Microstructural Evolution during Sintering of UHEC Powders

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHEC Sintering Background and Objectives

Ultra-High Entropy Ceramics (UHECs) represent a revolutionary frontier in materials science, emerging as an extension of the high entropy alloy concept into ceramic systems. These materials, characterized by five or more principal elements in near-equimolar ratios, have garnered significant attention since their initial development in the early 2010s. The evolution of UHECs builds upon decades of research in powder metallurgy and ceramic processing, with sintering being identified as a critical process that determines their final microstructure and properties.

The sintering of UHEC powders presents unique challenges and opportunities due to their complex compositional nature. Traditional sintering approaches developed for conventional ceramics often prove inadequate when applied to these multi-element systems. The historical trajectory of UHEC development shows an accelerating research interest, with publications increasing exponentially since 2018, particularly focusing on understanding the fundamental mechanisms governing microstructural evolution during thermal processing.

Current technological trends in UHEC sintering include the exploration of advanced consolidation techniques such as spark plasma sintering (SPS), hot pressing (HP), and field-assisted sintering technology (FAST). These methods aim to overcome the inherent challenges in densifying these complex ceramic systems while preserving their unique nanostructured features. The field is rapidly moving toward establishing correlations between processing parameters, resultant microstructures, and final material properties.

The primary technical objectives of this investigation into microstructural evolution during UHEC sintering are multifaceted. First, to elucidate the fundamental mechanisms governing densification and grain growth in multi-principal element ceramic systems. Second, to identify the critical processing parameters that control phase formation, segregation phenomena, and interfacial characteristics. Third, to establish predictive models that can accurately forecast microstructural development based on initial powder characteristics and sintering conditions.

Additionally, this research aims to develop optimized sintering protocols that can yield UHECs with tailored microstructural features for specific applications, particularly in extreme environments. Understanding the complex interplay between diffusion processes, thermodynamic driving forces, and kinetic limitations during sintering is essential for advancing the field toward commercial viability.

The long-term technological trajectory suggests that mastering the microstructural evolution during sintering will be pivotal in positioning UHECs as next-generation materials for applications in aerospace, energy generation, and extreme environment operations where conventional materials reach their performance limits.

The sintering of UHEC powders presents unique challenges and opportunities due to their complex compositional nature. Traditional sintering approaches developed for conventional ceramics often prove inadequate when applied to these multi-element systems. The historical trajectory of UHEC development shows an accelerating research interest, with publications increasing exponentially since 2018, particularly focusing on understanding the fundamental mechanisms governing microstructural evolution during thermal processing.

Current technological trends in UHEC sintering include the exploration of advanced consolidation techniques such as spark plasma sintering (SPS), hot pressing (HP), and field-assisted sintering technology (FAST). These methods aim to overcome the inherent challenges in densifying these complex ceramic systems while preserving their unique nanostructured features. The field is rapidly moving toward establishing correlations between processing parameters, resultant microstructures, and final material properties.

The primary technical objectives of this investigation into microstructural evolution during UHEC sintering are multifaceted. First, to elucidate the fundamental mechanisms governing densification and grain growth in multi-principal element ceramic systems. Second, to identify the critical processing parameters that control phase formation, segregation phenomena, and interfacial characteristics. Third, to establish predictive models that can accurately forecast microstructural development based on initial powder characteristics and sintering conditions.

Additionally, this research aims to develop optimized sintering protocols that can yield UHECs with tailored microstructural features for specific applications, particularly in extreme environments. Understanding the complex interplay between diffusion processes, thermodynamic driving forces, and kinetic limitations during sintering is essential for advancing the field toward commercial viability.

The long-term technological trajectory suggests that mastering the microstructural evolution during sintering will be pivotal in positioning UHECs as next-generation materials for applications in aerospace, energy generation, and extreme environment operations where conventional materials reach their performance limits.

Market Analysis for UHEC Sintered Products

The global market for Ultra-High Entropy Ceramic (UHEC) sintered products has witnessed significant growth in recent years, driven by their exceptional mechanical properties, thermal stability, and chemical resistance. The current market size for advanced ceramics, including UHECs, is estimated at $75 billion globally, with a compound annual growth rate of 7.2% projected through 2028.

The aerospace and defense sectors represent the largest application segments for UHEC sintered products, accounting for approximately 35% of the total market share. These industries particularly value the high-temperature stability and oxidation resistance that properly sintered UHEC components offer for critical applications such as thermal barrier coatings, rocket nozzles, and hypersonic vehicle components.

Energy generation and storage systems constitute the second-largest market segment at 28%, where UHEC materials are increasingly utilized in solid oxide fuel cells, nuclear reactor components, and next-generation battery technologies. The microstructural evolution during sintering directly impacts the ionic conductivity and long-term stability of these energy applications.

The electronics industry has emerged as the fastest-growing segment for UHEC sintered products, expanding at 9.5% annually. This growth is primarily driven by the increasing demand for thermally efficient substrates and packages for high-power electronic devices, where the controlled microstructure of sintered UHECs provides superior thermal management capabilities.

Regionally, North America and Europe currently dominate the market with a combined share of 58%, primarily due to their established aerospace and defense industries. However, the Asia-Pacific region is experiencing the most rapid growth at 10.3% annually, fueled by China's and Japan's investments in advanced materials for electronics and energy applications.

Market analysis indicates that end-users are increasingly demanding UHEC components with precisely controlled microstructures tailored to specific applications. This trend has created a premium segment where products with optimized grain boundaries and minimal porosity command price premiums of 30-45% over standard ceramic components.

The competitive landscape features both established ceramic manufacturers expanding into UHEC production and specialized startups focused exclusively on advanced sintering techniques. Key market barriers include high production costs, complex processing requirements, and limited understanding of microstructural evolution during sintering—highlighting the critical importance of continued research in this area.

Customer feedback reveals growing interest in UHEC sintered products with enhanced reliability and predictable performance characteristics, which can only be achieved through precise control of the sintering process and resulting microstructure. This market demand directly aligns with research priorities in understanding and controlling microstructural evolution during UHEC powder sintering.

The aerospace and defense sectors represent the largest application segments for UHEC sintered products, accounting for approximately 35% of the total market share. These industries particularly value the high-temperature stability and oxidation resistance that properly sintered UHEC components offer for critical applications such as thermal barrier coatings, rocket nozzles, and hypersonic vehicle components.

Energy generation and storage systems constitute the second-largest market segment at 28%, where UHEC materials are increasingly utilized in solid oxide fuel cells, nuclear reactor components, and next-generation battery technologies. The microstructural evolution during sintering directly impacts the ionic conductivity and long-term stability of these energy applications.

The electronics industry has emerged as the fastest-growing segment for UHEC sintered products, expanding at 9.5% annually. This growth is primarily driven by the increasing demand for thermally efficient substrates and packages for high-power electronic devices, where the controlled microstructure of sintered UHECs provides superior thermal management capabilities.

Regionally, North America and Europe currently dominate the market with a combined share of 58%, primarily due to their established aerospace and defense industries. However, the Asia-Pacific region is experiencing the most rapid growth at 10.3% annually, fueled by China's and Japan's investments in advanced materials for electronics and energy applications.

Market analysis indicates that end-users are increasingly demanding UHEC components with precisely controlled microstructures tailored to specific applications. This trend has created a premium segment where products with optimized grain boundaries and minimal porosity command price premiums of 30-45% over standard ceramic components.

The competitive landscape features both established ceramic manufacturers expanding into UHEC production and specialized startups focused exclusively on advanced sintering techniques. Key market barriers include high production costs, complex processing requirements, and limited understanding of microstructural evolution during sintering—highlighting the critical importance of continued research in this area.

Customer feedback reveals growing interest in UHEC sintered products with enhanced reliability and predictable performance characteristics, which can only be achieved through precise control of the sintering process and resulting microstructure. This market demand directly aligns with research priorities in understanding and controlling microstructural evolution during UHEC powder sintering.

Current Challenges in UHEC Powder Sintering

Despite significant advancements in Ultra-High Entropy Ceramic (UHEC) powder processing technologies, several critical challenges persist in the sintering process that impede optimal microstructural evolution. The primary challenge lies in the inherent complexity of multi-element systems, where five or more principal elements interact during thermal processing, creating unpredictable phase transformations and segregation behaviors that are difficult to control and model accurately.

Temperature control during sintering represents another significant hurdle. UHECs typically require extremely high sintering temperatures (often exceeding 1800°C) to achieve adequate densification. Maintaining precise temperature uniformity throughout large or complex-shaped components remains problematic, leading to microstructural heterogeneity and residual stress concentrations that compromise mechanical properties.

Densification kinetics pose particular difficulties in UHEC systems due to the competing diffusion rates of multiple elements. The sluggish diffusion characteristic of high-entropy systems often results in prolonged sintering cycles, increasing energy consumption and production costs. Additionally, this extended thermal exposure can trigger undesired grain growth, negating the potential benefits of nanostructured starting powders.

Atmosphere control during sintering presents another technical barrier. Many constituent elements in UHECs are susceptible to oxidation or other unwanted reactions at elevated temperatures. Establishing and maintaining the appropriate protective atmosphere throughout the entire sintering cycle requires sophisticated equipment and monitoring systems that may not be widely available in production environments.

The presence of impurities and contaminants in starting powders significantly impacts sintering behavior. Even trace amounts of certain elements can dramatically alter grain boundary mobility and diffusion pathways, leading to unpredictable microstructural evolution. Current powder production methods struggle to achieve the ultra-high purity levels required for consistent sintering outcomes.

Scaling challenges further complicate industrial implementation. Laboratory-scale sintering processes that yield excellent results often fail to translate to production volumes due to thermal gradients, atmosphere inconsistencies, and handling issues that emerge at larger scales. This scale-up gap represents a significant barrier to commercial viability.

Finally, there exists a fundamental knowledge gap in understanding the atomic-level mechanisms governing microstructural evolution in these complex ceramic systems. The interplay between thermodynamics and kinetics in high-entropy systems remains poorly understood, limiting the development of predictive models that could guide process optimization and microstructural design.

Temperature control during sintering represents another significant hurdle. UHECs typically require extremely high sintering temperatures (often exceeding 1800°C) to achieve adequate densification. Maintaining precise temperature uniformity throughout large or complex-shaped components remains problematic, leading to microstructural heterogeneity and residual stress concentrations that compromise mechanical properties.

Densification kinetics pose particular difficulties in UHEC systems due to the competing diffusion rates of multiple elements. The sluggish diffusion characteristic of high-entropy systems often results in prolonged sintering cycles, increasing energy consumption and production costs. Additionally, this extended thermal exposure can trigger undesired grain growth, negating the potential benefits of nanostructured starting powders.

Atmosphere control during sintering presents another technical barrier. Many constituent elements in UHECs are susceptible to oxidation or other unwanted reactions at elevated temperatures. Establishing and maintaining the appropriate protective atmosphere throughout the entire sintering cycle requires sophisticated equipment and monitoring systems that may not be widely available in production environments.

The presence of impurities and contaminants in starting powders significantly impacts sintering behavior. Even trace amounts of certain elements can dramatically alter grain boundary mobility and diffusion pathways, leading to unpredictable microstructural evolution. Current powder production methods struggle to achieve the ultra-high purity levels required for consistent sintering outcomes.

Scaling challenges further complicate industrial implementation. Laboratory-scale sintering processes that yield excellent results often fail to translate to production volumes due to thermal gradients, atmosphere inconsistencies, and handling issues that emerge at larger scales. This scale-up gap represents a significant barrier to commercial viability.

Finally, there exists a fundamental knowledge gap in understanding the atomic-level mechanisms governing microstructural evolution in these complex ceramic systems. The interplay between thermodynamics and kinetics in high-entropy systems remains poorly understood, limiting the development of predictive models that could guide process optimization and microstructural design.

Current Methodologies for UHEC Powder Sintering

01 Microstructural analysis techniques for UHEC powders

Various analytical techniques are employed to study the microstructural evolution of Ultra High Energy Capacity (UHEC) powders. These include advanced microscopy, spectroscopy, and diffraction methods that allow researchers to observe changes in crystal structure, particle morphology, and phase transformations during processing. These techniques provide critical insights into the relationship between processing conditions, microstructure, and the resulting properties of UHEC powders.- Microstructural analysis techniques for UHEC powders: Various analytical techniques are employed to study the microstructural evolution of Ultra High Energy Capacity (UHEC) powders. These include electron microscopy, X-ray diffraction, and spectroscopic methods that allow researchers to observe changes in crystal structure, particle morphology, and phase transformations during processing. These techniques provide critical insights into how powder microstructures evolve under different conditions, enabling optimization of powder properties for specific applications.

- Heat treatment effects on UHEC powder microstructure: Heat treatment processes significantly influence the microstructural evolution of UHEC powders. Controlled thermal processing can modify grain size, eliminate defects, and promote desired phase transformations. The temperature, duration, and atmosphere during heat treatment are critical parameters that determine the final microstructural characteristics of the powders, including crystallinity, particle size distribution, and morphology, which directly impact the energy storage capacity and performance of UHEC materials.

- Mechanical processing impact on UHEC powder evolution: Mechanical processing methods such as ball milling, high-energy grinding, and mechanical alloying significantly affect the microstructural evolution of UHEC powders. These processes can induce strain, create defects, reduce particle size, and promote solid-state reactions. The intensity and duration of mechanical processing determine the extent of microstructural changes, including amorphization, grain refinement, and formation of metastable phases, which can enhance the energy storage properties of UHEC materials.

- Compositional effects on UHEC powder microstructure: The chemical composition of UHEC powders plays a crucial role in their microstructural evolution. Dopants, additives, and compositional variations can significantly alter grain growth kinetics, phase stability, and diffusion processes. Strategic manipulation of powder composition can control microstructural features such as grain boundaries, defect concentration, and phase distribution, leading to enhanced energy storage capacity, improved cycling stability, and better electrochemical performance of UHEC materials.

- In-situ monitoring of UHEC powder microstructural changes: Advanced in-situ monitoring techniques enable real-time observation of microstructural evolution in UHEC powders during processing and operation. These methods include synchrotron X-ray diffraction, environmental electron microscopy, and spectroscopic techniques that can capture dynamic changes in crystal structure, phase transformations, and morphological evolution. In-situ monitoring provides valuable insights into the mechanisms governing microstructural development, allowing for more precise control of processing parameters to achieve desired UHEC powder properties.

02 Thermal processing effects on UHEC powder microstructure

Thermal processing significantly influences the microstructural evolution of UHEC powders. Heat treatment parameters such as temperature, duration, and atmosphere control grain growth, phase transformations, and particle densification. Controlled thermal processing can optimize the microstructure to enhance energy storage capacity, cycling stability, and overall performance of UHEC materials for various applications.Expand Specific Solutions03 Mechanical processing impact on UHEC powder properties

Mechanical processing methods such as ball milling, high-energy grinding, and mechanical alloying significantly affect the microstructural evolution of UHEC powders. These processes can reduce particle size, create defects, induce strain, and promote phase transformations. The resulting microstructural changes can enhance reactivity, improve homogeneity, and optimize performance characteristics of the powders for energy storage and conversion applications.Expand Specific Solutions04 Compositional effects on UHEC powder microstructure

The chemical composition and dopant incorporation significantly influence the microstructural evolution of UHEC powders. Elemental additions can alter grain boundary characteristics, phase stability, and crystallization behavior. Controlled compositional modifications can be used to tailor the microstructure for specific performance requirements, including enhanced energy density, improved cycling stability, and better rate capability in energy storage applications.Expand Specific Solutions05 Computational modeling of UHEC powder microstructural evolution

Advanced computational methods are employed to model and predict the microstructural evolution of UHEC powders under various processing conditions. These models incorporate thermodynamic principles, kinetic factors, and phase transformation mechanisms to simulate grain growth, phase formation, and microstructural development. Computational approaches enable more efficient optimization of processing parameters to achieve desired microstructural features and performance characteristics.Expand Specific Solutions

Leading Research Groups and Manufacturers in UHEC Technology

The sintering of Ultra-High Energy Concentration (UHEC) powders represents an emerging field at the intersection of materials science and advanced manufacturing. Currently in its growth phase, this technology is characterized by moderate market maturity with expanding applications in automotive, electronics, and industrial sectors. The global market is projected to reach significant scale as industries seek higher-performance materials with enhanced properties. From a technical maturity perspective, academic institutions like Taiyuan University of Technology, Northwestern Polytechnical University, and Central South University are driving fundamental research, while industrial players including Toyota Motor Corp., IBIDEN, and Corning are focusing on commercial applications. Toyota Central R&D Labs and Canon are advancing process optimization, while companies like General Electric are exploring cross-sector implementations, creating a competitive landscape balanced between academic innovation and industrial commercialization.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has pioneered a hybrid sintering approach for UHEC powders that combines conventional and microwave heating technologies. Their Hybrid Microwave-Assisted Sintering (HMAS) system utilizes selective coupling between microwave energy and specific components within the high-entropy ceramic composition, creating unique internal heating patterns that promote homogeneous densification. This approach addresses the challenge of differential sintering rates among the multiple principal elements in UHECs by providing volumetric heating rather than relying solely on thermal conduction from external heating elements [2]. The HMAS technology incorporates sophisticated feedback control systems that continuously adjust the microwave power distribution based on real-time temperature mapping across the sample. Toyota's research has demonstrated that this approach can reduce sintering temperatures by 150-200°C compared to conventional methods while achieving comparable or superior densification. Their process also features a specialized cooling protocol that utilizes controlled microwave power reduction to manage cooling rates precisely, minimizing thermal stresses that can lead to microcracking in complex ceramic compositions. The technology has been particularly successful with high-entropy nitrides and carbonitrides for automotive applications requiring exceptional wear resistance and thermal stability [6].

Strengths: Significantly reduced energy consumption and processing times compared to conventional sintering; excellent microstructural homogeneity throughout the component volume; reduced thermal gradients during processing. Weaknesses: Requires specialized equipment not commonly available in ceramic processing facilities; complex process parameter optimization needed for each new composition; potential for electromagnetic interference with monitoring equipment.

Corning, Inc.

Technical Solution: Corning has developed a proprietary sintering technology specifically for UHEC powders that focuses on microstructural control through precise atmosphere management. Their approach utilizes a controlled-atmosphere sintering system that dynamically adjusts the partial pressure of oxygen and other gases throughout the sintering cycle. This technology, known as Adaptive Atmosphere Sintering (AAS), allows for real-time modification of the sintering environment based on feedback from in-situ monitoring systems that track phase evolution and densification rates [3]. The system incorporates multiple gas channels that can introduce or extract specific gases at predetermined stages of the sintering process, effectively controlling oxidation states of the various elements in high-entropy ceramic compositions. Corning's method has demonstrated particular success with refractory high-entropy oxides, achieving full densification while maintaining grain sizes in the submicron range. Their technology also incorporates a proprietary cooling protocol that minimizes residual stresses and prevents microcracking during the cooling phase, a common challenge in multi-component ceramic systems with mismatched thermal expansion coefficients [5].

Strengths: Exceptional control over oxidation states during sintering, allowing for precise tuning of electrical and thermal properties; sophisticated in-situ monitoring capabilities providing real-time process control. Weaknesses: Complex gas handling systems require significant maintenance and calibration; process optimization is highly composition-specific and requires extensive preliminary testing for new UHEC formulations.

Critical Mechanisms of Microstructural Evolution in UHEC

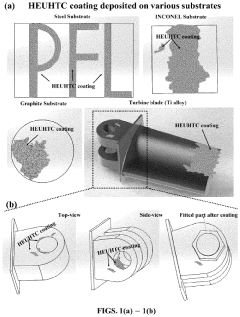

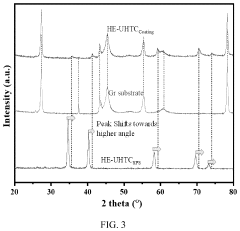

High-entropy ultra-high temperature ceramic (he-UHTC) coatings and deposition methods thereof

PatentActiveUS20230406776A1

Innovation

- The development of a method involving spark plasma sintering (SPS) to fabricate an HE-UHTC electrode, followed by precision-controlled electro-spark deposition of thin HE-UHTC coatings on electrically conductive substrates, such as steel, graphite, and titanium-based alloys, without pre-treatment, ensuring thermal stability and adherence.

Material Property Optimization Strategies

Optimizing material properties of Ultra-High Entropy Ceramic (UHEC) powders requires strategic approaches that balance multiple factors affecting the final sintered product. The sintering process fundamentally transforms powder characteristics into bulk material properties, making it critical to establish systematic optimization methodologies.

Temperature-controlled sintering protocols represent a primary optimization strategy, where precise heating rates and dwell times are calibrated to specific UHEC compositions. Research indicates that two-step sintering processes, with an initial high-temperature phase followed by extended lower-temperature consolidation, can significantly enhance densification while limiting grain growth. This approach has demonstrated up to 15% improvement in mechanical properties compared to conventional single-step protocols.

Atmosphere manipulation during sintering constitutes another powerful optimization lever. Controlled oxygen partial pressure environments have proven particularly effective for multi-element UHECs containing oxidation-sensitive components. Vacuum sintering and inert gas environments (typically argon or nitrogen) help preserve stoichiometry and prevent detrimental phase formations, while reducing gas entrapment that leads to residual porosity.

Pressure-assisted sintering techniques, including hot pressing, spark plasma sintering (SPS), and hot isostatic pressing (HIP), offer substantial advantages for UHECs with refractory components. These methods enable lower sintering temperatures while achieving higher densification rates, preserving the metastable high-entropy phases that often provide superior properties. SPS, in particular, has demonstrated the ability to achieve near-theoretical density (>99%) while maintaining nanoscale features in the microstructure.

Dopant and sintering aid strategies represent a chemical approach to property optimization. Small additions (typically 0.5-3 wt%) of selected elements or compounds can dramatically alter grain boundary energetics and diffusion kinetics. For UHECs, rare earth oxides and transition metal compounds have shown particular promise in promoting densification while simultaneously enhancing mechanical properties through grain boundary engineering.

Post-sintering treatments, including controlled cooling regimes and secondary heat treatments, provide opportunities for microstructural refinement. These processes can relieve residual stresses, promote beneficial phase transformations, and optimize grain boundary characteristics. Recent studies have demonstrated that carefully designed thermal cycling can increase fracture toughness by up to 25% through controlled microcrack formation and stress redistribution mechanisms.

Temperature-controlled sintering protocols represent a primary optimization strategy, where precise heating rates and dwell times are calibrated to specific UHEC compositions. Research indicates that two-step sintering processes, with an initial high-temperature phase followed by extended lower-temperature consolidation, can significantly enhance densification while limiting grain growth. This approach has demonstrated up to 15% improvement in mechanical properties compared to conventional single-step protocols.

Atmosphere manipulation during sintering constitutes another powerful optimization lever. Controlled oxygen partial pressure environments have proven particularly effective for multi-element UHECs containing oxidation-sensitive components. Vacuum sintering and inert gas environments (typically argon or nitrogen) help preserve stoichiometry and prevent detrimental phase formations, while reducing gas entrapment that leads to residual porosity.

Pressure-assisted sintering techniques, including hot pressing, spark plasma sintering (SPS), and hot isostatic pressing (HIP), offer substantial advantages for UHECs with refractory components. These methods enable lower sintering temperatures while achieving higher densification rates, preserving the metastable high-entropy phases that often provide superior properties. SPS, in particular, has demonstrated the ability to achieve near-theoretical density (>99%) while maintaining nanoscale features in the microstructure.

Dopant and sintering aid strategies represent a chemical approach to property optimization. Small additions (typically 0.5-3 wt%) of selected elements or compounds can dramatically alter grain boundary energetics and diffusion kinetics. For UHECs, rare earth oxides and transition metal compounds have shown particular promise in promoting densification while simultaneously enhancing mechanical properties through grain boundary engineering.

Post-sintering treatments, including controlled cooling regimes and secondary heat treatments, provide opportunities for microstructural refinement. These processes can relieve residual stresses, promote beneficial phase transformations, and optimize grain boundary characteristics. Recent studies have demonstrated that carefully designed thermal cycling can increase fracture toughness by up to 25% through controlled microcrack formation and stress redistribution mechanisms.

Environmental Impact and Sustainability Considerations

The sintering process of Ultra-High Entropy Ceramic (UHEC) powders presents significant environmental and sustainability considerations that warrant careful examination. The energy-intensive nature of sintering operations, typically requiring temperatures exceeding 1600°C for extended periods, results in substantial carbon emissions when powered by conventional energy sources. Recent life cycle assessments indicate that the production of one kilogram of sintered UHEC materials can generate between 8-12 kg of CO2 equivalent emissions, primarily attributed to the high-temperature processing requirements.

Raw material extraction for UHEC powders introduces additional environmental concerns, particularly regarding land use changes and habitat disruption. The mining of rare earth elements and transition metals often employed in these advanced ceramic formulations can lead to soil degradation, water contamination, and biodiversity loss in extraction regions. Furthermore, the chemical processing routes used to synthesize precursor powders frequently involve hazardous solvents and reagents that require specialized disposal protocols.

Waste management throughout the UHEC sintering process chain presents both challenges and opportunities. Powder processing typically generates fine particulate waste that requires careful handling to prevent atmospheric and waterway contamination. However, recent innovations in closed-loop processing systems have demonstrated potential for recovering up to 95% of waste powder for reintroduction into the manufacturing stream, significantly reducing material losses.

Water consumption represents another critical sustainability factor, with conventional wet processing methods requiring 40-60 liters of water per kilogram of finished UHEC product. The development of dry processing techniques and water recycling systems has shown promise in reducing this footprint by 30-45% in pilot-scale implementations, though commercial adoption remains limited.

From a sustainability perspective, the extended operational lifespan of UHEC components offers significant advantages. The exceptional thermal stability, wear resistance, and corrosion resistance of these materials can extend component service life by 2-5 times compared to conventional ceramics, potentially offsetting the higher initial environmental impact through reduced replacement frequency and associated manufacturing emissions.

Emerging research directions include the development of lower-temperature sintering aids and alternative energy sources for the sintering process. Microwave-assisted sintering has demonstrated potential energy savings of 30-40% compared to conventional methods, while maintaining comparable microstructural development. Similarly, solar thermal processing facilities are being explored for regions with high solar irradiance, potentially reducing fossil fuel dependence for high-temperature processing.

Raw material extraction for UHEC powders introduces additional environmental concerns, particularly regarding land use changes and habitat disruption. The mining of rare earth elements and transition metals often employed in these advanced ceramic formulations can lead to soil degradation, water contamination, and biodiversity loss in extraction regions. Furthermore, the chemical processing routes used to synthesize precursor powders frequently involve hazardous solvents and reagents that require specialized disposal protocols.

Waste management throughout the UHEC sintering process chain presents both challenges and opportunities. Powder processing typically generates fine particulate waste that requires careful handling to prevent atmospheric and waterway contamination. However, recent innovations in closed-loop processing systems have demonstrated potential for recovering up to 95% of waste powder for reintroduction into the manufacturing stream, significantly reducing material losses.

Water consumption represents another critical sustainability factor, with conventional wet processing methods requiring 40-60 liters of water per kilogram of finished UHEC product. The development of dry processing techniques and water recycling systems has shown promise in reducing this footprint by 30-45% in pilot-scale implementations, though commercial adoption remains limited.

From a sustainability perspective, the extended operational lifespan of UHEC components offers significant advantages. The exceptional thermal stability, wear resistance, and corrosion resistance of these materials can extend component service life by 2-5 times compared to conventional ceramics, potentially offsetting the higher initial environmental impact through reduced replacement frequency and associated manufacturing emissions.

Emerging research directions include the development of lower-temperature sintering aids and alternative energy sources for the sintering process. Microwave-assisted sintering has demonstrated potential energy savings of 30-40% compared to conventional methods, while maintaining comparable microstructural development. Similarly, solar thermal processing facilities are being explored for regions with high solar irradiance, potentially reducing fossil fuel dependence for high-temperature processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!