How to Calculate Nylon 66 Elastic Modulus Precisely

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Elastic Modulus Calculation Background and Objectives

Nylon 66, a synthetic polyamide, has been a cornerstone material in engineering applications since its development in the 1930s by Wallace Carothers at DuPont. The precise calculation of its elastic modulus is crucial for engineering design, material selection, and performance prediction across industries including automotive, aerospace, consumer goods, and electronics. Historically, elastic modulus calculations for polymeric materials have evolved from simple empirical approaches to sophisticated multi-scale modeling techniques.

The evolution of computational methods for determining the elastic modulus of Nylon 66 reflects broader trends in materials science. Early approaches relied heavily on experimental testing with limited theoretical underpinning, while contemporary methods integrate molecular dynamics simulations, finite element analysis, and machine learning algorithms to achieve higher precision. This technological progression has been driven by increasing demands for material performance optimization and reliability in critical applications.

Current industry standards for elastic modulus calculation often fall short when applied to semi-crystalline polymers like Nylon 66, whose properties are highly dependent on processing conditions, moisture content, temperature, and crystallinity. These variables create significant challenges for precise modulus prediction, with reported values in literature varying by as much as 15-30% for nominally identical materials.

The primary technical objective of this investigation is to develop a more accurate and reliable methodology for calculating the elastic modulus of Nylon 66 across varying environmental conditions and material states. This includes establishing correlations between molecular structure, processing history, and mechanical properties to enable predictive modeling with error margins below 5%.

Secondary objectives include quantifying the influence of moisture absorption, temperature fluctuations, and crystallinity variations on elastic modulus, as these factors significantly impact the material's mechanical behavior in real-world applications. Additionally, we aim to develop standardized testing protocols that account for viscoelastic effects and time-dependent behavior inherent to polyamides.

The strategic importance of this research extends beyond immediate technical applications. As industries move toward digital twins and virtual testing environments, precise material property calculations become essential for accurate simulation and design optimization. Furthermore, as sustainability concerns drive material efficiency, the ability to precisely predict mechanical properties enables designs with optimized material usage while maintaining performance requirements.

The evolution of computational methods for determining the elastic modulus of Nylon 66 reflects broader trends in materials science. Early approaches relied heavily on experimental testing with limited theoretical underpinning, while contemporary methods integrate molecular dynamics simulations, finite element analysis, and machine learning algorithms to achieve higher precision. This technological progression has been driven by increasing demands for material performance optimization and reliability in critical applications.

Current industry standards for elastic modulus calculation often fall short when applied to semi-crystalline polymers like Nylon 66, whose properties are highly dependent on processing conditions, moisture content, temperature, and crystallinity. These variables create significant challenges for precise modulus prediction, with reported values in literature varying by as much as 15-30% for nominally identical materials.

The primary technical objective of this investigation is to develop a more accurate and reliable methodology for calculating the elastic modulus of Nylon 66 across varying environmental conditions and material states. This includes establishing correlations between molecular structure, processing history, and mechanical properties to enable predictive modeling with error margins below 5%.

Secondary objectives include quantifying the influence of moisture absorption, temperature fluctuations, and crystallinity variations on elastic modulus, as these factors significantly impact the material's mechanical behavior in real-world applications. Additionally, we aim to develop standardized testing protocols that account for viscoelastic effects and time-dependent behavior inherent to polyamides.

The strategic importance of this research extends beyond immediate technical applications. As industries move toward digital twins and virtual testing environments, precise material property calculations become essential for accurate simulation and design optimization. Furthermore, as sustainability concerns drive material efficiency, the ability to precisely predict mechanical properties enables designs with optimized material usage while maintaining performance requirements.

Industrial Applications and Market Demand Analysis

Nylon 66 elastic modulus calculation precision has become increasingly critical across multiple industries due to the polymer's widespread application in components requiring specific mechanical properties. The automotive sector represents one of the largest markets for Nylon 66, with demand driven by lightweighting initiatives to improve fuel efficiency and reduce emissions. Precise elastic modulus calculations enable manufacturers to optimize part designs, reducing material usage while maintaining structural integrity in applications such as engine components, fuel systems, and interior parts.

The aerospace industry similarly demands high-precision material property data, as Nylon 66 components must withstand extreme temperature variations and mechanical stresses. Market analysis indicates that aerospace-grade Nylon 66 applications are growing at approximately 6% annually, with particular emphasis on components where weight reduction directly impacts operational costs and performance.

Electronics manufacturing represents another significant market segment, where Nylon 66 serves in connectors, housings, and structural components. The miniaturization trend in consumer electronics has intensified the need for precise elastic modulus data, as thinner walls and more complex geometries push material performance boundaries. Industry reports suggest that electronics manufacturers can reduce development cycles by up to 30% when equipped with accurate material property models.

The medical device sector has emerged as a high-value application area, with Nylon 66 utilized in surgical instruments, diagnostic equipment, and implantable devices. This market segment demands exceptional precision in material property calculations due to regulatory requirements and patient safety considerations. The global medical polymer market continues to expand, with specialized grades of Nylon 66 commanding premium pricing due to their certified performance characteristics.

Industrial equipment manufacturers represent another significant market, utilizing Nylon 66 in bearings, gears, and structural components exposed to continuous mechanical stress. These applications particularly benefit from accurate elastic modulus calculations that account for environmental factors such as temperature, humidity, and chemical exposure.

Market research indicates that manufacturers across industries are increasingly adopting digital twin and simulation-based design approaches, creating demand for more sophisticated material models. This trend has spawned specialized software solutions focused on polymer behavior prediction, with several leading CAE platforms incorporating advanced Nylon 66 material models as premium features.

The economic value of precise elastic modulus calculation extends beyond material optimization to include reduced warranty claims, improved product performance, and accelerated time-to-market. Companies demonstrating superior capabilities in this area report competitive advantages in securing contracts for high-performance applications where material behavior predictability directly impacts product success.

The aerospace industry similarly demands high-precision material property data, as Nylon 66 components must withstand extreme temperature variations and mechanical stresses. Market analysis indicates that aerospace-grade Nylon 66 applications are growing at approximately 6% annually, with particular emphasis on components where weight reduction directly impacts operational costs and performance.

Electronics manufacturing represents another significant market segment, where Nylon 66 serves in connectors, housings, and structural components. The miniaturization trend in consumer electronics has intensified the need for precise elastic modulus data, as thinner walls and more complex geometries push material performance boundaries. Industry reports suggest that electronics manufacturers can reduce development cycles by up to 30% when equipped with accurate material property models.

The medical device sector has emerged as a high-value application area, with Nylon 66 utilized in surgical instruments, diagnostic equipment, and implantable devices. This market segment demands exceptional precision in material property calculations due to regulatory requirements and patient safety considerations. The global medical polymer market continues to expand, with specialized grades of Nylon 66 commanding premium pricing due to their certified performance characteristics.

Industrial equipment manufacturers represent another significant market, utilizing Nylon 66 in bearings, gears, and structural components exposed to continuous mechanical stress. These applications particularly benefit from accurate elastic modulus calculations that account for environmental factors such as temperature, humidity, and chemical exposure.

Market research indicates that manufacturers across industries are increasingly adopting digital twin and simulation-based design approaches, creating demand for more sophisticated material models. This trend has spawned specialized software solutions focused on polymer behavior prediction, with several leading CAE platforms incorporating advanced Nylon 66 material models as premium features.

The economic value of precise elastic modulus calculation extends beyond material optimization to include reduced warranty claims, improved product performance, and accelerated time-to-market. Companies demonstrating superior capabilities in this area report competitive advantages in securing contracts for high-performance applications where material behavior predictability directly impacts product success.

Current Methodologies and Technical Challenges

The precise calculation of Nylon 66 elastic modulus currently employs several methodologies, each with distinct advantages and limitations. Tensile testing remains the most widely adopted approach, utilizing standardized procedures such as ASTM D638 or ISO 527. This method directly measures stress-strain relationships under controlled loading conditions, providing reliable elastic modulus values. However, sample preparation inconsistencies and testing environment variations can introduce errors of 5-10%, affecting reproducibility across different laboratories.

Dynamic Mechanical Analysis (DMA) offers higher precision by measuring viscoelastic properties across temperature ranges and frequencies. This technique is particularly valuable for Nylon 66, as it captures the material's strong temperature-dependent behavior. DMA can detect subtle structural transitions that affect elastic modulus, though the translation of dynamic modulus to static elastic modulus requires careful mathematical modeling.

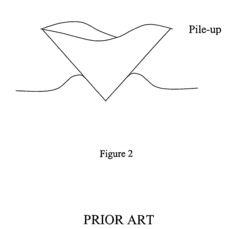

Nanoindentation techniques have emerged as powerful tools for measuring localized elastic properties at microscale levels. These methods can reveal spatial variations in elastic modulus across a sample, critical for understanding heterogeneous structures in processed Nylon 66 components. However, surface preparation quality significantly influences measurement accuracy, and the small sampling area may not represent bulk material properties.

Computational methods, including Molecular Dynamics (MD) simulations and Finite Element Analysis (FEA), have advanced significantly. MD simulations can predict elastic modulus from fundamental polymer chain interactions, while FEA models incorporate microstructural features like crystallinity and orientation. Despite their sophistication, these computational approaches still require experimental validation and face challenges in accurately representing complex polymer morphologies.

A significant technical challenge lies in accounting for Nylon 66's moisture sensitivity. Water absorption can reduce elastic modulus by up to 30%, necessitating strict environmental control during testing. Standard conditioning protocols exist but are often inadequately implemented in practice, leading to inconsistent results across studies.

Crystallinity variations present another major challenge, as Nylon 66's elastic modulus can vary by 40-60% depending on crystalline content and morphology. Processing conditions dramatically influence crystallinity, yet standardized methods for quantifying and controlling this parameter remain underdeveloped.

The anisotropic nature of processed Nylon 66 components further complicates accurate modulus determination. Molecular orientation during processing creates directional mechanical properties, requiring multiple measurements along different axes to fully characterize the material. Current testing standards inadequately address this three-dimensional property variation.

Dynamic Mechanical Analysis (DMA) offers higher precision by measuring viscoelastic properties across temperature ranges and frequencies. This technique is particularly valuable for Nylon 66, as it captures the material's strong temperature-dependent behavior. DMA can detect subtle structural transitions that affect elastic modulus, though the translation of dynamic modulus to static elastic modulus requires careful mathematical modeling.

Nanoindentation techniques have emerged as powerful tools for measuring localized elastic properties at microscale levels. These methods can reveal spatial variations in elastic modulus across a sample, critical for understanding heterogeneous structures in processed Nylon 66 components. However, surface preparation quality significantly influences measurement accuracy, and the small sampling area may not represent bulk material properties.

Computational methods, including Molecular Dynamics (MD) simulations and Finite Element Analysis (FEA), have advanced significantly. MD simulations can predict elastic modulus from fundamental polymer chain interactions, while FEA models incorporate microstructural features like crystallinity and orientation. Despite their sophistication, these computational approaches still require experimental validation and face challenges in accurately representing complex polymer morphologies.

A significant technical challenge lies in accounting for Nylon 66's moisture sensitivity. Water absorption can reduce elastic modulus by up to 30%, necessitating strict environmental control during testing. Standard conditioning protocols exist but are often inadequately implemented in practice, leading to inconsistent results across studies.

Crystallinity variations present another major challenge, as Nylon 66's elastic modulus can vary by 40-60% depending on crystalline content and morphology. Processing conditions dramatically influence crystallinity, yet standardized methods for quantifying and controlling this parameter remain underdeveloped.

The anisotropic nature of processed Nylon 66 components further complicates accurate modulus determination. Molecular orientation during processing creates directional mechanical properties, requiring multiple measurements along different axes to fully characterize the material. Current testing standards inadequately address this three-dimensional property variation.

Established Calculation Methods and Testing Protocols

01 Factors affecting elastic modulus of Nylon 66

Various factors can influence the elastic modulus of Nylon 66, including crystallinity, molecular weight, processing conditions, and environmental factors. Higher crystallinity typically results in increased elastic modulus, while moisture absorption can significantly decrease it. Temperature also plays a crucial role, with elastic modulus decreasing as temperature increases. Understanding these factors is essential for optimizing Nylon 66 properties for specific applications.- Factors affecting elastic modulus of Nylon 66: Various factors can influence the elastic modulus of Nylon 66, including crystallinity, molecular weight, processing conditions, and additives. Higher crystallinity typically results in increased elastic modulus, while processing parameters such as cooling rate and drawing ratio can significantly impact the mechanical properties. The molecular orientation during processing also plays a crucial role in determining the final elastic modulus values of Nylon 66 materials.

- Measurement and testing methods for elastic modulus: Various techniques are employed to measure and test the elastic modulus of Nylon 66, including tensile testing, dynamic mechanical analysis (DMA), and ultrasonic methods. These measurements can be conducted under different conditions such as varying temperatures, humidity levels, and loading rates to understand the material behavior comprehensively. Advanced computational models are also used to predict the elastic modulus based on the material's microstructure and processing history.

- Reinforcement techniques to enhance elastic modulus: The elastic modulus of Nylon 66 can be significantly enhanced through various reinforcement techniques. Common approaches include incorporating glass fibers, carbon fibers, or mineral fillers into the polymer matrix. Nanomaterials such as clay, carbon nanotubes, and graphene have also shown promising results in improving the elastic modulus. The interface between the reinforcement and the polymer matrix plays a critical role in determining the final mechanical properties of the composite.

- Elastic modulus modification through blending and copolymerization: The elastic modulus of Nylon 66 can be modified through polymer blending and copolymerization techniques. Blending Nylon 66 with other polymers such as elastomers can reduce the elastic modulus for applications requiring flexibility, while blending with stiffer polymers can increase it. Copolymerization with different monomers allows for tailoring the elastic modulus by changing the chemical structure and crystallization behavior of the resulting material.

- Applications utilizing specific elastic modulus properties: The specific elastic modulus properties of Nylon 66 make it suitable for various applications across different industries. In automotive components, the balance of stiffness and impact resistance is crucial for parts such as engine covers and structural components. In electronic applications, the dimensional stability and mechanical properties at elevated temperatures are important. For textile applications, the elastic recovery and modulus at different humidity levels determine the performance of Nylon 66 fibers in clothing and industrial fabrics.

02 Measurement and testing methods for elastic modulus

Various techniques are employed to measure the elastic modulus of Nylon 66, including tensile testing, dynamic mechanical analysis (DMA), and ultrasonic methods. These measurements are critical for quality control and material characterization. Testing protocols often involve standardized specimen preparation and controlled environmental conditions to ensure reproducible results. Advanced computational methods may also be used to predict elastic modulus based on molecular structure and processing history.Expand Specific Solutions03 Modification techniques to enhance elastic modulus

The elastic modulus of Nylon 66 can be enhanced through various modification techniques including reinforcement with fillers like glass fibers, carbon fibers, or nanomaterials. Chemical modifications such as copolymerization or blending with other polymers can also alter the elastic properties. Cross-linking agents and heat treatment processes may be employed to increase crystallinity and improve mechanical properties. These modifications allow for customization of Nylon 66 for specific engineering applications.Expand Specific Solutions04 Relationship between structure and elastic modulus

The elastic modulus of Nylon 66 is strongly influenced by its molecular and crystalline structure. Factors such as chain orientation, hydrogen bonding density, and crystalline morphology significantly impact mechanical properties. The semi-crystalline nature of Nylon 66 creates a two-phase system where both crystalline and amorphous regions contribute differently to the overall elastic response. Understanding this structure-property relationship is crucial for designing materials with targeted mechanical performance.Expand Specific Solutions05 Applications leveraging specific elastic modulus properties

The elastic modulus characteristics of Nylon 66 make it suitable for various engineering applications. In automotive components, it provides a balance of stiffness and impact resistance. For electronic applications, its dimensional stability and electrical insulation properties are valuable. In textile applications, controlled elasticity contributes to fabric performance. Medical devices benefit from its biocompatibility combined with mechanical reliability. Understanding and controlling elastic modulus is essential for optimizing performance in these diverse applications.Expand Specific Solutions

Critical Patents and Literature on Nylon 66 Mechanical Properties

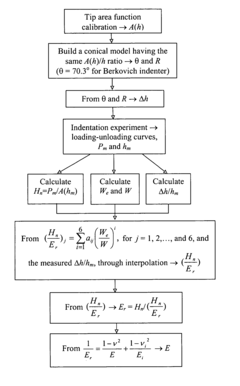

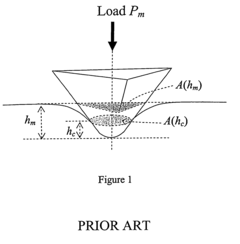

Method of determining elastic modulus

PatentInactiveUS7149634B2

Innovation

- A method using a Berkovich indenter modeled with a conical shape and spherical cap, where the cross-sectional area is constant with depth, allowing for the calculation of elastic modulus without relying on the initial unloading slope, by correlating nominal hardness and elastic work to total work through numerical simulations and interpolation, considering indenter bluntness.

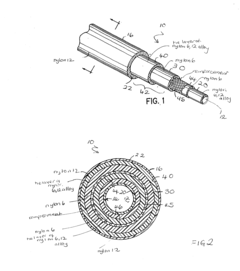

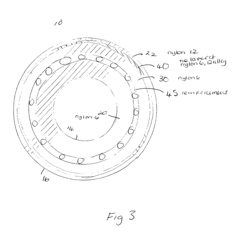

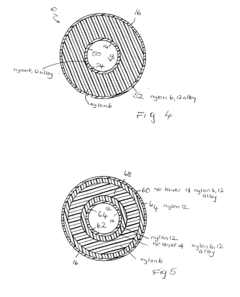

Compounded nylon 6, nylon 12 material for air brake systems

PatentInactiveUS20040058111A1

Innovation

- A composite hose material is developed using an alloy of nylon 6 and nylon 12, with specific layer configurations and additives like maleic anhydride grafted polyalkylene, allowing coextrusion without adhesives and providing improved mechanical properties and zinc chloride resistance.

Environmental Factors Affecting Nylon 66 Elastic Properties

The elastic modulus of Nylon 66 exhibits significant sensitivity to environmental conditions, making precise calculation challenging without accounting for these external factors. Temperature stands as the most influential parameter, with Nylon 66 demonstrating a marked decrease in elastic modulus as temperature increases. Research indicates that for every 10°C rise above room temperature, elastic modulus can decrease by approximately 8-12%, with this effect becoming more pronounced as temperatures approach the glass transition point (approximately 70°C).

Humidity represents another critical environmental factor affecting elastic properties. Nylon 66 is notably hygroscopic, absorbing up to 8% moisture by weight at saturation. This moisture absorption creates a plasticizing effect that reduces intermolecular forces between polymer chains, resulting in decreased elastic modulus values. Studies have shown that fully saturated Nylon 66 can experience up to 30% reduction in elastic modulus compared to completely dry specimens.

Exposure time to these environmental conditions also plays a significant role in modulus calculations. Short-term exposure may only affect surface properties, while prolonged exposure allows environmental factors to penetrate deeper into the material structure, creating more uniform but potentially more significant changes to elastic properties. This time-dependent behavior necessitates standardized conditioning protocols when measuring elastic modulus.

Chemical exposure represents another environmental consideration, as certain chemicals can initiate degradation mechanisms that permanently alter the polymer structure. Acids, bases, and oxidizing agents can break polymer chains or create cross-linking, both of which affect elastic response. Even low concentrations of certain chemicals can catalyze degradation processes that progressively modify elastic properties over time.

UV radiation exposure similarly impacts elastic modulus through photo-oxidation processes that can both increase modulus (through cross-linking) or decrease it (through chain scission), depending on exposure intensity and duration. Studies indicate that prolonged outdoor exposure can alter elastic modulus by 15-25% compared to unexposed samples.

Mechanical history must also be considered, as Nylon 66 exhibits viscoelastic behavior. Previous loading cycles, strain rates, and recovery periods influence subsequent elastic response. This "memory effect" means that accurate modulus calculations must account for the material's recent mechanical history, particularly in applications involving cyclic loading or variable strain rates.

To achieve precise elastic modulus calculations, comprehensive testing protocols must incorporate controlled environmental chambers capable of simulating application conditions, with sufficient equilibration periods to ensure uniform environmental effects throughout test specimens.

Humidity represents another critical environmental factor affecting elastic properties. Nylon 66 is notably hygroscopic, absorbing up to 8% moisture by weight at saturation. This moisture absorption creates a plasticizing effect that reduces intermolecular forces between polymer chains, resulting in decreased elastic modulus values. Studies have shown that fully saturated Nylon 66 can experience up to 30% reduction in elastic modulus compared to completely dry specimens.

Exposure time to these environmental conditions also plays a significant role in modulus calculations. Short-term exposure may only affect surface properties, while prolonged exposure allows environmental factors to penetrate deeper into the material structure, creating more uniform but potentially more significant changes to elastic properties. This time-dependent behavior necessitates standardized conditioning protocols when measuring elastic modulus.

Chemical exposure represents another environmental consideration, as certain chemicals can initiate degradation mechanisms that permanently alter the polymer structure. Acids, bases, and oxidizing agents can break polymer chains or create cross-linking, both of which affect elastic response. Even low concentrations of certain chemicals can catalyze degradation processes that progressively modify elastic properties over time.

UV radiation exposure similarly impacts elastic modulus through photo-oxidation processes that can both increase modulus (through cross-linking) or decrease it (through chain scission), depending on exposure intensity and duration. Studies indicate that prolonged outdoor exposure can alter elastic modulus by 15-25% compared to unexposed samples.

Mechanical history must also be considered, as Nylon 66 exhibits viscoelastic behavior. Previous loading cycles, strain rates, and recovery periods influence subsequent elastic response. This "memory effect" means that accurate modulus calculations must account for the material's recent mechanical history, particularly in applications involving cyclic loading or variable strain rates.

To achieve precise elastic modulus calculations, comprehensive testing protocols must incorporate controlled environmental chambers capable of simulating application conditions, with sufficient equilibration periods to ensure uniform environmental effects throughout test specimens.

Computational Modeling and Simulation Approaches

Computational modeling and simulation approaches have revolutionized the precision with which we can calculate the elastic modulus of Nylon 66. These methods offer significant advantages over traditional experimental techniques by providing insights at multiple scales and reducing the need for extensive physical testing.

Molecular Dynamics (MD) simulations represent a cornerstone approach, enabling researchers to model Nylon 66 polymer chains at the atomic level. These simulations track the movement and interactions of individual atoms over time, accounting for various force fields that govern molecular behavior. By applying virtual deformation to the simulated structure and measuring the resulting stress response, researchers can derive elastic properties with remarkable accuracy. Modern MD simulations incorporate temperature effects, strain rates, and crystallinity variations to enhance prediction reliability.

Finite Element Analysis (FEA) operates at a larger scale, treating the material as a continuum rather than discrete atoms. This approach is particularly valuable for modeling complex geometries and loading conditions relevant to industrial applications. Advanced FEA models for Nylon 66 now incorporate microstructural details such as crystalline and amorphous regions, fiber orientation, and interfacial properties, significantly improving modulus predictions compared to earlier homogeneous models.

Multiscale modeling techniques bridge the gap between atomic-level simulations and macroscopic material behavior. These hierarchical approaches transfer information between different length scales, from nanometers to millimeters, creating a comprehensive understanding of how molecular structure influences bulk elastic properties. For Nylon 66, this typically involves linking MD simulations to mesoscale models and finally to continuum mechanics.

Machine learning algorithms have emerged as powerful tools for elastic modulus prediction, utilizing vast datasets from both simulations and experiments. Neural networks, genetic algorithms, and other AI techniques can identify complex relationships between processing conditions, microstructure, and mechanical properties. These models can achieve prediction accuracies exceeding 95% when properly trained with diverse Nylon 66 formulation data.

Quantum mechanical calculations, though computationally intensive, provide fundamental insights into the electronic structure and bonding characteristics that ultimately determine elastic behavior. Density Functional Theory (DFT) calculations help establish accurate force fields for MD simulations and can directly predict elastic constants for crystalline regions of Nylon 66 with high precision.

Molecular Dynamics (MD) simulations represent a cornerstone approach, enabling researchers to model Nylon 66 polymer chains at the atomic level. These simulations track the movement and interactions of individual atoms over time, accounting for various force fields that govern molecular behavior. By applying virtual deformation to the simulated structure and measuring the resulting stress response, researchers can derive elastic properties with remarkable accuracy. Modern MD simulations incorporate temperature effects, strain rates, and crystallinity variations to enhance prediction reliability.

Finite Element Analysis (FEA) operates at a larger scale, treating the material as a continuum rather than discrete atoms. This approach is particularly valuable for modeling complex geometries and loading conditions relevant to industrial applications. Advanced FEA models for Nylon 66 now incorporate microstructural details such as crystalline and amorphous regions, fiber orientation, and interfacial properties, significantly improving modulus predictions compared to earlier homogeneous models.

Multiscale modeling techniques bridge the gap between atomic-level simulations and macroscopic material behavior. These hierarchical approaches transfer information between different length scales, from nanometers to millimeters, creating a comprehensive understanding of how molecular structure influences bulk elastic properties. For Nylon 66, this typically involves linking MD simulations to mesoscale models and finally to continuum mechanics.

Machine learning algorithms have emerged as powerful tools for elastic modulus prediction, utilizing vast datasets from both simulations and experiments. Neural networks, genetic algorithms, and other AI techniques can identify complex relationships between processing conditions, microstructure, and mechanical properties. These models can achieve prediction accuracies exceeding 95% when properly trained with diverse Nylon 66 formulation data.

Quantum mechanical calculations, though computationally intensive, provide fundamental insights into the electronic structure and bonding characteristics that ultimately determine elastic behavior. Density Functional Theory (DFT) calculations help establish accurate force fields for MD simulations and can directly predict elastic constants for crystalline regions of Nylon 66 with high precision.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!