How to Optimize Nylon 66 Synthesis for High Purity

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Synthesis Background and Objectives

Nylon 66, a synthetic polyamide, has revolutionized the materials industry since its invention by Wallace Carothers at DuPont in 1935. This versatile polymer, characterized by its exceptional mechanical properties, thermal stability, and chemical resistance, has become indispensable in numerous applications ranging from automotive components to textile fibers. The designation "66" refers to the six carbon atoms in each of the two monomers: hexamethylenediamine and adipic acid.

The conventional synthesis of Nylon 66 involves polycondensation of these two monomers, typically proceeding through the formation of a nylon salt intermediate. While this process has been industrialized for decades, achieving consistently high purity remains challenging due to several factors including side reactions, incomplete polymerization, and the presence of cyclic oligomers. These impurities significantly impact the mechanical properties, thermal stability, and processability of the final product.

Recent technological advancements have focused on enhancing the purity of Nylon 66 through improved synthesis methods. Continuous polymerization processes have gained prominence over batch processes, offering better control over reaction parameters and reducing thermal degradation. Additionally, innovations in catalyst systems have enabled more selective reactions with fewer byproducts.

The global market for high-purity Nylon 66 continues to expand, driven by demanding applications in electronics, automotive lightweight components, and high-performance textiles. These applications require exceptional consistency in molecular weight distribution, minimal content of cyclic oligomers, and reduced levels of residual monomers and catalysts.

Current optimization objectives center on several key aspects: minimizing the formation of cyclic oligomers during polymerization, reducing residual monomer content, eliminating metal catalyst residues, and achieving precise control over molecular weight distribution. These objectives align with broader industry trends toward more sustainable manufacturing processes with reduced energy consumption and minimal waste generation.

The technical challenges in optimizing Nylon 66 synthesis for high purity are multifaceted, involving complex reaction kinetics, heat and mass transfer limitations, and the need for sophisticated analytical methods to characterize impurities at increasingly lower detection limits. Addressing these challenges requires interdisciplinary approaches combining polymer chemistry, chemical engineering, and materials science.

This technical research aims to comprehensively evaluate current Nylon 66 synthesis methodologies, identify critical parameters affecting product purity, and explore innovative approaches to overcome existing limitations. The ultimate goal is to establish robust, scalable processes capable of consistently producing Nylon 66 with impurity levels below 0.1%, while maintaining economic viability and sustainability in industrial settings.

The conventional synthesis of Nylon 66 involves polycondensation of these two monomers, typically proceeding through the formation of a nylon salt intermediate. While this process has been industrialized for decades, achieving consistently high purity remains challenging due to several factors including side reactions, incomplete polymerization, and the presence of cyclic oligomers. These impurities significantly impact the mechanical properties, thermal stability, and processability of the final product.

Recent technological advancements have focused on enhancing the purity of Nylon 66 through improved synthesis methods. Continuous polymerization processes have gained prominence over batch processes, offering better control over reaction parameters and reducing thermal degradation. Additionally, innovations in catalyst systems have enabled more selective reactions with fewer byproducts.

The global market for high-purity Nylon 66 continues to expand, driven by demanding applications in electronics, automotive lightweight components, and high-performance textiles. These applications require exceptional consistency in molecular weight distribution, minimal content of cyclic oligomers, and reduced levels of residual monomers and catalysts.

Current optimization objectives center on several key aspects: minimizing the formation of cyclic oligomers during polymerization, reducing residual monomer content, eliminating metal catalyst residues, and achieving precise control over molecular weight distribution. These objectives align with broader industry trends toward more sustainable manufacturing processes with reduced energy consumption and minimal waste generation.

The technical challenges in optimizing Nylon 66 synthesis for high purity are multifaceted, involving complex reaction kinetics, heat and mass transfer limitations, and the need for sophisticated analytical methods to characterize impurities at increasingly lower detection limits. Addressing these challenges requires interdisciplinary approaches combining polymer chemistry, chemical engineering, and materials science.

This technical research aims to comprehensively evaluate current Nylon 66 synthesis methodologies, identify critical parameters affecting product purity, and explore innovative approaches to overcome existing limitations. The ultimate goal is to establish robust, scalable processes capable of consistently producing Nylon 66 with impurity levels below 0.1%, while maintaining economic viability and sustainability in industrial settings.

Market Demand Analysis for High-Purity Nylon 66

The global market for high-purity Nylon 66 continues to expand significantly, driven primarily by increasing demands from automotive, electronics, and industrial applications. Current market valuations place the high-purity Nylon 66 segment at approximately 2.5 billion USD, with projections indicating growth rates between 5-7% annually through 2028.

Automotive sector remains the largest consumer of high-purity Nylon 66, accounting for roughly 40% of total demand. This is attributed to the material's exceptional mechanical properties, heat resistance, and chemical stability, making it ideal for under-hood components and structural parts where purity directly impacts performance and longevity. The trend toward vehicle electrification has further intensified demand, as high-purity polymers are essential for battery components and high-voltage insulation systems.

Electronics manufacturing represents the fastest-growing application segment, with demand increasing at nearly 9% annually. The miniaturization of electronic devices and the expansion of 5G infrastructure require materials with consistent electrical properties and minimal impurities. High-purity Nylon 66 meets these requirements, particularly for connectors, switches, and circuit board components where even trace contaminants can compromise performance.

Regional analysis reveals Asia-Pacific as the dominant market, consuming approximately 45% of global high-purity Nylon 66 production. China and Japan lead this demand, followed by South Korea and India. North America and Europe together account for roughly 48% of the market, with specialized applications in aerospace and medical devices driving premium segment growth.

Price sensitivity analysis indicates that while high-purity grades command a 30-40% premium over standard Nylon 66, manufacturers are increasingly willing to absorb these costs due to the performance benefits and reduced failure rates. This trend is particularly evident in critical applications where material failure carries significant consequences.

Supply chain constraints have emerged as a significant market factor since 2020. Adiponitrile (ADN) shortages, a key precursor for hexamethylenediamine in Nylon 66 production, have created bottlenecks that disproportionately affect high-purity grades. This has prompted several major chemical companies to announce capacity expansions specifically targeting high-purity production capabilities.

Environmental regulations are reshaping market dynamics, with particular emphasis on reducing emissions during the synthesis process. Manufacturers capable of producing high-purity Nylon 66 through more sustainable methods are gaining competitive advantages, especially in European markets where regulatory pressures are most intense.

Automotive sector remains the largest consumer of high-purity Nylon 66, accounting for roughly 40% of total demand. This is attributed to the material's exceptional mechanical properties, heat resistance, and chemical stability, making it ideal for under-hood components and structural parts where purity directly impacts performance and longevity. The trend toward vehicle electrification has further intensified demand, as high-purity polymers are essential for battery components and high-voltage insulation systems.

Electronics manufacturing represents the fastest-growing application segment, with demand increasing at nearly 9% annually. The miniaturization of electronic devices and the expansion of 5G infrastructure require materials with consistent electrical properties and minimal impurities. High-purity Nylon 66 meets these requirements, particularly for connectors, switches, and circuit board components where even trace contaminants can compromise performance.

Regional analysis reveals Asia-Pacific as the dominant market, consuming approximately 45% of global high-purity Nylon 66 production. China and Japan lead this demand, followed by South Korea and India. North America and Europe together account for roughly 48% of the market, with specialized applications in aerospace and medical devices driving premium segment growth.

Price sensitivity analysis indicates that while high-purity grades command a 30-40% premium over standard Nylon 66, manufacturers are increasingly willing to absorb these costs due to the performance benefits and reduced failure rates. This trend is particularly evident in critical applications where material failure carries significant consequences.

Supply chain constraints have emerged as a significant market factor since 2020. Adiponitrile (ADN) shortages, a key precursor for hexamethylenediamine in Nylon 66 production, have created bottlenecks that disproportionately affect high-purity grades. This has prompted several major chemical companies to announce capacity expansions specifically targeting high-purity production capabilities.

Environmental regulations are reshaping market dynamics, with particular emphasis on reducing emissions during the synthesis process. Manufacturers capable of producing high-purity Nylon 66 through more sustainable methods are gaining competitive advantages, especially in European markets where regulatory pressures are most intense.

Current Synthesis Challenges and Technical Limitations

Despite significant advancements in Nylon 66 synthesis over decades, several persistent challenges continue to limit the achievement of high-purity products. The conventional adipic acid-hexamethylenediamine condensation polymerization process suffers from inherent limitations that affect final product quality. Temperature control during polymerization represents a critical challenge, as even minor fluctuations can lead to side reactions, resulting in unwanted byproducts that compromise polymer purity and mechanical properties.

Oxygen contamination during synthesis remains problematic, causing oxidative degradation of monomers and polymer chains. This degradation manifests as discoloration, reduced molecular weight, and inconsistent mechanical properties in the final product. Current industrial processes struggle to maintain completely oxygen-free environments throughout the entire synthesis process, particularly during high-temperature phases.

Water management presents another significant hurdle in achieving high-purity Nylon 66. The condensation reaction produces water as a byproduct, which must be efficiently removed to drive the reaction toward completion. Inadequate water removal leads to hydrolysis of amide bonds, reducing molecular weight and creating terminal groups that affect crystallinity and thermal stability.

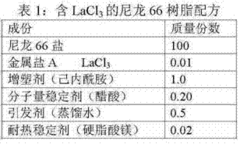

Catalyst selection and concentration optimization remain challenging aspects of the synthesis process. Traditional catalysts like phosphoric acid and phenylphosphinic acid can introduce impurities or cause side reactions when not precisely controlled. Finding catalysts that promote selective reactions while minimizing unwanted pathways continues to challenge researchers and manufacturers alike.

The formation of cyclic oligomers during polymerization represents another technical limitation. These cyclic structures not only reduce the molecular weight of the polymer but also act as plasticizers that alter the mechanical properties of the final product. Current technologies struggle to minimize their formation without compromising reaction rates or yields.

Monomer purity itself presents a fundamental challenge. Commercial-grade adipic acid and hexamethylenediamine often contain trace impurities that can initiate side reactions or terminate growing polymer chains prematurely. The economic feasibility of using ultra-high-purity monomers at industrial scales remains questionable, forcing manufacturers to develop processes that can accommodate less-than-ideal starting materials.

Equipment design limitations also impact synthesis optimization. Reactor geometry, mixing efficiency, and heat transfer capabilities can create localized "hot spots" or concentration gradients that promote side reactions. Scaling up laboratory-optimized processes to industrial production volumes introduces additional variables that can compromise product purity and consistency.

Oxygen contamination during synthesis remains problematic, causing oxidative degradation of monomers and polymer chains. This degradation manifests as discoloration, reduced molecular weight, and inconsistent mechanical properties in the final product. Current industrial processes struggle to maintain completely oxygen-free environments throughout the entire synthesis process, particularly during high-temperature phases.

Water management presents another significant hurdle in achieving high-purity Nylon 66. The condensation reaction produces water as a byproduct, which must be efficiently removed to drive the reaction toward completion. Inadequate water removal leads to hydrolysis of amide bonds, reducing molecular weight and creating terminal groups that affect crystallinity and thermal stability.

Catalyst selection and concentration optimization remain challenging aspects of the synthesis process. Traditional catalysts like phosphoric acid and phenylphosphinic acid can introduce impurities or cause side reactions when not precisely controlled. Finding catalysts that promote selective reactions while minimizing unwanted pathways continues to challenge researchers and manufacturers alike.

The formation of cyclic oligomers during polymerization represents another technical limitation. These cyclic structures not only reduce the molecular weight of the polymer but also act as plasticizers that alter the mechanical properties of the final product. Current technologies struggle to minimize their formation without compromising reaction rates or yields.

Monomer purity itself presents a fundamental challenge. Commercial-grade adipic acid and hexamethylenediamine often contain trace impurities that can initiate side reactions or terminate growing polymer chains prematurely. The economic feasibility of using ultra-high-purity monomers at industrial scales remains questionable, forcing manufacturers to develop processes that can accommodate less-than-ideal starting materials.

Equipment design limitations also impact synthesis optimization. Reactor geometry, mixing efficiency, and heat transfer capabilities can create localized "hot spots" or concentration gradients that promote side reactions. Scaling up laboratory-optimized processes to industrial production volumes introduces additional variables that can compromise product purity and consistency.

Current High-Purity Synthesis Approaches

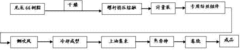

01 Purification methods for nylon 66 monomers

Various purification techniques are employed to ensure high purity of hexamethylenediamine and adipic acid monomers before polymerization. These methods include crystallization, distillation, and filtration processes that remove impurities which could negatively affect polymer properties. Purified monomers lead to higher molecular weight polymers with improved mechanical properties and thermal stability.- Purification methods for nylon 66 monomers: Various purification techniques are employed to ensure high-quality monomers for nylon 66 synthesis. These methods include crystallization, distillation, and filtration processes to remove impurities from adipic acid and hexamethylenediamine. Purified monomers lead to higher molecular weight polymers with improved mechanical properties and thermal stability, which is essential for high-performance applications.

- Catalyst systems for high-purity polymerization: Specialized catalyst systems can significantly impact the purity of synthesized nylon 66. These catalysts promote controlled polymerization reactions while minimizing side reactions that could introduce impurities. Advanced catalysts help achieve higher conversion rates, more uniform molecular weight distribution, and fewer byproducts, resulting in nylon 66 with superior properties for demanding applications.

- Post-polymerization purification techniques: After the initial polymerization of nylon 66, various post-processing methods can be applied to enhance purity. These include extraction processes, solid-state polymerization, and washing treatments to remove residual monomers, oligomers, and other contaminants. These techniques are crucial for achieving high-purity nylon 66 suitable for specialized applications requiring exceptional mechanical and thermal properties.

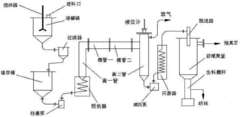

- Continuous process optimization for purity control: Continuous manufacturing processes for nylon 66 synthesis offer advantages for maintaining consistent purity levels. These processes involve precise control of reaction parameters such as temperature, pressure, and residence time, along with in-line monitoring systems. Optimized continuous processes minimize thermal degradation and side reactions, resulting in higher purity products with fewer color-forming impurities and more consistent properties.

- Analytical methods for purity assessment: Advanced analytical techniques are essential for evaluating the purity of synthesized nylon 66. These methods include high-performance liquid chromatography, gel permeation chromatography, spectroscopic techniques, and thermal analysis. Accurate purity assessment enables quality control throughout the manufacturing process, ensuring that the final nylon 66 product meets stringent specifications for high-performance applications in automotive, electrical, and industrial sectors.

02 Catalyst systems for high-purity synthesis

Specialized catalyst systems are used to enhance the polymerization reaction while minimizing side reactions that produce impurities. These catalysts control the reaction kinetics and improve conversion rates, resulting in higher molecular weight polymers with narrower molecular weight distribution. Proper catalyst selection and concentration are critical for achieving high-purity nylon 66 with consistent properties.Expand Specific Solutions03 Post-polymerization purification techniques

After polymerization, various techniques are employed to remove residual monomers, oligomers, and other impurities from nylon 66. These include solid-state polymerization, extraction processes, and washing treatments. These post-processing steps significantly improve the purity of the final product, enhancing its mechanical properties, color stability, and suitability for high-performance applications.Expand Specific Solutions04 Equipment and process optimization for high-purity synthesis

Specialized equipment designs and process parameters are critical for achieving high-purity nylon 66. This includes reactor design, precise temperature control systems, and optimized reaction conditions. Continuous polymerization processes with controlled residence time and efficient mixing can significantly reduce impurity formation. Advanced monitoring systems help maintain consistent quality throughout the production process.Expand Specific Solutions05 Analytical methods for purity determination

Various analytical techniques are employed to assess the purity of nylon 66 during and after synthesis. These include spectroscopic methods, chromatography, thermal analysis, and end-group titration. These techniques help identify and quantify impurities, determine molecular weight distribution, and verify the chemical structure of the polymer. Accurate purity determination is essential for quality control and ensuring the polymer meets application requirements.Expand Specific Solutions

Key Industrial Players in Nylon 66 Production

The Nylon 66 synthesis optimization market is currently in a mature growth phase with increasing demand for high-purity applications across automotive, textile, and engineering sectors. The global market size for Nylon 66 exceeds $7 billion, with projected annual growth of 5-7%. In terms of technical maturity, industry leaders like Toray Industries and China Shenma Group have established advanced synthesis processes, while companies such as Kingfa Sci. & Tech. and Shanghai PRET Composites are developing innovative catalytic methods for higher purity yields. Academic institutions including Beijing University of Chemical Technology and Donghua University are contributing significant research in reaction optimization and impurity control. The competitive landscape shows a balance between established chemical conglomerates and specialized materials companies focusing on high-performance applications requiring ultra-pure Nylon 66.

Toray Industries, Inc.

Technical Solution: Toray has developed a proprietary two-stage polymerization process for high-purity Nylon 66 synthesis that combines continuous and batch processing techniques. Their approach utilizes precise temperature control during the salt formation stage (70-80°C) followed by a controlled pressure reduction system during polycondensation that gradually decreases from 1.8 MPa to atmospheric pressure. This method incorporates a multi-stage extraction process to remove cyclic oligomers and low molecular weight impurities. Toray's process employs proprietary metal-based catalysts (typically titanium and phosphorus compounds) at concentrations below 50 ppm to minimize discoloration while maintaining reaction kinetics. Their system includes inline NIR spectroscopy monitoring to provide real-time molecular weight distribution data, allowing for adaptive process control that optimizes residence time based on polymerization progression.

Strengths: Superior control over molecular weight distribution (polydispersity index consistently below 2.2); excellent thermal stability with decomposition temperatures exceeding 350°C; reduced formation of cyclic oligomers (below 1.5% in final product). Weaknesses: Higher capital equipment costs; more complex process control requirements; slightly longer production cycle compared to single-stage processes.

China Shenma Group Co. Ltd.

Technical Solution: China Shenma Group has pioneered an integrated continuous polymerization technology for high-purity Nylon 66 production. Their process features a salt solution preparation system that maintains precise stoichiometric balance between hexamethylenediamine and adipic acid (molar ratio controlled to 1.00±0.005), coupled with advanced filtration technology that removes particulate impurities down to 0.5 microns. The polymerization occurs in a series of specially designed reactors with progressively increasing temperatures (220°C to 280°C) and decreasing pressures. Their innovation includes a proprietary vapor phase extraction system that continuously removes water and volatile byproducts, significantly reducing side reactions. Shenma employs a combination of phosphorus-based stabilizers and rare earth metal catalysts that enhance reaction rates while minimizing unwanted branching reactions. The process incorporates online viscosity measurement and automated pressure control systems that adjust process parameters in real-time to maintain consistent polymer properties.

Strengths: Exceptional product consistency with molecular weight variations below 3% between batches; high production efficiency with throughput exceeding 150 kg/hour per production line; reduced energy consumption compared to batch processes. Weaknesses: Higher sensitivity to feedstock quality variations; requires more sophisticated control systems and operator expertise; initial capital investment approximately 15-20% higher than conventional systems.

Critical Patents and Innovations in Purification Techniques

A synthesis method of nylon 66 and nylon 66

PatentActiveCN115612292B

Innovation

- Adding carbon black and antioxidant CA to the nylon 66 salt water solution, and performing pressure holding and vacuum treatment at high temperatures, combined with the use of polyphosphoric acid, significantly improves the heat aging resistance of nylon 66 and simplifies the synthesis process.

Nylon 66 resin, nylon 66 filament and preparation method thereof

PatentInactiveCN102206338B

Innovation

- Rare earth metal compounds are added to the nylon 66 salt melt, and special resins are produced through polymerization and post-polycondensation reactions. A transverse tube continuous polycondensation process is used to control spinning parameters such as temperature, pressure and spinneret aperture to achieve spinning of fine denier or Ultra-fine denier nylon 66 filament.

Environmental Impact and Sustainability Considerations

The synthesis of Nylon 66 presents significant environmental challenges that must be addressed to ensure sustainable production practices. Traditional manufacturing processes consume substantial energy and generate considerable waste, with the production of adipic acid—a key precursor—being particularly problematic due to its release of nitrous oxide (N2O), a potent greenhouse gas with approximately 300 times the global warming potential of carbon dioxide. Current estimates suggest that adipic acid production contributes to approximately 10% of global industrial N2O emissions.

Water usage represents another critical environmental concern in Nylon 66 synthesis. Conventional processes require large volumes of water for cooling, washing, and as a reaction medium. This not only depletes local water resources but also generates contaminated wastewater containing unreacted monomers, catalysts, and various organic compounds that require extensive treatment before discharge.

Chemical waste management poses additional challenges, as the synthesis involves hazardous substances including hexamethylenediamine and adipic acid, which can cause environmental damage if improperly handled. The purification stages, essential for high-purity production, often employ solvents and additives that further contribute to the environmental footprint of the process.

Recent sustainability innovations focus on developing catalytic systems that operate at lower temperatures and pressures, significantly reducing energy requirements. Green chemistry approaches have emerged, including bio-based alternatives for adipic acid production using glucose or other renewable feedstocks. These methods can reduce greenhouse gas emissions by up to 95% compared to conventional petroleum-based processes.

Closed-loop manufacturing systems represent another promising direction, enabling the recovery and reuse of solvents, unreacted monomers, and process water. Some advanced facilities have achieved water recycling rates exceeding 80%, dramatically reducing freshwater consumption and wastewater generation.

Life cycle assessment (LCA) studies indicate that optimizing Nylon 66 synthesis for high purity often involves environmental trade-offs. While more rigorous purification may yield higher-quality product, it typically requires additional energy and resources. Finding the optimal balance between product quality and environmental impact remains a key challenge for manufacturers seeking to improve sustainability metrics while maintaining commercial viability.

Regulatory frameworks increasingly influence production methods, with stricter emissions standards and extended producer responsibility policies driving innovation toward cleaner technologies. Companies leading in sustainable Nylon 66 production have demonstrated that environmental improvements can coincide with economic benefits through reduced resource consumption and waste management costs.

Water usage represents another critical environmental concern in Nylon 66 synthesis. Conventional processes require large volumes of water for cooling, washing, and as a reaction medium. This not only depletes local water resources but also generates contaminated wastewater containing unreacted monomers, catalysts, and various organic compounds that require extensive treatment before discharge.

Chemical waste management poses additional challenges, as the synthesis involves hazardous substances including hexamethylenediamine and adipic acid, which can cause environmental damage if improperly handled. The purification stages, essential for high-purity production, often employ solvents and additives that further contribute to the environmental footprint of the process.

Recent sustainability innovations focus on developing catalytic systems that operate at lower temperatures and pressures, significantly reducing energy requirements. Green chemistry approaches have emerged, including bio-based alternatives for adipic acid production using glucose or other renewable feedstocks. These methods can reduce greenhouse gas emissions by up to 95% compared to conventional petroleum-based processes.

Closed-loop manufacturing systems represent another promising direction, enabling the recovery and reuse of solvents, unreacted monomers, and process water. Some advanced facilities have achieved water recycling rates exceeding 80%, dramatically reducing freshwater consumption and wastewater generation.

Life cycle assessment (LCA) studies indicate that optimizing Nylon 66 synthesis for high purity often involves environmental trade-offs. While more rigorous purification may yield higher-quality product, it typically requires additional energy and resources. Finding the optimal balance between product quality and environmental impact remains a key challenge for manufacturers seeking to improve sustainability metrics while maintaining commercial viability.

Regulatory frameworks increasingly influence production methods, with stricter emissions standards and extended producer responsibility policies driving innovation toward cleaner technologies. Companies leading in sustainable Nylon 66 production have demonstrated that environmental improvements can coincide with economic benefits through reduced resource consumption and waste management costs.

Quality Control and Characterization Methods

Quality control and characterization methods are critical components in the optimization of Nylon 66 synthesis for high purity. Effective quality assessment begins with comprehensive raw material testing, where hexamethylenediamine and adipic acid must be evaluated for purity levels exceeding 99.5%. Impurity profiling through gas chromatography-mass spectrometry (GC-MS) and high-performance liquid chromatography (HPLC) enables the detection of trace contaminants that could compromise the final polymer quality.

During the polymerization process, in-line monitoring techniques provide real-time data on reaction progression. Viscometry measurements track the increasing molecular weight, while spectroscopic methods such as Fourier-transform infrared spectroscopy (FTIR) monitor functional group transformations. These continuous assessment methods allow for immediate process adjustments to maintain optimal synthesis conditions.

For final product characterization, differential scanning calorimetry (DSC) determines the melting point and crystallinity of the polymer, with high-purity Nylon 66 typically exhibiting a sharp melting point at 255-265°C. Thermogravimetric analysis (TGA) assesses thermal stability and decomposition behavior, providing insights into the polymer's structural integrity.

Molecular weight distribution analysis via gel permeation chromatography (GPC) serves as a critical quality indicator, with narrower distributions generally correlating with more consistent mechanical properties. End-group analysis through titration methods quantifies the concentration of terminal amine and carboxylic acid groups, which directly impacts the polymer's reactivity in subsequent processing steps.

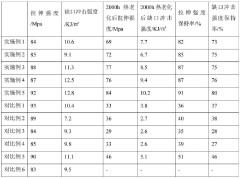

Mechanical testing protocols, including tensile strength, elongation at break, and impact resistance measurements, provide practical performance metrics that correlate with molecular structure and purity. For ultra-high purity applications, advanced techniques such as nuclear magnetic resonance (NMR) spectroscopy can detect structural anomalies at the molecular level.

Statistical process control (SPC) methodologies should be implemented to establish control limits for key quality parameters. This approach enables the identification of process drift before it results in quality deviations. Additionally, accelerated aging tests help predict long-term stability and performance under various environmental conditions, ensuring that the high-purity Nylon 66 maintains its properties throughout its intended service life.

During the polymerization process, in-line monitoring techniques provide real-time data on reaction progression. Viscometry measurements track the increasing molecular weight, while spectroscopic methods such as Fourier-transform infrared spectroscopy (FTIR) monitor functional group transformations. These continuous assessment methods allow for immediate process adjustments to maintain optimal synthesis conditions.

For final product characterization, differential scanning calorimetry (DSC) determines the melting point and crystallinity of the polymer, with high-purity Nylon 66 typically exhibiting a sharp melting point at 255-265°C. Thermogravimetric analysis (TGA) assesses thermal stability and decomposition behavior, providing insights into the polymer's structural integrity.

Molecular weight distribution analysis via gel permeation chromatography (GPC) serves as a critical quality indicator, with narrower distributions generally correlating with more consistent mechanical properties. End-group analysis through titration methods quantifies the concentration of terminal amine and carboxylic acid groups, which directly impacts the polymer's reactivity in subsequent processing steps.

Mechanical testing protocols, including tensile strength, elongation at break, and impact resistance measurements, provide practical performance metrics that correlate with molecular structure and purity. For ultra-high purity applications, advanced techniques such as nuclear magnetic resonance (NMR) spectroscopy can detect structural anomalies at the molecular level.

Statistical process control (SPC) methodologies should be implemented to establish control limits for key quality parameters. This approach enables the identification of process drift before it results in quality deviations. Additionally, accelerated aging tests help predict long-term stability and performance under various environmental conditions, ensuring that the high-purity Nylon 66 maintains its properties throughout its intended service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!