Nylon 66 vs PPS: Performance at Continuous High Temperatures

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Polymers Background and Objectives

High-temperature polymers have evolved significantly over the past decades, driven by increasing demands in automotive, aerospace, electronics, and industrial applications where materials must maintain structural integrity and performance under extreme thermal conditions. The development trajectory of these specialized polymers reflects a continuous pursuit of materials that can withstand higher operating temperatures while maintaining mechanical properties, chemical resistance, and dimensional stability.

Nylon 66 and Polyphenylene Sulfide (PPS) represent two distinct generations in the evolution of high-temperature resistant polymers. Nylon 66, developed in the 1930s by Wallace Carothers at DuPont, initially revolutionized the polymer industry with its combination of strength, wear resistance, and processability. However, its temperature limitations became apparent as industrial applications demanded materials capable of withstanding increasingly harsh environments.

PPS emerged in the 1960s as part of a new class of high-performance polymers specifically engineered to address these limitations. The development of PPS and similar high-temperature polymers marked a significant technological advancement, enabling applications previously impossible with conventional engineering plastics like Nylon 66.

The current technological landscape shows a clear trend toward materials that can maintain performance at continuous operating temperatures above 150°C, with growing interest in polymers capable of withstanding 200°C and beyond. This evolution is particularly relevant in sectors transitioning to electrification, where thermal management presents new challenges.

The primary objective of comparing Nylon 66 and PPS performance at continuous high temperatures is to establish clear parameters for material selection in critical applications. This comparison aims to quantify the temperature thresholds at which each polymer maintains acceptable mechanical properties, dimensional stability, and chemical resistance over extended periods.

Additionally, this technical investigation seeks to identify the fundamental molecular and structural characteristics that contribute to thermal stability differences between these polymers. Understanding these mechanisms is essential for predicting long-term performance and guiding future polymer development.

The broader goal extends beyond simple comparison to establishing comprehensive performance profiles that can inform engineering decisions across multiple industries. This includes identifying specific application niches where each polymer excels despite thermal challenges, and developing predictive models for estimating service life under various temperature profiles.

Nylon 66 and Polyphenylene Sulfide (PPS) represent two distinct generations in the evolution of high-temperature resistant polymers. Nylon 66, developed in the 1930s by Wallace Carothers at DuPont, initially revolutionized the polymer industry with its combination of strength, wear resistance, and processability. However, its temperature limitations became apparent as industrial applications demanded materials capable of withstanding increasingly harsh environments.

PPS emerged in the 1960s as part of a new class of high-performance polymers specifically engineered to address these limitations. The development of PPS and similar high-temperature polymers marked a significant technological advancement, enabling applications previously impossible with conventional engineering plastics like Nylon 66.

The current technological landscape shows a clear trend toward materials that can maintain performance at continuous operating temperatures above 150°C, with growing interest in polymers capable of withstanding 200°C and beyond. This evolution is particularly relevant in sectors transitioning to electrification, where thermal management presents new challenges.

The primary objective of comparing Nylon 66 and PPS performance at continuous high temperatures is to establish clear parameters for material selection in critical applications. This comparison aims to quantify the temperature thresholds at which each polymer maintains acceptable mechanical properties, dimensional stability, and chemical resistance over extended periods.

Additionally, this technical investigation seeks to identify the fundamental molecular and structural characteristics that contribute to thermal stability differences between these polymers. Understanding these mechanisms is essential for predicting long-term performance and guiding future polymer development.

The broader goal extends beyond simple comparison to establishing comprehensive performance profiles that can inform engineering decisions across multiple industries. This includes identifying specific application niches where each polymer excels despite thermal challenges, and developing predictive models for estimating service life under various temperature profiles.

Market Demand Analysis for Heat-Resistant Engineering Plastics

The global market for heat-resistant engineering plastics has experienced substantial growth in recent years, driven primarily by increasing demands from automotive, aerospace, electrical, and industrial sectors. These industries require materials capable of withstanding continuous high temperatures while maintaining structural integrity and performance characteristics.

The heat-resistant engineering plastics market was valued at approximately $22.5 billion in 2022 and is projected to reach $35.7 billion by 2028, growing at a CAGR of 7.9%. Within this segment, high-temperature resistant polymers like Nylon 66 and Polyphenylene Sulfide (PPS) represent key materials with distinct market positions and growth trajectories.

Nylon 66 currently dominates the market volume due to its established manufacturing infrastructure and relatively lower cost. However, PPS is experiencing faster growth rates, particularly in applications requiring superior thermal stability above 200°C. This shift reflects the industrial trend toward more demanding operating environments and miniaturization of components, which generate higher localized temperatures.

Automotive applications constitute the largest market segment for these materials, accounting for 38% of consumption. The transition toward electric vehicles has significantly altered demand patterns, with requirements for materials that can withstand continuous high temperatures in battery components, power electronics, and charging systems. PPS has gained substantial traction in this sector due to its exceptional dimensional stability at elevated temperatures.

Electronics and electrical applications represent the second-largest market segment at 27%, with growing demand for materials that maintain performance under continuous thermal stress in miniaturized devices. The aerospace industry, though smaller in volume, drives premium applications where the superior performance of PPS at extreme temperatures commands price premiums of 30-45% over Nylon 66 alternatives.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global consumption, with China and Japan leading manufacturing capacity. North America and Europe follow with 28% and 22% respectively, with these regions focusing on high-performance applications in aerospace and advanced automotive systems.

Market forecasts indicate that demand for PPS will grow at 9.3% annually through 2028, outpacing Nylon 66's 5.7% growth rate. This differential reflects the industry's progressive shift toward materials capable of withstanding more extreme thermal conditions, particularly in emerging technologies like 5G infrastructure, advanced electric vehicle systems, and next-generation industrial automation equipment.

The heat-resistant engineering plastics market was valued at approximately $22.5 billion in 2022 and is projected to reach $35.7 billion by 2028, growing at a CAGR of 7.9%. Within this segment, high-temperature resistant polymers like Nylon 66 and Polyphenylene Sulfide (PPS) represent key materials with distinct market positions and growth trajectories.

Nylon 66 currently dominates the market volume due to its established manufacturing infrastructure and relatively lower cost. However, PPS is experiencing faster growth rates, particularly in applications requiring superior thermal stability above 200°C. This shift reflects the industrial trend toward more demanding operating environments and miniaturization of components, which generate higher localized temperatures.

Automotive applications constitute the largest market segment for these materials, accounting for 38% of consumption. The transition toward electric vehicles has significantly altered demand patterns, with requirements for materials that can withstand continuous high temperatures in battery components, power electronics, and charging systems. PPS has gained substantial traction in this sector due to its exceptional dimensional stability at elevated temperatures.

Electronics and electrical applications represent the second-largest market segment at 27%, with growing demand for materials that maintain performance under continuous thermal stress in miniaturized devices. The aerospace industry, though smaller in volume, drives premium applications where the superior performance of PPS at extreme temperatures commands price premiums of 30-45% over Nylon 66 alternatives.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global consumption, with China and Japan leading manufacturing capacity. North America and Europe follow with 28% and 22% respectively, with these regions focusing on high-performance applications in aerospace and advanced automotive systems.

Market forecasts indicate that demand for PPS will grow at 9.3% annually through 2028, outpacing Nylon 66's 5.7% growth rate. This differential reflects the industry's progressive shift toward materials capable of withstanding more extreme thermal conditions, particularly in emerging technologies like 5G infrastructure, advanced electric vehicle systems, and next-generation industrial automation equipment.

Current State and Challenges of Nylon 66 and PPS

Nylon 66 and Polyphenylene Sulfide (PPS) represent two distinct classes of engineering thermoplastics with significant differences in their high-temperature performance capabilities. Currently, Nylon 66 dominates many industrial applications due to its balanced mechanical properties and cost-effectiveness, but faces significant limitations when exposed to continuous high temperatures above 120°C. Under such conditions, Nylon 66 experiences accelerated aging, dimensional instability, and mechanical property degradation, primarily due to its relatively low glass transition temperature and moisture absorption characteristics.

In contrast, PPS has established itself as a high-performance polymer capable of withstanding continuous operating temperatures up to 200-220°C. The current state of PPS technology showcases excellent dimensional stability, minimal moisture absorption, and superior chemical resistance compared to Nylon 66. These properties have positioned PPS as the preferred material for demanding high-temperature applications in automotive, aerospace, and electronics industries.

The primary technical challenge for Nylon 66 in high-temperature environments stems from its hygroscopic nature, which leads to hydrolysis at elevated temperatures, causing molecular weight reduction and consequent mechanical property deterioration. Industry efforts to overcome these limitations have focused on developing heat-stabilized grades and incorporating various additives, but fundamental chemical structure constraints remain a significant hurdle.

For PPS, despite its superior thermal performance, several challenges persist. Manufacturing complexity and higher processing temperatures (typically 310-340°C) require specialized equipment and energy-intensive processes, contributing to its significantly higher cost compared to Nylon 66. Additionally, unmodified PPS exhibits inherent brittleness, limiting its application in components requiring impact resistance or elongation properties.

Geographically, advanced Nylon 66 formulation development is concentrated in Western Europe, Japan, and the United States, with companies like DuPont, BASF, and Solvay leading innovation. PPS technology leadership is primarily centered in Japan and the United States, with Toray, DIC Corporation, and Solvay holding significant intellectual property portfolios and manufacturing capabilities.

Recent advancements in composite technologies have introduced hybrid solutions combining the beneficial properties of both materials, such as PPS-coated Nylon 66 components or multi-material injection molding. However, these approaches introduce new challenges related to adhesion between dissimilar materials, processing complexity, and cost-effectiveness at scale.

The sustainability aspect presents another significant challenge, as both materials have different environmental footprints. Nylon 66 production is more energy-efficient but relies on petroleum-derived raw materials, while PPS manufacturing is more energy-intensive but potentially offers longer service life in high-temperature applications, creating complex trade-offs in lifecycle assessment calculations.

In contrast, PPS has established itself as a high-performance polymer capable of withstanding continuous operating temperatures up to 200-220°C. The current state of PPS technology showcases excellent dimensional stability, minimal moisture absorption, and superior chemical resistance compared to Nylon 66. These properties have positioned PPS as the preferred material for demanding high-temperature applications in automotive, aerospace, and electronics industries.

The primary technical challenge for Nylon 66 in high-temperature environments stems from its hygroscopic nature, which leads to hydrolysis at elevated temperatures, causing molecular weight reduction and consequent mechanical property deterioration. Industry efforts to overcome these limitations have focused on developing heat-stabilized grades and incorporating various additives, but fundamental chemical structure constraints remain a significant hurdle.

For PPS, despite its superior thermal performance, several challenges persist. Manufacturing complexity and higher processing temperatures (typically 310-340°C) require specialized equipment and energy-intensive processes, contributing to its significantly higher cost compared to Nylon 66. Additionally, unmodified PPS exhibits inherent brittleness, limiting its application in components requiring impact resistance or elongation properties.

Geographically, advanced Nylon 66 formulation development is concentrated in Western Europe, Japan, and the United States, with companies like DuPont, BASF, and Solvay leading innovation. PPS technology leadership is primarily centered in Japan and the United States, with Toray, DIC Corporation, and Solvay holding significant intellectual property portfolios and manufacturing capabilities.

Recent advancements in composite technologies have introduced hybrid solutions combining the beneficial properties of both materials, such as PPS-coated Nylon 66 components or multi-material injection molding. However, these approaches introduce new challenges related to adhesion between dissimilar materials, processing complexity, and cost-effectiveness at scale.

The sustainability aspect presents another significant challenge, as both materials have different environmental footprints. Nylon 66 production is more energy-efficient but relies on petroleum-derived raw materials, while PPS manufacturing is more energy-intensive but potentially offers longer service life in high-temperature applications, creating complex trade-offs in lifecycle assessment calculations.

Technical Comparison of Nylon 66 and PPS Solutions

01 Thermal stability comparison between Nylon 66 and PPS

PPS demonstrates superior thermal stability compared to Nylon 66 at continuous high temperatures. While Nylon 66 typically maintains structural integrity up to 150-180°C, PPS can withstand continuous operating temperatures of 200-240°C. This significant difference makes PPS more suitable for high-temperature applications where thermal degradation is a concern. The superior thermal resistance of PPS is attributed to its rigid aromatic backbone structure with stable sulfide linkages.- Thermal stability comparison between Nylon 66 and PPS: PPS demonstrates superior thermal stability compared to Nylon 66 at continuous high temperatures. While Nylon 66 typically maintains its mechanical properties up to about 120-150°C, PPS can withstand continuous operating temperatures of 200-240°C. This significant difference makes PPS more suitable for high-temperature applications where thermal degradation is a concern. The aromatic structure of PPS contributes to its excellent heat resistance, dimensional stability, and minimal property loss during prolonged exposure to elevated temperatures.

- Mechanical properties at high temperatures: At continuous high temperatures, PPS maintains superior mechanical strength, stiffness, and dimensional stability compared to Nylon 66. While Nylon 66 experiences significant reduction in tensile strength and modulus above 150°C, PPS retains approximately 80% of its room temperature mechanical properties at 200°C. PPS also exhibits better creep resistance and fatigue strength under thermal cycling conditions. The crystalline structure of both polymers influences their mechanical performance, with PPS's higher crystallinity contributing to its enhanced performance in high-temperature mechanical applications.

- Chemical resistance in high-temperature environments: PPS demonstrates exceptional chemical resistance at elevated temperatures compared to Nylon 66. While Nylon 66 is susceptible to hydrolysis and degradation when exposed to moisture, acids, and certain chemicals at high temperatures, PPS maintains its chemical inertness even in harsh environments up to 200°C. PPS resists a wide range of solvents, acids, bases, and hydrocarbons at elevated temperatures, making it suitable for chemical processing equipment, automotive components exposed to hot fluids, and other demanding applications where chemical exposure at high temperatures is a concern.

- High-temperature applications and industry usage: The distinct high-temperature performance characteristics of Nylon 66 and PPS determine their applications across various industries. Nylon 66 is commonly used in automotive components, electrical connectors, and industrial parts where temperatures typically don't exceed 150°C continuously. PPS finds applications in more demanding environments such as automotive under-hood components, electrical/electronic parts requiring high-temperature soldering, industrial pumps handling hot fluids, aerospace components, and oil and gas equipment. The selection between these materials depends on specific temperature requirements, exposure duration, and environmental conditions of the application.

- Modifications and composites for enhanced thermal performance: Both Nylon 66 and PPS can be modified to enhance their high-temperature performance through additives, reinforcements, and blending. Glass fiber reinforcement significantly improves the heat deflection temperature and mechanical properties of both polymers at elevated temperatures. Nylon 66 can be modified with heat stabilizers and aromatic comonomers to extend its temperature range. PPS can be compounded with PTFE, graphite, or mineral fillers to enhance its tribological properties at high temperatures. These modifications allow for customized materials that bridge the performance gap between standard Nylon 66 and PPS for specific high-temperature applications.

02 Mechanical properties retention at elevated temperatures

At continuous high temperatures, PPS maintains its mechanical properties better than Nylon 66. While Nylon 66 experiences significant reduction in tensile strength and modulus above 150°C, PPS retains approximately 70-80% of its room temperature mechanical properties at 200°C. This superior retention of mechanical integrity makes PPS preferable for load-bearing applications in high-temperature environments. The dimensional stability of PPS also remains excellent at elevated temperatures, with minimal creep compared to Nylon 66.Expand Specific Solutions03 Chemical resistance in high-temperature environments

PPS exhibits exceptional chemical resistance at elevated temperatures compared to Nylon 66. While Nylon 66 is susceptible to hydrolysis and degradation when exposed to moisture, acids, and certain chemicals at high temperatures, PPS maintains its chemical inertness even under harsh conditions. This makes PPS suitable for applications involving aggressive chemicals at elevated temperatures, such as in chemical processing equipment, automotive under-hood components, and industrial pumps operating in corrosive environments.Expand Specific Solutions04 Reinforcement and composite formulations for improved high-temperature performance

Both Nylon 66 and PPS can be reinforced with fillers like glass fiber, carbon fiber, and minerals to enhance their high-temperature performance. Glass-reinforced PPS can maintain its properties at temperatures up to 260°C, while similarly reinforced Nylon 66 typically maxes out around 200°C. The addition of specific heat stabilizers and antioxidants can further improve the long-term thermal stability of both polymers. Hybrid composites combining both materials with appropriate reinforcements can provide balanced performance for specific high-temperature applications.Expand Specific Solutions05 Application-specific performance in high-temperature industrial settings

In industrial applications requiring continuous exposure to high temperatures, material selection between Nylon 66 and PPS depends on specific requirements. PPS is preferred for electrical components, pump housings, and automotive parts operating near heat sources due to its superior flame resistance, low smoke generation, and excellent electrical insulation properties at high temperatures. Nylon 66, while less thermally stable, offers better processability and lower cost for applications with intermittent high-temperature exposure. The service life of components made from either material is significantly affected by the actual operating temperature profile.Expand Specific Solutions

Key Manufacturers and Suppliers in High-Temperature Polymers

The Nylon 66 vs PPS high-temperature performance market is in a growth phase, with increasing demand for high-temperature resistant materials in automotive, electronics, and industrial applications. The global market size for high-performance polymers is expanding at approximately 6-8% annually, driven by lightweighting trends and sustainability requirements. Technologically, PPS offers superior continuous high-temperature resistance (200-240°C) compared to Nylon 66 (120-150°C), though at higher cost. Key players demonstrate varying technological maturity: established leaders like Kingfa Sci. & Tech., Ascend Performance Materials, and SK Chemicals possess advanced formulation capabilities, while emerging competitors such as Zhejiang Pret, Shenzhen Fuheng, and Jiangsu LiHan are rapidly developing specialized high-temperature polymer solutions through strategic R&D investments and partnerships with research institutions.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed proprietary high-temperature resistant PPS compounds that maintain structural integrity at continuous operating temperatures of 200-240°C, significantly outperforming Nylon 66's typical limit of 150-170°C. Their advanced PPS formulations incorporate specialized stabilizers and reinforcing agents (typically 30-40% glass fiber) that minimize thermal degradation while enhancing dimensional stability. Kingfa's PPS compounds demonstrate less than 0.1% moisture absorption compared to Nylon 66's 1.5-3.0%, resulting in consistent mechanical properties across varying humidity conditions. Their research has shown that after 1000 hours at 200°C, their PPS materials retain over 90% of tensile strength while comparable Nylon 66 compounds show 40-50% strength reduction. Kingfa has also developed hybrid solutions that combine the cost advantages of Nylon 66 with the thermal stability of PPS for applications requiring intermediate temperature resistance.

Strengths: Superior dimensional stability at high temperatures; excellent chemical resistance against automotive fluids and industrial chemicals; minimal moisture absorption ensuring consistent performance. Weaknesses: Higher processing temperatures (310-330°C) compared to Nylon 66 (280-300°C); more expensive raw material cost; potentially more brittle behavior requiring careful impact modification.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend has pioneered high-temperature resistant Nylon 66 formulations under their Vydyne® HT series, specifically engineered to compete with PPS in continuous high-temperature applications. Their proprietary technology incorporates copper-based heat stabilizers and specialized aromatic co-polymers that extend Nylon 66's temperature resistance to 210°C for short periods and 180-190°C for continuous use. Ascend's advanced compounding techniques create a unique crystalline structure that maintains mechanical integrity at elevated temperatures while preserving Nylon 66's inherent processing advantages. Their comparative testing demonstrates that their enhanced Nylon 66 compounds retain approximately 70% of tensile strength after 1000 hours at 180°C, approaching PPS performance while maintaining better impact resistance and processability. Ascend has also developed hybrid solutions that strategically position their materials as cost-effective alternatives to PPS in applications where the extreme chemical resistance of PPS isn't critical but temperature performance beyond standard Nylon 66 is required.

Strengths: Better impact resistance and toughness than PPS; easier processing with lower melt temperatures; more cost-effective solution for many high-temperature applications; excellent balance of mechanical properties. Weaknesses: Still exhibits higher moisture absorption than PPS; chemical resistance inferior to PPS especially against strong acids and bases; long-term creep resistance at maximum temperatures remains inferior to PPS.

Critical Properties Analysis at Elevated Temperatures

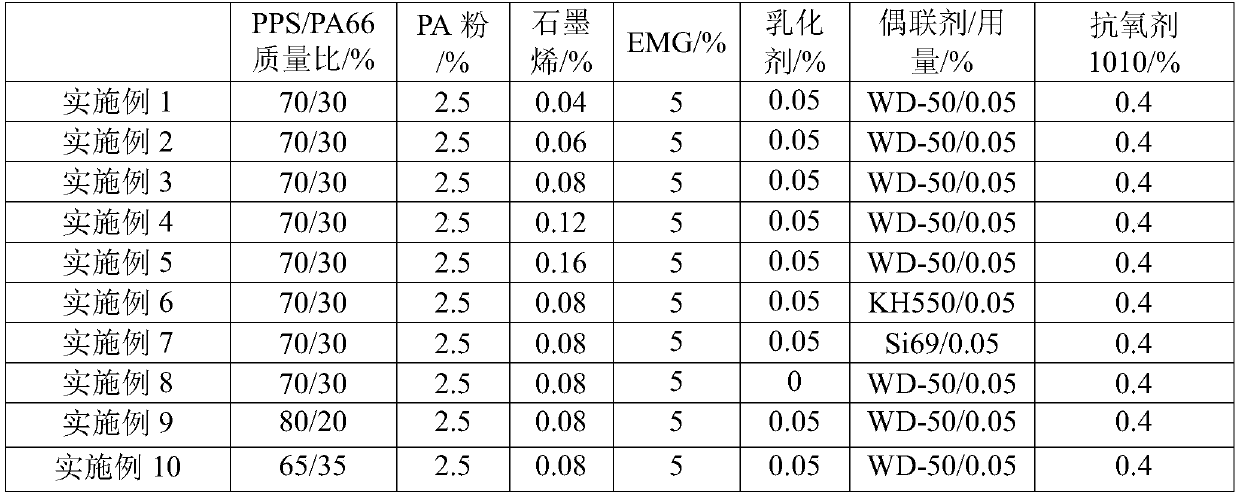

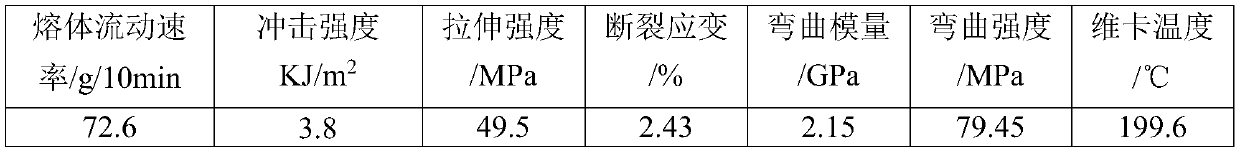

PPS/PA66/graphene composite material and preparation method thereof

PatentActiveCN109852058A

Innovation

- Using PPS/PA66/graphene composite material, graphene pre-dispersion was prepared by aqueous grinding method on polyamide micro-nano powder, and EMG was added during the extrusion blending process to improve the toughness and compatibility of the composite material. properties, reduce melt index and improve processing performance.

Nylon 66 resin, nylon 66 fibers and preparation method thereof

PatentInactiveCN102167814B

Innovation

- A compound of the second main group metal is added to the nylon 66 salt melt, and a special resin is produced through polymerization and post-polycondensation reaction. The transverse tube continuous polycondensation process is used to form a fine or ultra-fine denier that can be spun into a fine denier of less than 1.0 dtex. Nylon 66 fiber.

Environmental Impact and Sustainability Considerations

When comparing Nylon 66 and PPS from an environmental and sustainability perspective, significant differences emerge in their ecological footprints throughout their lifecycle. Nylon 66 production typically requires adipic acid and hexamethylenediamine, processes that generate nitrous oxide—a potent greenhouse gas with approximately 300 times the global warming potential of carbon dioxide. This manufacturing process contributes substantially to the polymer's carbon footprint, estimated at 6-9 kg CO2 equivalent per kilogram of material produced.

PPS (Polyphenylene Sulfide) manufacturing, while energy-intensive, produces fewer direct greenhouse gas emissions. However, the production process involves chlorinated compounds and sulfur chemicals that present different environmental challenges, particularly regarding potential water and soil contamination if not properly managed. The carbon footprint of PPS is generally estimated at 4-7 kg CO2 equivalent per kilogram, slightly lower than Nylon 66.

In high-temperature applications, the environmental impact diverges further. Nylon 66's lower continuous service temperature (approximately 120-150°C) often necessitates more frequent replacement in high-temperature environments compared to PPS (capable of withstanding 200-240°C continuously). This difference translates to reduced material consumption and waste generation over time when using PPS in appropriate applications, despite its higher initial production impact.

End-of-life considerations also favor PPS in certain aspects. While neither polymer is readily biodegradable, PPS exhibits exceptional chemical resistance that prevents leaching of harmful compounds into the environment during its use phase and after disposal. Conversely, Nylon 66 may degrade under certain conditions, potentially releasing decomposition products. However, Nylon 66 offers better recyclability potential through mechanical recycling and depolymerization techniques, whereas PPS recycling remains technically challenging and commercially limited.

Water usage presents another significant sustainability factor. Nylon 66 production typically requires 50-70 liters of water per kilogram of polymer, while PPS manufacturing generally uses 30-45 liters per kilogram. Additionally, the higher temperature resistance of PPS often eliminates the need for cooling systems in certain applications, potentially reducing water consumption during the use phase.

Recent sustainability initiatives have focused on developing bio-based precursors for Nylon 66, potentially reducing its fossil fuel dependency. Meanwhile, PPS manufacturers have invested in closed-loop production systems that recover and reuse process chemicals, minimizing waste discharge. These developments suggest that the environmental gap between these materials may narrow as manufacturing technologies evolve and circular economy principles gain wider implementation.

PPS (Polyphenylene Sulfide) manufacturing, while energy-intensive, produces fewer direct greenhouse gas emissions. However, the production process involves chlorinated compounds and sulfur chemicals that present different environmental challenges, particularly regarding potential water and soil contamination if not properly managed. The carbon footprint of PPS is generally estimated at 4-7 kg CO2 equivalent per kilogram, slightly lower than Nylon 66.

In high-temperature applications, the environmental impact diverges further. Nylon 66's lower continuous service temperature (approximately 120-150°C) often necessitates more frequent replacement in high-temperature environments compared to PPS (capable of withstanding 200-240°C continuously). This difference translates to reduced material consumption and waste generation over time when using PPS in appropriate applications, despite its higher initial production impact.

End-of-life considerations also favor PPS in certain aspects. While neither polymer is readily biodegradable, PPS exhibits exceptional chemical resistance that prevents leaching of harmful compounds into the environment during its use phase and after disposal. Conversely, Nylon 66 may degrade under certain conditions, potentially releasing decomposition products. However, Nylon 66 offers better recyclability potential through mechanical recycling and depolymerization techniques, whereas PPS recycling remains technically challenging and commercially limited.

Water usage presents another significant sustainability factor. Nylon 66 production typically requires 50-70 liters of water per kilogram of polymer, while PPS manufacturing generally uses 30-45 liters per kilogram. Additionally, the higher temperature resistance of PPS often eliminates the need for cooling systems in certain applications, potentially reducing water consumption during the use phase.

Recent sustainability initiatives have focused on developing bio-based precursors for Nylon 66, potentially reducing its fossil fuel dependency. Meanwhile, PPS manufacturers have invested in closed-loop production systems that recover and reuse process chemicals, minimizing waste discharge. These developments suggest that the environmental gap between these materials may narrow as manufacturing technologies evolve and circular economy principles gain wider implementation.

Cost-Performance Analysis and ROI Assessment

When evaluating the economic viability of Nylon 66 versus PPS (Polyphenylene Sulfide) for high-temperature applications, a comprehensive cost-performance analysis reveals significant differences that impact return on investment. Nylon 66 typically costs between $2.50-$4.00 per pound, while PPS commands a premium price range of $8.00-$12.00 per pound, representing a 3-4x cost differential at the material acquisition stage.

This price disparity must be weighed against performance longevity in high-temperature environments. Nylon 66 begins to lose mechanical properties at continuous exposure above 120°C, with significant degradation occurring at 150°C. In contrast, PPS maintains structural integrity up to 200-220°C continuously. This temperature performance differential translates directly to component lifespan in high-heat applications.

Lifecycle cost modeling indicates that while PPS components require higher initial investment, they typically demonstrate 2.5-3x longer service life in applications with continuous operating temperatures between 150-200°C. For automotive under-hood components, this can mean 8-10 years of service for PPS parts versus 3-4 years for Nylon 66 parts before replacement becomes necessary.

Manufacturing considerations also impact total cost assessment. PPS requires higher processing temperatures (310-340°C) compared to Nylon 66 (270-290°C), resulting in approximately 15-20% higher energy costs during injection molding. Additionally, PPS processing equipment typically requires more specialized high-temperature capabilities, adding capital expense considerations.

ROI calculations demonstrate that the breakeven point for PPS versus Nylon 66 varies significantly by application. In critical components where failure results in substantial downtime or safety concerns, PPS typically achieves ROI within 2-3 years. For less critical applications operating at the lower end of high-temperature ranges (130-150°C), Nylon 66 may maintain better ROI throughout the product lifecycle.

Industry-specific ROI assessments reveal that aerospace and advanced automotive applications generally justify PPS implementation, with ROI achievement in 18-24 months due to reduced maintenance cycles and compliance with stringent safety requirements. Industrial applications show more variable results, with ROI heavily dependent on specific operating conditions and failure consequences.

The environmental cost factor must also be considered, as longer-lasting PPS components reduce replacement frequency and associated waste. When factoring in disposal and replacement logistics costs, PPS demonstrates a 15-20% lower total environmental impact cost over a 10-year application lifespan in high-temperature environments.

This price disparity must be weighed against performance longevity in high-temperature environments. Nylon 66 begins to lose mechanical properties at continuous exposure above 120°C, with significant degradation occurring at 150°C. In contrast, PPS maintains structural integrity up to 200-220°C continuously. This temperature performance differential translates directly to component lifespan in high-heat applications.

Lifecycle cost modeling indicates that while PPS components require higher initial investment, they typically demonstrate 2.5-3x longer service life in applications with continuous operating temperatures between 150-200°C. For automotive under-hood components, this can mean 8-10 years of service for PPS parts versus 3-4 years for Nylon 66 parts before replacement becomes necessary.

Manufacturing considerations also impact total cost assessment. PPS requires higher processing temperatures (310-340°C) compared to Nylon 66 (270-290°C), resulting in approximately 15-20% higher energy costs during injection molding. Additionally, PPS processing equipment typically requires more specialized high-temperature capabilities, adding capital expense considerations.

ROI calculations demonstrate that the breakeven point for PPS versus Nylon 66 varies significantly by application. In critical components where failure results in substantial downtime or safety concerns, PPS typically achieves ROI within 2-3 years. For less critical applications operating at the lower end of high-temperature ranges (130-150°C), Nylon 66 may maintain better ROI throughout the product lifecycle.

Industry-specific ROI assessments reveal that aerospace and advanced automotive applications generally justify PPS implementation, with ROI achievement in 18-24 months due to reduced maintenance cycles and compliance with stringent safety requirements. Industrial applications show more variable results, with ROI heavily dependent on specific operating conditions and failure consequences.

The environmental cost factor must also be considered, as longer-lasting PPS components reduce replacement frequency and associated waste. When factoring in disposal and replacement logistics costs, PPS demonstrates a 15-20% lower total environmental impact cost over a 10-year application lifespan in high-temperature environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!