Boost Nylon 66 Flexibility with Copolymer Blending

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Flexibility Enhancement Background and Objectives

Nylon 66, first developed by DuPont in the 1930s, has established itself as a cornerstone engineering thermoplastic in various industries due to its exceptional mechanical properties, including high tensile strength, excellent abrasion resistance, and good thermal stability. However, its inherent rigidity and limited flexibility have constrained its application scope, particularly in scenarios requiring both strength and flexibility. This technical limitation has driven continuous research efforts to enhance the flexibility of Nylon 66 while preserving its desirable mechanical characteristics.

The evolution of Nylon 66 modification techniques has progressed significantly over the decades. Initial approaches focused on plasticizer addition, which provided temporary flexibility improvements but often resulted in migration issues and property degradation over time. The industry subsequently shifted toward more sophisticated methods, including copolymerization and polymer blending, which offer more permanent and stable solutions to the flexibility challenge.

Recent technological advancements in polymer science have opened new avenues for enhancing Nylon 66 flexibility through strategic copolymer blending. This approach involves incorporating flexible segments into the polymer backbone or creating interpenetrating networks that modify the material's mechanical behavior at the molecular level. The growing demand for high-performance, flexible engineering plastics across automotive, consumer electronics, and medical device industries has accelerated research in this domain.

The primary objective of this research is to systematically investigate and develop effective methodologies for enhancing Nylon 66 flexibility through copolymer blending techniques. Specifically, we aim to identify optimal copolymer compositions and blending parameters that can increase flexibility by at least 30% while maintaining at least 85% of the original tensile strength and thermal stability properties. Additionally, the research seeks to ensure that the modified materials retain Nylon 66's chemical resistance and dimensional stability under varying environmental conditions.

Furthermore, this investigation aims to establish clear structure-property relationships between different copolymer architectures and the resulting mechanical properties. Understanding these relationships will enable more precise tailoring of Nylon 66 properties for specific application requirements. The research will also explore the scalability of promising approaches, considering factors such as processing compatibility with existing manufacturing infrastructure, cost-effectiveness, and environmental sustainability.

By addressing these technical challenges, this research endeavors to expand the application spectrum of Nylon 66 into emerging fields such as flexible electronics, soft robotics, and advanced medical devices, where the combination of strength and flexibility is paramount. The successful development of more flexible Nylon 66 variants would represent a significant advancement in engineering thermoplastics and potentially create new market opportunities for this well-established polymer system.

The evolution of Nylon 66 modification techniques has progressed significantly over the decades. Initial approaches focused on plasticizer addition, which provided temporary flexibility improvements but often resulted in migration issues and property degradation over time. The industry subsequently shifted toward more sophisticated methods, including copolymerization and polymer blending, which offer more permanent and stable solutions to the flexibility challenge.

Recent technological advancements in polymer science have opened new avenues for enhancing Nylon 66 flexibility through strategic copolymer blending. This approach involves incorporating flexible segments into the polymer backbone or creating interpenetrating networks that modify the material's mechanical behavior at the molecular level. The growing demand for high-performance, flexible engineering plastics across automotive, consumer electronics, and medical device industries has accelerated research in this domain.

The primary objective of this research is to systematically investigate and develop effective methodologies for enhancing Nylon 66 flexibility through copolymer blending techniques. Specifically, we aim to identify optimal copolymer compositions and blending parameters that can increase flexibility by at least 30% while maintaining at least 85% of the original tensile strength and thermal stability properties. Additionally, the research seeks to ensure that the modified materials retain Nylon 66's chemical resistance and dimensional stability under varying environmental conditions.

Furthermore, this investigation aims to establish clear structure-property relationships between different copolymer architectures and the resulting mechanical properties. Understanding these relationships will enable more precise tailoring of Nylon 66 properties for specific application requirements. The research will also explore the scalability of promising approaches, considering factors such as processing compatibility with existing manufacturing infrastructure, cost-effectiveness, and environmental sustainability.

By addressing these technical challenges, this research endeavors to expand the application spectrum of Nylon 66 into emerging fields such as flexible electronics, soft robotics, and advanced medical devices, where the combination of strength and flexibility is paramount. The successful development of more flexible Nylon 66 variants would represent a significant advancement in engineering thermoplastics and potentially create new market opportunities for this well-established polymer system.

Market Demand Analysis for Flexible Nylon 66 Materials

The global market for flexible Nylon 66 materials has been experiencing significant growth, driven primarily by increasing demand across automotive, electrical & electronics, consumer goods, and industrial sectors. This growth trajectory is expected to continue as industries seek materials that combine durability with enhanced flexibility for complex applications.

In the automotive industry, which accounts for approximately 40% of the flexible Nylon 66 market, manufacturers are increasingly replacing metal components with lightweight, flexible engineering plastics to improve fuel efficiency and reduce emissions. The trend toward electric vehicles has further accelerated this demand, as these vehicles require components with superior thermal management and flexibility properties.

The electrical and electronics sector represents another substantial market segment, with growing requirements for flexible materials that can withstand high temperatures while providing excellent dimensional stability. Consumer electronics manufacturers particularly value Nylon 66 copolymer blends that offer improved impact resistance and flexibility for housings and internal components.

Consumer goods manufacturers have shown increasing interest in flexible Nylon 66 materials for applications ranging from sporting equipment to household appliances. The ability to create products with improved ergonomics and durability has driven adoption in this sector, with annual growth rates exceeding the industry average.

Market research indicates that regions with strong manufacturing bases, particularly Asia-Pacific and North America, dominate the demand landscape. China, Japan, and South Korea have emerged as key growth markets, with domestic consumption rising steadily as manufacturing capabilities expand. The European market remains stable with particular strength in Germany and Italy, where precision engineering applications drive demand.

Price sensitivity varies significantly by application, with automotive and aerospace industries willing to pay premium prices for materials that meet stringent performance requirements. Consumer goods manufacturers typically seek more cost-effective solutions while maintaining acceptable performance characteristics.

Recent market surveys reveal that customers increasingly prioritize materials with enhanced flexibility without compromising on Nylon 66's inherent strengths of temperature resistance and dimensional stability. This has created a specific market niche for copolymer blends that can deliver this balanced performance profile.

The global market value for flexible Nylon 66 materials is projected to grow substantially over the next five years, with particularly strong demand for solutions that address current limitations in low-temperature brittleness and impact resistance. Manufacturers who can successfully develop copolymer blends that enhance flexibility while maintaining other critical properties are positioned to capture significant market share in this evolving landscape.

In the automotive industry, which accounts for approximately 40% of the flexible Nylon 66 market, manufacturers are increasingly replacing metal components with lightweight, flexible engineering plastics to improve fuel efficiency and reduce emissions. The trend toward electric vehicles has further accelerated this demand, as these vehicles require components with superior thermal management and flexibility properties.

The electrical and electronics sector represents another substantial market segment, with growing requirements for flexible materials that can withstand high temperatures while providing excellent dimensional stability. Consumer electronics manufacturers particularly value Nylon 66 copolymer blends that offer improved impact resistance and flexibility for housings and internal components.

Consumer goods manufacturers have shown increasing interest in flexible Nylon 66 materials for applications ranging from sporting equipment to household appliances. The ability to create products with improved ergonomics and durability has driven adoption in this sector, with annual growth rates exceeding the industry average.

Market research indicates that regions with strong manufacturing bases, particularly Asia-Pacific and North America, dominate the demand landscape. China, Japan, and South Korea have emerged as key growth markets, with domestic consumption rising steadily as manufacturing capabilities expand. The European market remains stable with particular strength in Germany and Italy, where precision engineering applications drive demand.

Price sensitivity varies significantly by application, with automotive and aerospace industries willing to pay premium prices for materials that meet stringent performance requirements. Consumer goods manufacturers typically seek more cost-effective solutions while maintaining acceptable performance characteristics.

Recent market surveys reveal that customers increasingly prioritize materials with enhanced flexibility without compromising on Nylon 66's inherent strengths of temperature resistance and dimensional stability. This has created a specific market niche for copolymer blends that can deliver this balanced performance profile.

The global market value for flexible Nylon 66 materials is projected to grow substantially over the next five years, with particularly strong demand for solutions that address current limitations in low-temperature brittleness and impact resistance. Manufacturers who can successfully develop copolymer blends that enhance flexibility while maintaining other critical properties are positioned to capture significant market share in this evolving landscape.

Current Limitations and Challenges in Nylon 66 Flexibility

Despite its widespread industrial applications, Nylon 66 exhibits inherent limitations in flexibility that restrict its use in applications requiring elasticity and impact resistance. The homopolymer structure of Nylon 66, characterized by strong hydrogen bonding between amide groups and high crystallinity, results in a rigid material with excellent tensile strength but poor flexibility. This rigidity becomes particularly problematic in low-temperature environments, where the material becomes increasingly brittle and susceptible to fracture under stress.

The high melting point (approximately 260°C) and glass transition temperature (around 57°C) of Nylon 66 further contribute to its limited flexibility across operational temperature ranges. These thermal properties, while beneficial for high-temperature applications, create challenges when attempting to enhance flexibility without compromising other desirable characteristics such as chemical resistance and dimensional stability.

Current modification approaches through copolymer blending face several technical hurdles. When blending Nylon 66 with more flexible polymers, phase separation often occurs due to incompatibility between the polar Nylon 66 and non-polar flexible components. This incompatibility leads to poor interfacial adhesion, resulting in compromised mechanical properties and reduced overall performance of the blended material.

Additionally, the introduction of flexible segments through copolymerization frequently disrupts the crystalline structure of Nylon 66, leading to decreased thermal stability and reduced chemical resistance. Finding the optimal balance between enhanced flexibility and maintaining these critical properties represents a significant challenge in the development of modified Nylon 66 materials.

Processing difficulties also emerge when attempting to blend Nylon 66 with other polymers. The high processing temperatures required for Nylon 66 (typically 270-290°C) can cause degradation of many potential flexibility-enhancing additives or copolymers. This thermal mismatch limits the range of compatible materials that can be effectively incorporated into Nylon 66 blends.

The moisture sensitivity of Nylon 66 presents another challenge in copolymer blending approaches. Hygroscopic properties of the material can lead to inconsistent processing conditions and variable mechanical properties in the final product. Moisture absorption can also accelerate hydrolytic degradation at the interface between Nylon 66 and blended components, compromising long-term performance stability.

From a commercial perspective, cost-effectiveness remains a significant barrier. Many high-performance elastomers or specialized copolymers that could potentially enhance Nylon 66 flexibility come with substantially higher costs, limiting their practical application in mass-produced goods. This economic constraint drives the need for innovative approaches that can achieve the desired flexibility improvements while maintaining commercial viability.

The high melting point (approximately 260°C) and glass transition temperature (around 57°C) of Nylon 66 further contribute to its limited flexibility across operational temperature ranges. These thermal properties, while beneficial for high-temperature applications, create challenges when attempting to enhance flexibility without compromising other desirable characteristics such as chemical resistance and dimensional stability.

Current modification approaches through copolymer blending face several technical hurdles. When blending Nylon 66 with more flexible polymers, phase separation often occurs due to incompatibility between the polar Nylon 66 and non-polar flexible components. This incompatibility leads to poor interfacial adhesion, resulting in compromised mechanical properties and reduced overall performance of the blended material.

Additionally, the introduction of flexible segments through copolymerization frequently disrupts the crystalline structure of Nylon 66, leading to decreased thermal stability and reduced chemical resistance. Finding the optimal balance between enhanced flexibility and maintaining these critical properties represents a significant challenge in the development of modified Nylon 66 materials.

Processing difficulties also emerge when attempting to blend Nylon 66 with other polymers. The high processing temperatures required for Nylon 66 (typically 270-290°C) can cause degradation of many potential flexibility-enhancing additives or copolymers. This thermal mismatch limits the range of compatible materials that can be effectively incorporated into Nylon 66 blends.

The moisture sensitivity of Nylon 66 presents another challenge in copolymer blending approaches. Hygroscopic properties of the material can lead to inconsistent processing conditions and variable mechanical properties in the final product. Moisture absorption can also accelerate hydrolytic degradation at the interface between Nylon 66 and blended components, compromising long-term performance stability.

From a commercial perspective, cost-effectiveness remains a significant barrier. Many high-performance elastomers or specialized copolymers that could potentially enhance Nylon 66 flexibility come with substantially higher costs, limiting their practical application in mass-produced goods. This economic constraint drives the need for innovative approaches that can achieve the desired flexibility improvements while maintaining commercial viability.

Current Copolymer Blending Solutions for Nylon 66

01 Nylon 66 copolymer blends with elastomers for enhanced flexibility

Blending nylon 66 copolymers with elastomeric materials such as polyolefins, polyesters, or rubber compounds significantly improves flexibility while maintaining structural integrity. These elastomeric components create a phase-separated structure within the nylon matrix, allowing for greater chain mobility and reduced stiffness. The resulting materials exhibit improved impact resistance and elongation properties while preserving the thermal stability characteristic of nylon 66.- Blending nylon 66 with elastomeric polymers: Nylon 66 copolymers can be blended with elastomeric polymers such as polyolefins, polyesters, or polyurethanes to enhance flexibility. These elastomeric components introduce soft segments into the rigid nylon structure, resulting in improved impact resistance and flexibility while maintaining good thermal properties. The proportion of elastomer in the blend directly affects the degree of flexibility achieved in the final material.

- Copolymerization with flexible monomers: Incorporating flexible monomers during the polymerization process of nylon 66 creates copolymers with inherently improved flexibility. Monomers such as polyether diamines, long-chain aliphatic diamines, or cycloaliphatic diamines introduce flexible segments into the polymer backbone. This approach modifies the crystallinity and glass transition temperature of the resulting copolymer, leading to enhanced flexibility without significantly compromising other mechanical properties.

- Plasticizer addition for improved flexibility: Adding plasticizers to nylon 66 copolymer blends is an effective method to increase flexibility. Plasticizers such as sulfonamides, phthalates, or specialized polyols reduce intermolecular forces between polymer chains, increasing their mobility and resulting in a more flexible material. The type and concentration of plasticizer can be optimized to achieve the desired level of flexibility while minimizing negative effects on other properties such as tensile strength.

- Impact modifiers and compatibilizers: Impact modifiers and compatibilizers can be incorporated into nylon 66 copolymer blends to enhance flexibility and phase compatibility. Materials such as maleic anhydride-grafted polymers, core-shell rubber particles, or functionalized elastomers improve the interfacial adhesion between the nylon matrix and flexible components. This results in better dispersion of the flexible phase and enhanced overall flexibility without phase separation issues.

- Processing techniques for flexibility enhancement: Specific processing techniques can be employed to enhance the flexibility of nylon 66 copolymer blends. Methods such as reactive extrusion, controlled cooling rates, or specialized annealing processes can modify the crystalline structure and morphology of the polymer blend. These techniques can optimize the distribution of flexible components within the nylon matrix and create materials with tailored flexibility properties for specific applications.

02 Impact modifiers and plasticizers for nylon 66 flexibility

Incorporating specific impact modifiers and plasticizers into nylon 66 copolymer blends enhances flexibility through internal lubrication of polymer chains. These additives reduce intermolecular forces between nylon chains, lowering the glass transition temperature and increasing chain mobility. Common modifiers include maleic anhydride grafted compounds, low molecular weight esters, and specialized oligomeric plasticizers that remain compatible with the nylon matrix while significantly improving bend recovery and reducing brittleness.Expand Specific Solutions03 Copolymerization with flexible monomers

Direct copolymerization of nylon 66 with flexible monomers creates inherently more flexible polymer chains. By incorporating monomers with longer aliphatic segments, ether linkages, or branched structures during polymerization, the resulting copolymer has fewer hydrogen bonding sites and greater chain mobility. This approach produces materials with intrinsic flexibility rather than relying solely on external additives, resulting in more consistent mechanical properties throughout the material's lifetime.Expand Specific Solutions04 Processing techniques for flexible nylon 66 blends

Specialized processing techniques significantly impact the flexibility of nylon 66 copolymer blends. Methods such as reactive extrusion, controlled cooling rates, and specific shear conditions during processing can optimize the morphology of the blend components. These techniques promote finer dispersion of flexibility-enhancing additives and create beneficial crystalline structures that allow for greater molecular mobility. Post-processing treatments like annealing or controlled humidity exposure can further enhance flexibility properties.Expand Specific Solutions05 Nylon 66 blends with other engineering polymers

Blending nylon 66 copolymers with other engineering polymers creates synergistic combinations that enhance flexibility while maintaining other desirable properties. Partners include polycarbonates, polyethylene terephthalate, and other polyamides with different chain structures. These blends often utilize compatibilizers to ensure proper phase mixing and adhesion between the different polymer types. The resulting materials offer customizable flexibility alongside improved chemical resistance, dimensional stability, and processing characteristics compared to unmodified nylon 66.Expand Specific Solutions

Key Industry Players in Nylon 66 Modification

The Nylon 66 flexibility enhancement market is in a growth phase, with increasing demand for more versatile applications across automotive, electronics, and consumer goods sectors. The global market size for modified nylon materials is expanding rapidly, driven by lightweight material trends. In terms of technical maturity, established players like DuPont de Nemours, Ascend Performance Materials, and ExxonMobil Chemical lead with advanced copolymer technologies, while SABIC, Dow Global Technologies, and China Petroleum & Chemical Corp are making significant R&D investments. Academic institutions such as Sichuan University and Chinese Academy of Science are contributing fundamental research. Regional players like Kolon Materials, Shenzhen Fuheng, and Guangdong Mingju are developing specialized applications, creating a competitive landscape balanced between multinational corporations and emerging innovators.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend has developed a proprietary technology called "FlexiTech" for enhancing Nylon 66 flexibility through strategic copolymer blending. Their approach involves incorporating elastomeric segments into the polyamide backbone, creating block copolymers with alternating rigid and flexible segments. The process utilizes specialized catalysts that enable precise control over segment length and distribution, resulting in materials with improved impact resistance while maintaining thermal stability. Ascend's method includes a reactive extrusion process where polyamide segments are combined with polyether or polyester soft segments at carefully controlled temperatures (240-280°C) and residence times, allowing for optimal molecular weight distribution[1]. Their technology also incorporates proprietary compatibilizers that enhance the interface between the rigid and flexible domains, preventing phase separation during processing and use.

Strengths: Superior balance of flexibility and strength retention compared to conventional plasticizer approaches; excellent low-temperature impact performance down to -40°C; maintains chemical resistance properties of standard Nylon 66. Weaknesses: Higher production costs due to complex processing requirements; slightly reduced maximum service temperature compared to unmodified Nylon 66; requires specialized processing equipment for optimal results.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered an advanced copolymer blending system for Nylon 66 flexibility enhancement called "Zytel® Plus Flex Technology." This approach utilizes a multi-phase polymer architecture where carefully selected elastomeric copolymers are chemically bonded to the Nylon 66 backbone through reactive compatibilization. The technology employs proprietary chain extenders and coupling agents that create covalent bonds between the polyamide and modifier phases during melt processing. DuPont's process involves a precisely controlled reactive extrusion at 265-290°C with specialized screw configurations that optimize dispersive and distributive mixing[2]. Their method incorporates ionomer-based compatibilizers that enhance interfacial adhesion between phases, resulting in superior stress transfer and preventing delamination under mechanical stress. The technology also utilizes nano-scale reinforcements that maintain structural integrity while allowing molecular mobility in the amorphous regions, contributing to both flexibility and dimensional stability[3].

Strengths: Exceptional long-term heat aging resistance compared to conventional flexible polyamides; maintains up to 80% of mechanical properties after 3000 hours at 150°C; excellent chemical resistance to automotive fluids. Weaknesses: Higher raw material costs compared to standard Nylon 66 compounds; requires precise processing control to achieve optimal property balance; slightly higher moisture absorption than unmodified Nylon 66.

Critical Patents and Research on Nylon 66 Flexibility Enhancement

High impact nylon molding compositions

PatentInactiveUS4160790A

Innovation

- A synergistic approach is employed by blending nylon-6 with a copolymer of ethylene containing minor proportions of acrylic or methacrylic acid units and a copolymer of ethylene with C1-C4 alkyl esters of such acid, with specific weight ratios and random distribution of comonomer units, along with conventional additives and plasticizers, to enhance Izod impact resistance.

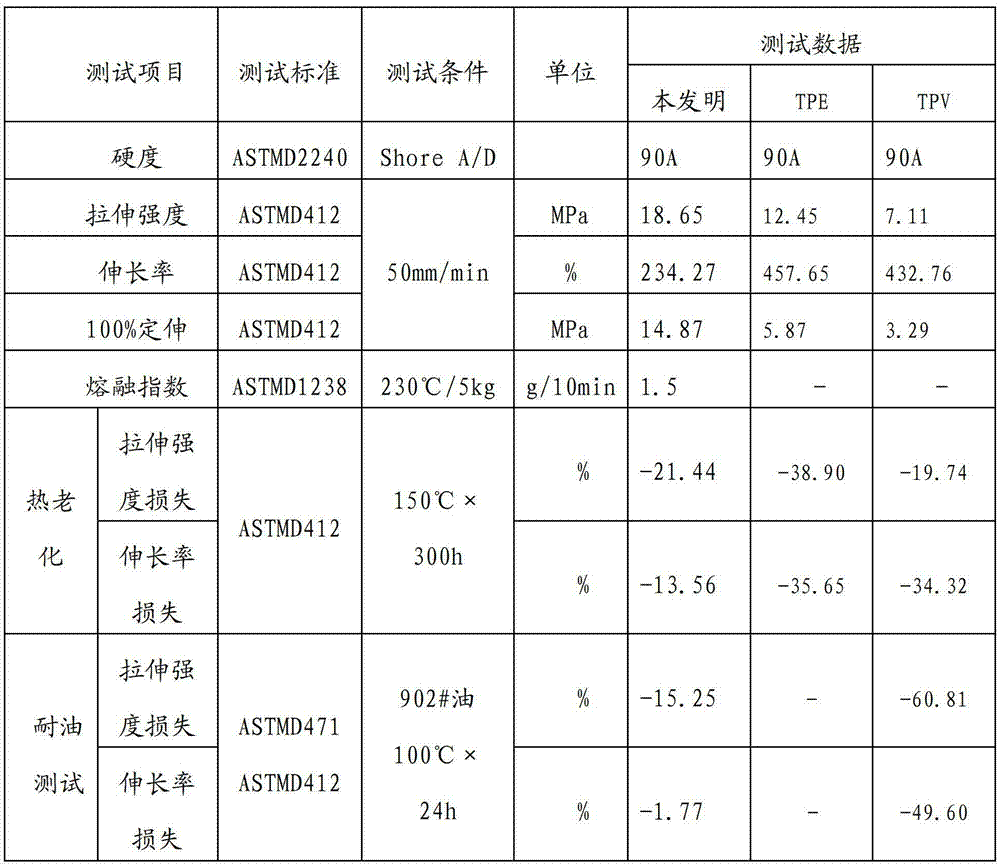

Nylon-66 modified elastomer and preparation method thereof

PatentActiveCN103113740A

Innovation

- It uses nylon 66 modified elastomer, including PA66, maleic anhydride-grafted EPDM rubber, SEBS and ultra-low density polyethylene. It is prepared through stirring and twin-screw extrusion processes to improve the material's high temperature resistance, oil resistance and tensile strength. tensile strength.

Environmental Impact and Sustainability Considerations

The environmental impact of enhancing Nylon 66 flexibility through copolymer blending represents a critical consideration in modern polymer development. Traditional Nylon 66 production and processing involve significant energy consumption and greenhouse gas emissions, primarily due to the high temperatures required during polymerization and molding processes. When introducing copolymer blending techniques to enhance flexibility, these environmental factors become increasingly complex and warrant careful examination.

Copolymer blending approaches can potentially reduce the overall environmental footprint compared to conventional plasticizer-based flexibility enhancement methods. Many traditional plasticizers contain phthalates and other compounds with known environmental persistence and toxicity concerns. By contrast, properly selected copolymers can achieve similar flexibility improvements while eliminating these problematic additives, resulting in a more environmentally benign final product.

The recyclability of flexible Nylon 66 copolymer blends presents both challenges and opportunities. On one hand, the introduction of secondary polymers can complicate recycling streams and potentially reduce the purity of recovered materials. On the other hand, enhanced flexibility may extend product lifespans and reduce waste generation. Recent research indicates that carefully designed copolymer systems can maintain recyclability while achieving the desired mechanical properties.

Biodegradability considerations must also factor into sustainability assessments of flexible Nylon 66 formulations. While conventional Nylon 66 exhibits limited biodegradability, certain bio-based copolymers can introduce controlled degradation pathways. This approach shows promise for applications where end-of-life environmental impact is particularly concerning, though it often comes with tradeoffs in durability and performance characteristics.

Life cycle assessment (LCA) studies comparing traditional Nylon 66 with flexibility-enhanced copolymer blends reveal nuanced sustainability profiles. The production phase of specialized copolymers may initially require more resources, but these impacts can be offset by improved product longevity, reduced material requirements through enhanced performance, and decreased need for environmentally problematic additives. Comprehensive LCA frameworks that account for all stages from raw material extraction through disposal are essential for accurate sustainability evaluation.

Regulatory considerations increasingly influence material selection in this domain. Global initiatives like REACH in Europe and similar programs in other regions have placed greater scrutiny on polymer additives, favoring inherently flexible copolymer systems over those requiring external plasticizers. Forward-thinking manufacturers are proactively developing copolymer blending approaches that anticipate future regulatory restrictions while maintaining performance requirements.

Copolymer blending approaches can potentially reduce the overall environmental footprint compared to conventional plasticizer-based flexibility enhancement methods. Many traditional plasticizers contain phthalates and other compounds with known environmental persistence and toxicity concerns. By contrast, properly selected copolymers can achieve similar flexibility improvements while eliminating these problematic additives, resulting in a more environmentally benign final product.

The recyclability of flexible Nylon 66 copolymer blends presents both challenges and opportunities. On one hand, the introduction of secondary polymers can complicate recycling streams and potentially reduce the purity of recovered materials. On the other hand, enhanced flexibility may extend product lifespans and reduce waste generation. Recent research indicates that carefully designed copolymer systems can maintain recyclability while achieving the desired mechanical properties.

Biodegradability considerations must also factor into sustainability assessments of flexible Nylon 66 formulations. While conventional Nylon 66 exhibits limited biodegradability, certain bio-based copolymers can introduce controlled degradation pathways. This approach shows promise for applications where end-of-life environmental impact is particularly concerning, though it often comes with tradeoffs in durability and performance characteristics.

Life cycle assessment (LCA) studies comparing traditional Nylon 66 with flexibility-enhanced copolymer blends reveal nuanced sustainability profiles. The production phase of specialized copolymers may initially require more resources, but these impacts can be offset by improved product longevity, reduced material requirements through enhanced performance, and decreased need for environmentally problematic additives. Comprehensive LCA frameworks that account for all stages from raw material extraction through disposal are essential for accurate sustainability evaluation.

Regulatory considerations increasingly influence material selection in this domain. Global initiatives like REACH in Europe and similar programs in other regions have placed greater scrutiny on polymer additives, favoring inherently flexible copolymer systems over those requiring external plasticizers. Forward-thinking manufacturers are proactively developing copolymer blending approaches that anticipate future regulatory restrictions while maintaining performance requirements.

Mechanical Property Testing and Quality Control Methods

Mechanical property testing and quality control methods are essential components in the research on enhancing Nylon 66 flexibility through copolymer blending. Standardized testing protocols must be established to accurately evaluate the mechanical performance of modified Nylon 66 materials, particularly focusing on flexibility parameters.

Tensile testing represents a fundamental method for assessing the flexibility enhancement of Nylon 66 copolymer blends. ASTM D638 and ISO 527 standards provide guidelines for measuring elongation at break, tensile strength, and Young's modulus. These parameters directly correlate with material flexibility and must be systematically evaluated across different blend compositions to establish optimal formulations.

Dynamic mechanical analysis (DMA) offers valuable insights into viscoelastic properties of the copolymer blends. By measuring storage modulus, loss modulus, and tan delta across temperature ranges, researchers can identify glass transition temperatures and determine how different copolymer ratios affect the material's flexibility under varying environmental conditions.

Impact resistance testing, including Izod and Charpy methods (ASTM D256, ISO 179), provides critical data on the material's ability to absorb energy during sudden loading. Enhanced flexibility in Nylon 66 should correlate with improved impact resistance, making these tests essential quality control checkpoints.

Flexural testing (ASTM D790) measures the material's behavior when subjected to bending forces, providing flexural modulus and flexural strength values that directly relate to flexibility performance in real-world applications. Three-point and four-point bending tests offer complementary data on material response under different loading conditions.

Quality control protocols must include rheological testing to monitor melt flow characteristics, as these properties significantly impact processing parameters and final product consistency. Melt flow index (MFI) testing according to ASTM D1238 should be incorporated into standard quality control procedures.

Accelerated aging tests are crucial for evaluating long-term performance stability of the enhanced Nylon 66 blends. Exposure to UV radiation, thermal cycling, and humidity according to ASTM G154 and ASTM D3045 helps predict how flexibility properties will evolve over the material's service life.

Statistical process control methods, including Six Sigma and design of experiments (DOE) approaches, should be implemented to optimize testing efficiency and ensure data reliability. Establishing control charts for critical mechanical properties enables early detection of process deviations and maintains consistent quality across production batches.

Tensile testing represents a fundamental method for assessing the flexibility enhancement of Nylon 66 copolymer blends. ASTM D638 and ISO 527 standards provide guidelines for measuring elongation at break, tensile strength, and Young's modulus. These parameters directly correlate with material flexibility and must be systematically evaluated across different blend compositions to establish optimal formulations.

Dynamic mechanical analysis (DMA) offers valuable insights into viscoelastic properties of the copolymer blends. By measuring storage modulus, loss modulus, and tan delta across temperature ranges, researchers can identify glass transition temperatures and determine how different copolymer ratios affect the material's flexibility under varying environmental conditions.

Impact resistance testing, including Izod and Charpy methods (ASTM D256, ISO 179), provides critical data on the material's ability to absorb energy during sudden loading. Enhanced flexibility in Nylon 66 should correlate with improved impact resistance, making these tests essential quality control checkpoints.

Flexural testing (ASTM D790) measures the material's behavior when subjected to bending forces, providing flexural modulus and flexural strength values that directly relate to flexibility performance in real-world applications. Three-point and four-point bending tests offer complementary data on material response under different loading conditions.

Quality control protocols must include rheological testing to monitor melt flow characteristics, as these properties significantly impact processing parameters and final product consistency. Melt flow index (MFI) testing according to ASTM D1238 should be incorporated into standard quality control procedures.

Accelerated aging tests are crucial for evaluating long-term performance stability of the enhanced Nylon 66 blends. Exposure to UV radiation, thermal cycling, and humidity according to ASTM G154 and ASTM D3045 helps predict how flexibility properties will evolve over the material's service life.

Statistical process control methods, including Six Sigma and design of experiments (DOE) approaches, should be implemented to optimize testing efficiency and ensure data reliability. Establishing control charts for critical mechanical properties enables early detection of process deviations and maintains consistent quality across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!