Nylon 66 vs Composite: Bending Strength for Structural Parts

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and Composites: Evolution and Objectives

The evolution of engineering materials has been a cornerstone of industrial advancement, with Nylon 66 representing one of the most significant breakthroughs in polymer science during the mid-20th century. Developed by Wallace Carothers at DuPont in 1935, Nylon 66 emerged as a revolutionary synthetic polymer that combined excellent mechanical properties with processability. Its introduction marked a paradigm shift from traditional materials to engineered polymers capable of meeting specific performance requirements in structural applications.

The historical trajectory of Nylon 66 has seen continuous refinement in molecular structure and processing techniques, leading to enhanced mechanical properties, particularly in terms of bending strength. Initially utilized in textiles and consumer goods, Nylon 66 gradually transitioned into engineering applications where its balance of strength, toughness, and chemical resistance proved invaluable for structural components.

Parallel to Nylon 66's evolution, composite materials have undergone their own remarkable development path. Beginning with simple glass fiber reinforced plastics (GFRPs) in the 1940s, composites have evolved into sophisticated engineered materials combining multiple constituents to achieve properties unattainable by homogeneous materials. The progression from random fiber orientation to precisely engineered layups has revolutionized the performance capabilities of composite structures.

The convergence of these two material technologies has created a complex landscape for engineers selecting materials for structural parts where bending strength is a critical parameter. Understanding this technological evolution provides essential context for evaluating current capabilities and limitations of both material systems.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Nylon 66 and various composite materials specifically in terms of their bending strength characteristics for structural applications. This analysis aims to establish quantitative benchmarks for performance evaluation, identify key factors influencing bending strength in both material systems, and determine optimal application scenarios based on mechanical requirements and environmental conditions.

Secondary objectives include mapping the relationship between processing parameters and resultant bending properties, evaluating long-term performance under cyclic loading conditions, and assessing the impact of environmental factors such as temperature, humidity, and chemical exposure on bending strength retention. Additionally, this research seeks to identify emerging trends in material modification techniques that may further enhance the bending performance of both Nylon 66 and composite systems.

Through this comprehensive examination of historical development and current capabilities, this research will establish a foundation for strategic material selection decisions in structural applications where bending loads represent a primary design consideration.

The historical trajectory of Nylon 66 has seen continuous refinement in molecular structure and processing techniques, leading to enhanced mechanical properties, particularly in terms of bending strength. Initially utilized in textiles and consumer goods, Nylon 66 gradually transitioned into engineering applications where its balance of strength, toughness, and chemical resistance proved invaluable for structural components.

Parallel to Nylon 66's evolution, composite materials have undergone their own remarkable development path. Beginning with simple glass fiber reinforced plastics (GFRPs) in the 1940s, composites have evolved into sophisticated engineered materials combining multiple constituents to achieve properties unattainable by homogeneous materials. The progression from random fiber orientation to precisely engineered layups has revolutionized the performance capabilities of composite structures.

The convergence of these two material technologies has created a complex landscape for engineers selecting materials for structural parts where bending strength is a critical parameter. Understanding this technological evolution provides essential context for evaluating current capabilities and limitations of both material systems.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Nylon 66 and various composite materials specifically in terms of their bending strength characteristics for structural applications. This analysis aims to establish quantitative benchmarks for performance evaluation, identify key factors influencing bending strength in both material systems, and determine optimal application scenarios based on mechanical requirements and environmental conditions.

Secondary objectives include mapping the relationship between processing parameters and resultant bending properties, evaluating long-term performance under cyclic loading conditions, and assessing the impact of environmental factors such as temperature, humidity, and chemical exposure on bending strength retention. Additionally, this research seeks to identify emerging trends in material modification techniques that may further enhance the bending performance of both Nylon 66 and composite systems.

Through this comprehensive examination of historical development and current capabilities, this research will establish a foundation for strategic material selection decisions in structural applications where bending loads represent a primary design consideration.

Market Demand Analysis for High-Strength Structural Materials

The global market for high-strength structural materials continues to expand rapidly, driven by increasing demands across automotive, aerospace, construction, and consumer electronics industries. These sectors require materials that offer superior mechanical properties while maintaining cost-effectiveness and processability. The comparison between traditional engineering polymers like Nylon 66 and advanced composites represents a critical decision point for manufacturers seeking optimal material solutions.

Current market analysis indicates that the global high-performance polymer market, which includes Nylon 66, is projected to reach $17.5 billion by 2026, growing at a CAGR of 6.2%. Meanwhile, the composite materials market is expanding even more rapidly, with a projected value of $126.3 billion by 2026 and a CAGR of 7.5%. This differential growth rate reflects the increasing preference for composite solutions in high-performance applications.

The automotive industry remains the largest consumer of high-strength structural materials, accounting for approximately 28% of market demand. Weight reduction initiatives to improve fuel efficiency and meet stringent emissions regulations are driving manufacturers to replace metal components with lighter alternatives. In this context, the superior strength-to-weight ratio of composites (typically 3-5 times higher than Nylon 66) presents a compelling value proposition despite higher material costs.

Aerospace applications represent the highest growth segment, with demand increasing at 9.3% annually. This sector prioritizes exceptional mechanical performance under extreme conditions, where composite materials demonstrate clear advantages in bending strength, fatigue resistance, and thermal stability compared to Nylon 66.

Regional market analysis reveals that North America and Europe currently dominate consumption of high-performance composites, while Asia-Pacific leads in Nylon 66 utilization. However, China and India are rapidly increasing their composite adoption rates as manufacturing capabilities mature and cost barriers decrease.

Price sensitivity remains a significant market factor. Nylon 66 typically costs $2-4 per kilogram, while fiber-reinforced composites range from $15-50 per kilogram depending on fiber type and manufacturing process. This price differential creates distinct market segments, with cost-sensitive applications favoring Nylon 66 despite its lower bending strength (typically 80-120 MPa versus 200-800 MPa for composites).

Market research indicates growing demand for hybrid solutions that combine the processability and cost advantages of engineering polymers with the performance benefits of composites. This trend is evidenced by the 23% annual growth in short-fiber reinforced thermoplastics that bridge the performance gap between neat Nylon 66 and continuous fiber composites.

Current market analysis indicates that the global high-performance polymer market, which includes Nylon 66, is projected to reach $17.5 billion by 2026, growing at a CAGR of 6.2%. Meanwhile, the composite materials market is expanding even more rapidly, with a projected value of $126.3 billion by 2026 and a CAGR of 7.5%. This differential growth rate reflects the increasing preference for composite solutions in high-performance applications.

The automotive industry remains the largest consumer of high-strength structural materials, accounting for approximately 28% of market demand. Weight reduction initiatives to improve fuel efficiency and meet stringent emissions regulations are driving manufacturers to replace metal components with lighter alternatives. In this context, the superior strength-to-weight ratio of composites (typically 3-5 times higher than Nylon 66) presents a compelling value proposition despite higher material costs.

Aerospace applications represent the highest growth segment, with demand increasing at 9.3% annually. This sector prioritizes exceptional mechanical performance under extreme conditions, where composite materials demonstrate clear advantages in bending strength, fatigue resistance, and thermal stability compared to Nylon 66.

Regional market analysis reveals that North America and Europe currently dominate consumption of high-performance composites, while Asia-Pacific leads in Nylon 66 utilization. However, China and India are rapidly increasing their composite adoption rates as manufacturing capabilities mature and cost barriers decrease.

Price sensitivity remains a significant market factor. Nylon 66 typically costs $2-4 per kilogram, while fiber-reinforced composites range from $15-50 per kilogram depending on fiber type and manufacturing process. This price differential creates distinct market segments, with cost-sensitive applications favoring Nylon 66 despite its lower bending strength (typically 80-120 MPa versus 200-800 MPa for composites).

Market research indicates growing demand for hybrid solutions that combine the processability and cost advantages of engineering polymers with the performance benefits of composites. This trend is evidenced by the 23% annual growth in short-fiber reinforced thermoplastics that bridge the performance gap between neat Nylon 66 and continuous fiber composites.

Current Technical Limitations and Challenges in Bending Applications

Despite the advantages of both Nylon 66 and composite materials in structural applications, significant technical limitations and challenges persist when these materials are subjected to bending forces. Nylon 66, while offering good mechanical properties, exhibits notable creep behavior under sustained loads, particularly at elevated temperatures. This viscoelastic response means that components may gradually deform over time even when stresses remain below the material's yield strength, compromising dimensional stability in precision applications.

Moisture absorption presents another critical challenge for Nylon 66 in bending applications. The material can absorb up to 2.5% of water by weight, resulting in dimensional changes and reduced mechanical properties. This hygroscopic nature creates significant variability in performance across different environmental conditions, making design calculations and long-term reliability predictions particularly difficult.

For composite materials, manufacturing inconsistencies represent a major limitation. The bending strength of composites is highly dependent on fiber orientation, volume fraction, and matrix-fiber interface quality. Even minor variations in manufacturing parameters can lead to significant deviations in mechanical properties, creating challenges for quality control and performance predictability in mass production scenarios.

Delamination remains one of the most prevalent failure modes in composite materials under bending loads. The interface between layers represents a weak point where crack initiation and propagation can occur, particularly under cyclic loading conditions. This interlaminar weakness significantly reduces the effective bending strength compared to theoretical calculations based on constituent properties.

Temperature sensitivity affects both material systems but manifests differently. While Nylon 66 experiences a dramatic reduction in stiffness and strength above its glass transition temperature (approximately 70°C), composites face challenges with thermal expansion mismatches between fibers and matrix materials, creating internal stresses that can lead to microcracking and performance degradation over time.

Cost-effectiveness in high-volume applications continues to favor Nylon 66 despite its technical limitations. The injection molding process allows for complex geometries with minimal material waste, whereas composite manufacturing processes like hand lay-up, resin transfer molding, or automated fiber placement involve higher material costs, longer cycle times, and more complex tooling requirements.

Non-destructive testing and quality assurance present additional challenges, particularly for composite structures. While Nylon 66 components can be relatively easily inspected using conventional methods, detecting internal defects in composite materials often requires specialized techniques such as ultrasonic scanning or computed tomography, adding complexity and cost to the manufacturing process.

Moisture absorption presents another critical challenge for Nylon 66 in bending applications. The material can absorb up to 2.5% of water by weight, resulting in dimensional changes and reduced mechanical properties. This hygroscopic nature creates significant variability in performance across different environmental conditions, making design calculations and long-term reliability predictions particularly difficult.

For composite materials, manufacturing inconsistencies represent a major limitation. The bending strength of composites is highly dependent on fiber orientation, volume fraction, and matrix-fiber interface quality. Even minor variations in manufacturing parameters can lead to significant deviations in mechanical properties, creating challenges for quality control and performance predictability in mass production scenarios.

Delamination remains one of the most prevalent failure modes in composite materials under bending loads. The interface between layers represents a weak point where crack initiation and propagation can occur, particularly under cyclic loading conditions. This interlaminar weakness significantly reduces the effective bending strength compared to theoretical calculations based on constituent properties.

Temperature sensitivity affects both material systems but manifests differently. While Nylon 66 experiences a dramatic reduction in stiffness and strength above its glass transition temperature (approximately 70°C), composites face challenges with thermal expansion mismatches between fibers and matrix materials, creating internal stresses that can lead to microcracking and performance degradation over time.

Cost-effectiveness in high-volume applications continues to favor Nylon 66 despite its technical limitations. The injection molding process allows for complex geometries with minimal material waste, whereas composite manufacturing processes like hand lay-up, resin transfer molding, or automated fiber placement involve higher material costs, longer cycle times, and more complex tooling requirements.

Non-destructive testing and quality assurance present additional challenges, particularly for composite structures. While Nylon 66 components can be relatively easily inspected using conventional methods, detecting internal defects in composite materials often requires specialized techniques such as ultrasonic scanning or computed tomography, adding complexity and cost to the manufacturing process.

Comparative Analysis of Nylon 66 and Composite Solutions

01 Fiber reinforcement for enhanced bending strength

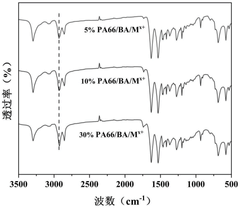

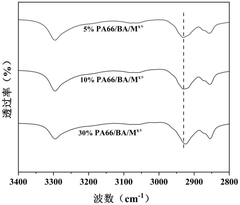

Various fibers can be incorporated into nylon 66 composites to significantly improve bending strength. These reinforcements include carbon fibers, glass fibers, and natural fibers which create a strong interfacial bond with the nylon 66 matrix. The fiber orientation, length, and volume fraction are critical parameters that affect the final bending properties of the composite. These reinforced composites show superior mechanical performance compared to pure nylon 66, making them suitable for structural applications requiring high load-bearing capacity.- Fiber reinforcement in nylon 66 composites: Various fiber materials can be incorporated into nylon 66 to enhance bending strength. These reinforcements include carbon fibers, glass fibers, and natural fibers which significantly improve the mechanical properties of the composite. The fiber orientation, length, and volume fraction are critical factors that determine the final bending strength of the composite. These reinforced composites show superior performance in applications requiring high mechanical strength and durability.

- Nanoparticle enhancement of nylon 66 composites: Incorporating nanoparticles such as carbon nanotubes, graphene, and metal oxide nanoparticles into nylon 66 matrices can significantly improve bending strength. These nanomaterials create strong interfacial bonding with the polymer matrix and provide effective stress transfer mechanisms. The dispersion method and surface modification of nanoparticles play crucial roles in achieving optimal mechanical properties. These nanocomposites exhibit enhanced bending strength while maintaining or improving other properties like thermal stability.

- Processing techniques for improved bending strength: Various processing techniques can be employed to enhance the bending strength of nylon 66 composites. These include injection molding optimization, extrusion parameters control, compression molding, and annealing treatments. The cooling rate, processing temperature, and pressure significantly influence the crystallinity and molecular orientation of nylon 66, which directly affects the bending strength. Advanced processing methods like reactive extrusion and in-situ polymerization can create stronger interfacial bonding between the matrix and reinforcements.

- Hybrid composite systems with nylon 66: Hybrid composite systems combining nylon 66 with other polymers or multiple reinforcement types can achieve synergistic improvements in bending strength. These systems may include combinations of different fiber types (carbon/glass), polymer blends (nylon 66/polypropylene), or hierarchical structures incorporating both micro and nano reinforcements. The hybrid approach allows for customization of mechanical properties while addressing specific application requirements. These composites often demonstrate superior bending strength compared to single-component reinforced systems.

- Surface treatments and coupling agents for interface optimization: Surface treatments of reinforcements and the use of coupling agents significantly improve the interfacial adhesion between nylon 66 and reinforcement materials, enhancing bending strength. Techniques include silane treatments, plasma modification, chemical functionalization, and the addition of maleic anhydride-based coupling agents. These modifications create stronger chemical bonds at the interface, improving stress transfer and preventing premature failure under bending loads. The improved interfacial adhesion results in composites with superior mechanical integrity and durability.

02 Impact of fillers and additives on bending properties

The addition of specific fillers and additives to nylon 66 composites can significantly modify their bending strength characteristics. Mineral fillers like clay, talc, and calcium carbonate can improve stiffness while maintaining adequate flexibility. Nano-additives such as carbon nanotubes and graphene provide exceptional reinforcement at low loading levels. Coupling agents and compatibilizers enhance the interfacial adhesion between the matrix and fillers, resulting in improved stress transfer and higher bending strength. The particle size distribution and dispersion quality of these additives play crucial roles in determining the final mechanical properties.Expand Specific Solutions03 Processing techniques affecting bending strength

Various processing methods significantly impact the bending strength of nylon 66 composites. Injection molding parameters such as melt temperature, injection pressure, and cooling rate influence the crystallinity and molecular orientation, which directly affect bending properties. Extrusion compounding conditions determine the dispersion quality of reinforcements and additives. Post-processing treatments like annealing can enhance crystallinity and relieve internal stresses, improving bending strength. Advanced techniques such as in-situ polymerization and reactive extrusion create stronger interfacial bonding between components, resulting in superior mechanical performance.Expand Specific Solutions04 Hybrid composite systems for optimized bending performance

Hybrid composite systems combining nylon 66 with other polymers or multiple reinforcement types offer optimized bending strength properties. Blending nylon 66 with other engineering plastics like polypropylene or polyethylene creates synergistic effects that enhance mechanical performance. Using combinations of different reinforcements, such as glass fibers with carbon fibers or mineral fillers with organic fibers, provides balanced mechanical properties. These hybrid systems allow for customization of bending strength, impact resistance, and weight according to specific application requirements. The interfacial compatibility between different components is crucial for achieving optimal performance in these complex composite systems.Expand Specific Solutions05 Environmental factors and durability of bending strength

Environmental factors significantly affect the long-term bending strength of nylon 66 composites. Moisture absorption is a critical concern as nylon 66 is hygroscopic, and water uptake can plasticize the matrix and reduce bending strength. Temperature fluctuations impact the dimensional stability and mechanical properties, with higher temperatures typically reducing bending strength. UV exposure can degrade the polymer matrix over time, affecting long-term performance. Stabilizers, UV absorbers, and moisture-resistant coatings can be incorporated to enhance durability. The addition of specific reinforcements and surface treatments can mitigate these environmental effects, maintaining bending strength over the service life of the composite material.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The composite materials market for structural parts is in a growth phase, with increasing demand driven by automotive, aerospace, and industrial applications. The market size is expanding as manufacturers seek lightweight, high-performance alternatives to traditional nylon 66. While nylon 66 offers established processing advantages and cost-effectiveness, composites provide superior bending strength and customizable mechanical properties. Companies like Kingfa Sci. & Tech., Shanghai Kingfa, and Jiangsu Boiln Plastics lead in modified plastics, while Zhuzhou Times New Materials and DuPont are advancing composite technologies. Research institutions such as Sichuan University and Dalian Institute of Chemical Physics are accelerating innovation in this field, pushing the technology maturity curve toward wider adoption of composite solutions for demanding structural applications.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has established a specialized research division focused on comparative analysis of nylon 66 and various composite materials for structural applications. Their technical approach centers on tailored reinforcement systems, with their ECOPLUS® nylon 66 compounds incorporating optimized glass fiber architectures (30-50% loading) that deliver flexural modulus values up to 14 GPa. Their composite alternatives include both short and long fiber reinforced thermoplastics with proprietary fiber-matrix interface treatments to enhance stress transfer. Kingfa employs a systematic testing methodology comparing materials across multiple environmental conditions, including temperature cycling, humidity aging, and chemical exposure to evaluate long-term performance stability. Their research has demonstrated that while their glass-filled nylon 66 compounds offer superior processing efficiency and consistent mechanical properties, their advanced composite formulations provide higher absolute bending strength values (up to 380 MPa) with reduced weight penalties.

Strengths: Cost-effective material solutions optimized for Asian manufacturing environments; extensive compounding expertise; strong position in automotive and industrial applications. Weaknesses: Less established in aerospace and high-performance applications; limited experience with continuous fiber composites; technical support network less developed outside Asia.

Zhuzhou Times New Materials Technology Co., Ltd.

Technical Solution: Zhuzhou Times has developed specialized material solutions comparing reinforced nylon 66 and composite alternatives specifically for transportation and industrial equipment applications. Their technical approach focuses on optimizing material performance under dynamic loading conditions, with their nylon 66 formulations incorporating both glass and carbon fiber reinforcements at varying loadings (25-60%). Their proprietary testing protocols evaluate not only static bending strength but also fatigue performance under cyclic loading, demonstrating that their high-performance nylon 66 grades maintain 85% of initial properties after 1 million cycles. For applications requiring higher absolute performance, their thermoplastic composite solutions incorporate continuous fiber reinforcement architectures that deliver bending strengths exceeding 420 MPa while maintaining processability through injection overmolding techniques. Zhuzhou Times has particularly focused on the cost-performance balance, developing material selection methodologies that incorporate total system cost including processing requirements and part consolidation opportunities.

Strengths: Strong position in transportation applications; cost-effective material solutions; integrated design and testing capabilities. Weaknesses: Limited global presence outside China; less established in aerospace applications; technical documentation primarily available in Chinese.

Key Patents and Innovations in Material Reinforcement

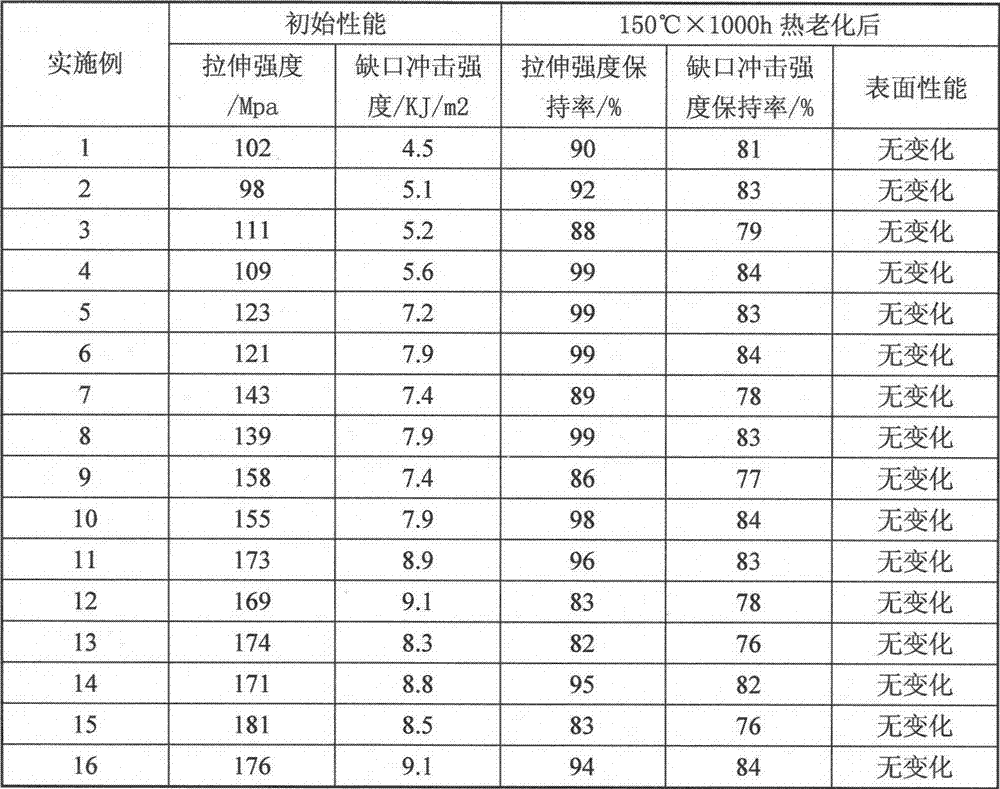

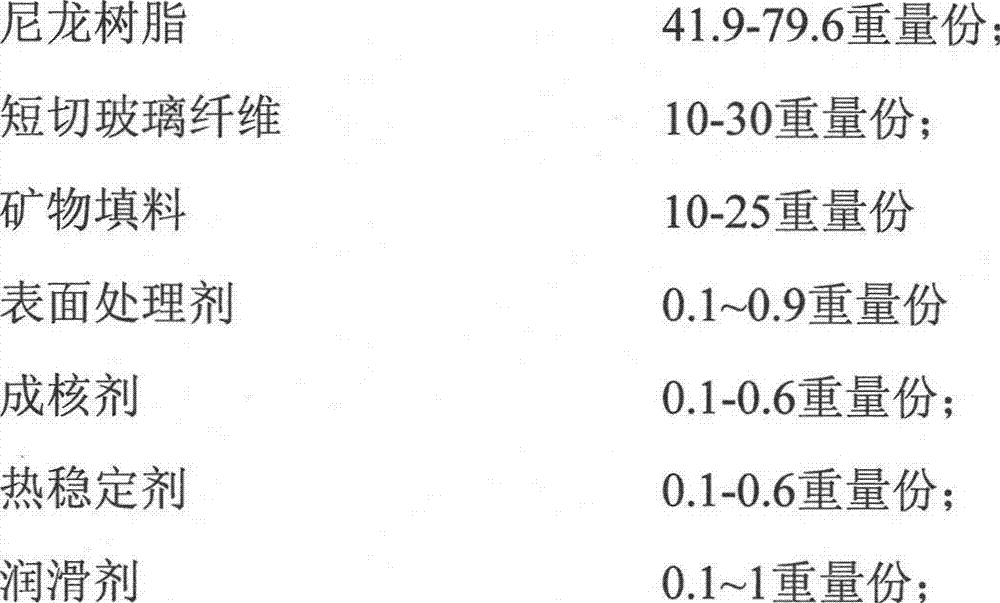

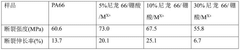

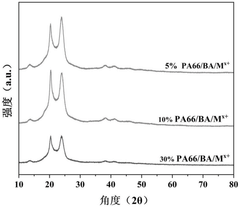

High heat resistance and low warping nylon 66 composite and preparation method thereof

PatentActiveCN103030972A

Innovation

- Using the composite filling method of glass fiber and mineral, adding heat stabilizer, nucleating agent and lubricant, surface treatment of mineral powder and glass fiber to improve the interface bonding performance, using a twin-screw extruder for granulation, to prepare a product with excellent size Nylon 66 composite material with excellent stability and long-term thermal and oxidative aging resistance.

Interconnection structure reinforced nylon composite material and preparation method thereof

PatentPendingCN119859404A

Innovation

- Using the method of interconnected structure enhancement, nylon 66 is dissolved in formic acid solution to form a gel liquid, and then mixed with boric acid and metal salt, and through water replacement and drying, a solid reinforced nylon composite material is formed. This method improves the tensile properties and tensile resistance of composite materials through the cross-linking of boric acid and metal cations.

Environmental Impact and Sustainability Considerations

The environmental impact of material selection for structural parts has become increasingly critical in product development cycles. When comparing Nylon 66 and composite materials for bending strength applications, sustainability considerations must be evaluated alongside mechanical properties. Nylon 66 production typically involves petroleum-based feedstocks and energy-intensive polymerization processes, resulting in significant carbon emissions. The manufacturing process generates approximately 6-9 kg CO2 equivalent per kilogram of material produced, contributing to its environmental footprint.

Composite materials present a more complex environmental profile. While carbon fiber reinforced polymers (CFRP) offer superior strength-to-weight ratios, their production is highly energy-intensive, with carbon fiber manufacturing requiring 183-286 MJ/kg of energy. Glass fiber composites present a lower environmental burden at 30-50 MJ/kg, though still exceeding that of many conventional polymers.

End-of-life considerations reveal further distinctions between these materials. Nylon 66 offers established recycling pathways, with mechanical recycling achieving recovery rates of 75-85% in optimal conditions. Chemical recycling technologies are advancing, potentially enabling closed-loop systems for polyamide materials. Conversely, composite materials present significant recycling challenges due to their heterogeneous nature, with most thermoset composites currently ending up in landfills or being downcycled.

Life cycle assessment (LCA) studies indicate that the environmental advantage may shift depending on application requirements. For structural parts where weight reduction is paramount, composites can deliver net environmental benefits through use-phase efficiency gains, particularly in transportation applications. Research indicates that each kilogram of weight saved in automotive applications can reduce lifetime CO2 emissions by 20 kg through improved fuel efficiency.

Water consumption patterns also differ significantly between these materials. Nylon 66 production requires approximately 300-500 liters of water per kilogram of material, while composite manufacturing processes generally consume less water but may involve more toxic chemicals requiring specialized treatment.

Recent regulatory developments are increasingly influencing material selection decisions. Extended Producer Responsibility (EPR) schemes in Europe and Asia are placing greater emphasis on end-of-life management, potentially favoring materials with established recycling infrastructure. The EU's Carbon Border Adjustment Mechanism may also impact the economic viability of carbon-intensive materials in coming years.

Innovations in bio-based alternatives for both material categories are emerging as potential solutions. Bio-based polyamides derived from castor oil and other renewable feedstocks can reduce the carbon footprint of nylon products by 20-50%, while natural fiber composites utilizing flax, hemp, or bamboo fibers offer promising environmental profiles compared to traditional glass or carbon fiber reinforcements.

Composite materials present a more complex environmental profile. While carbon fiber reinforced polymers (CFRP) offer superior strength-to-weight ratios, their production is highly energy-intensive, with carbon fiber manufacturing requiring 183-286 MJ/kg of energy. Glass fiber composites present a lower environmental burden at 30-50 MJ/kg, though still exceeding that of many conventional polymers.

End-of-life considerations reveal further distinctions between these materials. Nylon 66 offers established recycling pathways, with mechanical recycling achieving recovery rates of 75-85% in optimal conditions. Chemical recycling technologies are advancing, potentially enabling closed-loop systems for polyamide materials. Conversely, composite materials present significant recycling challenges due to their heterogeneous nature, with most thermoset composites currently ending up in landfills or being downcycled.

Life cycle assessment (LCA) studies indicate that the environmental advantage may shift depending on application requirements. For structural parts where weight reduction is paramount, composites can deliver net environmental benefits through use-phase efficiency gains, particularly in transportation applications. Research indicates that each kilogram of weight saved in automotive applications can reduce lifetime CO2 emissions by 20 kg through improved fuel efficiency.

Water consumption patterns also differ significantly between these materials. Nylon 66 production requires approximately 300-500 liters of water per kilogram of material, while composite manufacturing processes generally consume less water but may involve more toxic chemicals requiring specialized treatment.

Recent regulatory developments are increasingly influencing material selection decisions. Extended Producer Responsibility (EPR) schemes in Europe and Asia are placing greater emphasis on end-of-life management, potentially favoring materials with established recycling infrastructure. The EU's Carbon Border Adjustment Mechanism may also impact the economic viability of carbon-intensive materials in coming years.

Innovations in bio-based alternatives for both material categories are emerging as potential solutions. Bio-based polyamides derived from castor oil and other renewable feedstocks can reduce the carbon footprint of nylon products by 20-50%, while natural fiber composites utilizing flax, hemp, or bamboo fibers offer promising environmental profiles compared to traditional glass or carbon fiber reinforcements.

Cost-Performance Analysis for Industrial Applications

When evaluating Nylon 66 versus composite materials for structural parts requiring bending strength, cost-performance analysis reveals significant trade-offs that impact industrial applications. Nylon 66 typically ranges from $2-5 per kilogram, while fiber-reinforced composites can cost between $15-50 per kilogram depending on fiber type and manufacturing process. This substantial price differential must be weighed against performance benefits in various industrial contexts.

The cost-efficiency ratio demonstrates that while Nylon 66 offers adequate performance for moderate-stress applications at a lower price point, composites deliver superior strength-to-weight ratios that may justify their higher costs in critical applications. For instance, in automotive components, the 3-5 times higher material cost of carbon fiber composites can be offset by 40-60% weight reduction, resulting in long-term fuel savings and enhanced performance.

Manufacturing complexity further impacts the cost-performance equation. Nylon 66 parts can be produced through injection molding with cycle times of 30-90 seconds per part, allowing high-volume production with relatively low tooling investment. Composite manufacturing typically requires more complex processes such as compression molding, resin transfer molding, or hand lay-up, with cycle times ranging from minutes to hours per part, significantly increasing labor costs and reducing production throughput.

Lifecycle cost analysis reveals additional considerations beyond initial material expenses. Nylon 66 components may require more frequent replacement in high-stress applications, with typical service life reductions of 30-50% compared to composite alternatives when subjected to continuous mechanical stress or harsh environmental conditions. This replacement frequency must be factored into total ownership cost calculations.

Environmental factors also influence the cost-performance equation. Nylon 66 production generates approximately 6-9 kg CO2 equivalent per kilogram of material, while carbon fiber composites generate 20-25 kg CO2 equivalent. However, the extended service life and weight reduction benefits of composites may offset these initial environmental impacts over the product lifecycle, particularly in transportation applications where weight directly correlates with energy consumption.

Industry-specific requirements further differentiate the cost-performance profiles. In aerospace applications, where weight reduction directly translates to operational cost savings, composites' premium price is more readily justified. Conversely, in consumer goods or non-critical industrial components, Nylon 66's lower cost and adequate performance often present the optimal solution despite modest mechanical property limitations.

The cost-efficiency ratio demonstrates that while Nylon 66 offers adequate performance for moderate-stress applications at a lower price point, composites deliver superior strength-to-weight ratios that may justify their higher costs in critical applications. For instance, in automotive components, the 3-5 times higher material cost of carbon fiber composites can be offset by 40-60% weight reduction, resulting in long-term fuel savings and enhanced performance.

Manufacturing complexity further impacts the cost-performance equation. Nylon 66 parts can be produced through injection molding with cycle times of 30-90 seconds per part, allowing high-volume production with relatively low tooling investment. Composite manufacturing typically requires more complex processes such as compression molding, resin transfer molding, or hand lay-up, with cycle times ranging from minutes to hours per part, significantly increasing labor costs and reducing production throughput.

Lifecycle cost analysis reveals additional considerations beyond initial material expenses. Nylon 66 components may require more frequent replacement in high-stress applications, with typical service life reductions of 30-50% compared to composite alternatives when subjected to continuous mechanical stress or harsh environmental conditions. This replacement frequency must be factored into total ownership cost calculations.

Environmental factors also influence the cost-performance equation. Nylon 66 production generates approximately 6-9 kg CO2 equivalent per kilogram of material, while carbon fiber composites generate 20-25 kg CO2 equivalent. However, the extended service life and weight reduction benefits of composites may offset these initial environmental impacts over the product lifecycle, particularly in transportation applications where weight directly correlates with energy consumption.

Industry-specific requirements further differentiate the cost-performance profiles. In aerospace applications, where weight reduction directly translates to operational cost savings, composites' premium price is more readily justified. Conversely, in consumer goods or non-critical industrial components, Nylon 66's lower cost and adequate performance often present the optimal solution despite modest mechanical property limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!