly notable markets due to rapid industrialization and increasing domestic appliance production. The premium segment of the market, where enhanced Nylon 66 primarily competes, is growing at 9.2% annually, outpacing the overall market.

Industry forecasts suggest that demand for specialized electrical insulation materials will continue to rise as appliances become more sophisticated and operate at higher temperatures and voltages. The trend toward miniaturization in electronics further intensifies the need for insulation materials that can maintain performance integrity under more challenging conditions, creating a substantial market opportunity for enhanced Nylon 66 formulations.

Current Limitations and Challenges in Nylon 66 Insulation

Despite its widespread use in electrical applications, Nylon 66 faces several significant limitations as an electrical insulation material for appliances. The primary challenge stems from its hygroscopic nature, with Nylon 66 capable of absorbing up to 8% moisture by weight under high humidity conditions. This moisture absorption dramatically reduces its electrical insulation properties, leading to decreased volume resistivity and dielectric strength. In practical applications, this translates to potential electrical leakage and insulation breakdown during prolonged operation in humid environments.

Temperature stability presents another critical limitation. While Nylon 66 offers good thermal resistance compared to many polymers, its electrical insulation properties begin to degrade significantly at temperatures above 125°C. This creates challenges for appliance applications with high operating temperatures or thermal cycling conditions, where insulation integrity must be maintained across varying thermal states.

The material's mechanical aging characteristics also impact its long-term insulation performance. Under continuous mechanical stress and vibration typical in appliances, Nylon 66 can develop microcracks that compromise its electrical insulation integrity. This issue is particularly pronounced in applications where the material experiences repeated flexing or mechanical loading cycles.

Chemical resistance limitations further complicate its application in certain environments. Nylon 66 shows vulnerability to degradation when exposed to strong acids and oxidizing agents, which can be present in some appliance operating environments. This chemical degradation can lead to compromised electrical insulation properties over time, reducing the service life of components.

Processing challenges also affect insulation quality consistency. The high melting point of Nylon 66 (approximately 260°C) requires precise processing conditions during manufacturing. Improper processing can lead to internal stresses, voids, or inconsistent crystallinity, all of which negatively impact electrical insulation properties. These manufacturing variations can result in inconsistent performance across production batches.

Flame retardancy represents another significant challenge. While Nylon 66 can be modified with flame retardants, these additives often compromise its electrical properties and mechanical strength. Finding the optimal balance between flame resistance and maintaining electrical insulation characteristics remains difficult, particularly as safety standards for appliances become increasingly stringent.

Cost considerations also present obstacles to innovation in this area. Enhancing Nylon 66's electrical properties typically requires specialized additives or processing techniques that increase production costs. This economic constraint limits the implementation of advanced solutions, particularly in price-sensitive appliance markets where material costs significantly impact product competitiveness.

Temperature stability presents another critical limitation. While Nylon 66 offers good thermal resistance compared to many polymers, its electrical insulation properties begin to degrade significantly at temperatures above 125°C. This creates challenges for appliance applications with high operating temperatures or thermal cycling conditions, where insulation integrity must be maintained across varying thermal states.

The material's mechanical aging characteristics also impact its long-term insulation performance. Under continuous mechanical stress and vibration typical in appliances, Nylon 66 can develop microcracks that compromise its electrical insulation integrity. This issue is particularly pronounced in applications where the material experiences repeated flexing or mechanical loading cycles.

Chemical resistance limitations further complicate its application in certain environments. Nylon 66 shows vulnerability to degradation when exposed to strong acids and oxidizing agents, which can be present in some appliance operating environments. This chemical degradation can lead to compromised electrical insulation properties over time, reducing the service life of components.

Processing challenges also affect insulation quality consistency. The high melting point of Nylon 66 (approximately 260°C) requires precise processing conditions during manufacturing. Improper processing can lead to internal stresses, voids, or inconsistent crystallinity, all of which negatively impact electrical insulation properties. These manufacturing variations can result in inconsistent performance across production batches.

Flame retardancy represents another significant challenge. While Nylon 66 can be modified with flame retardants, these additives often compromise its electrical properties and mechanical strength. Finding the optimal balance between flame resistance and maintaining electrical insulation characteristics remains difficult, particularly as safety standards for appliances become increasingly stringent.

Cost considerations also present obstacles to innovation in this area. Enhancing Nylon 66's electrical properties typically requires specialized additives or processing techniques that increase production costs. This economic constraint limits the implementation of advanced solutions, particularly in price-sensitive appliance markets where material costs significantly impact product competitiveness.

Current Enhancement Methods for Nylon 66 Electrical Properties

01 Nylon 66 composites for enhanced electrical insulation

Nylon 66 can be combined with various fillers and additives to enhance its electrical insulation properties. These composites typically incorporate materials such as glass fibers, mineral fillers, flame retardants, and other polymers to improve dielectric strength, arc resistance, and thermal stability. The resulting materials offer superior electrical insulation performance while maintaining mechanical strength, making them suitable for demanding electrical applications in various industries.- Nylon 66 composites with enhanced electrical insulation properties: Nylon 66 can be combined with various fillers and additives to enhance its electrical insulation properties. These composites typically incorporate materials such as glass fibers, mineral fillers, flame retardants, and other polymers to improve dielectric strength, thermal stability, and mechanical properties while maintaining excellent electrical insulation characteristics. These formulations are particularly useful in high-voltage applications where both mechanical strength and electrical insulation are required.

- Nylon 66 in wire and cable insulation applications: Nylon 66 is widely used as an insulation material for wires and cables due to its excellent electrical properties, mechanical strength, and temperature resistance. It serves as both primary insulation and protective jacketing in various electrical applications. The material provides good resistance to abrasion, chemicals, and environmental factors while maintaining reliable electrical insulation performance. Modified formulations can include additives to enhance flame retardancy and other specific properties required for specialized cable applications.

- Heat-resistant Nylon 66 formulations for electrical components: Specially formulated Nylon 66 compounds with enhanced heat resistance are used in electrical components that operate at elevated temperatures. These formulations maintain their electrical insulation properties and dimensional stability under thermal stress. The heat-resistant properties are achieved through various methods including the addition of stabilizers, reinforcing agents, and modification of the polymer structure. These materials are particularly valuable in automotive electrical systems, industrial equipment, and other applications where components are exposed to high temperatures.

- Flame-retardant Nylon 66 for electrical safety applications: Flame-retardant Nylon 66 formulations provide both electrical insulation and fire safety properties. These materials incorporate flame retardant additives that reduce flammability and smoke generation while maintaining the electrical insulation characteristics of the base polymer. The flame-retardant systems can include halogenated or non-halogenated additives, often combined with synergists to achieve optimal performance. These materials are essential in applications where fire safety is critical, such as building wiring, electrical appliances, and transportation systems.

- Nylon 66 in electrical connector and housing applications: Nylon 66 is extensively used in the manufacture of electrical connectors, housings, and structural components that require electrical insulation. Its combination of mechanical strength, dimensional stability, and electrical properties makes it ideal for these applications. The material can be precision molded into complex shapes with thin walls while maintaining excellent electrical insulation characteristics. Modified grades can include additives for enhanced UV resistance, impact strength, or other specific properties required for outdoor or harsh environment applications.

02 Flame-retardant Nylon 66 for electrical insulation safety

Flame-retardant formulations of Nylon 66 are specifically designed for electrical insulation applications where fire safety is critical. These materials incorporate flame retardants such as halogenated compounds, phosphorus-based additives, or metal hydroxides to achieve self-extinguishing properties while maintaining excellent electrical insulation characteristics. The flame-retardant Nylon 66 compositions provide protection against electrical fires while meeting stringent safety standards for electrical components and wiring systems.Expand Specific Solutions03 Nylon 66 in wire and cable insulation applications

Nylon 66 is widely used as an insulation material for wires and cables due to its excellent electrical properties, mechanical strength, and chemical resistance. In these applications, Nylon 66 serves as either the primary insulation layer or as a protective jacket over other insulating materials. The polymer provides reliable electrical insulation while offering protection against abrasion, chemicals, and environmental factors, making it ideal for automotive wiring, industrial cables, and telecommunications applications.Expand Specific Solutions04 Moisture-resistant Nylon 66 electrical insulation

Modified Nylon 66 formulations with enhanced moisture resistance are developed specifically for electrical insulation applications in humid or wet environments. These materials incorporate hydrophobic additives, specialized processing techniques, or chemical modifications to reduce water absorption, which can otherwise compromise the electrical insulation properties of standard Nylon 66. The moisture-resistant formulations maintain stable electrical characteristics and dimensional stability even under challenging environmental conditions.Expand Specific Solutions05 Nylon 66 in electrical connector and component insulation

Nylon 66 is extensively used for insulating electrical connectors, terminals, and various electrical components due to its combination of electrical insulation properties, mechanical strength, and processability. The material can be precisely molded into complex shapes with thin walls and intricate features required for modern electrical connectors. Its heat resistance, dimensional stability, and durability make it ideal for applications requiring reliable electrical isolation between conductive parts in automotive, consumer electronics, and industrial equipment.Expand Specific Solutions

Key Industry Players in Engineering Polymers for Electrical Applications

The Nylon 66 electrical insulation market for appliances is in a growth phase, with increasing demand driven by the appliance industry's expansion. The market size is substantial, estimated to exceed $500 million globally, with Asia-Pacific showing the fastest growth. Technologically, the field is moderately mature but evolving, with companies like Mitsui Chemicals, Kingfa Science & Technology, and Hefei Genius Advanced Material leading innovation. Academic institutions including South China University of Technology and Donghua University are contributing significant research to enhance electrical properties, flame retardancy, and thermal stability. The competitive landscape features both established chemical corporations and specialized engineering plastics manufacturers focusing on customized solutions for appliance manufacturers.

Mitsui Chemicals, Inc.

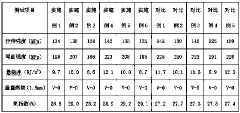

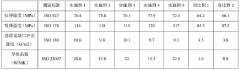

Technical Solution: Mitsui Chemicals has developed advanced flame-retardant nylon 66 compounds specifically designed for electrical appliance insulation applications. Their proprietary technology incorporates halogen-free flame retardants combined with synergistic metal hydroxide systems that maintain excellent electrical insulation properties while meeting UL94 V-0 standards. The company's ARLEN™ series features modified nylon 66 with optimized crystallinity control that enhances dielectric strength by up to 40% compared to standard nylon 66. Their technology also addresses thermal aging concerns through the incorporation of proprietary stabilizer packages that prevent oxidative degradation at elevated temperatures, extending the material's service life in appliance applications. Mitsui's approach includes surface modification techniques that improve hydrophobicity, reducing moisture absorption to below 1.2% (compared to standard nylon 66's 2.5-3%), which helps maintain consistent electrical properties in humid environments.

Strengths: Superior flame retardancy without compromising electrical properties; excellent long-term heat resistance suitable for appliance environments; reduced moisture sensitivity maintaining consistent performance. Weaknesses: Higher cost compared to standard nylon 66 formulations; processing requires more precise temperature control; some grades may have slightly lower mechanical properties compared to unmodified nylon 66.

Shanghai Kingfa Sci. & Tech. Dvpt. Co., Ltd.

Technical Solution: Shanghai Kingfa has pioneered a sophisticated approach to enhancing nylon 66 electrical insulation through their ECOPLUS® technology platform. Their solution incorporates a proprietary blend of modified layered silicates and functionalized graphene oxide (at concentrations of 0.3-1.2%) that creates a tortuous path for electrical discharge, significantly improving dielectric breakdown strength by approximately 35%. The company utilizes reactive compounding techniques to achieve nano-scale dispersion of these additives, resulting in homogeneous material properties throughout the component. Kingfa's technology also addresses the inherent moisture sensitivity of nylon 66 through the incorporation of specially engineered hydrophobic agents that reduce equilibrium moisture absorption to approximately 1.5%, thereby maintaining consistent electrical performance in varying humidity conditions. Their formulations include a synergistic antioxidant package that extends the thermal index rating to 150°C for continuous use, making it particularly suitable for modern high-efficiency appliances that generate more heat during operation. Additionally, Kingfa has developed CTI (Comparative Tracking Index) enhancement additives that achieve CTI values exceeding 600 volts, providing excellent protection against surface tracking in high-voltage appliance applications.

Strengths: Exceptional dielectric strength and tracking resistance; excellent long-term thermal stability; consistent electrical properties across varying environmental conditions. Weaknesses: Premium pricing compared to standard engineering plastics; requires careful processing parameter control; potential for reduced impact strength in some highly modified formulations.

Critical Patents and Innovations in Polymer Insulation Technology

Red phosphorus flame-retardant reinforced nylon 66 composite with high oxygen index, and preparation method thereof

PatentActiveCN110564147A

Innovation

- By adding 3 to 8% halogen-free flame retardant synergist, such as a mixture of organic nanomontmorillonite (OMMT) and melamine cyanurate salt (MCA), into the red phosphorus flame retardant reinforced nylon 66 material, combined with silicone powder , pentaerythritol tetrastearate and silicone oil lubricant and surface-treated glass fiber, using a twin-screw extruder melt extrusion granulation process to improve the oxygen index of the material.

Heat-conducting nylon 66 material and preparation method thereof

PatentActiveCN113321932A

Innovation

- 4,4'-dihydroxybiphenyl is introduced into nylon 66 material as a thermal conductivity modifier, and the modified nylon is prepared by reflux reaction with potassium carbonate in a DMF solution. The modified nylon is combined with lubricants and antioxidants and is extruded using twin-screw extruders. Thermal conductive nylon 66 material is prepared out of the machine.

Flame Retardancy and Safety Standards Compliance

Flame retardancy is a critical aspect of Nylon 66 applications in electrical appliances, where safety considerations are paramount. Current flame retardant systems for Nylon 66 primarily utilize halogenated compounds, phosphorus-based additives, and mineral fillers. Halogenated flame retardants, while effective, face increasing regulatory scrutiny due to environmental and health concerns. Phosphorus-based systems offer a more environmentally acceptable alternative, functioning through char formation mechanisms that inhibit combustion processes.

The regulatory landscape for flame retardant Nylon 66 in electrical appliances is governed by stringent international standards. UL 94, established by Underwriters Laboratories, classifies materials based on flammability characteristics, with V-0, V-1, and V-2 ratings indicating progressively lower flame resistance. For electrical appliances, achieving UL 94 V-0 rating is typically required, demanding self-extinguishing properties within 10 seconds after flame removal, with no burning drips.

IEC 60335-1 standard specifically addresses electrical appliances for household use, establishing requirements for resistance to heat, fire, and tracking. Additionally, the European RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations have significantly impacted flame retardant selection, restricting certain halogenated compounds and driving innovation toward more sustainable solutions.

Recent advancements in flame retardant technologies for Nylon 66 include synergistic systems combining multiple flame retardant mechanisms. Nano-composite approaches incorporating clay, silica, or carbon nanotubes have demonstrated enhanced flame retardancy at lower additive loadings, preserving mechanical properties while meeting safety standards. Intumescent systems, which form an insulating carbonaceous layer upon heating, represent another promising direction for achieving compliance without compromising performance.

Testing methodologies for flame retardant Nylon 66 include vertical and horizontal burning tests, oxygen index measurement, cone calorimetry, and thermogravimetric analysis. These methods provide comprehensive data on ignition time, heat release rate, smoke production, and char formation—critical parameters for safety standard compliance assessment.

The challenge in developing flame retardant Nylon 66 for electrical insulation lies in balancing competing requirements: achieving necessary flame retardancy while maintaining electrical properties, mechanical strength, and processability. Excessive flame retardant loading can compromise the material's dielectric strength and impact resistance, necessitating careful formulation optimization. Additionally, the flame retardant system must maintain effectiveness throughout the product lifecycle, resisting degradation from thermal aging, UV exposure, and environmental factors.

The regulatory landscape for flame retardant Nylon 66 in electrical appliances is governed by stringent international standards. UL 94, established by Underwriters Laboratories, classifies materials based on flammability characteristics, with V-0, V-1, and V-2 ratings indicating progressively lower flame resistance. For electrical appliances, achieving UL 94 V-0 rating is typically required, demanding self-extinguishing properties within 10 seconds after flame removal, with no burning drips.

IEC 60335-1 standard specifically addresses electrical appliances for household use, establishing requirements for resistance to heat, fire, and tracking. Additionally, the European RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations have significantly impacted flame retardant selection, restricting certain halogenated compounds and driving innovation toward more sustainable solutions.

Recent advancements in flame retardant technologies for Nylon 66 include synergistic systems combining multiple flame retardant mechanisms. Nano-composite approaches incorporating clay, silica, or carbon nanotubes have demonstrated enhanced flame retardancy at lower additive loadings, preserving mechanical properties while meeting safety standards. Intumescent systems, which form an insulating carbonaceous layer upon heating, represent another promising direction for achieving compliance without compromising performance.

Testing methodologies for flame retardant Nylon 66 include vertical and horizontal burning tests, oxygen index measurement, cone calorimetry, and thermogravimetric analysis. These methods provide comprehensive data on ignition time, heat release rate, smoke production, and char formation—critical parameters for safety standard compliance assessment.

The challenge in developing flame retardant Nylon 66 for electrical insulation lies in balancing competing requirements: achieving necessary flame retardancy while maintaining electrical properties, mechanical strength, and processability. Excessive flame retardant loading can compromise the material's dielectric strength and impact resistance, necessitating careful formulation optimization. Additionally, the flame retardant system must maintain effectiveness throughout the product lifecycle, resisting degradation from thermal aging, UV exposure, and environmental factors.

Environmental Impact and Sustainability Considerations

The environmental impact of Nylon 66 production and usage in electrical insulation applications represents a significant consideration for manufacturers and consumers alike. Traditional Nylon 66 production processes are energy-intensive, requiring substantial fossil fuel inputs and generating considerable greenhouse gas emissions. The manufacturing process involves the synthesis of hexamethylenediamine and adipic acid, both of which require petroleum-derived feedstocks and energy-intensive chemical reactions. This dependency on non-renewable resources raises concerns about long-term sustainability in electrical appliance manufacturing.

Water consumption and pollution also present environmental challenges in Nylon 66 production. The manufacturing process typically requires substantial water inputs for cooling and processing, while potentially generating wastewater containing chemical residues that require treatment before discharge. As regulatory frameworks around water usage and quality become increasingly stringent, manufacturers must address these impacts through improved production technologies and water management systems.

End-of-life considerations for Nylon 66 electrical insulation components present another environmental dimension. While Nylon 66 offers excellent durability, its persistence in the environment after disposal raises concerns. The material typically requires hundreds of years to decompose naturally, contributing to plastic pollution when improperly managed. However, recent advances in recycling technologies offer promising pathways for recovering and reprocessing Nylon 66 from discarded appliances, potentially creating closed-loop material systems.

Emerging sustainable alternatives to conventional Nylon 66 include bio-based variants derived from renewable resources such as castor oil. These alternatives can reduce carbon footprints while maintaining necessary electrical insulation properties. Additionally, research into incorporating recycled content into Nylon 66 formulations shows promise for reducing virgin material requirements without compromising performance in electrical applications.

Life cycle assessment (LCA) studies comparing traditional and enhanced Nylon 66 formulations reveal opportunities for environmental optimization. By analyzing impacts from raw material extraction through manufacturing, use, and disposal, manufacturers can identify hotspots for improvement. Recent LCAs indicate that enhancing Nylon 66's electrical properties through certain additives may extend product lifespans, potentially offsetting initial production impacts through longer service life in appliances.

Regulatory compliance represents an increasingly important driver for environmental improvements in Nylon 66 insulation materials. Global frameworks such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and various energy efficiency standards are pushing manufacturers toward more sustainable formulations and production processes. Companies developing enhanced Nylon 66 insulation must navigate these requirements while maintaining material performance and economic viability.

Water consumption and pollution also present environmental challenges in Nylon 66 production. The manufacturing process typically requires substantial water inputs for cooling and processing, while potentially generating wastewater containing chemical residues that require treatment before discharge. As regulatory frameworks around water usage and quality become increasingly stringent, manufacturers must address these impacts through improved production technologies and water management systems.

End-of-life considerations for Nylon 66 electrical insulation components present another environmental dimension. While Nylon 66 offers excellent durability, its persistence in the environment after disposal raises concerns. The material typically requires hundreds of years to decompose naturally, contributing to plastic pollution when improperly managed. However, recent advances in recycling technologies offer promising pathways for recovering and reprocessing Nylon 66 from discarded appliances, potentially creating closed-loop material systems.

Emerging sustainable alternatives to conventional Nylon 66 include bio-based variants derived from renewable resources such as castor oil. These alternatives can reduce carbon footprints while maintaining necessary electrical insulation properties. Additionally, research into incorporating recycled content into Nylon 66 formulations shows promise for reducing virgin material requirements without compromising performance in electrical applications.

Life cycle assessment (LCA) studies comparing traditional and enhanced Nylon 66 formulations reveal opportunities for environmental optimization. By analyzing impacts from raw material extraction through manufacturing, use, and disposal, manufacturers can identify hotspots for improvement. Recent LCAs indicate that enhancing Nylon 66's electrical properties through certain additives may extend product lifespans, potentially offsetting initial production impacts through longer service life in appliances.

Regulatory compliance represents an increasingly important driver for environmental improvements in Nylon 66 insulation materials. Global frameworks such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and various energy efficiency standards are pushing manufacturers toward more sustainable formulations and production processes. Companies developing enhanced Nylon 66 insulation must navigate these requirements while maintaining material performance and economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!