Comparative Analysis of Sodium and Lithium Ion Battery Lifespans

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Objectives

Battery technology has undergone significant evolution since its inception, with lithium-ion batteries dominating the market for decades. However, the emergence of sodium-ion batteries has sparked renewed interest in alternative energy storage solutions. This comparative analysis aims to explore the lifespan characteristics of sodium and lithium-ion batteries, focusing on their technological progression and future objectives.

The development of lithium-ion batteries can be traced back to the 1970s, with commercial introduction in the early 1990s. These batteries quickly became the standard for portable electronics and electric vehicles due to their high energy density and relatively long cycle life. Over the years, improvements in electrode materials, electrolytes, and manufacturing processes have led to substantial increases in energy density, charging speeds, and overall lifespan.

Sodium-ion batteries, while conceptually similar to their lithium counterparts, have a more recent history of intensive research and development. The renewed interest in sodium-ion technology stems from the abundance and low cost of sodium resources compared to lithium. This has led to a surge in research efforts aimed at improving the performance and lifespan of sodium-ion batteries to match or exceed that of lithium-ion batteries.

The primary objective in the comparative analysis of sodium and lithium-ion battery lifespans is to determine the potential of sodium-ion technology as a viable alternative or complement to lithium-ion batteries. This involves assessing various factors that influence battery lifespan, including cycle life, capacity retention, and degradation mechanisms under different operating conditions.

Key technological goals in this field include enhancing the energy density of sodium-ion batteries to approach that of lithium-ion batteries, improving the stability of electrode materials to increase cycle life, and developing electrolytes that enable faster charging and better performance at extreme temperatures. Additionally, researchers aim to optimize the overall cell design to mitigate issues such as dendrite formation and electrolyte decomposition, which can significantly impact battery lifespan.

Another crucial objective is to understand and mitigate the specific degradation mechanisms in sodium-ion batteries, which may differ from those in lithium-ion batteries due to the larger size of sodium ions and their different chemical properties. This knowledge is essential for developing strategies to extend the lifespan of sodium-ion batteries and make them competitive with lithium-ion technology in various applications.

As the demand for energy storage solutions continues to grow, particularly in renewable energy integration and electric vehicle markets, the development of long-lasting, cost-effective batteries becomes increasingly critical. The comparative analysis of sodium and lithium-ion battery lifespans is not only a technological pursuit but also a strategic endeavor to diversify energy storage options and ensure sustainable development in the face of potential resource constraints.

The development of lithium-ion batteries can be traced back to the 1970s, with commercial introduction in the early 1990s. These batteries quickly became the standard for portable electronics and electric vehicles due to their high energy density and relatively long cycle life. Over the years, improvements in electrode materials, electrolytes, and manufacturing processes have led to substantial increases in energy density, charging speeds, and overall lifespan.

Sodium-ion batteries, while conceptually similar to their lithium counterparts, have a more recent history of intensive research and development. The renewed interest in sodium-ion technology stems from the abundance and low cost of sodium resources compared to lithium. This has led to a surge in research efforts aimed at improving the performance and lifespan of sodium-ion batteries to match or exceed that of lithium-ion batteries.

The primary objective in the comparative analysis of sodium and lithium-ion battery lifespans is to determine the potential of sodium-ion technology as a viable alternative or complement to lithium-ion batteries. This involves assessing various factors that influence battery lifespan, including cycle life, capacity retention, and degradation mechanisms under different operating conditions.

Key technological goals in this field include enhancing the energy density of sodium-ion batteries to approach that of lithium-ion batteries, improving the stability of electrode materials to increase cycle life, and developing electrolytes that enable faster charging and better performance at extreme temperatures. Additionally, researchers aim to optimize the overall cell design to mitigate issues such as dendrite formation and electrolyte decomposition, which can significantly impact battery lifespan.

Another crucial objective is to understand and mitigate the specific degradation mechanisms in sodium-ion batteries, which may differ from those in lithium-ion batteries due to the larger size of sodium ions and their different chemical properties. This knowledge is essential for developing strategies to extend the lifespan of sodium-ion batteries and make them competitive with lithium-ion technology in various applications.

As the demand for energy storage solutions continues to grow, particularly in renewable energy integration and electric vehicle markets, the development of long-lasting, cost-effective batteries becomes increasingly critical. The comparative analysis of sodium and lithium-ion battery lifespans is not only a technological pursuit but also a strategic endeavor to diversify energy storage options and ensure sustainable development in the face of potential resource constraints.

Market Demand Analysis for Energy Storage Solutions

The energy storage market has witnessed significant growth in recent years, driven by the increasing demand for renewable energy integration, grid stability, and electrification of transportation. The global energy storage market is projected to reach substantial growth by 2030, with a compound annual growth rate (CAGR) exceeding 20% during the forecast period. This surge in demand is primarily attributed to the rapid adoption of electric vehicles, the expansion of renewable energy sources, and the need for grid modernization.

In the context of sodium and lithium-ion batteries, market demand analysis reveals a growing interest in sodium-ion technology as a potential alternative to lithium-ion batteries. While lithium-ion batteries currently dominate the energy storage market, concerns over the long-term availability and cost of lithium have sparked interest in sodium-ion technology. The abundance and widespread distribution of sodium resources make it an attractive option for large-scale energy storage applications.

The automotive sector represents a significant driver for energy storage solutions, with electric vehicle sales projected to increase substantially in the coming years. This growth creates a substantial demand for high-performance, long-lasting battery technologies. While lithium-ion batteries currently lead in this sector, the potential for sodium-ion batteries to offer comparable performance at a lower cost is generating interest among automotive manufacturers.

Grid-scale energy storage is another key market segment experiencing rapid growth. As countries worldwide aim to increase their renewable energy capacity, the need for efficient and cost-effective energy storage solutions becomes paramount. Sodium-ion batteries show promise in this area, particularly for stationary storage applications where energy density is less critical than cost and longevity.

Consumer electronics and portable devices continue to drive demand for compact, high-energy-density storage solutions. While lithium-ion batteries have long been the standard in this sector, there is growing interest in alternatives that can offer improved safety and lower costs. Sodium-ion technology is being explored for potential applications in this market, although challenges related to energy density need to be addressed.

The industrial and commercial sectors are also significant contributors to the energy storage market demand. These sectors require reliable, long-lasting storage solutions for backup power, peak shaving, and energy management. The potential for sodium-ion batteries to offer a more cost-effective alternative to lithium-ion in these applications is driving research and development efforts.

As environmental concerns and sustainability initiatives gain prominence, there is an increasing demand for energy storage solutions with lower environmental impact. This trend favors the development of sodium-ion technology, which relies on more abundant and environmentally friendly materials compared to lithium-ion batteries.

In the context of sodium and lithium-ion batteries, market demand analysis reveals a growing interest in sodium-ion technology as a potential alternative to lithium-ion batteries. While lithium-ion batteries currently dominate the energy storage market, concerns over the long-term availability and cost of lithium have sparked interest in sodium-ion technology. The abundance and widespread distribution of sodium resources make it an attractive option for large-scale energy storage applications.

The automotive sector represents a significant driver for energy storage solutions, with electric vehicle sales projected to increase substantially in the coming years. This growth creates a substantial demand for high-performance, long-lasting battery technologies. While lithium-ion batteries currently lead in this sector, the potential for sodium-ion batteries to offer comparable performance at a lower cost is generating interest among automotive manufacturers.

Grid-scale energy storage is another key market segment experiencing rapid growth. As countries worldwide aim to increase their renewable energy capacity, the need for efficient and cost-effective energy storage solutions becomes paramount. Sodium-ion batteries show promise in this area, particularly for stationary storage applications where energy density is less critical than cost and longevity.

Consumer electronics and portable devices continue to drive demand for compact, high-energy-density storage solutions. While lithium-ion batteries have long been the standard in this sector, there is growing interest in alternatives that can offer improved safety and lower costs. Sodium-ion technology is being explored for potential applications in this market, although challenges related to energy density need to be addressed.

The industrial and commercial sectors are also significant contributors to the energy storage market demand. These sectors require reliable, long-lasting storage solutions for backup power, peak shaving, and energy management. The potential for sodium-ion batteries to offer a more cost-effective alternative to lithium-ion in these applications is driving research and development efforts.

As environmental concerns and sustainability initiatives gain prominence, there is an increasing demand for energy storage solutions with lower environmental impact. This trend favors the development of sodium-ion technology, which relies on more abundant and environmentally friendly materials compared to lithium-ion batteries.

Current Challenges in Battery Lifespan Enhancement

Despite significant advancements in battery technology, enhancing the lifespan of both sodium and lithium-ion batteries remains a critical challenge in the energy storage industry. One of the primary issues facing both battery types is capacity fade, which occurs due to various degradation mechanisms during charge-discharge cycles.

For lithium-ion batteries, the formation and growth of the solid electrolyte interphase (SEI) layer on the anode surface contribute significantly to capacity loss. This layer consumes active lithium and increases internal resistance, leading to reduced energy storage capacity and power output over time. Additionally, structural changes in electrode materials, particularly in the cathode, can cause capacity fade through the loss of active material and decreased ionic conductivity.

Sodium-ion batteries face similar challenges, with the added complexity of larger sodium ions causing more severe structural stress on electrode materials. This can lead to faster degradation and shorter overall lifespans compared to their lithium-ion counterparts. The development of stable electrode materials that can withstand repeated sodium insertion and extraction remains a significant hurdle.

Thermal management is another critical challenge for both battery types. High temperatures accelerate side reactions and degradation processes, while low temperatures can lead to lithium plating in lithium-ion batteries and reduced ionic conductivity in both systems. Developing effective thermal management strategies that work across a wide range of operating conditions is essential for extending battery life.

Electrolyte stability is also a key factor in battery lifespan. Both sodium and lithium-ion batteries suffer from electrolyte decomposition at high voltages, leading to gas formation, increased internal pressure, and potential safety hazards. Finding electrolyte formulations that remain stable over a wider voltage window while maintaining good ionic conductivity is an ongoing challenge.

Addressing these challenges requires a multifaceted approach, combining materials science, electrochemistry, and engineering solutions. Researchers are exploring advanced electrode materials, such as silicon anodes for lithium-ion batteries and layered oxide cathodes for sodium-ion batteries, to improve capacity retention. Novel electrolyte additives and coatings are being developed to stabilize the electrode-electrolyte interface and suppress side reactions.

Furthermore, the implementation of advanced battery management systems (BMS) is crucial for optimizing battery performance and longevity. These systems can help mitigate degradation by controlling charging protocols, managing temperature, and balancing cell voltages. However, developing BMS algorithms that can accurately predict and adapt to battery aging across different chemistries and use cases remains a significant challenge.

For lithium-ion batteries, the formation and growth of the solid electrolyte interphase (SEI) layer on the anode surface contribute significantly to capacity loss. This layer consumes active lithium and increases internal resistance, leading to reduced energy storage capacity and power output over time. Additionally, structural changes in electrode materials, particularly in the cathode, can cause capacity fade through the loss of active material and decreased ionic conductivity.

Sodium-ion batteries face similar challenges, with the added complexity of larger sodium ions causing more severe structural stress on electrode materials. This can lead to faster degradation and shorter overall lifespans compared to their lithium-ion counterparts. The development of stable electrode materials that can withstand repeated sodium insertion and extraction remains a significant hurdle.

Thermal management is another critical challenge for both battery types. High temperatures accelerate side reactions and degradation processes, while low temperatures can lead to lithium plating in lithium-ion batteries and reduced ionic conductivity in both systems. Developing effective thermal management strategies that work across a wide range of operating conditions is essential for extending battery life.

Electrolyte stability is also a key factor in battery lifespan. Both sodium and lithium-ion batteries suffer from electrolyte decomposition at high voltages, leading to gas formation, increased internal pressure, and potential safety hazards. Finding electrolyte formulations that remain stable over a wider voltage window while maintaining good ionic conductivity is an ongoing challenge.

Addressing these challenges requires a multifaceted approach, combining materials science, electrochemistry, and engineering solutions. Researchers are exploring advanced electrode materials, such as silicon anodes for lithium-ion batteries and layered oxide cathodes for sodium-ion batteries, to improve capacity retention. Novel electrolyte additives and coatings are being developed to stabilize the electrode-electrolyte interface and suppress side reactions.

Furthermore, the implementation of advanced battery management systems (BMS) is crucial for optimizing battery performance and longevity. These systems can help mitigate degradation by controlling charging protocols, managing temperature, and balancing cell voltages. However, developing BMS algorithms that can accurately predict and adapt to battery aging across different chemistries and use cases remains a significant challenge.

Existing Lifespan Extension Techniques

01 Electrolyte composition for improved battery lifespan

Optimizing the electrolyte composition can significantly enhance the lifespan of sodium and lithium-ion batteries. This includes using additives, adjusting salt concentrations, and incorporating novel electrolyte formulations to reduce degradation and improve cycling stability.- Electrolyte composition for improved battery lifespan: Optimizing the electrolyte composition can significantly enhance the lifespan of sodium and lithium-ion batteries. This includes using additives, adjusting salt concentrations, and incorporating novel electrolyte formulations to reduce degradation and improve cycling stability.

- Advanced electrode materials for longer battery life: Developing and utilizing advanced electrode materials, such as nanostructured composites or doped compounds, can improve the capacity retention and overall lifespan of sodium and lithium-ion batteries. These materials often exhibit better structural stability and enhanced electrochemical performance.

- Battery management systems for lifespan extension: Implementing sophisticated battery management systems can help extend the lifespan of sodium and lithium-ion batteries. These systems optimize charging and discharging processes, monitor battery health, and employ advanced algorithms to prevent degradation and improve overall battery longevity.

- Protective coatings and surface modifications: Applying protective coatings or surface modifications to battery components, particularly electrodes, can enhance their stability and resistance to degradation. This approach helps to maintain battery performance over extended periods, thereby increasing the overall lifespan of sodium and lithium-ion batteries.

- Novel cell designs for improved longevity: Innovative cell designs, including new architectures and component arrangements, can significantly impact the lifespan of sodium and lithium-ion batteries. These designs often focus on improving thermal management, reducing mechanical stress, and optimizing ion transport within the battery structure.

02 Advanced electrode materials for longer battery life

Developing and utilizing advanced electrode materials, such as nanostructured composites or doped compounds, can improve the capacity retention and overall lifespan of sodium and lithium-ion batteries. These materials often exhibit better structural stability and enhanced electrochemical performance.Expand Specific Solutions03 Battery management systems for lifespan extension

Implementing sophisticated battery management systems can help extend the lifespan of sodium and lithium-ion batteries. These systems optimize charging and discharging processes, monitor battery health, and employ predictive algorithms to prevent degradation and maximize cycle life.Expand Specific Solutions04 Thermal management techniques for battery longevity

Effective thermal management strategies play a crucial role in extending the lifespan of sodium and lithium-ion batteries. This includes innovative cooling systems, heat dissipation methods, and temperature control mechanisms to prevent thermal degradation and maintain optimal operating conditions.Expand Specific Solutions05 Novel battery architectures for improved lifespan

Developing new battery architectures, such as solid-state designs or hybrid systems, can significantly enhance the lifespan of sodium and lithium-ion batteries. These innovative structures often address common degradation mechanisms and offer improved stability over traditional battery designs.Expand Specific Solutions

Key Players in Battery Manufacturing Industry

The comparative analysis of sodium and lithium ion battery lifespans is currently in a transitional phase, with the market for sodium-ion batteries still emerging but showing significant potential. While lithium-ion technology dominates the current market, estimated at over $40 billion globally, sodium-ion batteries are gaining traction due to their cost-effectiveness and abundant raw materials. Companies like Faradion Ltd. and CATL are leading the development of sodium-ion technology, with major players such as LG Chem and Toyota also investing in research. The technology is approaching commercial viability, but still lags behind lithium-ion in terms of energy density and cycle life, indicating a need for further advancements to compete effectively in the energy storage market.

Faradion Ltd.

Technical Solution: Faradion is a pioneer in sodium-ion battery technology, focusing on developing high-performance, cost-effective energy storage solutions. Their proprietary technology uses a layered oxide cathode (Na0.67[Mn0.5Fe0.5]O2) and hard carbon anode, achieving an energy density of 140 Wh/kg at the cell level [7]. Faradion's batteries employ a unique electrolyte formulation that enhances the stability of the solid electrolyte interphase (SEI), resulting in improved cycle life. Their cells have demonstrated over 1000 cycles with 80% capacity retention at 1C charge/discharge rates [8]. Faradion has also developed a scalable manufacturing process that leverages existing lithium-ion production infrastructure, potentially reducing the cost and time to market for sodium-ion batteries.

Strengths: Focused expertise in sodium-ion technology; potential for low-cost production using existing manufacturing infrastructure. Weaknesses: Energy density still lower than advanced lithium-ion batteries; limited track record in large-scale production.

Toyota Motor Corp.

Technical Solution: Toyota has been actively researching both lithium-ion and sodium-ion battery technologies to diversify its energy storage options. For lithium-ion batteries, Toyota has developed solid-state battery technology, which promises higher energy density and improved safety. Their solid-state batteries use a sulfide superionic conductor, achieving an ionic conductivity of 2.5 mS/cm at room temperature [3]. In parallel, Toyota is exploring sodium-ion batteries as a complementary technology. They have developed a hard carbon anode material with a reversible capacity of 300 mAh/g and a Prussian blue analogue cathode, resulting in a full cell energy density of 90 Wh/kg [4]. Toyota's approach aims to optimize both lithium and sodium-ion technologies for different applications, considering factors such as cost, performance, and resource availability.

Strengths: Diversified battery technology portfolio; strong R&D capabilities in both lithium and sodium-ion chemistries. Weaknesses: Sodium-ion technology still lags behind lithium-ion in terms of energy density and commercial readiness.

Core Innovations in Electrode Materials

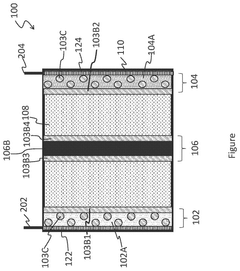

Sodium ion batteries and methods of manufacture thereof

PatentPendingUS20250105341A1

Innovation

- Incorporating a zeolite layer on the anode, cathode, or separator in sodium ion batteries, which undergoes a sodium ion exchange process to eliminate undesirable cations, enhancing electrolyte wettability, capturing trace water and transition metal ions, and acting as a scavenger for hydrofluoric acid to protect the cathode from corrosion.

Sodium ion battery

PatentWO2010110465A1

Innovation

- A sodium ion battery design utilizing a negative electrode made of aluminum or aluminum alloy with a carbon active material capable of doping and dedoping sodium ions, paired with a sodium inorganic compound positive electrode and a non-aqueous electrolyte, enhances cycle life and reduces costs by leveraging abundant resources.

Environmental Impact of Battery Production

The environmental impact of battery production is a critical consideration in the comparative analysis of sodium and lithium-ion battery lifespans. Both battery technologies have significant ecological footprints, but their impacts differ in several key aspects.

Lithium-ion battery production has been extensively studied due to its widespread use. The extraction of lithium, primarily from salt flats in South America, can lead to water depletion and soil contamination. The process is water-intensive, potentially affecting local ecosystems and communities. Additionally, the mining of other essential materials like cobalt, often sourced from conflict-prone regions, raises ethical concerns alongside environmental ones.

In contrast, sodium-ion batteries rely on more abundant and widely distributed raw materials. Sodium is extracted from seawater or rock salt, processes generally considered less environmentally damaging than lithium extraction. However, the production of other components, such as hard carbon anodes, still carries environmental implications that require careful assessment.

Both battery types involve energy-intensive manufacturing processes, contributing to greenhouse gas emissions. The production of lithium-ion batteries typically generates more CO2 emissions per kWh of storage capacity compared to sodium-ion batteries. This difference is partly due to the higher energy requirements for processing lithium and the complex cathode materials used in lithium-ion cells.

Water consumption is another crucial factor. Lithium extraction can require up to 500,000 gallons of water per metric ton of lithium, potentially straining water resources in arid regions. Sodium extraction, being less water-intensive, may offer advantages in this regard, though the full lifecycle water usage of sodium-ion batteries needs further study.

The disposal and recycling of batteries at the end of their lifespan also contribute to their environmental impact. Lithium-ion batteries have established recycling processes, but these are often energy-intensive and not universally implemented. The recycling infrastructure for sodium-ion batteries is still in its infancy, presenting both challenges and opportunities for developing more sustainable end-of-life solutions.

It's important to note that the environmental impact of battery production extends beyond the manufacturing phase. The sourcing of raw materials, transportation, and energy used during the battery's operational life all contribute to its overall ecological footprint. As technology advances, improvements in production efficiency and recycling techniques may alter the comparative environmental impacts of these battery technologies.

In conclusion, while both sodium and lithium-ion batteries have environmental implications in their production, sodium-ion batteries currently show potential for reduced ecological impact due to more abundant raw materials and potentially less intensive extraction processes. However, comprehensive lifecycle assessments are needed to fully understand and compare the long-term environmental consequences of these two battery technologies.

Lithium-ion battery production has been extensively studied due to its widespread use. The extraction of lithium, primarily from salt flats in South America, can lead to water depletion and soil contamination. The process is water-intensive, potentially affecting local ecosystems and communities. Additionally, the mining of other essential materials like cobalt, often sourced from conflict-prone regions, raises ethical concerns alongside environmental ones.

In contrast, sodium-ion batteries rely on more abundant and widely distributed raw materials. Sodium is extracted from seawater or rock salt, processes generally considered less environmentally damaging than lithium extraction. However, the production of other components, such as hard carbon anodes, still carries environmental implications that require careful assessment.

Both battery types involve energy-intensive manufacturing processes, contributing to greenhouse gas emissions. The production of lithium-ion batteries typically generates more CO2 emissions per kWh of storage capacity compared to sodium-ion batteries. This difference is partly due to the higher energy requirements for processing lithium and the complex cathode materials used in lithium-ion cells.

Water consumption is another crucial factor. Lithium extraction can require up to 500,000 gallons of water per metric ton of lithium, potentially straining water resources in arid regions. Sodium extraction, being less water-intensive, may offer advantages in this regard, though the full lifecycle water usage of sodium-ion batteries needs further study.

The disposal and recycling of batteries at the end of their lifespan also contribute to their environmental impact. Lithium-ion batteries have established recycling processes, but these are often energy-intensive and not universally implemented. The recycling infrastructure for sodium-ion batteries is still in its infancy, presenting both challenges and opportunities for developing more sustainable end-of-life solutions.

It's important to note that the environmental impact of battery production extends beyond the manufacturing phase. The sourcing of raw materials, transportation, and energy used during the battery's operational life all contribute to its overall ecological footprint. As technology advances, improvements in production efficiency and recycling techniques may alter the comparative environmental impacts of these battery technologies.

In conclusion, while both sodium and lithium-ion batteries have environmental implications in their production, sodium-ion batteries currently show potential for reduced ecological impact due to more abundant raw materials and potentially less intensive extraction processes. However, comprehensive lifecycle assessments are needed to fully understand and compare the long-term environmental consequences of these two battery technologies.

Cost-Benefit Analysis of Na-ion vs Li-ion Batteries

The cost-benefit analysis of sodium-ion (Na-ion) versus lithium-ion (Li-ion) batteries reveals significant economic and performance implications for various applications. Initial production costs for Na-ion batteries are generally lower due to the abundance and widespread distribution of sodium resources. This cost advantage is particularly pronounced in large-scale energy storage systems where the price per kilowatt-hour is a critical factor.

However, the cost-benefit equation becomes more complex when considering the entire lifecycle of the batteries. Li-ion batteries currently offer higher energy density, which translates to longer range in electric vehicles and more compact storage solutions. This advantage can offset the higher initial costs in applications where space or weight is at a premium.

Longevity is another crucial factor in the cost-benefit analysis. While Na-ion batteries show promising cycle life in laboratory settings, Li-ion technology has a proven track record in real-world applications. The longer lifespan of some Li-ion chemistries can result in lower total cost of ownership over time, despite higher upfront costs.

Manufacturing scalability also plays a role in the cost-benefit comparison. The established Li-ion battery industry benefits from economies of scale, which helps to keep production costs competitive. Na-ion battery production, while potentially simpler, has not yet achieved the same level of industrial maturity, which could impact short-term cost-effectiveness.

Environmental considerations further complicate the analysis. Na-ion batteries offer potential advantages in terms of recyclability and reduced reliance on critical materials. This could lead to long-term cost benefits as regulations around battery recycling and material sourcing become more stringent.

Safety features of Na-ion batteries, such as lower fire risk and more stable thermal behavior, may result in reduced costs for safety systems and insurance in certain applications. This could be particularly beneficial in large-scale stationary storage where safety concerns are paramount.

In conclusion, the cost-benefit analysis of Na-ion versus Li-ion batteries is highly dependent on the specific application and time horizon considered. While Na-ion technology shows promise for cost-effective large-scale storage, Li-ion batteries maintain advantages in high-performance applications. As Na-ion technology matures and production scales up, the cost-benefit balance is likely to evolve, potentially leading to a more diversified battery market catering to different application needs and cost sensitivities.

However, the cost-benefit equation becomes more complex when considering the entire lifecycle of the batteries. Li-ion batteries currently offer higher energy density, which translates to longer range in electric vehicles and more compact storage solutions. This advantage can offset the higher initial costs in applications where space or weight is at a premium.

Longevity is another crucial factor in the cost-benefit analysis. While Na-ion batteries show promising cycle life in laboratory settings, Li-ion technology has a proven track record in real-world applications. The longer lifespan of some Li-ion chemistries can result in lower total cost of ownership over time, despite higher upfront costs.

Manufacturing scalability also plays a role in the cost-benefit comparison. The established Li-ion battery industry benefits from economies of scale, which helps to keep production costs competitive. Na-ion battery production, while potentially simpler, has not yet achieved the same level of industrial maturity, which could impact short-term cost-effectiveness.

Environmental considerations further complicate the analysis. Na-ion batteries offer potential advantages in terms of recyclability and reduced reliance on critical materials. This could lead to long-term cost benefits as regulations around battery recycling and material sourcing become more stringent.

Safety features of Na-ion batteries, such as lower fire risk and more stable thermal behavior, may result in reduced costs for safety systems and insurance in certain applications. This could be particularly beneficial in large-scale stationary storage where safety concerns are paramount.

In conclusion, the cost-benefit analysis of Na-ion versus Li-ion batteries is highly dependent on the specific application and time horizon considered. While Na-ion technology shows promise for cost-effective large-scale storage, Li-ion batteries maintain advantages in high-performance applications. As Na-ion technology matures and production scales up, the cost-benefit balance is likely to evolve, potentially leading to a more diversified battery market catering to different application needs and cost sensitivities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!