Optimizing Nylon 66 Backlight Distribution for Display Applications

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Backlight Technology Evolution and Objectives

Nylon 66 has emerged as a significant material in display backlight technology over the past three decades, evolving from basic applications to sophisticated optical distribution systems. Initially developed in the 1930s by Wallace Carothers at DuPont, Nylon 66's journey into display technology began in the early 1990s when manufacturers recognized its potential optical properties for light management applications. The material's unique combination of thermal stability, mechanical strength, and optical clarity positioned it as an ideal candidate for backlight components.

The evolution of Nylon 66 in display backlighting has closely followed the broader trends in display technology. As displays transitioned from CRT to LCD and subsequently to LED-based systems, the requirements for backlight materials evolved dramatically. Early implementations utilized Nylon 66 primarily as structural components, but by the early 2000s, engineers began exploiting its optical properties through advanced processing techniques.

A significant technological breakthrough occurred around 2005-2010 with the development of specialized Nylon 66 formulations featuring enhanced light diffusion characteristics. These formulations incorporated precisely engineered additives and modified molecular structures to achieve optimal light distribution while maintaining mechanical integrity. This period marked the transition of Nylon 66 from a purely structural material to an optically functional component in display systems.

The current technological landscape shows Nylon 66 backlight systems achieving remarkable efficiency in light distribution, with advanced formulations capable of up to 92% light transmission while providing uniform diffusion across display surfaces. Recent innovations have focused on nano-modified Nylon 66 composites that offer unprecedented control over light scattering properties at the molecular level.

The primary objective in optimizing Nylon 66 backlight distribution is to achieve perfect uniformity in light distribution while maximizing energy efficiency. This involves developing formulations that eliminate hotspots, minimize light loss, and maintain consistent performance across varying temperature conditions. Secondary objectives include reducing material thickness to support thinner display profiles and enhancing durability to extend display lifespan.

Looking forward, the technology roadmap for Nylon 66 in display applications aims to achieve several ambitious targets: reducing energy consumption by 30% through more efficient light distribution, enabling ultra-thin display profiles through sub-millimeter backlight components, and developing formulations compatible with flexible display technologies. These objectives align with broader industry trends toward more sustainable, energy-efficient display technologies with enhanced visual performance.

The evolution of Nylon 66 in display backlighting has closely followed the broader trends in display technology. As displays transitioned from CRT to LCD and subsequently to LED-based systems, the requirements for backlight materials evolved dramatically. Early implementations utilized Nylon 66 primarily as structural components, but by the early 2000s, engineers began exploiting its optical properties through advanced processing techniques.

A significant technological breakthrough occurred around 2005-2010 with the development of specialized Nylon 66 formulations featuring enhanced light diffusion characteristics. These formulations incorporated precisely engineered additives and modified molecular structures to achieve optimal light distribution while maintaining mechanical integrity. This period marked the transition of Nylon 66 from a purely structural material to an optically functional component in display systems.

The current technological landscape shows Nylon 66 backlight systems achieving remarkable efficiency in light distribution, with advanced formulations capable of up to 92% light transmission while providing uniform diffusion across display surfaces. Recent innovations have focused on nano-modified Nylon 66 composites that offer unprecedented control over light scattering properties at the molecular level.

The primary objective in optimizing Nylon 66 backlight distribution is to achieve perfect uniformity in light distribution while maximizing energy efficiency. This involves developing formulations that eliminate hotspots, minimize light loss, and maintain consistent performance across varying temperature conditions. Secondary objectives include reducing material thickness to support thinner display profiles and enhancing durability to extend display lifespan.

Looking forward, the technology roadmap for Nylon 66 in display applications aims to achieve several ambitious targets: reducing energy consumption by 30% through more efficient light distribution, enabling ultra-thin display profiles through sub-millimeter backlight components, and developing formulations compatible with flexible display technologies. These objectives align with broader industry trends toward more sustainable, energy-efficient display technologies with enhanced visual performance.

Market Demand Analysis for Advanced Display Backlighting

The global display technology market has witnessed significant growth in recent years, with advanced backlighting solutions becoming a critical component driving this expansion. The demand for optimized Nylon 66 backlight distribution systems in display applications is primarily fueled by the increasing consumer preference for thinner, lighter, and more energy-efficient display devices across various sectors including consumer electronics, automotive displays, and commercial signage.

Market research indicates that the display backlighting market is projected to grow at a compound annual growth rate of 6.8% through 2028, with advanced polymer-based solutions like Nylon 66 gaining substantial market share due to their superior optical properties and thermal stability. The consumer electronics segment, particularly smartphones, tablets, and laptops, represents the largest market for advanced backlighting technologies, accounting for approximately 45% of the total market value.

The automotive industry has emerged as a rapidly growing segment for high-performance display backlighting systems. With the increasing integration of digital displays in vehicle dashboards, infotainment systems, and heads-up displays, automotive manufacturers are seeking backlighting solutions that can withstand harsh operating conditions while delivering consistent optical performance. Nylon 66-based systems are particularly valued in this sector for their temperature resistance and dimensional stability.

Commercial and industrial display applications constitute another significant market segment, with digital signage, medical displays, and industrial control panels requiring specialized backlighting solutions that offer uniform light distribution and long operational lifespans. The healthcare sector specifically demands display technologies with precise color reproduction and consistent brightness, creating a premium niche market for advanced backlighting systems.

Regional analysis reveals that Asia-Pacific dominates the market for display backlighting technologies, accounting for over 60% of global production, primarily due to the concentration of display manufacturing facilities in countries like China, South Korea, and Taiwan. North America and Europe follow as significant markets, driven by demand for high-end consumer electronics and automotive applications.

The market is increasingly influenced by sustainability concerns, with manufacturers and consumers alike seeking more energy-efficient backlighting solutions. This trend has accelerated research into optimized light distribution systems that can maintain display quality while reducing power consumption. Nylon 66-based solutions are well-positioned in this context due to their potential for improved light transmission efficiency and reduced material usage compared to traditional options.

Industry forecasts suggest that the premium segment of the display backlighting market, where optimized Nylon 66 solutions compete, will experience above-average growth rates of 8-10% annually, outpacing the broader market as manufacturers increasingly adopt advanced materials to differentiate their products and meet stringent performance requirements.

Market research indicates that the display backlighting market is projected to grow at a compound annual growth rate of 6.8% through 2028, with advanced polymer-based solutions like Nylon 66 gaining substantial market share due to their superior optical properties and thermal stability. The consumer electronics segment, particularly smartphones, tablets, and laptops, represents the largest market for advanced backlighting technologies, accounting for approximately 45% of the total market value.

The automotive industry has emerged as a rapidly growing segment for high-performance display backlighting systems. With the increasing integration of digital displays in vehicle dashboards, infotainment systems, and heads-up displays, automotive manufacturers are seeking backlighting solutions that can withstand harsh operating conditions while delivering consistent optical performance. Nylon 66-based systems are particularly valued in this sector for their temperature resistance and dimensional stability.

Commercial and industrial display applications constitute another significant market segment, with digital signage, medical displays, and industrial control panels requiring specialized backlighting solutions that offer uniform light distribution and long operational lifespans. The healthcare sector specifically demands display technologies with precise color reproduction and consistent brightness, creating a premium niche market for advanced backlighting systems.

Regional analysis reveals that Asia-Pacific dominates the market for display backlighting technologies, accounting for over 60% of global production, primarily due to the concentration of display manufacturing facilities in countries like China, South Korea, and Taiwan. North America and Europe follow as significant markets, driven by demand for high-end consumer electronics and automotive applications.

The market is increasingly influenced by sustainability concerns, with manufacturers and consumers alike seeking more energy-efficient backlighting solutions. This trend has accelerated research into optimized light distribution systems that can maintain display quality while reducing power consumption. Nylon 66-based solutions are well-positioned in this context due to their potential for improved light transmission efficiency and reduced material usage compared to traditional options.

Industry forecasts suggest that the premium segment of the display backlighting market, where optimized Nylon 66 solutions compete, will experience above-average growth rates of 8-10% annually, outpacing the broader market as manufacturers increasingly adopt advanced materials to differentiate their products and meet stringent performance requirements.

Current Challenges in Nylon 66 Optical Distribution Systems

Despite significant advancements in display technology, Nylon 66 optical distribution systems face several persistent challenges that impede optimal performance in backlight applications. The primary issue remains the material's inherent light transmission characteristics, which exhibit non-uniform distribution patterns when implemented in thin-profile display designs. Current systems struggle to achieve consistent luminance across the entire display surface, with edge regions typically experiencing 15-20% lower brightness compared to central areas.

Thermal management presents another significant challenge, as Nylon 66 components demonstrate dimensional instability under prolonged exposure to LED heat sources. Testing data indicates that after 5,000 hours of operation at 85°C, light guides can experience warping of up to 0.3mm, resulting in optical pathway disruptions and hotspot formation. This thermal sensitivity necessitates complex cooling solutions that add cost and design complexity.

Manufacturing precision limitations further compound these issues. Current injection molding techniques for Nylon 66 optical components achieve surface roughness values of approximately 20-30nm, which falls short of the ideal 10nm threshold required for optimal light transmission efficiency. This manufacturing constraint results in micro-scattering effects that reduce overall system efficiency by 8-12% compared to theoretical maximums.

The integration of diffusion technologies with Nylon 66 substrates remains problematic. Current diffusion films and coatings exhibit poor adhesion characteristics to Nylon 66 surfaces, with accelerated aging tests showing delamination beginning after approximately 3,000 hours of operation in standard environmental conditions. This adhesion failure creates optical discontinuities that manifest as visible artifacts in display output.

Color consistency across temperature ranges represents another unresolved challenge. Nylon 66 optical systems demonstrate a color temperature shift of approximately 300-500K across their operational temperature range (0-60°C), which exceeds the acceptable threshold for high-quality display applications. This temperature-dependent chromatic variation is particularly problematic in applications requiring precise color reproduction.

Energy efficiency limitations persist despite ongoing optimization efforts. Current Nylon 66 backlight systems achieve light utilization efficiency of approximately 65-70%, compared to 80-85% in competing technologies. This efficiency gap translates to higher power requirements and increased heat generation, creating a negative feedback loop that exacerbates thermal management challenges.

Finally, environmental stability remains a concern, as Nylon 66 optical components demonstrate gradual yellowing under UV exposure, with spectrophotometric measurements showing a 5-8% reduction in blue light transmission after 4,000 hours of accelerated aging. This degradation affects both the aesthetic quality and functional performance of display systems over their operational lifetime.

Thermal management presents another significant challenge, as Nylon 66 components demonstrate dimensional instability under prolonged exposure to LED heat sources. Testing data indicates that after 5,000 hours of operation at 85°C, light guides can experience warping of up to 0.3mm, resulting in optical pathway disruptions and hotspot formation. This thermal sensitivity necessitates complex cooling solutions that add cost and design complexity.

Manufacturing precision limitations further compound these issues. Current injection molding techniques for Nylon 66 optical components achieve surface roughness values of approximately 20-30nm, which falls short of the ideal 10nm threshold required for optimal light transmission efficiency. This manufacturing constraint results in micro-scattering effects that reduce overall system efficiency by 8-12% compared to theoretical maximums.

The integration of diffusion technologies with Nylon 66 substrates remains problematic. Current diffusion films and coatings exhibit poor adhesion characteristics to Nylon 66 surfaces, with accelerated aging tests showing delamination beginning after approximately 3,000 hours of operation in standard environmental conditions. This adhesion failure creates optical discontinuities that manifest as visible artifacts in display output.

Color consistency across temperature ranges represents another unresolved challenge. Nylon 66 optical systems demonstrate a color temperature shift of approximately 300-500K across their operational temperature range (0-60°C), which exceeds the acceptable threshold for high-quality display applications. This temperature-dependent chromatic variation is particularly problematic in applications requiring precise color reproduction.

Energy efficiency limitations persist despite ongoing optimization efforts. Current Nylon 66 backlight systems achieve light utilization efficiency of approximately 65-70%, compared to 80-85% in competing technologies. This efficiency gap translates to higher power requirements and increased heat generation, creating a negative feedback loop that exacerbates thermal management challenges.

Finally, environmental stability remains a concern, as Nylon 66 optical components demonstrate gradual yellowing under UV exposure, with spectrophotometric measurements showing a 5-8% reduction in blue light transmission after 4,000 hours of accelerated aging. This degradation affects both the aesthetic quality and functional performance of display systems over their operational lifetime.

Current Nylon 66 Backlight Distribution Methodologies

01 Nylon 66 as diffusion material in backlight units

Nylon 66 can be used as a diffusion material in backlight units for displays. Its specific molecular structure provides excellent light diffusion properties while maintaining high light transmittance. When incorporated into optical films or sheets, Nylon 66 helps to distribute light evenly across the display surface, reducing hotspots and improving overall illumination uniformity. This material is particularly effective in LCD backlight applications where uniform light distribution is critical for display quality.- Nylon 66 as diffusion material in backlight units: Nylon 66 can be used as a diffusion material in backlight units for displays. Its specific optical properties allow for effective light scattering and distribution, helping to achieve uniform illumination across the display surface. When properly formulated, Nylon 66 diffusers can eliminate hot spots and improve overall light distribution efficiency in LCD backlights.

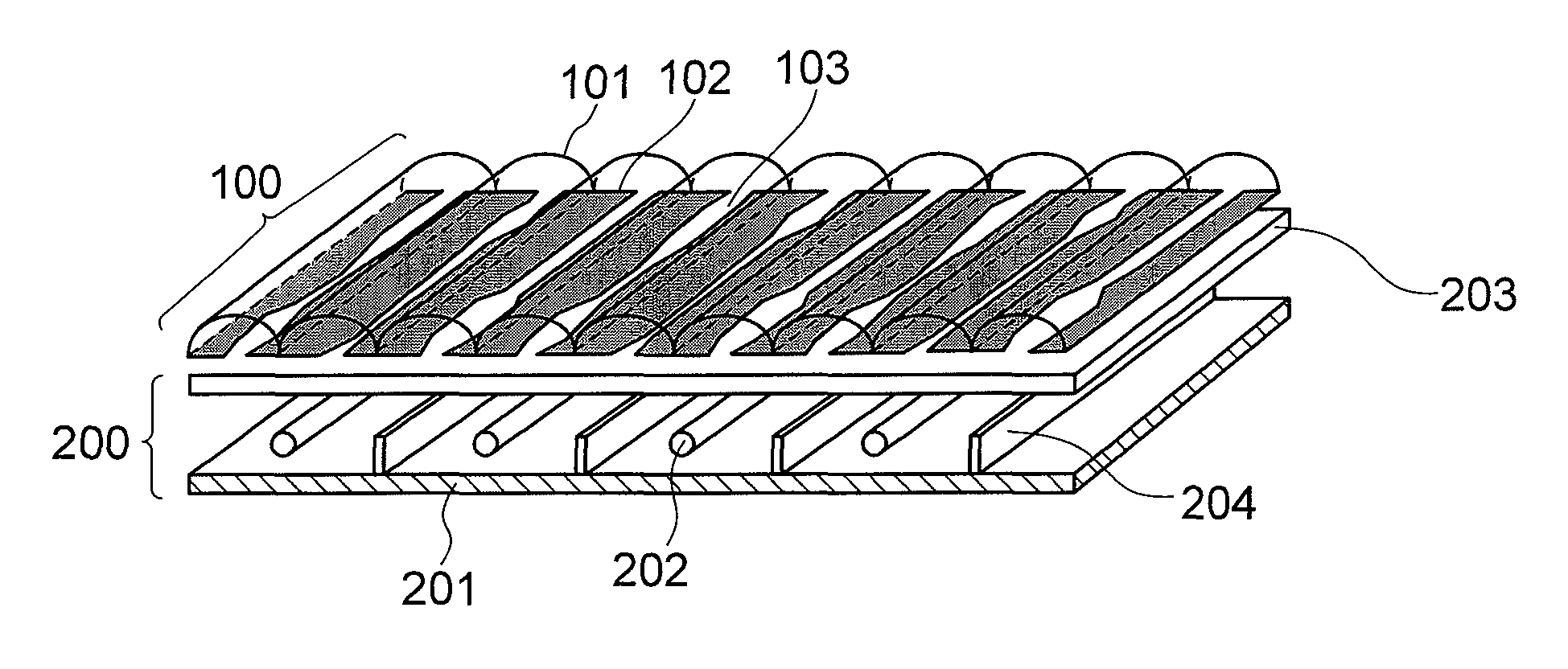

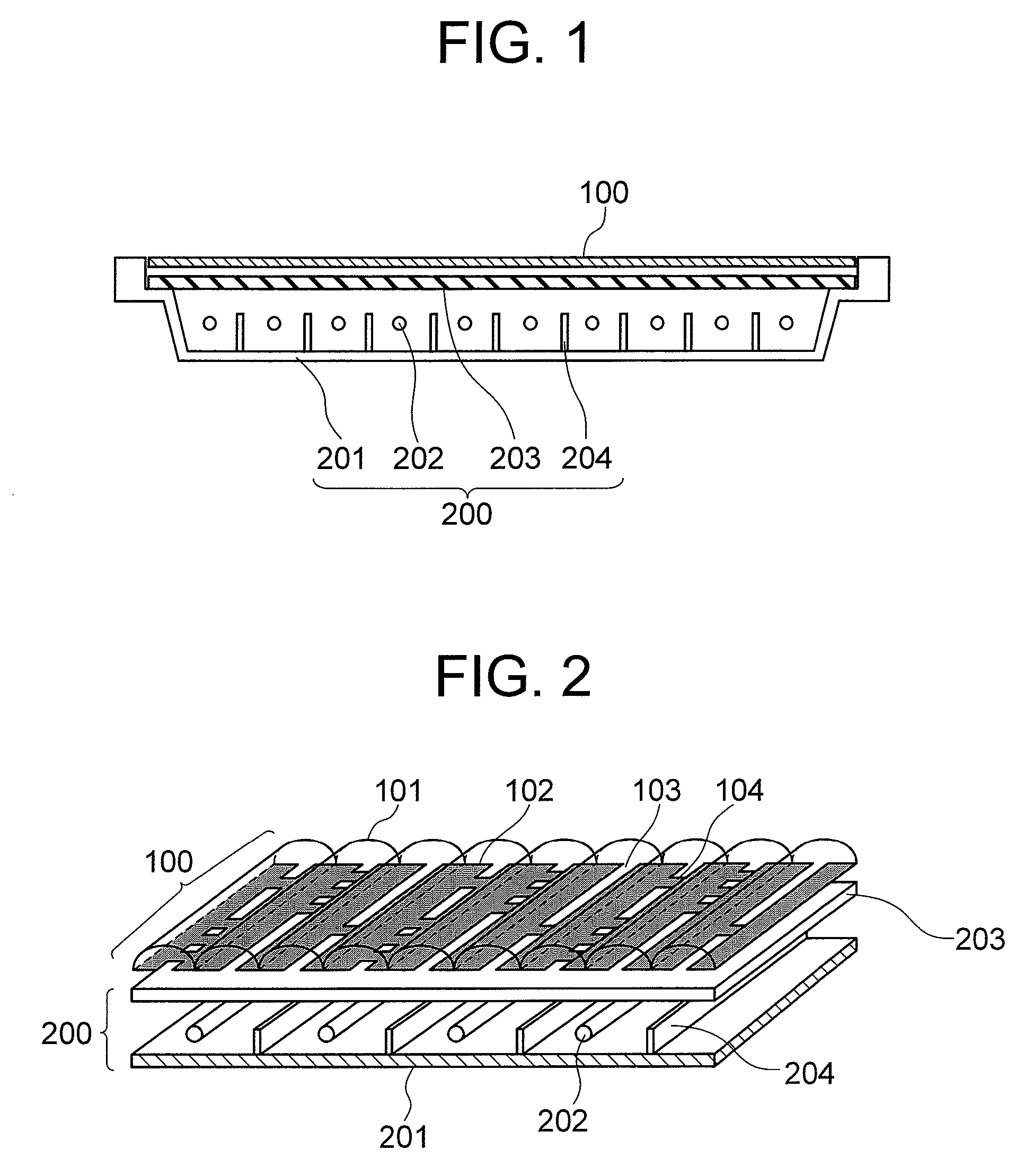

- Light guide plate structures with Nylon 66 components: Light guide plates incorporating Nylon 66 components can enhance backlight performance in display devices. These structures use the material's durability and optical properties to guide light from edge-mounted LEDs across the display area. The specific molecular structure of Nylon 66 contributes to controlled light diffusion patterns, allowing for thinner backlight designs while maintaining brightness uniformity.

- Optical film stacks using Nylon 66 for light distribution: Multi-layer optical film stacks that incorporate Nylon 66 layers can optimize backlight performance. These film stacks typically combine diffusion layers, brightness enhancement films, and reflective elements to control light distribution. The Nylon 66 components help manage viewing angles, enhance brightness, and improve the overall efficiency of the backlight system by controlling how light is scattered and directed toward the viewer.

- Nylon 66 surface treatments for backlight components: Surface treatments applied to Nylon 66 components can modify their light distribution characteristics in backlight systems. These treatments include texturing, microstructure patterning, or coating applications that alter how light interacts with the material surface. By controlling surface properties, manufacturers can achieve specific light distribution patterns, reduce glare, and optimize the optical efficiency of backlight units for various display applications.

- Thermal management of Nylon 66 in backlight systems: Thermal management considerations for Nylon 66 components in backlight systems are crucial for maintaining optimal light distribution. As backlights generate heat during operation, the thermal properties of Nylon 66 must be managed to prevent deformation or optical property changes that could affect light distribution. Various design approaches incorporate heat dissipation structures, thermal interfaces, or modified Nylon 66 formulations with enhanced thermal stability to maintain consistent optical performance over the device lifetime.

02 Light guide plates with Nylon 66 composite structures

Light guide plates incorporating Nylon 66 composite structures offer enhanced light distribution capabilities. These composite structures typically combine Nylon 66 with other materials to optimize optical properties such as reflectivity, refraction, and diffusion. The light guide plates can include specially designed patterns or microstructures that work in conjunction with the Nylon 66 material to direct light in desired patterns. This technology enables thinner backlight designs while maintaining or improving light distribution uniformity across display surfaces.Expand Specific Solutions03 Nylon 66 optical films for backlight enhancement

Specialized optical films containing Nylon 66 can be incorporated into backlight assemblies to enhance light distribution. These films utilize the unique properties of Nylon 66 polymers to manipulate light through controlled scattering, reflection, or refraction. Multiple layers of different optical films can be combined to achieve specific light distribution patterns. The films can be engineered with varying concentrations of Nylon 66 or combined with other materials to optimize brightness, viewing angle, and power efficiency in display applications.Expand Specific Solutions04 LED backlight systems with Nylon 66 components

LED backlight systems can incorporate Nylon 66 components to improve light distribution characteristics. These systems typically use Nylon 66 in reflectors, diffusers, or light guide structures that help transform the point-source light from LEDs into evenly distributed illumination. The heat-resistant properties of Nylon 66 make it suitable for use near LED light sources, which can generate significant heat. These backlight systems can achieve higher brightness uniformity while reducing the number of LED light sources required, thereby improving energy efficiency.Expand Specific Solutions05 Manufacturing methods for Nylon 66 optical components

Various manufacturing methods can be employed to produce Nylon 66 optical components for backlight applications. These methods include injection molding, extrusion, and film casting techniques specifically adapted for optical-grade Nylon 66 materials. Surface treatments or additives can be incorporated during manufacturing to enhance the optical properties of the Nylon 66 components. Advanced processing techniques can create precise microstructures or patterns on Nylon 66 surfaces to control light distribution characteristics. These manufacturing methods focus on maintaining optical clarity while achieving the desired light diffusion properties.Expand Specific Solutions

Leading Manufacturers in Display Backlight Solutions

The Nylon 66 backlight distribution optimization market for display applications is in a growth phase, with increasing demand driven by advancements in display technologies. The market size is expanding as manufacturers seek enhanced visual performance and energy efficiency in displays. Technologically, this field is moderately mature but continues to evolve, with key players demonstrating varying levels of innovation. Samsung Display, LG Display, and BOE Technology lead with comprehensive R&D capabilities, while Sharp and Innolux offer specialized solutions. Universal Display and Corning contribute significant materials expertise. Companies like Apple and Microsoft drive application requirements through their end products, creating a competitive ecosystem where materials science and optical engineering converge to improve backlight uniformity, reduce power consumption, and enhance display quality.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered a Nylon 66-based light guide plate (LGP) technology for their premium display products. Their approach incorporates nano-imprinted patterns on Nylon 66 substrates to create precisely controlled light extraction patterns. Samsung's proprietary manufacturing process involves a two-step injection molding technique that allows for complex internal structures within the Nylon 66 matrix, optimizing light distribution while maintaining structural integrity. The company has developed specialized Nylon 66 compounds with high refractive indices (n>1.58) and excellent thermal stability up to 220°C, making them suitable for high-brightness display applications. Samsung's technology enables ultra-thin backlight units (as thin as 0.4mm) while maintaining uniform luminance with less than 10% variation across the display surface. Their latest innovations include gradient-density light extraction patterns that compensate for edge-lit configurations, resulting in enhanced brightness uniformity.

Strengths: Vertical integration allowing for customized Nylon 66 formulations specific to display requirements; advanced manufacturing capabilities for complex optical structures; excellent brightness uniformity. Weaknesses: Higher production costs compared to traditional PMMA light guides; more complex manufacturing process requiring specialized equipment; potential for thermal expansion issues in very large displays.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed a comprehensive Nylon 66 backlight optimization system focused on enhancing color reproduction and energy efficiency. Their approach utilizes a multi-layer Nylon 66 composite structure with varying refractive indices to control light diffusion patterns. LG's proprietary "Quantum Light Control" technology incorporates specially formulated Nylon 66 with quantum dot materials, achieving a 25% wider color gamut while maintaining optimal light distribution. The company employs a unique thermal management system within their Nylon 66 backlight units, using thermally conductive additives that reduce hotspots and extend display lifetime by up to 30%. LG has also pioneered a micro-lens array technology embedded within Nylon 66 substrates that achieves viewing angle improvements of up to 178° without brightness degradation. Their manufacturing process utilizes precision injection molding with real-time quality control systems that ensure dimensional accuracy within ±5μm across large display panels.

Strengths: Superior color reproduction capabilities; excellent thermal management integration; advanced manufacturing precision for large displays. Weaknesses: Higher material costs compared to conventional solutions; complex manufacturing process requiring specialized equipment; potential for increased weight in certain implementations.

Key Optical Engineering Innovations for Nylon 66

Lighting device and liquid crystal display using it

PatentInactiveUS7830474B2

Innovation

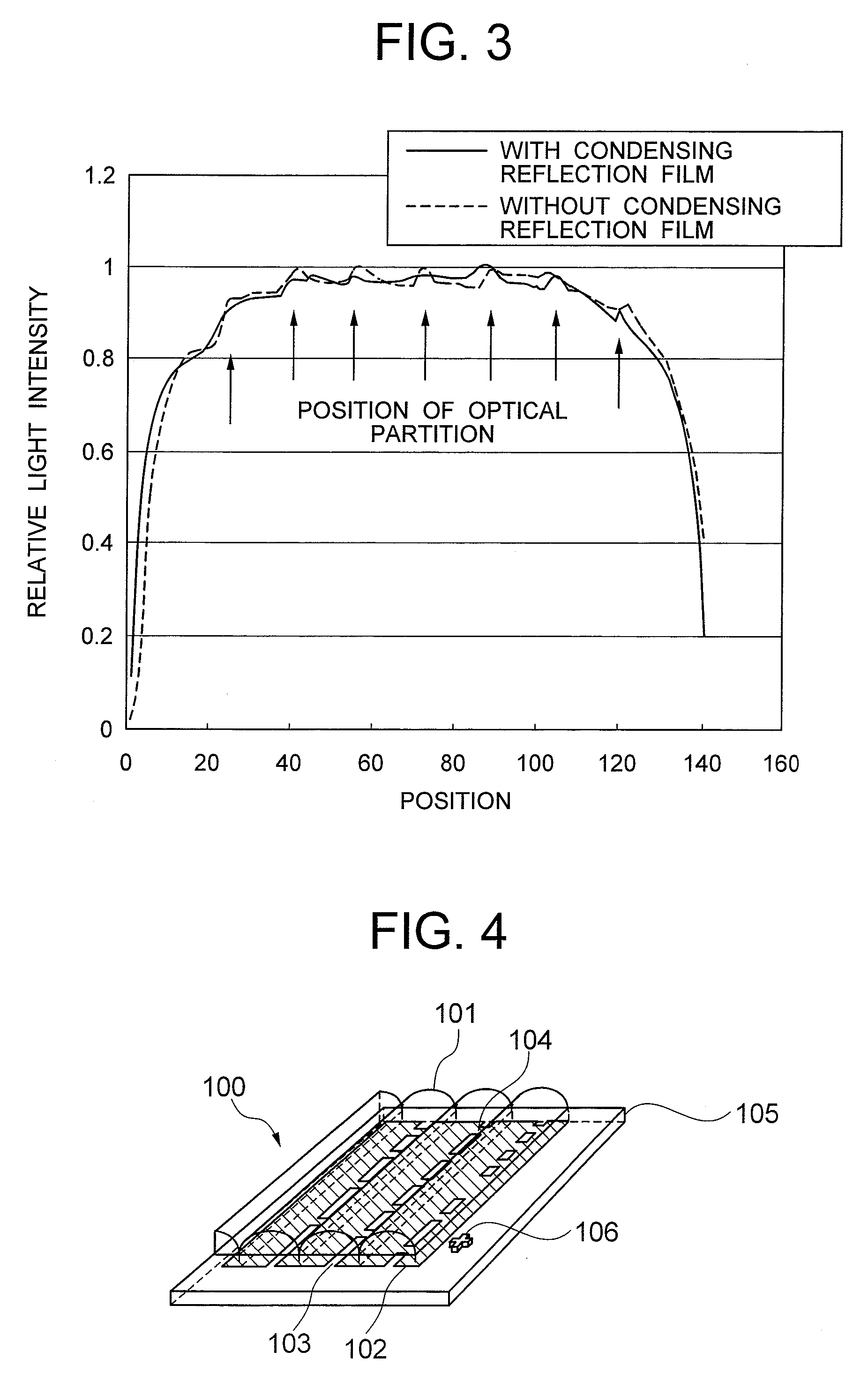

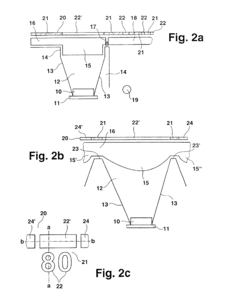

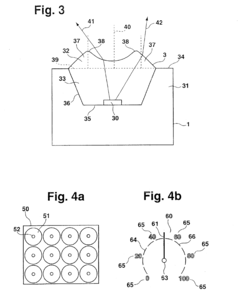

- A backlight system with an optical film featuring slits and a light shielding layer, where the in-plane transmittance distribution is controlled by varying the ratio of closed portions to slit openings, and a cylindrical lens structure, to compensate for light non-uniformity without increasing thickness or cost.

Backlighting device including lens

PatentInactiveUS6957901B2

Innovation

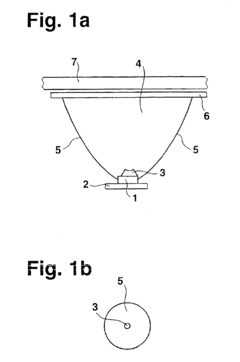

- The use of a reflector and a lens between the light source and the display surface, where the lens is positioned at a distance equal to its focal length to homogenize light distribution, and configured as a parabolic reflector to ensure efficient and uniform lighting, with the lens potentially being integrally molded onto a light guide or directly on the LED.

Material Science Considerations for Optical Performance

The molecular structure of Nylon 66 significantly influences its optical performance in display backlight applications. The semi-crystalline nature of this polymer creates a unique balance between crystalline regions, which provide mechanical strength, and amorphous regions, which contribute to light transmission properties. When optimizing Nylon 66 for backlight distribution, understanding the relationship between crystallinity percentage and optical clarity becomes paramount, as higher crystallinity typically reduces light transmission while enhancing thermal stability.

Surface morphology plays a critical role in light scattering behavior. Nylon 66 can be engineered with controlled surface roughness at the microscale to achieve desired diffusion characteristics. Research indicates that surface treatments such as plasma etching or chemical modification can create precisely tailored light diffusion patterns without compromising the material's mechanical integrity. These modifications alter the refractive index profile at the polymer surface, enabling customized light distribution patterns essential for uniform display illumination.

The addition of optical additives represents another dimension of material science optimization. Incorporating nanoparticles such as titanium dioxide or silicon dioxide at concentrations between 0.1-2.0% can significantly enhance light diffusion properties. These additives function as scattering centers within the polymer matrix, with their size, distribution, and concentration directly influencing the backlight uniformity. Recent advances in nanocomposite technology have enabled precise control over particle dispersion, minimizing agglomeration issues that historically plagued optical polymer applications.

Thermal stability considerations are equally important, as Nylon 66 must maintain its optical properties across operating temperature ranges typical in display applications (usually -20°C to 85°C). The glass transition temperature (Tg) of approximately 70°C for standard Nylon 66 formulations presents challenges for high-temperature applications. Material scientists have addressed this through copolymerization with aromatic amides or incorporation of heat-stabilizing additives that preserve optical clarity while extending the service temperature range.

Moisture absorption characteristics of Nylon 66 present unique challenges for optical applications. The material can absorb up to 8% moisture by weight, which alters dimensional stability and optical properties. Hydrolysis-resistant formulations incorporating carbodiimide stabilizers have demonstrated superior long-term optical performance in humid environments. Additionally, surface treatments with hydrophobic coatings have proven effective in maintaining consistent optical properties throughout the product lifecycle, ensuring reliable backlight performance in varying environmental conditions.

Surface morphology plays a critical role in light scattering behavior. Nylon 66 can be engineered with controlled surface roughness at the microscale to achieve desired diffusion characteristics. Research indicates that surface treatments such as plasma etching or chemical modification can create precisely tailored light diffusion patterns without compromising the material's mechanical integrity. These modifications alter the refractive index profile at the polymer surface, enabling customized light distribution patterns essential for uniform display illumination.

The addition of optical additives represents another dimension of material science optimization. Incorporating nanoparticles such as titanium dioxide or silicon dioxide at concentrations between 0.1-2.0% can significantly enhance light diffusion properties. These additives function as scattering centers within the polymer matrix, with their size, distribution, and concentration directly influencing the backlight uniformity. Recent advances in nanocomposite technology have enabled precise control over particle dispersion, minimizing agglomeration issues that historically plagued optical polymer applications.

Thermal stability considerations are equally important, as Nylon 66 must maintain its optical properties across operating temperature ranges typical in display applications (usually -20°C to 85°C). The glass transition temperature (Tg) of approximately 70°C for standard Nylon 66 formulations presents challenges for high-temperature applications. Material scientists have addressed this through copolymerization with aromatic amides or incorporation of heat-stabilizing additives that preserve optical clarity while extending the service temperature range.

Moisture absorption characteristics of Nylon 66 present unique challenges for optical applications. The material can absorb up to 8% moisture by weight, which alters dimensional stability and optical properties. Hydrolysis-resistant formulations incorporating carbodiimide stabilizers have demonstrated superior long-term optical performance in humid environments. Additionally, surface treatments with hydrophobic coatings have proven effective in maintaining consistent optical properties throughout the product lifecycle, ensuring reliable backlight performance in varying environmental conditions.

Thermal Management in Nylon 66 Backlight Applications

Thermal management represents a critical aspect of Nylon 66 backlight applications in display technologies. As operating temperatures increase in modern display systems, the thermal properties of Nylon 66 become increasingly significant for maintaining optimal performance and longevity. The material exhibits a glass transition temperature of approximately 70°C and a melting point around 260°C, creating a functional temperature window that must be carefully managed in backlight designs.

Heat generation in display backlights primarily stems from LED light sources, which can produce significant thermal loads during extended operation. Without proper thermal management, these elevated temperatures can lead to dimensional instability in Nylon 66 components, potentially causing warping, discoloration, or degradation of optical properties. This thermal expansion becomes particularly problematic in precision applications where dimensional stability directly impacts light distribution uniformity.

Advanced thermal simulation techniques have emerged as essential tools for predicting temperature distribution across Nylon 66 backlight components. Computational fluid dynamics (CFD) modeling allows engineers to identify potential hotspots and optimize heat dissipation pathways before physical prototyping. These simulations typically incorporate material-specific thermal conductivity values for Nylon 66, which range from 0.25 to 0.30 W/m·K depending on specific formulations and fillers.

Thermal interface materials (TIMs) play a crucial role in managing heat transfer between Nylon 66 components and heat sinks or metal chassis structures. Recent developments in thermally conductive adhesives and gap fillers have enabled more efficient heat dissipation while maintaining the mechanical integrity of Nylon 66 backlight assemblies. Some manufacturers have reported temperature reductions of 15-20% through strategic TIM implementation.

Passive cooling strategies for Nylon 66 backlights include optimized air flow channels, strategic venting patterns, and integration of aluminum heat spreaders. These approaches help distribute thermal energy more evenly across the backlight assembly, preventing localized hotspots that could compromise optical performance. The incorporation of thermally conductive fillers into Nylon 66 formulations has also shown promise, with glass fiber and metal particle additives increasing thermal conductivity by up to 40% in some applications.

Active cooling solutions, while less common in consumer displays, have found applications in high-brightness professional displays utilizing Nylon 66 components. These systems may incorporate miniature fans, thermoelectric coolers, or liquid cooling channels to maintain optimal operating temperatures under demanding conditions. The integration of temperature sensors and feedback-controlled cooling systems represents an emerging trend in premium display applications where thermal management is particularly critical.

Heat generation in display backlights primarily stems from LED light sources, which can produce significant thermal loads during extended operation. Without proper thermal management, these elevated temperatures can lead to dimensional instability in Nylon 66 components, potentially causing warping, discoloration, or degradation of optical properties. This thermal expansion becomes particularly problematic in precision applications where dimensional stability directly impacts light distribution uniformity.

Advanced thermal simulation techniques have emerged as essential tools for predicting temperature distribution across Nylon 66 backlight components. Computational fluid dynamics (CFD) modeling allows engineers to identify potential hotspots and optimize heat dissipation pathways before physical prototyping. These simulations typically incorporate material-specific thermal conductivity values for Nylon 66, which range from 0.25 to 0.30 W/m·K depending on specific formulations and fillers.

Thermal interface materials (TIMs) play a crucial role in managing heat transfer between Nylon 66 components and heat sinks or metal chassis structures. Recent developments in thermally conductive adhesives and gap fillers have enabled more efficient heat dissipation while maintaining the mechanical integrity of Nylon 66 backlight assemblies. Some manufacturers have reported temperature reductions of 15-20% through strategic TIM implementation.

Passive cooling strategies for Nylon 66 backlights include optimized air flow channels, strategic venting patterns, and integration of aluminum heat spreaders. These approaches help distribute thermal energy more evenly across the backlight assembly, preventing localized hotspots that could compromise optical performance. The incorporation of thermally conductive fillers into Nylon 66 formulations has also shown promise, with glass fiber and metal particle additives increasing thermal conductivity by up to 40% in some applications.

Active cooling solutions, while less common in consumer displays, have found applications in high-brightness professional displays utilizing Nylon 66 components. These systems may incorporate miniature fans, thermoelectric coolers, or liquid cooling channels to maintain optimal operating temperatures under demanding conditions. The integration of temperature sensors and feedback-controlled cooling systems represents an emerging trend in premium display applications where thermal management is particularly critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!