Optimizing Nylon 66 for Electrical Connectors’ Performance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Evolution and Performance Targets

Nylon 66 has undergone significant evolution since its initial development in the 1930s by Wallace Carothers at DuPont. This synthetic polyamide revolutionized the materials industry with its exceptional mechanical properties, heat resistance, and chemical stability. The trajectory of Nylon 66 development has been characterized by continuous refinement of its molecular structure, processing techniques, and the incorporation of various additives to enhance specific properties.

In the electrical connector industry, the evolution of Nylon 66 has been particularly noteworthy. Early applications primarily leveraged its basic mechanical strength and electrical insulation properties. However, as electronic devices became more sophisticated and operating environments more demanding, the performance requirements for connector materials expanded dramatically.

The 1970s-1980s marked a significant shift with the introduction of glass fiber reinforcement, which substantially improved the mechanical strength and dimensional stability of Nylon 66 components. This advancement enabled connectors to maintain critical tolerances under mechanical stress and thermal cycling conditions.

The 1990s saw the development of flame-retardant Nylon 66 formulations, addressing the growing safety concerns in electrical applications. These formulations incorporated halogenated or non-halogenated flame retardants while maintaining the essential mechanical and electrical properties of the base polymer.

Recent decades have witnessed more targeted modifications to enhance specific performance attributes critical for modern electrical connectors. These include improved hydrolysis resistance to combat moisture-induced degradation, enhanced thermal stability for high-temperature applications, and reduced coefficient of thermal expansion for better dimensional stability in varying environmental conditions.

Current technical targets for Nylon 66 in electrical connector applications focus on several key performance parameters. First, increasing the continuous use temperature beyond the current 125°C limit to accommodate more demanding automotive and industrial applications. Second, improving the material's resistance to electrical tracking and arcing, which becomes increasingly important as voltages increase in power electronics and electric vehicle systems.

Additionally, there is a growing emphasis on enhancing the long-term reliability of Nylon 66 connectors under combined stresses of temperature, humidity, and electrical load. This includes developing formulations with improved resistance to stress cracking, better retention of mechanical properties after aging, and enhanced resistance to surface degradation from environmental contaminants.

Future performance targets are increasingly being shaped by sustainability considerations, with research directed toward bio-based Nylon 66 alternatives and formulations that facilitate end-of-life recycling without compromising the critical performance attributes required for electrical connector applications.

In the electrical connector industry, the evolution of Nylon 66 has been particularly noteworthy. Early applications primarily leveraged its basic mechanical strength and electrical insulation properties. However, as electronic devices became more sophisticated and operating environments more demanding, the performance requirements for connector materials expanded dramatically.

The 1970s-1980s marked a significant shift with the introduction of glass fiber reinforcement, which substantially improved the mechanical strength and dimensional stability of Nylon 66 components. This advancement enabled connectors to maintain critical tolerances under mechanical stress and thermal cycling conditions.

The 1990s saw the development of flame-retardant Nylon 66 formulations, addressing the growing safety concerns in electrical applications. These formulations incorporated halogenated or non-halogenated flame retardants while maintaining the essential mechanical and electrical properties of the base polymer.

Recent decades have witnessed more targeted modifications to enhance specific performance attributes critical for modern electrical connectors. These include improved hydrolysis resistance to combat moisture-induced degradation, enhanced thermal stability for high-temperature applications, and reduced coefficient of thermal expansion for better dimensional stability in varying environmental conditions.

Current technical targets for Nylon 66 in electrical connector applications focus on several key performance parameters. First, increasing the continuous use temperature beyond the current 125°C limit to accommodate more demanding automotive and industrial applications. Second, improving the material's resistance to electrical tracking and arcing, which becomes increasingly important as voltages increase in power electronics and electric vehicle systems.

Additionally, there is a growing emphasis on enhancing the long-term reliability of Nylon 66 connectors under combined stresses of temperature, humidity, and electrical load. This includes developing formulations with improved resistance to stress cracking, better retention of mechanical properties after aging, and enhanced resistance to surface degradation from environmental contaminants.

Future performance targets are increasingly being shaped by sustainability considerations, with research directed toward bio-based Nylon 66 alternatives and formulations that facilitate end-of-life recycling without compromising the critical performance attributes required for electrical connector applications.

Market Analysis for High-Performance Electrical Connector Materials

The global electrical connector market is experiencing robust growth, driven by increasing demand across automotive, aerospace, telecommunications, and consumer electronics sectors. Market research indicates the electrical connector industry is valued at approximately $70 billion in 2023, with projections to reach $110 billion by 2028, representing a compound annual growth rate of 9.5%. Within this expanding market, materials for high-performance connectors constitute a critical segment, with engineering polymers like Nylon 66 capturing significant market share.

The demand for high-performance electrical connector materials is primarily fueled by several converging trends. Miniaturization of electronic devices requires connectors that maintain electrical performance while occupying minimal space. Simultaneously, the automotive industry's shift toward electric vehicles has dramatically increased the need for connectors capable of handling higher voltages and currents while maintaining safety and reliability under harsh conditions.

Nylon 66 has emerged as a preferred material for electrical connectors due to its exceptional balance of mechanical strength, thermal stability, and electrical insulation properties. Market analysis reveals that approximately 35% of engineering polymers used in electrical connectors are polyamides, with Nylon 66 representing the largest share within this category. The material's ability to withstand temperatures up to 125°C continuously makes it particularly valuable for automotive applications where under-hood environments present significant thermal challenges.

Regional analysis shows Asia-Pacific dominating the market for high-performance connector materials, accounting for 45% of global consumption. This dominance is attributed to the region's extensive electronics manufacturing base and growing automotive production. North America and Europe follow with 25% and 20% market shares respectively, with particular strength in aerospace and industrial applications requiring premium connector solutions.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost-effectiveness, automotive and aerospace sectors demonstrate willingness to pay premium prices for materials offering enhanced performance characteristics such as improved flame retardancy, higher temperature resistance, and superior dimensional stability.

Market forecasts indicate growing demand for specialized grades of Nylon 66 with enhanced properties. Flame-retardant variants that comply with UL94 V-0 standards without compromising mechanical properties are experiencing 15% annual growth. Similarly, grades with improved hydrolysis resistance for humid environments and those with enhanced electrical properties for high-frequency applications are seeing increased adoption rates.

Competition in this space is intensifying as material suppliers develop proprietary formulations to address specific performance requirements. The market is witnessing increased investment in research and development focused on optimizing Nylon 66 compounds through advanced additives, reinforcements, and processing technologies to meet evolving connector performance demands.

The demand for high-performance electrical connector materials is primarily fueled by several converging trends. Miniaturization of electronic devices requires connectors that maintain electrical performance while occupying minimal space. Simultaneously, the automotive industry's shift toward electric vehicles has dramatically increased the need for connectors capable of handling higher voltages and currents while maintaining safety and reliability under harsh conditions.

Nylon 66 has emerged as a preferred material for electrical connectors due to its exceptional balance of mechanical strength, thermal stability, and electrical insulation properties. Market analysis reveals that approximately 35% of engineering polymers used in electrical connectors are polyamides, with Nylon 66 representing the largest share within this category. The material's ability to withstand temperatures up to 125°C continuously makes it particularly valuable for automotive applications where under-hood environments present significant thermal challenges.

Regional analysis shows Asia-Pacific dominating the market for high-performance connector materials, accounting for 45% of global consumption. This dominance is attributed to the region's extensive electronics manufacturing base and growing automotive production. North America and Europe follow with 25% and 20% market shares respectively, with particular strength in aerospace and industrial applications requiring premium connector solutions.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost-effectiveness, automotive and aerospace sectors demonstrate willingness to pay premium prices for materials offering enhanced performance characteristics such as improved flame retardancy, higher temperature resistance, and superior dimensional stability.

Market forecasts indicate growing demand for specialized grades of Nylon 66 with enhanced properties. Flame-retardant variants that comply with UL94 V-0 standards without compromising mechanical properties are experiencing 15% annual growth. Similarly, grades with improved hydrolysis resistance for humid environments and those with enhanced electrical properties for high-frequency applications are seeing increased adoption rates.

Competition in this space is intensifying as material suppliers develop proprietary formulations to address specific performance requirements. The market is witnessing increased investment in research and development focused on optimizing Nylon 66 compounds through advanced additives, reinforcements, and processing technologies to meet evolving connector performance demands.

Technical Challenges in Nylon 66 Electrical Applications

The implementation of Nylon 66 in electrical connectors faces several significant technical challenges that must be addressed to optimize performance. One primary concern is the material's hygroscopic nature, which causes it to absorb moisture from the environment. This moisture absorption can lead to dimensional instability, reduced mechanical strength, and altered electrical properties. In high-humidity environments, Nylon 66 connectors may experience up to 2.5% moisture uptake, potentially compromising their structural integrity and electrical insulation capabilities.

Thermal stability presents another critical challenge. While Nylon 66 offers good heat resistance with a melting point of approximately 260°C, prolonged exposure to temperatures above 150°C can accelerate aging and degradation processes. This is particularly problematic in automotive and industrial applications where connectors may be subjected to elevated temperatures for extended periods. The material's glass transition temperature (Tg) of around 70°C means that mechanical properties begin to change significantly above this threshold.

Electrical performance limitations constitute a third major challenge. Although Nylon 66 provides good electrical insulation with a dielectric strength of 15-20 kV/mm, this property deteriorates with moisture absorption and aging. Additionally, its comparative tracking index (CTI) of 600 volts, while respectable, is lower than some alternative materials, potentially limiting its use in high-voltage applications where surface tracking is a concern.

The material's flammability characteristics also present challenges for electrical applications. Standard Nylon 66 has a UL94 rating of HB (horizontal burning), which may not meet stringent flame retardancy requirements for certain electrical applications. Flame retardant additives can improve this rating to V-0, but often at the expense of mechanical properties, processability, and cost.

Processing difficulties further complicate optimization efforts. Nylon 66 requires careful drying before processing (typically to less than 0.2% moisture content) to prevent hydrolytic degradation during molding. The material's relatively narrow processing window demands precise temperature control to avoid both insufficient flow and thermal degradation. Mold shrinkage of 1-2% must also be accurately accounted for to achieve dimensional precision in connector components.

Long-term aging effects represent another significant challenge. Under electrical stress, thermal cycling, and environmental exposure, Nylon 66 can experience embrittlement, discoloration, and degradation of mechanical and electrical properties. This aging process is accelerated by UV exposure, oxidation, and electrical stress factors such as partial discharges, potentially limiting the service life of connectors in demanding applications.

Thermal stability presents another critical challenge. While Nylon 66 offers good heat resistance with a melting point of approximately 260°C, prolonged exposure to temperatures above 150°C can accelerate aging and degradation processes. This is particularly problematic in automotive and industrial applications where connectors may be subjected to elevated temperatures for extended periods. The material's glass transition temperature (Tg) of around 70°C means that mechanical properties begin to change significantly above this threshold.

Electrical performance limitations constitute a third major challenge. Although Nylon 66 provides good electrical insulation with a dielectric strength of 15-20 kV/mm, this property deteriorates with moisture absorption and aging. Additionally, its comparative tracking index (CTI) of 600 volts, while respectable, is lower than some alternative materials, potentially limiting its use in high-voltage applications where surface tracking is a concern.

The material's flammability characteristics also present challenges for electrical applications. Standard Nylon 66 has a UL94 rating of HB (horizontal burning), which may not meet stringent flame retardancy requirements for certain electrical applications. Flame retardant additives can improve this rating to V-0, but often at the expense of mechanical properties, processability, and cost.

Processing difficulties further complicate optimization efforts. Nylon 66 requires careful drying before processing (typically to less than 0.2% moisture content) to prevent hydrolytic degradation during molding. The material's relatively narrow processing window demands precise temperature control to avoid both insufficient flow and thermal degradation. Mold shrinkage of 1-2% must also be accurately accounted for to achieve dimensional precision in connector components.

Long-term aging effects represent another significant challenge. Under electrical stress, thermal cycling, and environmental exposure, Nylon 66 can experience embrittlement, discoloration, and degradation of mechanical and electrical properties. This aging process is accelerated by UV exposure, oxidation, and electrical stress factors such as partial discharges, potentially limiting the service life of connectors in demanding applications.

Current Optimization Methods for Nylon 66 Electrical Properties

01 Mechanical properties enhancement of Nylon 66

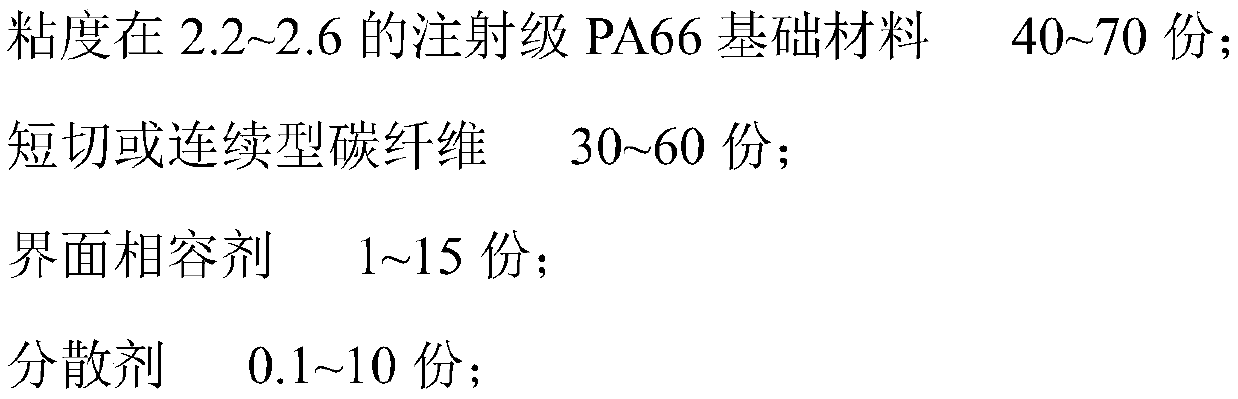

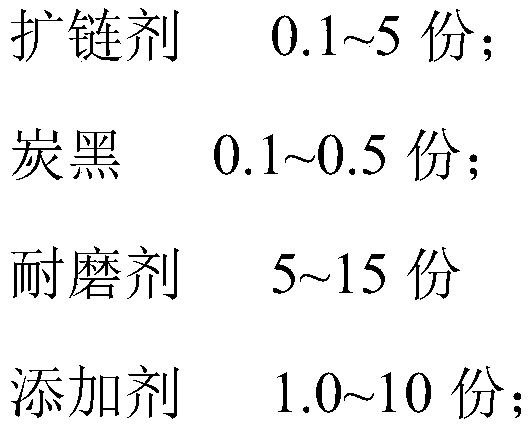

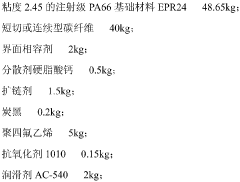

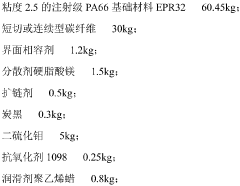

Various methods can be employed to enhance the mechanical properties of Nylon 66, including the addition of reinforcing materials such as glass fibers, carbon fibers, or mineral fillers. These additives significantly improve tensile strength, impact resistance, and dimensional stability. Modified processing techniques can also optimize crystallinity and molecular orientation, resulting in superior mechanical performance for applications requiring high strength and durability.- Mechanical properties enhancement of Nylon 66: Various methods can be employed to enhance the mechanical properties of Nylon 66, including tensile strength, impact resistance, and durability. These methods involve adding reinforcing materials such as glass fibers, carbon fibers, or mineral fillers. The reinforced Nylon 66 exhibits improved strength-to-weight ratio, making it suitable for applications requiring high mechanical performance under stress conditions.

- Thermal stability and heat resistance improvement: Techniques for improving the thermal stability and heat resistance of Nylon 66 involve incorporating heat stabilizers, nucleating agents, and specialized additives. These modifications allow Nylon 66 to maintain its structural integrity and mechanical properties at elevated temperatures, extending its service temperature range and preventing degradation during processing and end-use applications.

- Chemical resistance and weatherability enhancement: Methods to improve the chemical resistance and weatherability of Nylon 66 include surface treatments, UV stabilizers, and specialized coatings. These enhancements protect the polymer from degradation caused by exposure to chemicals, moisture, UV radiation, and other environmental factors, extending the material's service life in outdoor and harsh chemical environments.

- Processing improvements and moldability: Innovations in processing techniques and formulations to enhance the moldability and processability of Nylon 66. These include flow modifiers, nucleating agents, and specialized processing aids that improve melt flow characteristics, reduce cycle times, and enhance surface finish quality. These improvements allow for more complex part geometries and better dimensional stability in molded components.

- Composite formulations and blends with other materials: Development of Nylon 66 composites and blends with other polymers or materials to achieve synergistic performance benefits. These formulations combine the inherent strengths of Nylon 66 with complementary properties from other materials, resulting in composites with enhanced performance characteristics such as reduced water absorption, improved dimensional stability, better electrical properties, or enhanced flame resistance.

02 Thermal stability and heat resistance improvements

Enhancing the thermal properties of Nylon 66 involves incorporating heat stabilizers, nucleating agents, and specialized additives that improve crystallization behavior. These modifications enable the material to maintain structural integrity at elevated temperatures, increase heat deflection temperature, and reduce thermal expansion. Advanced formulations can extend the service temperature range, making the material suitable for high-temperature automotive and industrial applications.Expand Specific Solutions03 Chemical resistance and weatherability enhancements

Improving the chemical resistance and weatherability of Nylon 66 involves incorporating UV stabilizers, antioxidants, and specialized surface treatments. These modifications protect against degradation from exposure to chemicals, UV radiation, and environmental factors. Enhanced formulations demonstrate superior resistance to hydrolysis, oxidation, and color stability, extending the material's service life in outdoor and chemically aggressive environments.Expand Specific Solutions04 Flame retardancy and safety improvements

Enhancing the flame retardant properties of Nylon 66 involves incorporating halogen-free flame retardants, phosphorus-based compounds, and synergistic additive systems. These modifications reduce flammability, smoke generation, and heat release rates during combustion. Advanced flame-retardant formulations maintain the mechanical properties while meeting stringent safety standards for applications in electronics, transportation, and construction sectors.Expand Specific Solutions05 Processing improvements and composite formulations

Advanced processing techniques and composite formulations can significantly enhance Nylon 66 performance. These include optimized molding parameters, specialized nucleating agents for controlled crystallization, and compatibilizers for improved dispersion of additives. Hybrid composites combining Nylon 66 with other polymers or nanomaterials create synergistic effects, resulting in materials with balanced properties such as reduced warpage, improved flow characteristics, and enhanced surface finish.Expand Specific Solutions

Leading Manufacturers and Material Suppliers Landscape

The Nylon 66 electrical connector market is in a growth phase, driven by increasing demand for high-performance materials in electronics and automotive sectors. The market size is expanding at a steady rate, with global valuation expected to reach significant figures due to rising applications in electrical systems requiring heat resistance and dimensional stability. Technologically, the field shows moderate maturity with ongoing innovation. Key players include Hon Hai Precision Industry (Foxconn) dominating connector manufacturing, while materials specialists like Kingfa Sci. & Tech. and its subsidiaries lead in Nylon 66 modification. Companies such as Jiangsu Boiln Plastics and Shenzhen Fuheng New Materials are advancing flame-retardant and reinforced formulations, while Renesas Electronics and Aptiv Technologies drive application-specific developments for enhanced electrical performance.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed a comprehensive approach to optimizing Nylon 66 for electrical connectors through their proprietary flame-retardant technology. Their solution incorporates halogen-free flame retardants with nano-scale metal hydroxides and phosphorus-based compounds to achieve UL94 V-0 ratings while maintaining excellent electrical properties. The company has implemented a multi-stage processing technique that includes precise control of crystallization during molding to enhance dimensional stability critical for connector applications. Their modified Nylon 66 compounds feature improved heat resistance up to 150°C continuous use temperature and enhanced CTI (Comparative Tracking Index) values exceeding 600V, making them suitable for high-voltage applications. Kingfa's materials also incorporate UV stabilizers and antioxidants specifically formulated to prevent degradation in harsh environments where electrical connectors are deployed.

Strengths: Superior flame retardancy without compromising mechanical properties; excellent electrical insulation characteristics; enhanced thermal stability for high-temperature applications. Weaknesses: Higher production costs compared to standard Nylon 66; potential for increased water absorption which may affect dimensional stability in highly humid environments; more complex processing requirements.

Hefei Genius Advanced Material Co., Ltd.

Technical Solution: Hefei Genius Advanced Material has developed a cutting-edge approach to Nylon 66 optimization for electrical connectors through their proprietary compounding technology. Their solution features a carefully engineered blend of nano-scale reinforcements and impact modifiers that enhance both mechanical and electrical performance. The company's material innovation includes a unique processing technique that controls the crystalline structure of Nylon 66, resulting in improved dimensional stability and reduced water absorption - critical factors for maintaining connector tolerances. Their formulations incorporate specialized heat stabilizers that extend the material's temperature resistance up to 155°C continuous use while maintaining excellent electrical insulation properties. Hefei Genius has also developed a surface modification technology that enhances the material's resistance to tracking and arcing, achieving CTI values exceeding 600V. Their compounds feature carefully selected additives that improve flow characteristics during molding, enabling the production of complex connector geometries with thin walls and precise dimensions.

Strengths: Exceptional dimensional stability and reduced water absorption compared to standard Nylon 66; excellent electrical properties retention at elevated temperatures; superior resistance to electrical tracking and arcing. Weaknesses: Higher material cost compared to conventional compounds; more complex processing parameters requiring specialized equipment; limited global distribution network outside China.

Key Patents and Innovations in Nylon 66 Modification

Preparation method of recyclable wear-resistant high-thermal-conductivity nylon 66 composite material

PatentActiveCN112646370A

Innovation

- Using a preparation method containing nylon 66 resin, graphene microflakes, modified nano-silica, carbon fiber and other raw materials, through stirring, melting, extrusion and other processes, a composite material with high thermal conductivity and wear resistance is formed. Graphene, modified The synergistic effect of flexible nanosilica and carbon fiber improves the thermal conductivity and mechanical properties of the material, and improves the interface bonding force through silane coupling agents and compatibilizers.

Nylon 66 composite material for connecting rod sleeve and preparation method thereof

PatentActiveCN110079083A

Innovation

- Using nylon 66 composite material, by adding carbon fiber, specific chain extender and interfacial compatibilizer to the raw material components, melt grafting technology is used to prepare the interfacial compatibilizer and dispersant, and the blending is carried out in two steps and the mixing sequence is defined. , improve the material's adhesion and mechanical properties, enhance wear resistance and corrosion resistance.

Flame Retardancy and Safety Standards Compliance

Flame retardancy represents a critical aspect of Nylon 66 optimization for electrical connector applications, particularly given the potential fire hazards associated with electrical systems. The polymer must meet stringent safety standards to ensure reliable performance under extreme conditions while minimizing risks to users and equipment.

Current flame retardancy approaches for Nylon 66 in electrical connectors primarily involve the incorporation of halogenated or non-halogenated flame retardant additives. Halogenated systems, including brominated compounds, have historically dominated the market due to their effectiveness and cost efficiency. However, environmental and health concerns have driven a significant shift toward non-halogenated alternatives such as phosphorus-based compounds, metal hydroxides, and nitrogen-based systems.

The regulatory landscape governing flame retardancy in electrical connectors is complex and varies by region. UL 94, established by Underwriters Laboratories, remains the predominant standard globally, with V-0, V-1, and V-2 ratings indicating different levels of flame resistance. For electrical connectors, achieving UL 94 V-0 classification is typically required, demanding that materials self-extinguish within 10 seconds after flame removal with no burning drips.

European standards have become increasingly stringent with the implementation of RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, which restrict certain halogenated flame retardants. This regulatory pressure has accelerated innovation in environmentally friendly flame retardant systems for Nylon 66.

Recent advancements include synergistic flame retardant systems that combine multiple mechanisms to achieve superior performance at lower loading levels. Nano-composite approaches incorporating clay, graphene, or metal oxide nanoparticles have shown promise in enhancing flame retardancy while maintaining mechanical properties. These systems create protective char layers during combustion, limiting heat transfer and oxygen access.

The challenge in optimizing flame-retardant Nylon 66 for electrical connectors lies in balancing safety requirements with electrical performance. Many flame retardant additives negatively impact critical properties such as dielectric strength, comparative tracking index (CTI), and insulation resistance. Additionally, some additives accelerate moisture absorption, potentially compromising dimensional stability and electrical properties over time.

Testing protocols for flame-retardant Nylon 66 must evaluate not only UL 94 ratings but also glow-wire ignition temperature (GWIT), glow-wire flammability index (GWFI), and hot-wire ignition (HWI) performance. These comprehensive assessments ensure materials can withstand real-world electrical fault conditions without initiating fires.

Current flame retardancy approaches for Nylon 66 in electrical connectors primarily involve the incorporation of halogenated or non-halogenated flame retardant additives. Halogenated systems, including brominated compounds, have historically dominated the market due to their effectiveness and cost efficiency. However, environmental and health concerns have driven a significant shift toward non-halogenated alternatives such as phosphorus-based compounds, metal hydroxides, and nitrogen-based systems.

The regulatory landscape governing flame retardancy in electrical connectors is complex and varies by region. UL 94, established by Underwriters Laboratories, remains the predominant standard globally, with V-0, V-1, and V-2 ratings indicating different levels of flame resistance. For electrical connectors, achieving UL 94 V-0 classification is typically required, demanding that materials self-extinguish within 10 seconds after flame removal with no burning drips.

European standards have become increasingly stringent with the implementation of RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, which restrict certain halogenated flame retardants. This regulatory pressure has accelerated innovation in environmentally friendly flame retardant systems for Nylon 66.

Recent advancements include synergistic flame retardant systems that combine multiple mechanisms to achieve superior performance at lower loading levels. Nano-composite approaches incorporating clay, graphene, or metal oxide nanoparticles have shown promise in enhancing flame retardancy while maintaining mechanical properties. These systems create protective char layers during combustion, limiting heat transfer and oxygen access.

The challenge in optimizing flame-retardant Nylon 66 for electrical connectors lies in balancing safety requirements with electrical performance. Many flame retardant additives negatively impact critical properties such as dielectric strength, comparative tracking index (CTI), and insulation resistance. Additionally, some additives accelerate moisture absorption, potentially compromising dimensional stability and electrical properties over time.

Testing protocols for flame-retardant Nylon 66 must evaluate not only UL 94 ratings but also glow-wire ignition temperature (GWIT), glow-wire flammability index (GWFI), and hot-wire ignition (HWI) performance. These comprehensive assessments ensure materials can withstand real-world electrical fault conditions without initiating fires.

Environmental Impact and Sustainability Considerations

The environmental impact of Nylon 66 in electrical connector applications presents significant sustainability challenges that manufacturers must address. Traditional production methods for Nylon 66 involve energy-intensive processes that generate substantial greenhouse gas emissions. The polymerization process alone requires high temperatures and pressures, contributing approximately 5-7 kg of CO2 equivalent per kilogram of material produced. Additionally, the raw materials for Nylon 66, adipic acid and hexamethylenediamine, are derived from petroleum resources, further increasing its carbon footprint.

Water usage represents another critical environmental concern, with conventional Nylon 66 manufacturing consuming 60-100 liters of water per kilogram of material. Wastewater from these processes often contains residual monomers and catalysts that require specialized treatment before discharge. The electrical connector industry must consider these impacts when optimizing material formulations.

End-of-life considerations for Nylon 66 electrical connectors reveal additional sustainability challenges. These components typically have lifespans of 10-15 years in automotive applications and 15-20 years in industrial settings. However, the composite nature of many connectors—combining Nylon 66 with glass fibers, flame retardants, and metal contacts—complicates recycling efforts. Current recycling rates for these components remain below 30% globally.

Recent innovations offer promising pathways toward more sustainable Nylon 66 connectors. Bio-based alternatives derived partially from castor oil or other renewable sources can reduce fossil fuel dependency by 20-40%. Several manufacturers have developed Nylon 66 grades containing 30-50% recycled content without compromising electrical or mechanical performance. These materials demonstrate only marginal increases in moisture absorption (1-2%) compared to virgin materials.

Lifecycle assessment studies indicate that optimizing Nylon 66 formulations can yield significant environmental benefits. Reducing glass fiber content from 33% to 25% while maintaining performance specifications through alternative reinforcement technologies can decrease embodied energy by approximately 15%. Similarly, halogen-free flame retardant systems can reduce toxicity concerns while meeting UL94 V-0 requirements.

Regulatory frameworks increasingly influence material selection for electrical connectors. The European Union's RoHS and REACH regulations restrict certain additives commonly used in Nylon 66 formulations. Meanwhile, emerging Extended Producer Responsibility programs in various markets are creating financial incentives for designing more recyclable connector systems. Manufacturers optimizing Nylon 66 formulations must navigate these evolving requirements while maintaining performance standards.

Water usage represents another critical environmental concern, with conventional Nylon 66 manufacturing consuming 60-100 liters of water per kilogram of material. Wastewater from these processes often contains residual monomers and catalysts that require specialized treatment before discharge. The electrical connector industry must consider these impacts when optimizing material formulations.

End-of-life considerations for Nylon 66 electrical connectors reveal additional sustainability challenges. These components typically have lifespans of 10-15 years in automotive applications and 15-20 years in industrial settings. However, the composite nature of many connectors—combining Nylon 66 with glass fibers, flame retardants, and metal contacts—complicates recycling efforts. Current recycling rates for these components remain below 30% globally.

Recent innovations offer promising pathways toward more sustainable Nylon 66 connectors. Bio-based alternatives derived partially from castor oil or other renewable sources can reduce fossil fuel dependency by 20-40%. Several manufacturers have developed Nylon 66 grades containing 30-50% recycled content without compromising electrical or mechanical performance. These materials demonstrate only marginal increases in moisture absorption (1-2%) compared to virgin materials.

Lifecycle assessment studies indicate that optimizing Nylon 66 formulations can yield significant environmental benefits. Reducing glass fiber content from 33% to 25% while maintaining performance specifications through alternative reinforcement technologies can decrease embodied energy by approximately 15%. Similarly, halogen-free flame retardant systems can reduce toxicity concerns while meeting UL94 V-0 requirements.

Regulatory frameworks increasingly influence material selection for electrical connectors. The European Union's RoHS and REACH regulations restrict certain additives commonly used in Nylon 66 formulations. Meanwhile, emerging Extended Producer Responsibility programs in various markets are creating financial incentives for designing more recyclable connector systems. Manufacturers optimizing Nylon 66 formulations must navigate these evolving requirements while maintaining performance standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!