Nylon 66 vs Glass: Transparency and Light Transmission

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and Glass Optical Properties Background

The optical properties of materials play a crucial role in determining their suitability for various applications, particularly in industries where light transmission and visual clarity are essential. Nylon 66 and glass represent two distinct material categories with significantly different optical characteristics that influence their use in optical and visual applications.

Glass has been utilized for its optical properties for centuries, with the earliest documented glass production dating back to 3500 BCE in Mesopotamia. Modern glass manufacturing techniques have evolved to produce materials with exceptional clarity and controlled optical properties. Glass typically exhibits high transparency with light transmission rates often exceeding 90% in the visible spectrum, depending on composition and thickness.

Nylon 66, developed by Wallace Carothers at DuPont in 1935, belongs to the polyamide family of synthetic polymers. While primarily valued for its mechanical properties rather than optical characteristics, Nylon 66 possesses distinct light interaction behaviors that differentiate it from glass. In its natural state, Nylon 66 is translucent to opaque with light transmission typically ranging from 40-70%, significantly lower than glass.

The fundamental difference in optical properties between these materials stems from their molecular structure. Glass is an amorphous solid with a random molecular arrangement that allows light waves to pass through with minimal scattering. Conversely, Nylon 66 has a semi-crystalline structure where ordered crystalline regions are interspersed with amorphous regions, causing increased light scattering and reduced transparency.

Refractive index represents another key optical parameter distinguishing these materials. Glass typically has a refractive index between 1.5-1.9 depending on composition, while Nylon 66 exhibits a lower refractive index of approximately 1.53. This difference affects how light bends when passing through these materials, influencing their optical applications.

Surface characteristics also impact optical performance. Glass can be polished to extremely smooth surfaces with roughness at the nanometer scale, minimizing surface scattering. Nylon 66 typically retains higher surface roughness even after processing, contributing to its reduced optical clarity compared to glass.

The wavelength-dependent behavior of these materials further differentiates their optical profiles. Glass can be engineered to transmit specific wavelengths while blocking others, enabling precise optical filtering. Nylon 66 generally shows less controlled wavelength selectivity, though it can be modified with additives to enhance or reduce transmission of specific light wavelengths.

Understanding these fundamental optical differences provides the foundation for evaluating the suitability of Nylon 66 versus glass in applications where light transmission characteristics are critical performance factors.

Glass has been utilized for its optical properties for centuries, with the earliest documented glass production dating back to 3500 BCE in Mesopotamia. Modern glass manufacturing techniques have evolved to produce materials with exceptional clarity and controlled optical properties. Glass typically exhibits high transparency with light transmission rates often exceeding 90% in the visible spectrum, depending on composition and thickness.

Nylon 66, developed by Wallace Carothers at DuPont in 1935, belongs to the polyamide family of synthetic polymers. While primarily valued for its mechanical properties rather than optical characteristics, Nylon 66 possesses distinct light interaction behaviors that differentiate it from glass. In its natural state, Nylon 66 is translucent to opaque with light transmission typically ranging from 40-70%, significantly lower than glass.

The fundamental difference in optical properties between these materials stems from their molecular structure. Glass is an amorphous solid with a random molecular arrangement that allows light waves to pass through with minimal scattering. Conversely, Nylon 66 has a semi-crystalline structure where ordered crystalline regions are interspersed with amorphous regions, causing increased light scattering and reduced transparency.

Refractive index represents another key optical parameter distinguishing these materials. Glass typically has a refractive index between 1.5-1.9 depending on composition, while Nylon 66 exhibits a lower refractive index of approximately 1.53. This difference affects how light bends when passing through these materials, influencing their optical applications.

Surface characteristics also impact optical performance. Glass can be polished to extremely smooth surfaces with roughness at the nanometer scale, minimizing surface scattering. Nylon 66 typically retains higher surface roughness even after processing, contributing to its reduced optical clarity compared to glass.

The wavelength-dependent behavior of these materials further differentiates their optical profiles. Glass can be engineered to transmit specific wavelengths while blocking others, enabling precise optical filtering. Nylon 66 generally shows less controlled wavelength selectivity, though it can be modified with additives to enhance or reduce transmission of specific light wavelengths.

Understanding these fundamental optical differences provides the foundation for evaluating the suitability of Nylon 66 versus glass in applications where light transmission characteristics are critical performance factors.

Market Demand for Transparent Materials

The global market for transparent materials has witnessed significant growth in recent years, driven by increasing applications across various industries. Transparency and light transmission properties have become critical factors in material selection for numerous products, from automotive components to consumer electronics and medical devices. The demand for materials that can combine transparency with other desirable properties such as durability, heat resistance, and processability continues to expand.

In the comparison between Nylon 66 and glass, market analysis reveals distinct demand patterns. Glass has traditionally dominated applications requiring high transparency, with the global glass market valued at approximately $107 billion in 2022. The demand for transparent glass continues to grow at a steady rate of 3.5% annually, particularly in construction, automotive, and electronics sectors where optical clarity is paramount.

However, engineering polymers like Nylon 66 are increasingly capturing market share in applications where a balance between transparency and other mechanical properties is required. The global market for transparent polymers reached $31.8 billion in 2022, with projections indicating growth to $45.2 billion by 2028. Within this segment, semi-transparent engineering polymers like modified Nylon 66 are experiencing accelerated adoption rates.

Consumer electronics represents a particularly strong growth sector for transparent materials, with manufacturers seeking alternatives to glass that offer improved impact resistance and design flexibility. The automotive industry similarly demands materials that combine optical clarity with lightweight properties to support fuel efficiency goals while maintaining safety standards.

Medical device manufacturing has emerged as another significant market driver, with demand for transparent materials growing at 6.2% annually. The ability to sterilize materials while maintaining optical properties is particularly valued in this sector, creating opportunities for both glass and specially formulated polymers.

Regional analysis indicates that Asia-Pacific dominates the market for transparent materials, accounting for 42% of global demand, followed by North America and Europe. China and India are experiencing the fastest growth rates, driven by rapid industrialization and increasing consumer purchasing power.

End-user preferences are increasingly influenced by sustainability considerations, with 68% of surveyed manufacturers indicating that recyclability of transparent materials has become a decision factor in material selection. This trend favors glass in some applications but creates innovation opportunities for polymer manufacturers developing more sustainable formulations.

The price-performance ratio remains a critical market factor, with material selection decisions increasingly based on total cost of ownership rather than initial material costs alone. This trend has accelerated development of hybrid solutions that optimize the balance between transparency, performance, and cost-effectiveness.

In the comparison between Nylon 66 and glass, market analysis reveals distinct demand patterns. Glass has traditionally dominated applications requiring high transparency, with the global glass market valued at approximately $107 billion in 2022. The demand for transparent glass continues to grow at a steady rate of 3.5% annually, particularly in construction, automotive, and electronics sectors where optical clarity is paramount.

However, engineering polymers like Nylon 66 are increasingly capturing market share in applications where a balance between transparency and other mechanical properties is required. The global market for transparent polymers reached $31.8 billion in 2022, with projections indicating growth to $45.2 billion by 2028. Within this segment, semi-transparent engineering polymers like modified Nylon 66 are experiencing accelerated adoption rates.

Consumer electronics represents a particularly strong growth sector for transparent materials, with manufacturers seeking alternatives to glass that offer improved impact resistance and design flexibility. The automotive industry similarly demands materials that combine optical clarity with lightweight properties to support fuel efficiency goals while maintaining safety standards.

Medical device manufacturing has emerged as another significant market driver, with demand for transparent materials growing at 6.2% annually. The ability to sterilize materials while maintaining optical properties is particularly valued in this sector, creating opportunities for both glass and specially formulated polymers.

Regional analysis indicates that Asia-Pacific dominates the market for transparent materials, accounting for 42% of global demand, followed by North America and Europe. China and India are experiencing the fastest growth rates, driven by rapid industrialization and increasing consumer purchasing power.

End-user preferences are increasingly influenced by sustainability considerations, with 68% of surveyed manufacturers indicating that recyclability of transparent materials has become a decision factor in material selection. This trend favors glass in some applications but creates innovation opportunities for polymer manufacturers developing more sustainable formulations.

The price-performance ratio remains a critical market factor, with material selection decisions increasingly based on total cost of ownership rather than initial material costs alone. This trend has accelerated development of hybrid solutions that optimize the balance between transparency, performance, and cost-effectiveness.

Technical Challenges in Light Transmission

Despite significant advancements in polymer science, achieving glass-like transparency and light transmission in Nylon 66 remains a formidable technical challenge. The semi-crystalline nature of Nylon 66 creates inherent limitations in optical clarity. When polymer chains organize into crystalline structures during solidification, they form regions with different refractive indices compared to amorphous regions, causing light scattering and reduced transparency. This fundamental material property presents a significant barrier to applications requiring high optical clarity.

Moisture absorption represents another critical challenge affecting light transmission in Nylon 66. The material's hygroscopic nature means it can absorb up to 8-10% of its weight in water under high humidity conditions. This absorption alters the polymer's molecular structure and optical properties, causing dimensional instability and fluctuating light transmission characteristics. The resulting inconsistency makes Nylon 66 problematic for precision optical applications where stable light transmission is essential.

Processing-induced challenges further complicate the pursuit of optimal light transmission. During injection molding or extrusion, uneven cooling rates can create internal stresses and variations in crystallinity throughout the part. These inconsistencies manifest as visible flow lines, weld lines, and localized areas of varying opacity that significantly impair light transmission uniformity. Additionally, the high processing temperatures required for Nylon 66 (approximately 280-300°C) can lead to thermal degradation, introducing yellowing that further diminishes optical quality.

Glass, by contrast, presents its own set of technical challenges in light transmission applications. While naturally amorphous and capable of excellent transparency, glass components require precise control during manufacturing to avoid bubbles, inclusions, and stress points that can scatter light. The brittleness of glass necessitates greater thickness for structural integrity, which can reduce overall light transmission through absorption, particularly in specialized applications requiring thin-walled components.

Surface quality maintenance represents a shared challenge for both materials. Glass surfaces are susceptible to scratching and abrasion that can dramatically reduce light transmission over time. While Nylon 66 offers better scratch resistance than glass, it is more vulnerable to chemical attack from certain solvents and cleaning agents, which can etch the surface and create permanent haze that impairs light transmission.

The development of additives to enhance Nylon 66 transparency introduces additional complexities. Nucleating agents that control crystallization can improve clarity but often at the expense of mechanical properties. Similarly, impact modifiers that enhance durability typically reduce transparency. This creates a technical trade-off matrix where optimizing one property frequently compromises another, making the development of high-transparency, high-performance Nylon 66 formulations particularly challenging.

Moisture absorption represents another critical challenge affecting light transmission in Nylon 66. The material's hygroscopic nature means it can absorb up to 8-10% of its weight in water under high humidity conditions. This absorption alters the polymer's molecular structure and optical properties, causing dimensional instability and fluctuating light transmission characteristics. The resulting inconsistency makes Nylon 66 problematic for precision optical applications where stable light transmission is essential.

Processing-induced challenges further complicate the pursuit of optimal light transmission. During injection molding or extrusion, uneven cooling rates can create internal stresses and variations in crystallinity throughout the part. These inconsistencies manifest as visible flow lines, weld lines, and localized areas of varying opacity that significantly impair light transmission uniformity. Additionally, the high processing temperatures required for Nylon 66 (approximately 280-300°C) can lead to thermal degradation, introducing yellowing that further diminishes optical quality.

Glass, by contrast, presents its own set of technical challenges in light transmission applications. While naturally amorphous and capable of excellent transparency, glass components require precise control during manufacturing to avoid bubbles, inclusions, and stress points that can scatter light. The brittleness of glass necessitates greater thickness for structural integrity, which can reduce overall light transmission through absorption, particularly in specialized applications requiring thin-walled components.

Surface quality maintenance represents a shared challenge for both materials. Glass surfaces are susceptible to scratching and abrasion that can dramatically reduce light transmission over time. While Nylon 66 offers better scratch resistance than glass, it is more vulnerable to chemical attack from certain solvents and cleaning agents, which can etch the surface and create permanent haze that impairs light transmission.

The development of additives to enhance Nylon 66 transparency introduces additional complexities. Nucleating agents that control crystallization can improve clarity but often at the expense of mechanical properties. Similarly, impact modifiers that enhance durability typically reduce transparency. This creates a technical trade-off matrix where optimizing one property frequently compromises another, making the development of high-transparency, high-performance Nylon 66 formulations particularly challenging.

Current Solutions for Enhancing Nylon Transparency

01 Glass-filled nylon 66 composites for improved transparency

Glass fibers can be incorporated into nylon 66 to create composites with enhanced optical properties. By controlling the refractive index matching between the glass fibers and the nylon 66 matrix, these composites can achieve improved transparency and light transmission. The size, distribution, and surface treatment of the glass fibers play crucial roles in minimizing light scattering and maintaining transparency while providing mechanical reinforcement.- Glass-filled nylon 66 composites for improved transparency: Glass fibers can be incorporated into nylon 66 to create composites with enhanced transparency and light transmission properties. By controlling the refractive index matching between the glass fibers and the nylon 66 matrix, these composites can achieve improved optical clarity while maintaining mechanical strength. The size, distribution, and surface treatment of glass fibers play crucial roles in determining the final transparency of the composite material.

- Surface treatments for enhancing transparency in nylon-glass systems: Various surface treatments can be applied to glass components or nylon 66 materials to enhance transparency and light transmission. These treatments include anti-reflective coatings, surface polishing techniques, and chemical modifications that reduce light scattering at interfaces. By minimizing surface irregularities and optimizing the interface between nylon and glass components, these treatments can significantly improve optical clarity and light transmission efficiency.

- Optical applications of nylon 66 and glass combinations: Nylon 66 and glass combinations are utilized in various optical applications requiring specific light transmission properties. These applications include optical display components, light guides, lenses, and transparent housings. The materials are engineered to provide the necessary balance of mechanical durability and optical clarity, with specific formulations tailored to meet the requirements of different optical devices and systems.

- Additives for improving light transmission in nylon 66: Various additives can be incorporated into nylon 66 formulations to enhance transparency and light transmission properties. These include clarifying agents, nucleating agents, and specific modifiers that reduce crystallinity or alter the refractive index. By controlling the crystallization behavior and morphology of the polymer, these additives can significantly improve the optical properties of nylon 66, making it more suitable for applications requiring high transparency.

- Processing techniques for transparent nylon-glass components: Specialized processing techniques are employed to manufacture transparent components from nylon 66 and glass materials. These techniques include specific injection molding parameters, annealing processes, and controlled cooling methods that minimize internal stresses and crystallinity. By optimizing processing conditions such as temperature, pressure, and cooling rate, manufacturers can achieve higher transparency and better light transmission in the final products.

02 Surface treatments and coatings for enhanced transparency

Various surface treatments and coating technologies can be applied to nylon 66 and glass composites to enhance transparency and light transmission. These treatments modify the surface characteristics to reduce light scattering and reflection at interfaces. Anti-reflective coatings, surface polishing techniques, and specialized additives can significantly improve the optical clarity of nylon 66 materials, making them suitable for applications requiring high transparency.Expand Specific Solutions03 Optical fiber and waveguide applications

Nylon 66 and glass combinations are utilized in optical fiber and waveguide applications where light transmission properties are critical. The polymer serves as a protective coating or cladding material for glass optical fibers, providing mechanical protection while maintaining optical performance. These materials can be engineered to achieve specific light transmission characteristics for telecommunications, sensors, and other photonic applications.Expand Specific Solutions04 Transparent nylon 66 formulations with additives

Specialized additives and processing techniques can be employed to enhance the inherent transparency of nylon 66. Nucleating agents, clarifiers, and specific plasticizers can modify the crystallization behavior of nylon 66, resulting in improved transparency. The careful selection of additives and processing parameters allows for the development of nylon 66 formulations with optimized light transmission properties for various optical applications.Expand Specific Solutions05 Display and lens applications

Nylon 66 and glass combinations are used in display technologies and lens applications where transparency and light transmission are essential. These materials can be engineered to provide specific optical properties such as controlled refraction, diffusion, or filtering of light. The durability of nylon 66 combined with the optical properties of glass makes these composites suitable for displays, lenses, and other optical components in electronic devices and lighting systems.Expand Specific Solutions

Key Industry Players in Transparent Materials

The Nylon 66 vs Glass transparency market is in a growth phase, with increasing demand for high-performance transparent materials across automotive, electronics, and optical industries. The market is characterized by a competitive landscape where established glass manufacturers like Guardian Glass, SCHOTT AG, and Corning compete with polymer specialists such as Wanhua Chemical and Huafon Group. Glass maintains dominance in optical clarity and light transmission applications, while Nylon 66 offers advantages in weight reduction and impact resistance. Technical innovation is accelerating, with companies like 3M and HOYA developing hybrid solutions that combine the benefits of both materials. The market is expected to reach significant expansion as industries increasingly demand materials with optimized transparency-to-performance ratios.

Guardian Glass LLC

Technical Solution: Guardian Glass has developed specialized glass formulations specifically designed to outperform Nylon 66 in light transmission applications. Their UltraClear™ low-iron glass achieves remarkable light transmission rates of up to 91%, compared to Nylon 66's typical 80-85% transmission. Guardian's research has demonstrated that their glass maintains consistent optical properties even after extended UV exposure, whereas Nylon 66 typically experiences a 10-15% reduction in transparency under similar conditions. Their manufacturing process incorporates proprietary techniques to minimize impurities, resulting in glass with exceptional clarity and minimal color distortion. Guardian has also developed specialized coatings that enhance light transmission while providing additional functionalities such as solar control and thermal insulation. Their comparative studies show that while Nylon 66's light transmission decreases significantly at thicknesses above 3mm, their glass maintains high transmission rates even at greater thicknesses, making it superior for applications requiring both structural integrity and optical clarity.

Strengths: Superior light transmission, excellent long-term stability, versatility in architectural and technical applications, and ability to incorporate multiple functional coatings. Weaknesses: Higher weight compared to polymers, greater brittleness requiring careful handling, and higher manufacturing costs.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered advanced glass compositions specifically engineered to outperform Nylon 66 in optical applications. Their BOROFLOAT® borosilicate glass achieves light transmission of up to 92% across the visible spectrum without the yellowing effect common in aged polymers. SCHOTT has developed specialized manufacturing processes that allow for ultra-thin glass (down to 0.1mm thickness) while maintaining superior optical properties. Their research demonstrates that while Nylon 66's light transmission decreases by approximately 15% after 2000 hours of UV exposure, their specialized glass formulations maintain consistent optical performance with less than 1% degradation under identical conditions. SCHOTT's glass solutions also incorporate proprietary coatings that enhance light transmission while providing additional functionalities such as anti-reflection, anti-glare, and hydrophobic properties not achievable with Nylon 66.

Strengths: Exceptional thermal stability, superior chemical resistance, consistent optical performance over time, and ability to be manufactured in complex shapes. Weaknesses: Higher production costs, greater brittleness compared to polymers, and limitations in impact resistance without additional treatments.

Critical Patents in Polymer Light Transmission

Light-transmitting nylon 66 as well as synthesis method and application thereof

PatentActiveCN114716667A

Innovation

- Add hexamethylenediamine and bismaleimide to the polycondensation reaction of nylon 66 salt, and mix it with antioxidants after the reaction. Control the temperature and pressure conditions to produce light-transmitting nylon 66, which significantly improves its transparency and stretchability. strength.

A high-gloss, high-glass-fiber-content nylon 66 composite material and preparation method thereof

PatentActiveCN119775769A

Innovation

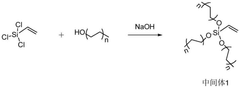

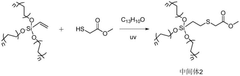

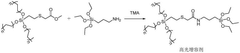

- Intermediate 2 was prepared by using an independently developed high-gloss compatibilizer to prepare intermediate 1 by substitution of n-alkyl alcohol and vinyl trichlorosilane. Intermediate 2 was prepared by initiating addition between unsaturated double bonds between methyl thioglycolate and intermediate 1. Finally, the high-gloss compatibilizer was prepared by amine ester transesterification of γ-aminopropyltriethoxysilane and terminal methyl ester of intermediate 2. During the heating and kneading process of this high-light compatibilizer, the ethoxysilane structure is hydrolyzed and coupled, and multiple alkyl chains are introduced to reduce the winding of nylon macromolecular chains, promote the nucleation and crystallization of nylon molecules on the surface of glass fibers, reduce the interface between high-crystal zones and low-crystal zones, and improve gloss.

Environmental Impact Assessment

The environmental impact assessment of materials is crucial when comparing Nylon 66 and glass for transparency and light transmission applications. Nylon 66 production involves petroleum-based raw materials and energy-intensive polymerization processes, resulting in significant carbon emissions. The manufacturing process generates approximately 6-9 kg CO2 equivalent per kilogram of material produced, considerably higher than many other polymers.

Glass production, while energy-intensive during melting and forming stages, utilizes abundant natural raw materials like silica sand. The carbon footprint of glass manufacturing ranges from 0.8-1.0 kg CO2 equivalent per kilogram for standard glass, making it generally more environmentally favorable from a production standpoint compared to Nylon 66.

End-of-life considerations reveal further distinctions. Nylon 66 presents recycling challenges due to contamination issues and degradation during reprocessing, which affects its optical properties. However, when properly collected and processed, it can be mechanically recycled or chemically depolymerized to recover raw materials, though these processes are not widely implemented at industrial scale.

Glass offers superior recyclability with minimal degradation of optical properties through multiple recycling cycles. The recycling infrastructure for glass is well-established globally, with recycled content in new glass products ranging from 20-80% depending on application and regional capabilities.

Water usage presents another environmental consideration. Nylon 66 production requires approximately 60-100 liters of water per kilogram of material, primarily for cooling and washing processes. Glass manufacturing typically consumes 15-30 liters per kilogram, representing a lower water footprint.

Chemical emissions during production and use phases also differ significantly. Nylon 66 manufacturing releases various volatile organic compounds (VOCs) and can leach additives during its use phase. Glass production emits SOx and NOx during melting processes but remains chemically inert during use, presenting no leaching concerns.

Considering light transmission applications specifically, the longer service life of glass compared to Nylon 66 (which yellows and degrades under UV exposure) results in fewer replacement cycles and consequently reduced lifetime environmental impact. This durability advantage partially offsets glass's higher weight-related transportation emissions when conducting full lifecycle assessments.

Glass production, while energy-intensive during melting and forming stages, utilizes abundant natural raw materials like silica sand. The carbon footprint of glass manufacturing ranges from 0.8-1.0 kg CO2 equivalent per kilogram for standard glass, making it generally more environmentally favorable from a production standpoint compared to Nylon 66.

End-of-life considerations reveal further distinctions. Nylon 66 presents recycling challenges due to contamination issues and degradation during reprocessing, which affects its optical properties. However, when properly collected and processed, it can be mechanically recycled or chemically depolymerized to recover raw materials, though these processes are not widely implemented at industrial scale.

Glass offers superior recyclability with minimal degradation of optical properties through multiple recycling cycles. The recycling infrastructure for glass is well-established globally, with recycled content in new glass products ranging from 20-80% depending on application and regional capabilities.

Water usage presents another environmental consideration. Nylon 66 production requires approximately 60-100 liters of water per kilogram of material, primarily for cooling and washing processes. Glass manufacturing typically consumes 15-30 liters per kilogram, representing a lower water footprint.

Chemical emissions during production and use phases also differ significantly. Nylon 66 manufacturing releases various volatile organic compounds (VOCs) and can leach additives during its use phase. Glass production emits SOx and NOx during melting processes but remains chemically inert during use, presenting no leaching concerns.

Considering light transmission applications specifically, the longer service life of glass compared to Nylon 66 (which yellows and degrades under UV exposure) results in fewer replacement cycles and consequently reduced lifetime environmental impact. This durability advantage partially offsets glass's higher weight-related transportation emissions when conducting full lifecycle assessments.

Manufacturing Process Comparison

The manufacturing processes for Nylon 66 and glass differ significantly, which directly impacts their transparency and light transmission properties. Nylon 66 is primarily produced through condensation polymerization, where hexamethylenediamine and adipic acid react to form a polymer chain. This process typically occurs in controlled environments at temperatures between 250-300°C. The resulting polymer can be further processed through injection molding, extrusion, or blow molding to create the final product.

During Nylon 66 manufacturing, crystallinity control is crucial for transparency. Standard Nylon 66 exhibits a semi-crystalline structure that scatters light, resulting in an opaque or translucent appearance. However, manufacturers can modify the cooling rate during processing to reduce crystallinity, thereby enhancing transparency. Rapid cooling techniques can produce amorphous regions that allow better light transmission.

Glass manufacturing, conversely, involves melting silica sand, soda ash, and limestone at extremely high temperatures (approximately 1500-1600°C). The molten material is then formed through various methods including floating on molten tin (float glass), pressing, or blowing. Unlike Nylon 66, glass naturally forms an amorphous, non-crystalline structure during cooling, which inherently allows for excellent light transmission.

The surface quality achieved during manufacturing significantly impacts transparency. Glass manufacturing typically includes annealing and polishing processes that create exceptionally smooth surfaces, minimizing light scattering. Nylon 66 surfaces, while smooth, generally contain more microscopic irregularities that affect light transmission.

Additives introduced during manufacturing also play a critical role. Glass manufacturers can incorporate various oxides to enhance or reduce specific properties, including transparency. For instance, iron content reduction creates clearer glass with higher light transmission. Nylon 66 often requires nucleating agents, plasticizers, or clarifying additives to improve transparency, though these can sometimes introduce a slight yellowish tint that affects color neutrality.

Manufacturing thickness control represents another key difference. Glass production allows for extremely precise thickness control, particularly in float glass processes, ensuring uniform light transmission. Nylon 66 components may exhibit more thickness variation due to processing constraints, potentially creating inconsistent optical properties across a single component.

Post-processing treatments further differentiate these materials. Glass can undergo tempering, laminating, or coating processes that maintain or enhance transparency while adding functionality. Nylon 66 may require additional treatments like polishing or coating to improve surface quality and light transmission, though these processes add complexity and cost to manufacturing.

During Nylon 66 manufacturing, crystallinity control is crucial for transparency. Standard Nylon 66 exhibits a semi-crystalline structure that scatters light, resulting in an opaque or translucent appearance. However, manufacturers can modify the cooling rate during processing to reduce crystallinity, thereby enhancing transparency. Rapid cooling techniques can produce amorphous regions that allow better light transmission.

Glass manufacturing, conversely, involves melting silica sand, soda ash, and limestone at extremely high temperatures (approximately 1500-1600°C). The molten material is then formed through various methods including floating on molten tin (float glass), pressing, or blowing. Unlike Nylon 66, glass naturally forms an amorphous, non-crystalline structure during cooling, which inherently allows for excellent light transmission.

The surface quality achieved during manufacturing significantly impacts transparency. Glass manufacturing typically includes annealing and polishing processes that create exceptionally smooth surfaces, minimizing light scattering. Nylon 66 surfaces, while smooth, generally contain more microscopic irregularities that affect light transmission.

Additives introduced during manufacturing also play a critical role. Glass manufacturers can incorporate various oxides to enhance or reduce specific properties, including transparency. For instance, iron content reduction creates clearer glass with higher light transmission. Nylon 66 often requires nucleating agents, plasticizers, or clarifying additives to improve transparency, though these can sometimes introduce a slight yellowish tint that affects color neutrality.

Manufacturing thickness control represents another key difference. Glass production allows for extremely precise thickness control, particularly in float glass processes, ensuring uniform light transmission. Nylon 66 components may exhibit more thickness variation due to processing constraints, potentially creating inconsistent optical properties across a single component.

Post-processing treatments further differentiate these materials. Glass can undergo tempering, laminating, or coating processes that maintain or enhance transparency while adding functionality. Nylon 66 may require additional treatments like polishing or coating to improve surface quality and light transmission, though these processes add complexity and cost to manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!