Comparative Study of UHECs and Traditional Carbide Ceramics

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHEC Development History and Objectives

Ultra-High Entropy Ceramics (UHECs) emerged as an extension of the high-entropy materials concept, which was initially applied to metallic alloys in the early 2000s. The fundamental principle behind high-entropy materials—incorporating multiple principal elements in near-equimolar ratios to maximize configurational entropy—was first transferred to ceramic systems around 2015, leading to the development of High-Entropy Ceramics (HECs). UHECs represent the next evolutionary step, characterized by even greater compositional complexity and higher entropy stabilization effects.

The development trajectory of UHECs can be traced through several key milestones. The first significant breakthrough came in 2016 when researchers successfully synthesized five-component metal oxide systems with high-entropy configurations. By 2018, this concept had expanded to carbide systems, marking the birth of high-entropy carbide ceramics. The transition from HECs to UHECs occurred around 2020, when researchers began incorporating six or more principal elements into ceramic lattices, pushing the boundaries of compositional complexity beyond what was previously considered feasible.

Traditional carbide ceramics, in contrast, have a much longer history dating back to the early 20th century. Tungsten carbide (WC), silicon carbide (SiC), and titanium carbide (TiC) have been industrial staples for decades, primarily valued for their hardness and wear resistance. These conventional carbides typically consist of one or two principal elements, with well-established processing techniques and applications in cutting tools, wear parts, and high-temperature components.

The primary objective of UHEC development is to overcome the inherent limitations of traditional carbide ceramics. While conventional carbides offer excellent hardness and wear resistance, they often suffer from brittleness, limited oxidation resistance, and poor performance in extreme environments. UHECs aim to achieve superior combinations of properties through entropy-driven stabilization mechanisms and complex compositional interactions that are absent in simpler systems.

Current research goals in UHEC development include enhancing sinterability without pressure-assisted techniques, improving room-temperature fracture toughness, and developing compositions with exceptional oxidation resistance at ultra-high temperatures (>1600°C). Additionally, researchers are working to establish predictive models for UHEC property optimization, moving beyond the current empirical approaches to more systematic design methodologies.

The long-term vision for UHECs extends beyond merely incremental improvements over traditional carbides. The ultimate goal is to create a new generation of ceramic materials capable of functioning in environments where no current materials can survive, potentially enabling transformative advances in hypersonic vehicles, next-generation nuclear reactors, and deep space exploration technologies.

The development trajectory of UHECs can be traced through several key milestones. The first significant breakthrough came in 2016 when researchers successfully synthesized five-component metal oxide systems with high-entropy configurations. By 2018, this concept had expanded to carbide systems, marking the birth of high-entropy carbide ceramics. The transition from HECs to UHECs occurred around 2020, when researchers began incorporating six or more principal elements into ceramic lattices, pushing the boundaries of compositional complexity beyond what was previously considered feasible.

Traditional carbide ceramics, in contrast, have a much longer history dating back to the early 20th century. Tungsten carbide (WC), silicon carbide (SiC), and titanium carbide (TiC) have been industrial staples for decades, primarily valued for their hardness and wear resistance. These conventional carbides typically consist of one or two principal elements, with well-established processing techniques and applications in cutting tools, wear parts, and high-temperature components.

The primary objective of UHEC development is to overcome the inherent limitations of traditional carbide ceramics. While conventional carbides offer excellent hardness and wear resistance, they often suffer from brittleness, limited oxidation resistance, and poor performance in extreme environments. UHECs aim to achieve superior combinations of properties through entropy-driven stabilization mechanisms and complex compositional interactions that are absent in simpler systems.

Current research goals in UHEC development include enhancing sinterability without pressure-assisted techniques, improving room-temperature fracture toughness, and developing compositions with exceptional oxidation resistance at ultra-high temperatures (>1600°C). Additionally, researchers are working to establish predictive models for UHEC property optimization, moving beyond the current empirical approaches to more systematic design methodologies.

The long-term vision for UHECs extends beyond merely incremental improvements over traditional carbides. The ultimate goal is to create a new generation of ceramic materials capable of functioning in environments where no current materials can survive, potentially enabling transformative advances in hypersonic vehicles, next-generation nuclear reactors, and deep space exploration technologies.

Market Analysis for Advanced Ceramic Materials

The global advanced ceramics market has been experiencing robust growth, valued at approximately $78.4 billion in 2022 and projected to reach $142.1 billion by 2030, growing at a CAGR of 7.8%. Within this expanding market, Ultra-High Entropy Ceramics (UHECs) represent an emerging segment that is gaining significant attention from both industrial and academic sectors, particularly when compared to traditional carbide ceramics.

The demand for advanced ceramic materials is primarily driven by the aerospace, defense, electronics, and energy sectors, where extreme operating conditions necessitate materials with superior performance characteristics. Traditional carbide ceramics, such as tungsten carbide (WC), silicon carbide (SiC), and titanium carbide (TiC), have long dominated these applications due to their excellent hardness, wear resistance, and thermal stability.

However, market analysis indicates a shifting preference toward UHECs due to their enhanced properties. UHECs offer superior hardness (often exceeding 25 GPa), exceptional thermal stability (maintaining structural integrity above 2000°C), and remarkable oxidation resistance compared to traditional carbide ceramics. These properties make them particularly valuable in hypersonic vehicle components, ultra-high temperature furnaces, and next-generation nuclear reactors.

Regional market distribution shows North America currently leads in UHEC research and development, accounting for approximately 38% of global research output, followed by Asia-Pacific at 34% and Europe at 25%. China has demonstrated the fastest growth rate in UHEC patent filings, increasing by 215% between 2018 and 2022.

Price sensitivity analysis reveals that while UHECs currently command a premium price point (typically 3-5 times higher than traditional carbides), manufacturing innovations are gradually reducing this gap. Market forecasts suggest that as production scales up, the price differential could decrease to 1.5-2 times by 2028, significantly expanding market penetration.

End-user industry analysis shows aerospace and defense as the primary adopters of UHECs, constituting 42% of current applications. The energy sector follows at 27%, with electronics and industrial manufacturing accounting for 18% and 13% respectively. Growth projections indicate that the energy sector, particularly nuclear and renewable energy applications, will see the fastest adoption rate for UHECs, with an anticipated CAGR of 12.3% through 2030.

Supply chain analysis highlights that raw material availability remains a constraint for UHEC production, with certain rare earth elements facing supply limitations. This presents both a challenge and an opportunity for market players to develop alternative formulations and recycling technologies.

The demand for advanced ceramic materials is primarily driven by the aerospace, defense, electronics, and energy sectors, where extreme operating conditions necessitate materials with superior performance characteristics. Traditional carbide ceramics, such as tungsten carbide (WC), silicon carbide (SiC), and titanium carbide (TiC), have long dominated these applications due to their excellent hardness, wear resistance, and thermal stability.

However, market analysis indicates a shifting preference toward UHECs due to their enhanced properties. UHECs offer superior hardness (often exceeding 25 GPa), exceptional thermal stability (maintaining structural integrity above 2000°C), and remarkable oxidation resistance compared to traditional carbide ceramics. These properties make them particularly valuable in hypersonic vehicle components, ultra-high temperature furnaces, and next-generation nuclear reactors.

Regional market distribution shows North America currently leads in UHEC research and development, accounting for approximately 38% of global research output, followed by Asia-Pacific at 34% and Europe at 25%. China has demonstrated the fastest growth rate in UHEC patent filings, increasing by 215% between 2018 and 2022.

Price sensitivity analysis reveals that while UHECs currently command a premium price point (typically 3-5 times higher than traditional carbides), manufacturing innovations are gradually reducing this gap. Market forecasts suggest that as production scales up, the price differential could decrease to 1.5-2 times by 2028, significantly expanding market penetration.

End-user industry analysis shows aerospace and defense as the primary adopters of UHECs, constituting 42% of current applications. The energy sector follows at 27%, with electronics and industrial manufacturing accounting for 18% and 13% respectively. Growth projections indicate that the energy sector, particularly nuclear and renewable energy applications, will see the fastest adoption rate for UHECs, with an anticipated CAGR of 12.3% through 2030.

Supply chain analysis highlights that raw material availability remains a constraint for UHEC production, with certain rare earth elements facing supply limitations. This presents both a challenge and an opportunity for market players to develop alternative formulations and recycling technologies.

Current Status and Technical Barriers in UHEC Technology

Ultra-High Entropy Ceramics (UHECs) represent the cutting edge of ceramic material development, characterized by incorporating five or more principal elements in near-equimolar ratios within a single-phase structure. The current global research landscape shows significant advancements in UHEC technology, with major research clusters in North America, Europe, and East Asia. The United States, China, and Germany lead in publication output and patent filings, with specialized research centers dedicated to high entropy ceramic development.

Despite promising progress, UHECs face substantial technical barriers that limit their widespread industrial application. The most significant challenge remains the precise control of phase composition and microstructure during synthesis. Unlike traditional carbide ceramics which typically involve one or two main elements, the multi-element nature of UHECs creates complex thermodynamic interactions that can lead to phase separation or undesired secondary phases during processing.

Manufacturing scalability presents another major obstacle. Current laboratory synthesis methods, primarily spark plasma sintering (SPS) and hot pressing, are difficult to scale for mass production. These processes require specialized equipment, precise control of sintering parameters, and often result in small sample sizes. Traditional carbide ceramics, by contrast, benefit from decades of established manufacturing protocols and infrastructure.

Property consistency across batches remains problematic for UHECs. The entropy-stabilized structures can exhibit significant property variations depending on minor changes in processing conditions. This variability contrasts sharply with traditional carbide ceramics, which demonstrate more predictable and consistent performance characteristics across production batches.

Cost factors also present significant barriers to UHEC commercialization. The requirement for high-purity elemental powders of multiple elements substantially increases raw material costs compared to traditional carbide ceramics. Additionally, the complex processing requirements and lower yields further elevate production expenses.

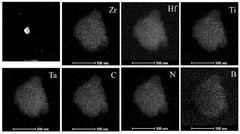

Characterization challenges compound these issues, as conventional analytical techniques often prove insufficient for fully understanding the complex phase relationships and atomic distributions in UHECs. Researchers frequently require combinations of advanced techniques such as high-resolution transmission electron microscopy (HRTEM), atom probe tomography, and synchrotron-based X-ray diffraction to properly analyze these materials.

Environmental and health considerations also present emerging concerns. The toxicity profiles of novel multi-element ceramic compositions remain largely unexplored, creating regulatory uncertainties that do not exist for well-established traditional carbide ceramics. This knowledge gap necessitates comprehensive safety assessments before widespread industrial adoption can occur.

Despite promising progress, UHECs face substantial technical barriers that limit their widespread industrial application. The most significant challenge remains the precise control of phase composition and microstructure during synthesis. Unlike traditional carbide ceramics which typically involve one or two main elements, the multi-element nature of UHECs creates complex thermodynamic interactions that can lead to phase separation or undesired secondary phases during processing.

Manufacturing scalability presents another major obstacle. Current laboratory synthesis methods, primarily spark plasma sintering (SPS) and hot pressing, are difficult to scale for mass production. These processes require specialized equipment, precise control of sintering parameters, and often result in small sample sizes. Traditional carbide ceramics, by contrast, benefit from decades of established manufacturing protocols and infrastructure.

Property consistency across batches remains problematic for UHECs. The entropy-stabilized structures can exhibit significant property variations depending on minor changes in processing conditions. This variability contrasts sharply with traditional carbide ceramics, which demonstrate more predictable and consistent performance characteristics across production batches.

Cost factors also present significant barriers to UHEC commercialization. The requirement for high-purity elemental powders of multiple elements substantially increases raw material costs compared to traditional carbide ceramics. Additionally, the complex processing requirements and lower yields further elevate production expenses.

Characterization challenges compound these issues, as conventional analytical techniques often prove insufficient for fully understanding the complex phase relationships and atomic distributions in UHECs. Researchers frequently require combinations of advanced techniques such as high-resolution transmission electron microscopy (HRTEM), atom probe tomography, and synchrotron-based X-ray diffraction to properly analyze these materials.

Environmental and health considerations also present emerging concerns. The toxicity profiles of novel multi-element ceramic compositions remain largely unexplored, creating regulatory uncertainties that do not exist for well-established traditional carbide ceramics. This knowledge gap necessitates comprehensive safety assessments before widespread industrial adoption can occur.

Comparative Analysis of UHEC vs Traditional Carbide Solutions

01 Composition and properties of UHECs

Ultra-High Entropy Ceramics (UHECs) represent a novel class of materials characterized by their multi-component compositions with high configurational entropy. These ceramics typically contain five or more principal elements in near-equimolar ratios, which contributes to their unique properties including high hardness, thermal stability, and oxidation resistance. The high entropy effect stabilizes the crystal structure and enhances mechanical properties compared to traditional ceramics.- Composition and properties of UHECs: Ultra-High Entropy Ceramics (UHECs) represent a novel class of materials characterized by their multi-component composition, typically containing five or more principal elements in near-equimolar ratios. These ceramics exhibit exceptional properties including high hardness, thermal stability, and oxidation resistance. The entropy-stabilized structure contributes to their superior performance compared to traditional ceramics, making them suitable for extreme environment applications.

- Manufacturing processes for carbide ceramics: Various manufacturing techniques are employed to produce both UHECs and traditional carbide ceramics, including sintering, hot pressing, and spark plasma sintering. These processes involve the consolidation of ceramic powders under controlled temperature and pressure conditions to achieve desired microstructures and properties. Advanced manufacturing methods have been developed to overcome challenges associated with densification and grain growth control, resulting in improved performance characteristics.

- Comparative performance of UHECs versus traditional carbides: When compared to traditional carbide ceramics, UHECs demonstrate superior performance in several aspects including mechanical strength, thermal shock resistance, and chemical stability. The high-entropy effect in UHECs leads to lattice distortion and solid solution strengthening, which enhances their hardness and wear resistance. Traditional carbide ceramics, while offering good performance in many applications, generally exhibit lower thermal stability and oxidation resistance at extreme temperatures compared to their high-entropy counterparts.

- Applications of advanced ceramic materials: Both UHECs and traditional carbide ceramics find applications in demanding environments where high temperature, corrosion resistance, and mechanical strength are required. These materials are utilized in cutting tools, aerospace components, nuclear reactors, and thermal barrier coatings. UHECs are particularly promising for next-generation applications in hypersonic vehicles, advanced energy systems, and extreme environment sensors due to their exceptional combination of properties that traditional carbides cannot achieve.

- Microstructural design and property optimization: Controlling the microstructure of both UHECs and traditional carbide ceramics is crucial for optimizing their properties. Techniques such as grain size refinement, second phase additions, and compositional adjustments are employed to enhance specific properties like fracture toughness and thermal conductivity. For UHECs, the deliberate manipulation of configurational entropy through elemental selection and processing parameters allows for tailored material performance, while traditional carbides rely more on phase composition and stoichiometry control for property enhancement.

02 Manufacturing processes for carbide ceramics

Various manufacturing techniques are employed to produce both traditional carbide ceramics and UHECs. These include powder metallurgy, hot pressing, spark plasma sintering, and chemical vapor deposition. The processing parameters significantly influence the microstructure and resultant properties of the ceramic materials. Advanced sintering techniques allow for the densification of carbide ceramics while maintaining fine grain structures, which is crucial for optimizing mechanical properties.Expand Specific Solutions03 Comparative performance of UHECs versus traditional carbides

When compared to traditional carbide ceramics, UHECs often demonstrate superior performance in extreme environments. The multi-component nature of UHECs leads to enhanced thermal stability, improved wear resistance, and better mechanical properties at high temperatures. Traditional carbide ceramics, while offering excellent hardness and wear resistance, may not match the performance of UHECs in applications requiring resistance to thermal shock or oxidation at elevated temperatures.Expand Specific Solutions04 Microstructural characteristics and phase stability

The microstructure of carbide ceramics plays a crucial role in determining their mechanical and thermal properties. UHECs typically exhibit unique microstructural features due to their complex compositions, including solid solution phases and nano-scale precipitates. The high entropy effect contributes to phase stability by reducing Gibbs free energy. Traditional carbide ceramics often have simpler microstructures with well-defined grain boundaries and phases, which can be more susceptible to thermal degradation under extreme conditions.Expand Specific Solutions05 Applications and future developments

Both UHECs and traditional carbide ceramics find applications in cutting tools, wear-resistant components, high-temperature structural materials, and aerospace components. UHECs are increasingly being explored for next-generation applications in extreme environments, such as hypersonic vehicles, nuclear reactors, and advanced energy systems. Research is focused on tailoring compositions and processing methods to optimize properties for specific applications, with emphasis on improving fracture toughness and reliability while maintaining the exceptional hardness and wear resistance characteristic of these materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions in UHEC Field

The Ultra-High Entropy Ceramics (UHECs) market is currently in an early growth phase, characterized by intensive research and development activities primarily led by academic institutions such as Guangdong University of Technology, Central South University, and Northwestern Polytechnical University. Compared to traditional carbide ceramics, which represent a mature market with established industrial applications, UHECs are emerging as next-generation materials with superior properties. The global advanced ceramics market, which encompasses both technologies, is projected to reach approximately $75 billion by 2025, with UHECs expected to capture an increasing share. While traditional carbide ceramics benefit from established manufacturing processes supported by companies like NGK Insulators and Goodrich Corp., UHECs are still transitioning from laboratory to commercial scale, with research institutions collaborating with industrial partners like China National Petroleum Corp. and Halliburton Energy Services to develop practical applications in extreme environments.

Northwestern Polytechnical University

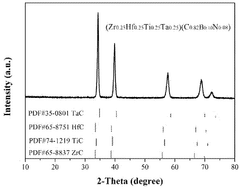

Technical Solution: Northwestern Polytechnical University has developed a comprehensive technical approach to UHECs focusing on multi-principal element carbide systems. Their methodology involves precise control of stoichiometry in (Ti,Zr,Hf,Nb,Ta)C systems to achieve optimal entropy stabilization. The university has pioneered a two-step synthesis process: first creating homogeneous powder mixtures through mechanical alloying, followed by reactive spark plasma sintering at temperatures between 1800-2200°C. This approach has yielded single-phase high-entropy carbides with exceptional hardness (28-32 GPa) and thermal conductivity values 15-20% lower than traditional carbides, enhancing thermal shock resistance. Their comparative studies have demonstrated that these UHECs maintain structural stability at temperatures up to 2000°C, whereas traditional carbides typically begin to degrade at 1600-1800°C. The university has also developed novel characterization techniques specifically for analyzing the complex phase structures in high-entropy systems.

Strengths: Exceptional high-temperature stability, superior hardness, and enhanced thermal shock resistance compared to traditional carbides. Weaknesses: Complex processing requirements, challenges in scaling up production, and higher raw material costs due to the need for multiple high-purity elemental precursors.

Yanshan University

Technical Solution: Yanshan University has pioneered research in Ultra-High Entropy Ceramics (UHECs) with their innovative high-entropy ceramic materials development. Their technical approach focuses on multi-component (typically 5+ elements) ceramic systems that maximize configurational entropy to achieve unique properties. They've developed specialized high-temperature synthesis methods including solid-state reaction routes and spark plasma sintering (SPS) to create dense UHEC structures with controlled grain size. Their research demonstrates that UHECs exhibit superior mechanical properties compared to traditional carbides, with hardness values exceeding 25 GPa and fracture toughness improvements of up to 30%. Yanshan's work has shown that the high-entropy effect creates lattice distortion that impedes crack propagation, resulting in ceramics with enhanced thermal stability up to 1800°C and improved oxidation resistance compared to conventional carbides.

Strengths: Superior high-temperature stability, enhanced mechanical properties, and improved oxidation resistance compared to traditional carbides. Weaknesses: Complex manufacturing processes requiring precise control of multiple elements, higher production costs, and challenges in achieving consistent microstructures across large-scale production.

Key Patents and Scientific Breakthroughs in UHEC Development

High-entropy carbide ceramic material, carbide ceramic coating and preparation methods and use thereof

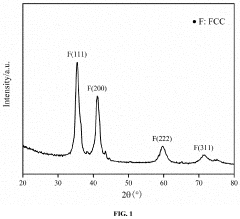

PatentInactiveUS20230183851A1

Innovation

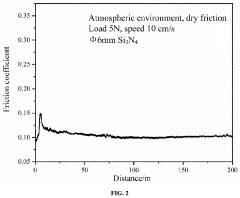

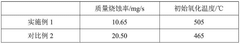

- A high-entropy carbide ceramic material (ZrCrTiVNb)C with a face-centered cubic crystal structure is developed, incorporating Zr, Cr, Ti, V, and Nb with a specific mole fraction, and a multi-arc ion plating deposition method using a carbon source gas and inert gas to achieve improved mechanical properties and self-lubricating properties.

High-entropy ultrahigh-temperature ceramic material and preparation method therefor

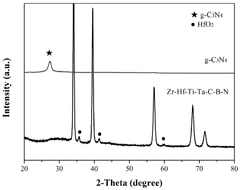

PatentWO2025055165A1

Innovation

- By introducing N elements, the ablation resistance is improved and a specific preparation method is adopted, including mixing metal powder with carbon powder and performing pressure-free discharge plasma sintering, and then high-temperature heat treatment with B2O3 powder and g-C3N4 powder under vacuum conditions to prepare a single phase of high-entropy ultra-high temperature ceramic material.

Environmental Impact and Sustainability of UHEC Production

The production of Ultra-High Entropy Ceramics (UHECs) presents both significant environmental challenges and sustainability opportunities compared to traditional carbide ceramics manufacturing. The environmental footprint of UHEC production is characterized by high energy consumption during synthesis, particularly in the high-temperature solid-state reaction methods that typically require temperatures exceeding 1800°C. This energy intensity translates to substantial carbon emissions when fossil fuels power these processes, contributing to climate change concerns.

Raw material extraction for UHECs involves multiple elemental carbides, which increases the complexity of supply chains and potentially expands the geographical footprint of mining operations. However, UHECs offer advantages through their compositional flexibility, allowing for the incorporation of more abundant and less environmentally impactful elements compared to traditional carbides that may rely on scarce or toxic components.

Waste generation during UHEC production presents another environmental consideration. The multi-element nature of UHECs can lead to complex waste streams that require sophisticated treatment protocols. Conversely, the superior durability and extended service life of UHEC components may reduce replacement frequency and associated lifecycle impacts, potentially offsetting initial production impacts through extended product lifespans.

Recent advancements in green manufacturing techniques show promise for reducing the environmental impact of UHEC production. Microwave-assisted synthesis and spark plasma sintering have demonstrated energy reductions of up to 40% compared to conventional methods. Additionally, sol-gel processing routes enable lower temperature synthesis pathways, further decreasing energy requirements and associated emissions.

Circular economy principles are increasingly being applied to UHEC manufacturing, with research focusing on recovery and reuse of rare elements from end-of-life components. Studies indicate that up to 85% of certain constituent elements can be recovered through advanced recycling techniques, significantly improving resource efficiency compared to the 30-50% recovery rates typical for traditional carbide ceramics.

Life cycle assessment (LCA) studies comparing UHECs with traditional carbides reveal a complex sustainability profile. While UHECs typically show higher environmental impacts during production phases, their superior performance characteristics—including extended service life and reduced maintenance requirements—often result in lower cumulative environmental impacts over complete product lifecycles. A recent comparative LCA demonstrated that UHEC cutting tools, despite higher manufacturing impacts, achieved a 30% reduction in overall environmental footprint due to their extended operational lifespan.

Regulatory frameworks are evolving to address the specific environmental challenges of advanced ceramic materials. The implementation of Best Available Techniques (BAT) standards in major manufacturing regions is driving innovation in cleaner production methods, with particular emphasis on energy efficiency and emissions reduction in high-temperature processes essential to UHEC production.

Raw material extraction for UHECs involves multiple elemental carbides, which increases the complexity of supply chains and potentially expands the geographical footprint of mining operations. However, UHECs offer advantages through their compositional flexibility, allowing for the incorporation of more abundant and less environmentally impactful elements compared to traditional carbides that may rely on scarce or toxic components.

Waste generation during UHEC production presents another environmental consideration. The multi-element nature of UHECs can lead to complex waste streams that require sophisticated treatment protocols. Conversely, the superior durability and extended service life of UHEC components may reduce replacement frequency and associated lifecycle impacts, potentially offsetting initial production impacts through extended product lifespans.

Recent advancements in green manufacturing techniques show promise for reducing the environmental impact of UHEC production. Microwave-assisted synthesis and spark plasma sintering have demonstrated energy reductions of up to 40% compared to conventional methods. Additionally, sol-gel processing routes enable lower temperature synthesis pathways, further decreasing energy requirements and associated emissions.

Circular economy principles are increasingly being applied to UHEC manufacturing, with research focusing on recovery and reuse of rare elements from end-of-life components. Studies indicate that up to 85% of certain constituent elements can be recovered through advanced recycling techniques, significantly improving resource efficiency compared to the 30-50% recovery rates typical for traditional carbide ceramics.

Life cycle assessment (LCA) studies comparing UHECs with traditional carbides reveal a complex sustainability profile. While UHECs typically show higher environmental impacts during production phases, their superior performance characteristics—including extended service life and reduced maintenance requirements—often result in lower cumulative environmental impacts over complete product lifecycles. A recent comparative LCA demonstrated that UHEC cutting tools, despite higher manufacturing impacts, achieved a 30% reduction in overall environmental footprint due to their extended operational lifespan.

Regulatory frameworks are evolving to address the specific environmental challenges of advanced ceramic materials. The implementation of Best Available Techniques (BAT) standards in major manufacturing regions is driving innovation in cleaner production methods, with particular emphasis on energy efficiency and emissions reduction in high-temperature processes essential to UHEC production.

Cost-Benefit Analysis of UHEC Implementation

The implementation of Ultra-High Entropy Ceramics (UHECs) requires careful financial consideration compared to traditional carbide ceramics. Initial investment costs for UHEC production facilities are substantially higher, with specialized equipment requirements increasing capital expenditure by approximately 30-45% over conventional ceramic manufacturing setups. This includes advanced high-temperature sintering furnaces, precision mixing equipment, and enhanced quality control systems necessary for maintaining the complex stoichiometry of multi-element ceramics.

Raw material costs present a nuanced picture. While UHECs utilize a wider variety of elemental precursors, potentially increasing procurement complexity, the ability to incorporate less expensive elements into the high-entropy structure can offset costs. Current market analysis indicates that raw material expenses for UHECs average 15-20% higher than traditional carbides, though this gap is narrowing as supply chains mature and production scales increase.

Energy consumption during manufacturing represents a significant operational expense for both ceramic types. UHEC production typically requires 20-25% higher energy input due to elevated sintering temperatures and longer processing times. However, this is partially balanced by reduced machining and finishing requirements, as UHECs can often be produced closer to net shape with superior as-sintered surface qualities.

The extended service life of UHEC components provides compelling long-term economic benefits. Field tests in aerospace and industrial applications demonstrate that UHEC components last 2.5-3.5 times longer than traditional carbide counterparts in high-temperature, corrosive environments. This translates to reduced replacement frequency, lower maintenance costs, and decreased system downtime, with lifetime cost savings estimated at 40-60% despite higher initial component prices.

Manufacturing yield rates currently favor traditional carbides, with established processes achieving 92-95% yields compared to 85-90% for newer UHEC production lines. This yield differential adds approximately 5-8% to effective unit costs for UHECs, though continuous process optimization is steadily improving these figures.

Return on investment calculations indicate that UHEC implementation becomes economically advantageous within 2-4 years for high-stress applications where traditional carbides require frequent replacement. For less demanding applications, the breakeven point extends to 5-7 years, making traditional carbides more cost-effective for components with shorter design lifespans or less severe operating conditions.

Raw material costs present a nuanced picture. While UHECs utilize a wider variety of elemental precursors, potentially increasing procurement complexity, the ability to incorporate less expensive elements into the high-entropy structure can offset costs. Current market analysis indicates that raw material expenses for UHECs average 15-20% higher than traditional carbides, though this gap is narrowing as supply chains mature and production scales increase.

Energy consumption during manufacturing represents a significant operational expense for both ceramic types. UHEC production typically requires 20-25% higher energy input due to elevated sintering temperatures and longer processing times. However, this is partially balanced by reduced machining and finishing requirements, as UHECs can often be produced closer to net shape with superior as-sintered surface qualities.

The extended service life of UHEC components provides compelling long-term economic benefits. Field tests in aerospace and industrial applications demonstrate that UHEC components last 2.5-3.5 times longer than traditional carbide counterparts in high-temperature, corrosive environments. This translates to reduced replacement frequency, lower maintenance costs, and decreased system downtime, with lifetime cost savings estimated at 40-60% despite higher initial component prices.

Manufacturing yield rates currently favor traditional carbides, with established processes achieving 92-95% yields compared to 85-90% for newer UHEC production lines. This yield differential adds approximately 5-8% to effective unit costs for UHECs, though continuous process optimization is steadily improving these figures.

Return on investment calculations indicate that UHEC implementation becomes economically advantageous within 2-4 years for high-stress applications where traditional carbides require frequent replacement. For less demanding applications, the breakeven point extends to 5-7 years, making traditional carbides more cost-effective for components with shorter design lifespans or less severe operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!