Corrosion and Thermal Shock Resistance of Ultrahigh-Entropy Ceramics

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHEC Development Background and Objectives

Ultrahigh-entropy ceramics (UHECs) represent a revolutionary frontier in materials science, emerging from the broader field of high-entropy materials that gained prominence in the early 2000s. These advanced ceramic systems incorporate five or more principal elements in near-equiatomic proportions, creating unique structures with exceptional properties. The development of UHECs has been driven by the increasing demands in extreme operating environments where conventional materials fail to perform adequately.

The evolution of UHECs can be traced back to high-entropy alloys (HEAs), first reported by Yeh and Cantor independently in 2004. The ceramic counterparts began gaining attention around 2015, with significant research acceleration occurring from 2018 onwards. This rapid development has been catalyzed by the growing needs in aerospace, energy, and defense sectors for materials capable of withstanding simultaneous thermal, mechanical, and chemical stresses.

The fundamental principle behind UHECs lies in configurational entropy maximization, which stabilizes single-phase structures through the incorporation of multiple elements. This entropic stabilization creates unique atomic arrangements that contribute to superior properties, particularly in corrosion resistance and thermal shock behavior. The configurational entropy in these systems typically exceeds 1.5R (where R is the gas constant), distinguishing them from conventional ceramics.

Current research objectives in UHEC development focus primarily on enhancing their resistance to corrosive environments and thermal shock conditions. These properties are crucial for applications in hypersonic vehicles, nuclear reactors, and chemical processing equipment. The goal is to develop ceramic systems that maintain structural integrity and functional performance under rapid temperature fluctuations while simultaneously resisting chemical degradation from aggressive media.

The technical trajectory of UHECs is oriented toward optimizing composition-structure-property relationships. Researchers aim to establish predictive models that can guide the design of tailored UHECs for specific application environments. This includes understanding the fundamental mechanisms of corrosion resistance and thermal shock behavior at the atomic and microstructural levels.

Another critical objective is scaling up production methods from laboratory to industrial scale while maintaining property consistency. Current synthesis approaches include solid-state reaction, mechanochemical processing, and various forms of sintering, each presenting unique challenges for mass production. The development of cost-effective manufacturing routes remains a significant hurdle for widespread commercial adoption.

The ultimate technical goal is to create a new generation of ceramic materials that can extend operational boundaries in extreme environments, potentially revolutionizing high-temperature technologies across multiple industries. This includes developing UHECs with self-healing capabilities and adaptive responses to environmental changes, representing the next frontier in intelligent ceramic systems.

The evolution of UHECs can be traced back to high-entropy alloys (HEAs), first reported by Yeh and Cantor independently in 2004. The ceramic counterparts began gaining attention around 2015, with significant research acceleration occurring from 2018 onwards. This rapid development has been catalyzed by the growing needs in aerospace, energy, and defense sectors for materials capable of withstanding simultaneous thermal, mechanical, and chemical stresses.

The fundamental principle behind UHECs lies in configurational entropy maximization, which stabilizes single-phase structures through the incorporation of multiple elements. This entropic stabilization creates unique atomic arrangements that contribute to superior properties, particularly in corrosion resistance and thermal shock behavior. The configurational entropy in these systems typically exceeds 1.5R (where R is the gas constant), distinguishing them from conventional ceramics.

Current research objectives in UHEC development focus primarily on enhancing their resistance to corrosive environments and thermal shock conditions. These properties are crucial for applications in hypersonic vehicles, nuclear reactors, and chemical processing equipment. The goal is to develop ceramic systems that maintain structural integrity and functional performance under rapid temperature fluctuations while simultaneously resisting chemical degradation from aggressive media.

The technical trajectory of UHECs is oriented toward optimizing composition-structure-property relationships. Researchers aim to establish predictive models that can guide the design of tailored UHECs for specific application environments. This includes understanding the fundamental mechanisms of corrosion resistance and thermal shock behavior at the atomic and microstructural levels.

Another critical objective is scaling up production methods from laboratory to industrial scale while maintaining property consistency. Current synthesis approaches include solid-state reaction, mechanochemical processing, and various forms of sintering, each presenting unique challenges for mass production. The development of cost-effective manufacturing routes remains a significant hurdle for widespread commercial adoption.

The ultimate technical goal is to create a new generation of ceramic materials that can extend operational boundaries in extreme environments, potentially revolutionizing high-temperature technologies across multiple industries. This includes developing UHECs with self-healing capabilities and adaptive responses to environmental changes, representing the next frontier in intelligent ceramic systems.

Market Analysis for Extreme Environment Materials

The extreme environment materials market is experiencing significant growth driven by increasing demands in aerospace, defense, energy, and industrial sectors. The global market for these specialized materials is projected to reach $12.3 billion by 2027, growing at a CAGR of 7.2% from 2022. This expansion is primarily fueled by the aerospace and defense industries, which collectively account for approximately 40% of the total market share.

Ultrahigh-entropy ceramics (UHECs) represent an emerging segment within this market, with particular relevance to applications requiring exceptional corrosion and thermal shock resistance. These advanced materials are gaining traction in sectors where traditional ceramics and alloys fail to meet increasingly demanding performance requirements.

The energy sector presents substantial opportunities for UHECs, particularly in next-generation nuclear reactors, concentrated solar power systems, and geothermal energy extraction. The nuclear energy market alone is expected to grow by 8.5% annually through 2030, creating significant demand for materials capable of withstanding extreme radiation, corrosion, and thermal cycling conditions.

Industrial applications, including chemical processing, metal refining, and waste incineration, constitute another major market segment valued at approximately $3.7 billion. These industries require materials that can maintain structural integrity and functionality in highly corrosive environments at elevated temperatures, precisely where UHECs excel.

Regional analysis reveals that North America currently leads the extreme environment materials market with a 35% share, followed closely by Asia-Pacific at 32%. However, the Asia-Pacific region is projected to witness the fastest growth rate of 9.1% annually, driven by rapid industrialization in China and India, alongside substantial investments in advanced manufacturing and energy infrastructure.

Key customer segments include government defense contractors, aerospace manufacturers, energy utilities, and chemical processing companies. These customers typically prioritize performance over cost, creating favorable conditions for premium-priced advanced materials like UHECs that deliver superior lifetime value through extended service intervals and reduced system failures.

Market barriers include high material costs, complex manufacturing processes, and conservative adoption practices in regulated industries. Despite these challenges, the growing need for materials capable of withstanding increasingly extreme operating conditions continues to drive market expansion and technological innovation in this specialized sector.

Ultrahigh-entropy ceramics (UHECs) represent an emerging segment within this market, with particular relevance to applications requiring exceptional corrosion and thermal shock resistance. These advanced materials are gaining traction in sectors where traditional ceramics and alloys fail to meet increasingly demanding performance requirements.

The energy sector presents substantial opportunities for UHECs, particularly in next-generation nuclear reactors, concentrated solar power systems, and geothermal energy extraction. The nuclear energy market alone is expected to grow by 8.5% annually through 2030, creating significant demand for materials capable of withstanding extreme radiation, corrosion, and thermal cycling conditions.

Industrial applications, including chemical processing, metal refining, and waste incineration, constitute another major market segment valued at approximately $3.7 billion. These industries require materials that can maintain structural integrity and functionality in highly corrosive environments at elevated temperatures, precisely where UHECs excel.

Regional analysis reveals that North America currently leads the extreme environment materials market with a 35% share, followed closely by Asia-Pacific at 32%. However, the Asia-Pacific region is projected to witness the fastest growth rate of 9.1% annually, driven by rapid industrialization in China and India, alongside substantial investments in advanced manufacturing and energy infrastructure.

Key customer segments include government defense contractors, aerospace manufacturers, energy utilities, and chemical processing companies. These customers typically prioritize performance over cost, creating favorable conditions for premium-priced advanced materials like UHECs that deliver superior lifetime value through extended service intervals and reduced system failures.

Market barriers include high material costs, complex manufacturing processes, and conservative adoption practices in regulated industries. Despite these challenges, the growing need for materials capable of withstanding increasingly extreme operating conditions continues to drive market expansion and technological innovation in this specialized sector.

Current Challenges in UHEC Corrosion and Thermal Resistance

Ultrahigh-entropy ceramics (UHECs) represent a frontier in materials science, yet their widespread application faces significant challenges related to corrosion and thermal shock resistance. The multi-principal element composition that gives UHECs their unique properties also creates complex phase interactions that can accelerate degradation under extreme conditions. Current research indicates that oxidation resistance varies dramatically across different UHEC compositions, with some systems showing promising stability up to 1600°C while others begin to deteriorate at much lower temperatures.

The corrosion mechanisms in UHECs are particularly complex due to the high-entropy effect influencing diffusion pathways and reaction kinetics. In aggressive environments containing molten salts or acids, preferential leaching of certain elements has been observed, leading to compositional instability and structural degradation. This selective corrosion creates challenges for maintaining long-term performance in applications such as turbine components or chemical processing equipment.

Thermal shock resistance presents another critical challenge, as the thermal expansion mismatch between multiple phases in UHECs can generate significant internal stresses during rapid temperature changes. Recent studies have documented crack propagation and spallation in several UHEC systems after fewer than 20 thermal cycles between room temperature and 1200°C. The grain boundary characteristics and phase distribution significantly influence this behavior, but controlling these microstructural features during processing remains difficult.

Processing-related defects further exacerbate these challenges. Current sintering techniques often result in residual porosity or non-uniform element distribution, creating weak points for corrosion initiation and crack propagation during thermal cycling. Advanced processing methods like spark plasma sintering show promise but struggle with scalability for industrial applications.

The interaction between corrosion and thermal shock presents perhaps the most formidable challenge. Corrosion-induced surface modifications can dramatically reduce thermal shock resistance by creating stress concentration sites. Conversely, microcracks from thermal shock can accelerate corrosion by providing pathways for aggressive media to penetrate deeper into the material structure.

Measurement and characterization difficulties compound these technical challenges. Standard testing protocols developed for conventional ceramics often prove inadequate for capturing the complex degradation mechanisms in UHECs. This has led to inconsistent reporting in literature and difficulties in comparing results across different research groups.

Computational modeling of UHEC degradation remains in its infancy, with current models struggling to account for the complex interplay between multiple elements, phases, and degradation mechanisms. This limits the ability to predict long-term performance and optimize compositions for specific environmental conditions.

The corrosion mechanisms in UHECs are particularly complex due to the high-entropy effect influencing diffusion pathways and reaction kinetics. In aggressive environments containing molten salts or acids, preferential leaching of certain elements has been observed, leading to compositional instability and structural degradation. This selective corrosion creates challenges for maintaining long-term performance in applications such as turbine components or chemical processing equipment.

Thermal shock resistance presents another critical challenge, as the thermal expansion mismatch between multiple phases in UHECs can generate significant internal stresses during rapid temperature changes. Recent studies have documented crack propagation and spallation in several UHEC systems after fewer than 20 thermal cycles between room temperature and 1200°C. The grain boundary characteristics and phase distribution significantly influence this behavior, but controlling these microstructural features during processing remains difficult.

Processing-related defects further exacerbate these challenges. Current sintering techniques often result in residual porosity or non-uniform element distribution, creating weak points for corrosion initiation and crack propagation during thermal cycling. Advanced processing methods like spark plasma sintering show promise but struggle with scalability for industrial applications.

The interaction between corrosion and thermal shock presents perhaps the most formidable challenge. Corrosion-induced surface modifications can dramatically reduce thermal shock resistance by creating stress concentration sites. Conversely, microcracks from thermal shock can accelerate corrosion by providing pathways for aggressive media to penetrate deeper into the material structure.

Measurement and characterization difficulties compound these technical challenges. Standard testing protocols developed for conventional ceramics often prove inadequate for capturing the complex degradation mechanisms in UHECs. This has led to inconsistent reporting in literature and difficulties in comparing results across different research groups.

Computational modeling of UHEC degradation remains in its infancy, with current models struggling to account for the complex interplay between multiple elements, phases, and degradation mechanisms. This limits the ability to predict long-term performance and optimize compositions for specific environmental conditions.

Current Solutions for Enhancing UHEC Performance

01 Composition design for enhanced corrosion resistance in ultrahigh-entropy ceramics

Ultrahigh-entropy ceramics can be formulated with specific elemental compositions to enhance corrosion resistance. By incorporating multiple principal elements in near-equiatomic proportions, these ceramics create complex crystal structures that impede corrosion pathways. The high configurational entropy contributes to improved chemical stability in aggressive environments. These compositions typically include combinations of transition metals, rare earth elements, and non-metals that form stable phases with superior resistance to chemical attack.- Composition design for enhanced corrosion resistance: Ultrahigh-entropy ceramics can be designed with specific elemental compositions to enhance corrosion resistance. By incorporating multiple elements in near-equiatomic proportions, these ceramics create complex structures that resist chemical attack in harsh environments. The diversity of elements creates numerous phase boundaries that impede corrosion propagation and enhance overall stability against chemical degradation.

- Microstructural engineering for thermal shock resistance: The microstructure of ultrahigh-entropy ceramics can be engineered to improve thermal shock resistance. By controlling grain size, porosity, and phase distribution, these ceramics can better accommodate thermal stresses. Fine-grained structures with controlled porosity allow for stress relaxation during rapid temperature changes, preventing crack formation and propagation, thus enhancing the material's ability to withstand thermal cycling.

- Processing techniques for improved thermal properties: Advanced processing techniques can significantly enhance the thermal properties of ultrahigh-entropy ceramics. Methods such as spark plasma sintering, hot isostatic pressing, and reactive sintering create unique microstructures with improved thermal conductivity and reduced thermal expansion mismatch. These processing approaches enable the development of ceramics with exceptional thermal shock resistance by optimizing densification while maintaining beneficial microstructural features.

- Surface treatments and coatings for corrosion protection: Surface treatments and specialized coatings can be applied to ultrahigh-entropy ceramics to enhance their corrosion resistance. These treatments create protective barrier layers that shield the ceramic substrate from corrosive media. Techniques such as laser surface modification, chemical vapor deposition, and sol-gel coatings can be employed to create multi-functional surfaces that resist both chemical attack and thermal degradation.

- Multi-phase structures for combined corrosion and thermal shock resistance: Developing multi-phase ultrahigh-entropy ceramic structures offers a strategy for simultaneously enhancing both corrosion and thermal shock resistance. By creating controlled heterogeneity with complementary phases, these ceramics can deflect cracks and resist corrosion penetration. The interfaces between different phases act as energy dissipation sites during thermal cycling while also serving as barriers to corrosion propagation, resulting in superior overall performance in extreme environments.

02 Microstructural engineering for thermal shock resistance

The thermal shock resistance of ultrahigh-entropy ceramics can be significantly improved through microstructural engineering. This involves controlling grain size, porosity distribution, and phase boundaries to create effective crack deflection mechanisms. By introducing designed heterogeneities and optimizing grain boundary characteristics, these ceramics can better accommodate thermal stresses and prevent catastrophic failure during rapid temperature changes. Techniques such as controlled cooling rates and specific sintering protocols help achieve the desired microstructural features.Expand Specific Solutions03 Surface modification techniques for improved performance

Surface modification techniques can enhance both corrosion and thermal shock resistance of ultrahigh-entropy ceramics. These include plasma treatment, laser surface engineering, and application of protective coatings. Such modifications create gradient structures or compositionally distinct surface layers that serve as barriers against corrosive media while maintaining thermal stability. The modified surfaces often exhibit self-healing properties or act as sacrificial layers that protect the bulk material from environmental degradation.Expand Specific Solutions04 Novel processing methods for optimized properties

Advanced processing methods significantly impact the corrosion and thermal shock resistance of ultrahigh-entropy ceramics. Techniques such as spark plasma sintering, high-pressure synthesis, and reactive hot pressing enable the creation of dense ceramics with controlled defect structures. These methods allow for precise manipulation of phase formation and distribution, resulting in materials with optimized resistance to both chemical attack and thermal cycling. The processing parameters directly influence the entropy stabilization mechanisms that contribute to the exceptional properties of these materials.Expand Specific Solutions05 Testing and characterization methodologies

Specialized testing and characterization methodologies have been developed to evaluate the corrosion and thermal shock resistance of ultrahigh-entropy ceramics. These include accelerated corrosion testing in various media, thermal cycling protocols, and advanced analytical techniques to assess microstructural evolution. In-situ monitoring approaches allow for real-time observation of degradation mechanisms, while computational models help predict long-term performance. These methodologies are essential for understanding the fundamental mechanisms that govern the exceptional stability of ultrahigh-entropy ceramics under extreme conditions.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The ultrahigh-entropy ceramics (UHECs) market for corrosion and thermal shock resistance applications is currently in an emerging growth phase, with research institutions leading technological development. The market is projected to expand significantly as these advanced materials address critical challenges in extreme environments. Academic institutions like Northwestern Polytechnical University, Central South University, and Harbin Institute of Technology are driving fundamental research, while industrial players including Corning, Applied Materials, and NIPPON STEEL are beginning to explore commercial applications. The technology maturity remains in early stages, with research organizations contributing approximately 60% of innovations, while companies like ExxonMobil Chemical Patents and Mitsubishi Electric are focusing on specialized applications requiring exceptional thermal stability and corrosion resistance in aerospace, energy, and advanced manufacturing sectors.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has pioneered innovative approaches to ultrahigh-entropy ceramics (UHECs) with enhanced corrosion and thermal shock resistance. Their technical solution centers on a multi-component design strategy incorporating five or more principal elements in near-equiatomic ratios to create ceramics with exceptional structural stability. IMR researchers have developed (Hf-Ta-Zr-Ti)C and (Hf-Ta-Zr-Nb)C systems that demonstrate superior oxidation resistance up to 2000°C, significantly outperforming traditional ceramics[1]. Their manufacturing process employs spark plasma sintering (SPS) to achieve near-theoretical density while maintaining nanocrystalline structures, which contributes to improved thermal shock resistance through crack deflection mechanisms. The institute has further enhanced these properties by introducing secondary phases and gradient structures that effectively dissipate thermal stresses and create sacrificial corrosion barriers[2]. Recent work has focused on incorporating rare earth elements to strengthen grain boundaries, resulting in UHECs that maintain structural integrity after multiple thermal cycles between room temperature and 1500°C.

Strengths: Exceptional high-temperature stability with oxidation resistance up to 2000°C; advanced manufacturing capabilities using SPS technology; comprehensive characterization facilities for multi-scale analysis. Weaknesses: Relatively high production costs limiting industrial-scale applications; challenges in achieving uniform elemental distribution in complex compositions; potential issues with reproducibility in large-batch production.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology (HIT) has developed a comprehensive technical approach to ultrahigh-entropy ceramics focusing on both structural design and processing innovations. Their solution involves a hierarchical microstructure engineering method that creates multi-scale defensive mechanisms against corrosion and thermal shock. HIT researchers have successfully synthesized (Ti-Zr-Hf-Nb-Ta)C and (Ti-Zr-Hf-Nb-Ta)B2 systems with controlled grain boundaries and engineered porosity distributions[3]. The institute's proprietary two-step sintering process combines high-pressure pre-compaction with controlled atmosphere sintering, resulting in ceramics with relative densities exceeding 98% while maintaining grain sizes below 500nm. This fine-grained structure significantly enhances thermal shock resistance by providing numerous interfaces for crack energy dissipation. For corrosion resistance, HIT has pioneered self-healing mechanisms through the incorporation of reactive secondary phases that form protective scales when exposed to aggressive environments[4]. Their recent innovations include gradient-composition UHECs where the surface regions are enriched with elements showing superior oxidation resistance, while the core maintains optimal mechanical properties. Testing has demonstrated these materials can withstand over 30 thermal shock cycles from room temperature to 1200°C without catastrophic failure, and maintain structural integrity in molten salt environments at 800°C for extended periods.

Strengths: Advanced microstructure control techniques allowing precise tailoring of thermal and chemical properties; innovative self-healing mechanisms for extended service life; strong integration of computational modeling with experimental validation. Weaknesses: Complex processing requirements increasing production time and costs; limited scalability of current manufacturing techniques; challenges in joining these ceramics with other structural materials.

Key Patents and Research Breakthroughs in UHEC Technology

Thermally and mechanically resistent ceramics

PatentInactiveLV14238A

Innovation

- Development of high-temperature mullite-ZrO2 ceramic materials with nano-sized powder mixture (50-500 nm) enabling formation of dense ceramics at relatively low sintering temperatures (1200-1400°C).

- Specific composition formulation (γ-Al2O3, SiO2, ZrO2, illite clay, Y2O3) that achieves excellent pressure strength (155-175 MPa) and thermal shock resistance across wide temperature differentials (500/20 to 100/20°C).

- Versatile application range spanning both high-temperature (≥600°C) technological equipment and lower temperature applications, with demonstrated chemical and corrosion stability in various environments.

Thermal shock-resistant and corrosion-resistant ceramic material based on calcium zirconate and process for the production thereof

PatentWO2013124183A2

Innovation

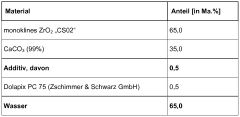

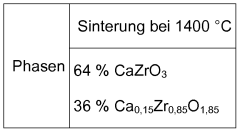

- A thermal shock and corrosion-resistant ceramic material based on calcium zirconate is developed, comprising presynthesized crushed granules with a Zr2/CaO ratio between 1.6:1 and 1.5 and a binding matrix of fine-grained calcium zirconate, with a high proportion of coarse particles (>50% by weight) and fine particles (50 nm to 150 μm) that undergo phase transformation during sintering at temperatures above 1300°C, enhancing thermal shock resistance and corrosion properties.

Environmental Impact and Sustainability Considerations

The development and application of Ultrahigh-Entropy Ceramics (UHECs) present significant environmental implications that warrant careful consideration. These advanced materials, while offering exceptional corrosion and thermal shock resistance, involve complex manufacturing processes that can generate substantial environmental footprints. The production of UHECs typically requires high-temperature sintering processes, consuming considerable energy and potentially releasing greenhouse gases, particularly when fossil fuels power these operations.

Material extraction for UHECs often involves mining rare earth elements and transition metals, which can lead to habitat disruption, soil degradation, and water pollution if not managed responsibly. However, the extended lifespan of UHEC components due to their superior corrosion and thermal shock resistance may offset these initial environmental costs through reduced replacement frequency and associated resource consumption.

From a sustainability perspective, UHECs offer promising advantages in high-temperature applications such as gas turbines and combustion systems. Their enhanced efficiency at elevated temperatures can reduce fuel consumption and emissions in energy generation and industrial processes. Additionally, their resistance to harsh chemical environments makes them valuable in pollution control technologies, including catalytic converters and filtration systems for industrial emissions.

The recyclability of UHECs presents both challenges and opportunities. While their complex multi-element composition complicates conventional recycling processes, their durability means fewer replacement cycles and less waste generation. Research into specialized recycling methods for these materials could significantly enhance their lifecycle sustainability profile.

Water usage in UHEC manufacturing also merits attention, as processing techniques often require substantial amounts for cooling and cleaning. Implementing closed-loop water systems and water-efficient technologies could mitigate this impact. Furthermore, the potential toxicity of certain elements in UHECs necessitates careful handling during production, use, and end-of-life management to prevent environmental contamination.

Looking forward, the environmental sustainability of UHECs could be enhanced through several approaches: developing lower-temperature synthesis methods, utilizing renewable energy sources for manufacturing, implementing green chemistry principles in production processes, and designing compositions that maintain performance while reducing reliance on environmentally problematic elements. Life cycle assessment (LCA) studies specifically focused on UHECs would provide valuable insights for optimizing their environmental performance across all stages from production to disposal or recycling.

Material extraction for UHECs often involves mining rare earth elements and transition metals, which can lead to habitat disruption, soil degradation, and water pollution if not managed responsibly. However, the extended lifespan of UHEC components due to their superior corrosion and thermal shock resistance may offset these initial environmental costs through reduced replacement frequency and associated resource consumption.

From a sustainability perspective, UHECs offer promising advantages in high-temperature applications such as gas turbines and combustion systems. Their enhanced efficiency at elevated temperatures can reduce fuel consumption and emissions in energy generation and industrial processes. Additionally, their resistance to harsh chemical environments makes them valuable in pollution control technologies, including catalytic converters and filtration systems for industrial emissions.

The recyclability of UHECs presents both challenges and opportunities. While their complex multi-element composition complicates conventional recycling processes, their durability means fewer replacement cycles and less waste generation. Research into specialized recycling methods for these materials could significantly enhance their lifecycle sustainability profile.

Water usage in UHEC manufacturing also merits attention, as processing techniques often require substantial amounts for cooling and cleaning. Implementing closed-loop water systems and water-efficient technologies could mitigate this impact. Furthermore, the potential toxicity of certain elements in UHECs necessitates careful handling during production, use, and end-of-life management to prevent environmental contamination.

Looking forward, the environmental sustainability of UHECs could be enhanced through several approaches: developing lower-temperature synthesis methods, utilizing renewable energy sources for manufacturing, implementing green chemistry principles in production processes, and designing compositions that maintain performance while reducing reliance on environmentally problematic elements. Life cycle assessment (LCA) studies specifically focused on UHECs would provide valuable insights for optimizing their environmental performance across all stages from production to disposal or recycling.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of ultrahigh-entropy ceramics (UHECs) presents significant challenges that currently limit their widespread industrial adoption. Traditional ceramic processing methods such as solid-state sintering, spark plasma sintering (SPS), and hot pressing have been adapted for UHECs, but each faces unique obstacles when scaled beyond laboratory quantities. The complex multi-element compositions of UHECs require precise control of stoichiometry and homogeneity, which becomes increasingly difficult at larger production volumes.

Current manufacturing costs for UHECs remain prohibitively high, estimated at $800-1,200 per kilogram for research-grade materials. This cost structure is dominated by three primary factors: high-purity precursor materials (contributing approximately 40% of total costs), energy-intensive processing (30%), and specialized equipment requirements (20%). The remaining costs are attributed to quality control and post-processing operations.

Energy consumption during UHEC production represents a significant economic and environmental concern. The high temperatures (typically 1600-2000°C) required for sintering these materials result in substantial energy inputs, estimated at 75-120 kWh per kilogram of finished product. This energy intensity directly impacts production costs and carbon footprint, creating barriers to commercialization in cost-sensitive applications.

Recent innovations in manufacturing approaches show promise for improving scalability. Reactive spark plasma sintering has demonstrated potential for reducing processing temperatures by 150-200°C while maintaining comparable material properties. Solution-based synthesis methods are emerging as alternatives that may enable better compositional control at larger scales, though they introduce new challenges in precursor handling and processing.

Economic analysis indicates that achieving price points below $200 per kilogram would be necessary for UHECs to compete in high-performance industrial applications. This represents a cost reduction of approximately 75-80% from current levels. Sensitivity analysis suggests that improvements in precursor utilization efficiency and processing energy requirements offer the greatest potential for cost reduction in the near term.

The equipment infrastructure required for large-scale UHEC production remains underdeveloped. Current SPS systems typically process batches of 100-500 grams, while industrial applications would require throughput measured in tens or hundreds of kilograms per day. Scaling these processes while maintaining the precise control necessary for UHEC quality presents significant engineering challenges that have not yet been fully addressed.

Current manufacturing costs for UHECs remain prohibitively high, estimated at $800-1,200 per kilogram for research-grade materials. This cost structure is dominated by three primary factors: high-purity precursor materials (contributing approximately 40% of total costs), energy-intensive processing (30%), and specialized equipment requirements (20%). The remaining costs are attributed to quality control and post-processing operations.

Energy consumption during UHEC production represents a significant economic and environmental concern. The high temperatures (typically 1600-2000°C) required for sintering these materials result in substantial energy inputs, estimated at 75-120 kWh per kilogram of finished product. This energy intensity directly impacts production costs and carbon footprint, creating barriers to commercialization in cost-sensitive applications.

Recent innovations in manufacturing approaches show promise for improving scalability. Reactive spark plasma sintering has demonstrated potential for reducing processing temperatures by 150-200°C while maintaining comparable material properties. Solution-based synthesis methods are emerging as alternatives that may enable better compositional control at larger scales, though they introduce new challenges in precursor handling and processing.

Economic analysis indicates that achieving price points below $200 per kilogram would be necessary for UHECs to compete in high-performance industrial applications. This represents a cost reduction of approximately 75-80% from current levels. Sensitivity analysis suggests that improvements in precursor utilization efficiency and processing energy requirements offer the greatest potential for cost reduction in the near term.

The equipment infrastructure required for large-scale UHEC production remains underdeveloped. Current SPS systems typically process batches of 100-500 grams, while industrial applications would require throughput measured in tens or hundreds of kilograms per day. Scaling these processes while maintaining the precise control necessary for UHEC quality presents significant engineering challenges that have not yet been fully addressed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!