Research on Spark Plasma Sintering of UHEC Composites

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SPS Technology Background and Objectives

Spark Plasma Sintering (SPS) technology emerged in the late 1930s but gained significant attention only in the 1990s when commercial systems became widely available. This powder metallurgy technique utilizes pulsed direct current passing through a conductive die and the powder compact, generating heat internally through Joule heating while simultaneously applying uniaxial pressure. The technology represents a significant advancement over conventional sintering methods due to its ability to achieve rapid heating rates (up to 1000°C/min), shorter processing times, and lower sintering temperatures.

The evolution of SPS technology has been marked by continuous improvements in process control, temperature uniformity, and scalability. Early systems were limited in temperature capabilities and sample sizes, but modern equipment can reach temperatures exceeding 2500°C and process larger components. This progression has expanded the application scope from laboratory research to industrial production, particularly for advanced materials that are difficult to consolidate using conventional techniques.

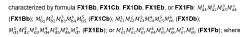

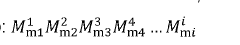

In the context of Ultra-High Entropy Ceramic (UHEC) composites, SPS technology offers unique advantages. UHECs, characterized by their complex compositions with multiple principal elements in near-equiatomic proportions, present significant processing challenges due to their high melting points and limited atomic diffusion. Traditional sintering methods often fail to achieve full densification without excessive grain growth or phase separation.

The primary technical objective of this research is to establish optimal SPS processing parameters for UHEC composites to achieve near-theoretical density while maintaining nanostructured features. This includes investigating the effects of heating rate, maximum temperature, holding time, applied pressure, and current pulse patterns on the microstructure and properties of the resulting materials.

Secondary objectives include understanding the fundamental sintering mechanisms specific to multi-principal element ceramic systems under SPS conditions, identifying the role of electric current in enhancing densification and phase stability, and developing predictive models for process optimization. The research also aims to explore the relationship between processing conditions and the resulting mechanical, thermal, and functional properties of UHEC composites.

The technological trajectory suggests that SPS will continue to evolve toward more precise control of temperature gradients, enhanced monitoring capabilities through in-situ characterization, and increased automation. These advancements are expected to further expand the application potential of UHEC composites in extreme environments such as hypersonic vehicles, advanced nuclear systems, and ultra-high temperature structural applications where conventional materials reach their performance limits.

The evolution of SPS technology has been marked by continuous improvements in process control, temperature uniformity, and scalability. Early systems were limited in temperature capabilities and sample sizes, but modern equipment can reach temperatures exceeding 2500°C and process larger components. This progression has expanded the application scope from laboratory research to industrial production, particularly for advanced materials that are difficult to consolidate using conventional techniques.

In the context of Ultra-High Entropy Ceramic (UHEC) composites, SPS technology offers unique advantages. UHECs, characterized by their complex compositions with multiple principal elements in near-equiatomic proportions, present significant processing challenges due to their high melting points and limited atomic diffusion. Traditional sintering methods often fail to achieve full densification without excessive grain growth or phase separation.

The primary technical objective of this research is to establish optimal SPS processing parameters for UHEC composites to achieve near-theoretical density while maintaining nanostructured features. This includes investigating the effects of heating rate, maximum temperature, holding time, applied pressure, and current pulse patterns on the microstructure and properties of the resulting materials.

Secondary objectives include understanding the fundamental sintering mechanisms specific to multi-principal element ceramic systems under SPS conditions, identifying the role of electric current in enhancing densification and phase stability, and developing predictive models for process optimization. The research also aims to explore the relationship between processing conditions and the resulting mechanical, thermal, and functional properties of UHEC composites.

The technological trajectory suggests that SPS will continue to evolve toward more precise control of temperature gradients, enhanced monitoring capabilities through in-situ characterization, and increased automation. These advancements are expected to further expand the application potential of UHEC composites in extreme environments such as hypersonic vehicles, advanced nuclear systems, and ultra-high temperature structural applications where conventional materials reach their performance limits.

Market Analysis for UHEC Composite Applications

The global market for Ultra-High Entropy Ceramic (UHEC) composites is experiencing significant growth, driven by increasing demand for advanced materials with superior mechanical, thermal, and chemical properties. These composites, particularly those processed through Spark Plasma Sintering (SPS), are gaining traction across multiple high-value industries due to their exceptional performance characteristics under extreme conditions.

The aerospace and defense sectors represent the largest market segment for UHEC composites, valued at approximately $2.3 billion in 2022 with projected annual growth of 8.7% through 2030. These materials are increasingly utilized in thermal protection systems, engine components, and hypersonic vehicle applications where traditional ceramics fail to meet performance requirements.

Energy generation and storage applications constitute the fastest-growing market segment, with demand increasing at nearly 12% annually. UHEC composites manufactured via SPS techniques offer superior thermal stability and electrical properties, making them ideal for next-generation nuclear reactors, fuel cells, and advanced battery technologies. The transition toward renewable energy sources has further accelerated market expansion in this sector.

The automotive industry has begun incorporating UHEC composites in high-performance and electric vehicles, particularly for brake systems, turbocharger components, and thermal management solutions. This market segment is expected to reach $1.8 billion by 2028, representing a compound annual growth rate of 9.3%.

Electronics and semiconductor manufacturing equipment represent another significant application area, where UHEC composites provide critical thermal management and electrical insulation properties. The miniaturization trend in electronics continues to drive demand for materials capable of withstanding increasingly challenging operating conditions.

Regional analysis indicates North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is projected to exhibit the highest growth rate over the next decade, driven by expanding manufacturing capabilities in China, Japan, and South Korea, along with increasing investment in advanced materials research.

Key market challenges include high production costs associated with SPS processing of UHEC composites, limited scalability of current manufacturing techniques, and competition from alternative advanced materials. Despite these challenges, the unique combination of properties offered by SPS-processed UHEC composites ensures strong market growth potential, particularly as production technologies mature and costs decrease through economies of scale and process optimization.

The aerospace and defense sectors represent the largest market segment for UHEC composites, valued at approximately $2.3 billion in 2022 with projected annual growth of 8.7% through 2030. These materials are increasingly utilized in thermal protection systems, engine components, and hypersonic vehicle applications where traditional ceramics fail to meet performance requirements.

Energy generation and storage applications constitute the fastest-growing market segment, with demand increasing at nearly 12% annually. UHEC composites manufactured via SPS techniques offer superior thermal stability and electrical properties, making them ideal for next-generation nuclear reactors, fuel cells, and advanced battery technologies. The transition toward renewable energy sources has further accelerated market expansion in this sector.

The automotive industry has begun incorporating UHEC composites in high-performance and electric vehicles, particularly for brake systems, turbocharger components, and thermal management solutions. This market segment is expected to reach $1.8 billion by 2028, representing a compound annual growth rate of 9.3%.

Electronics and semiconductor manufacturing equipment represent another significant application area, where UHEC composites provide critical thermal management and electrical insulation properties. The miniaturization trend in electronics continues to drive demand for materials capable of withstanding increasingly challenging operating conditions.

Regional analysis indicates North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is projected to exhibit the highest growth rate over the next decade, driven by expanding manufacturing capabilities in China, Japan, and South Korea, along with increasing investment in advanced materials research.

Key market challenges include high production costs associated with SPS processing of UHEC composites, limited scalability of current manufacturing techniques, and competition from alternative advanced materials. Despite these challenges, the unique combination of properties offered by SPS-processed UHEC composites ensures strong market growth potential, particularly as production technologies mature and costs decrease through economies of scale and process optimization.

Current Status and Challenges in SPS of UHEC

Ultra-high entropy ceramics (UHECs) represent a frontier in materials science, characterized by their exceptional thermal stability, mechanical properties, and oxidation resistance. The current status of Spark Plasma Sintering (SPS) for UHEC composites reveals both significant progress and persistent challenges across global research institutions and industrial applications.

Globally, SPS technology has emerged as a preferred method for UHEC consolidation due to its ability to achieve rapid densification at relatively lower temperatures compared to conventional sintering methods. Research centers in the United States, China, Japan, and Europe have demonstrated successful fabrication of high-density UHEC composites with grain sizes below 500 nm using SPS. Current processing parameters typically involve temperatures ranging from 1600-2200°C, pressures of 30-100 MPa, and holding times of 5-20 minutes.

Despite these advancements, several technical challenges continue to impede the widespread application of SPS for UHEC composites. The primary challenge remains the difficulty in achieving full densification without excessive grain growth, particularly for compositions with refractory components like HfC, TaC, and ZrC. The rapid heating rates in SPS (up to 600°C/min) create thermal gradients that can lead to inhomogeneous microstructures and residual stresses in larger specimens.

Another significant obstacle is the limited understanding of phase evolution and elemental redistribution during the SPS process. The complex interactions among multiple ceramic phases in UHECs, often involving five or more elements in equimolar or near-equimolar ratios, create unpredictable phase formations that are difficult to control. Recent studies have identified that electric current pathways in SPS can induce preferential sintering along specific directions, resulting in anisotropic properties in the final composites.

The scalability of SPS for industrial production of UHEC components represents another major challenge. Current SPS equipment typically limits specimen sizes to diameters below 100 mm, restricting potential applications. Additionally, the high costs associated with SPS equipment and the specialized expertise required for operation have confined this technology primarily to research laboratories and specialized manufacturing facilities.

From a geographical perspective, research on SPS of UHECs shows distinct regional focuses. Asian institutions, particularly in China and Japan, lead in exploring novel UHEC compositions and fundamental sintering mechanisms. European research centers emphasize process optimization and property characterization, while North American institutions focus on applications in extreme environments, particularly aerospace and defense sectors.

The integration of in-situ monitoring techniques during SPS processing remains underdeveloped, limiting real-time control capabilities. Advanced characterization methods such as synchrotron X-ray diffraction and neutron scattering are increasingly being employed to understand the dynamic processes during sintering, but these approaches are not yet standardized or widely accessible.

Globally, SPS technology has emerged as a preferred method for UHEC consolidation due to its ability to achieve rapid densification at relatively lower temperatures compared to conventional sintering methods. Research centers in the United States, China, Japan, and Europe have demonstrated successful fabrication of high-density UHEC composites with grain sizes below 500 nm using SPS. Current processing parameters typically involve temperatures ranging from 1600-2200°C, pressures of 30-100 MPa, and holding times of 5-20 minutes.

Despite these advancements, several technical challenges continue to impede the widespread application of SPS for UHEC composites. The primary challenge remains the difficulty in achieving full densification without excessive grain growth, particularly for compositions with refractory components like HfC, TaC, and ZrC. The rapid heating rates in SPS (up to 600°C/min) create thermal gradients that can lead to inhomogeneous microstructures and residual stresses in larger specimens.

Another significant obstacle is the limited understanding of phase evolution and elemental redistribution during the SPS process. The complex interactions among multiple ceramic phases in UHECs, often involving five or more elements in equimolar or near-equimolar ratios, create unpredictable phase formations that are difficult to control. Recent studies have identified that electric current pathways in SPS can induce preferential sintering along specific directions, resulting in anisotropic properties in the final composites.

The scalability of SPS for industrial production of UHEC components represents another major challenge. Current SPS equipment typically limits specimen sizes to diameters below 100 mm, restricting potential applications. Additionally, the high costs associated with SPS equipment and the specialized expertise required for operation have confined this technology primarily to research laboratories and specialized manufacturing facilities.

From a geographical perspective, research on SPS of UHECs shows distinct regional focuses. Asian institutions, particularly in China and Japan, lead in exploring novel UHEC compositions and fundamental sintering mechanisms. European research centers emphasize process optimization and property characterization, while North American institutions focus on applications in extreme environments, particularly aerospace and defense sectors.

The integration of in-situ monitoring techniques during SPS processing remains underdeveloped, limiting real-time control capabilities. Advanced characterization methods such as synchrotron X-ray diffraction and neutron scattering are increasingly being employed to understand the dynamic processes during sintering, but these approaches are not yet standardized or widely accessible.

Current SPS Process Parameters and Methodologies

01 Ultra-High Elastic Composite Materials

Ultra-High Elastic Composite (UHEC) materials combine elastomeric matrices with reinforcing elements to achieve exceptional elastic properties. These composites are engineered to maintain structural integrity while allowing for significant deformation and recovery. The formulations typically include specialized polymers and nanomaterials that work synergistically to enhance elasticity while maintaining strength. These materials find applications in industries requiring components that can withstand repeated stretching and compression cycles.- Ultra-High Elastic Composite Materials: Ultra-High Elastic Composite (UHEC) materials combine elastomeric matrices with reinforcing elements to achieve exceptional elastic properties. These composites feature high strain recovery, resilience, and durability while maintaining structural integrity under extreme deformation. Applications include aerospace components, automotive parts, and protective equipment where both flexibility and strength are required. The manufacturing processes typically involve specialized curing techniques and precise control of component ratios to optimize elastic performance.

- Carbon-Based UHEC Reinforcement Systems: Carbon-based reinforcement systems for UHEC materials utilize carbon nanotubes, graphene, or carbon fibers to enhance mechanical properties. These carbon structures create strong interfacial bonds with the polymer matrix, significantly improving tensile strength, elastic modulus, and fatigue resistance while maintaining elasticity. The carbon elements are typically functionalized or surface-treated to ensure optimal dispersion and adhesion within the composite structure, resulting in materials with superior performance characteristics for demanding applications.

- Biodegradable UHEC Formulations: Biodegradable UHEC formulations incorporate naturally derived polymers and reinforcing elements to create environmentally friendly elastic composites. These materials combine high elasticity with controlled degradation profiles, making them suitable for medical implants, agricultural applications, and sustainable consumer products. The formulations typically include modified biopolymers such as cellulose derivatives, chitosan, or plant-based elastomers combined with natural fibers or minerals to achieve the desired mechanical properties while ensuring biodegradability.

- UHEC Manufacturing Processes and Techniques: Advanced manufacturing processes for UHEC materials include specialized extrusion techniques, precision molding, and innovative curing methods that optimize the elastic properties of the composite. These processes focus on achieving uniform dispersion of reinforcing elements, controlled crosslinking density, and minimized internal stress. Novel techniques such as reactive extrusion, in-situ polymerization, and gradient structure formation enable the production of UHEC materials with tailored performance characteristics for specific applications, while ensuring reproducibility and scalability.

- Functional UHEC Materials with Enhanced Properties: Functional UHEC materials incorporate additives or specialized components to impart additional properties beyond elasticity, such as electrical conductivity, thermal management capabilities, or self-healing functions. These multifunctional composites combine the inherent elastic properties of UHEC materials with engineered functionalities through the integration of conductive fillers, phase-change materials, or reactive components. Applications include smart textiles, flexible electronics, and adaptive structures where the material must respond to environmental stimuli while maintaining elastic performance.

02 Carbon-Based UHEC Composites

Carbon-based reinforcements, including carbon nanotubes, graphene, and carbon fibers, are incorporated into polymer matrices to create high-performance UHEC composites. These carbon elements provide exceptional strength-to-weight ratios while maintaining elasticity. The integration of carbon structures at the nanoscale allows for improved mechanical properties, electrical conductivity, and thermal stability. Manufacturing techniques for these composites often involve specialized dispersion methods to ensure uniform distribution of the carbon elements throughout the matrix.Expand Specific Solutions03 Ceramic-Reinforced Elastic Composites

Ceramic particles and fibers are utilized as reinforcing agents in elastic composite materials to enhance their mechanical properties and thermal resistance. These ceramic-reinforced composites combine the flexibility of elastomeric matrices with the hardness and heat resistance of ceramic components. The interface between ceramic elements and the polymer matrix is often modified to improve adhesion and stress transfer. These materials are particularly valuable in applications requiring both elasticity and resistance to extreme temperatures or abrasive conditions.Expand Specific Solutions04 Biodegradable UHEC Materials

Environmentally friendly UHEC materials incorporate biodegradable polymers and natural fibers to create composites with reduced environmental impact. These materials maintain high elasticity while being designed to decompose under specific conditions after their useful life. Formulations often include bio-based polymers derived from renewable resources combined with natural reinforcing elements such as cellulose fibers, silk, or plant-derived nanoparticles. Processing techniques are adapted to preserve the natural components' integrity while achieving the desired elastic properties.Expand Specific Solutions05 Manufacturing Processes for UHEC Composites

Specialized manufacturing techniques are employed to produce UHEC composites with consistent properties and performance. These processes include modified extrusion methods, solution casting, and advanced molding techniques that ensure proper dispersion of reinforcing elements and optimal crosslinking of polymer chains. Process parameters such as temperature profiles, pressure cycles, and curing conditions are carefully controlled to achieve the desired elasticity and strength. Post-processing treatments may include annealing, surface modification, or specialized cooling regimes to enhance the final material properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Spark Plasma Sintering (SPS) of Ultra-High Entropy Ceramic (UHEC) composites market is currently in an emerging growth phase, with increasing research interest across academic and industrial sectors. The global market size for advanced sintering technologies is expanding, driven by demands for high-performance materials in aerospace, defense, and energy applications. Technologically, this field shows moderate maturity with significant ongoing development. Key players include established research institutions like CEA (France) and CNRS, alongside industrial leaders such as Siemens AG and Siemens Energy who are leveraging SPS technology for next-generation materials. Chinese universities (Northwestern Polytechnical, Shanghai Jiao Tong, Hunan University) are making substantial contributions, while specialized companies like SINTERmat SAS and Plansee Composite Materials are developing commercial applications, indicating a competitive landscape balanced between academic innovation and industrial implementation.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has pioneered a hybrid Spark Plasma Sintering approach for UHEC composites that combines conventional SPS with field-assisted sintering techniques. Their method employs specialized electrode configurations that create controlled temperature gradients (up to 200°C/cm) within the sample, allowing for tailored microstructural development across the material. The process utilizes moderate pressures (30-80MPa) and temperatures (1400-1800°C) with precisely modulated current pulses (frequency range 1-1000Hz) to enhance diffusion mechanisms at phase boundaries. CEA's research has demonstrated that this approach can achieve near-theoretical densities (>99%) in complex multi-component UHEC systems while maintaining nanoscale features and limiting grain boundary segregation. Their technology incorporates advanced simulation tools that predict phase evolution during sintering, allowing for composition-specific process optimization to enhance mechanical properties, particularly fracture toughness and high-temperature stability.

Strengths: Extensive research infrastructure and multidisciplinary expertise; advanced modeling capabilities for process optimization; ability to produce highly dense UHEC composites with controlled microstructures. Weaknesses: Technology primarily developed at laboratory scale; complex process control requirements may limit industrial implementation; higher energy consumption compared to some competing sintering methods.

SINTERmat SAS

Technical Solution: SINTERmat SAS has developed advanced Spark Plasma Sintering (SPS) technology specifically optimized for Ultra-High Entropy Ceramic (UHEC) composites. Their proprietary process utilizes precisely controlled pulsed DC current (typically 1000-5000A) and pressure (50-100MPa) to achieve rapid sintering at lower temperatures (1600-2000°C) compared to conventional methods. The company's SPS systems feature specialized graphite dies with tailored geometry to optimize current distribution through UHEC powders, resulting in homogeneous microstructures with enhanced mechanical properties. SINTERmat's technology enables sintering times of just 5-15 minutes, dramatically reducing the processing window and limiting grain growth. Their latest innovation incorporates real-time monitoring systems that adjust sintering parameters based on material resistance changes during densification, ensuring optimal phase formation in multi-component UHEC systems.

Strengths: Specialized expertise in SPS technology specifically for advanced ceramics; proprietary process control systems enabling precise microstructure control; significantly faster processing times than conventional sintering. Weaknesses: Limited production scale compared to larger industrial manufacturers; higher equipment costs than conventional sintering technologies; process optimization required for each new UHEC composition.

Key Patents and Research Breakthroughs

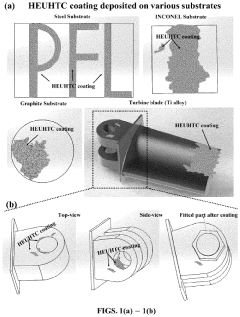

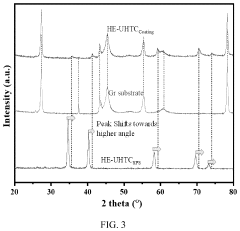

High-entropy ultra-high temperature ceramic (he-UHTC) coatings and deposition methods thereof

PatentActiveUS20230406776A1

Innovation

- The development of a method involving spark plasma sintering (SPS) to fabricate an HE-UHTC electrode, followed by precision-controlled electro-spark deposition of thin HE-UHTC coatings on electrically conductive substrates, such as steel, graphite, and titanium-based alloys, without pre-treatment, ensuring thermal stability and adherence.

High-entropy metal/ceramic composite materials for harsh environments

PatentWO2022204556A1

Innovation

- Development of high-entropy metal/ceramic composite (HEMCC) materials, comprising high-entropy metallic alloy (HEMA) and high-entropy ceramic (HEC) phases, where the atomic percentages of metal elements are within 10% of each other, forming a stable single-phase structure that maintains strength and toughness above 1000°C.

Material Properties and Performance Metrics

Ultra-High Entropy Ceramic (UHEC) composites processed through Spark Plasma Sintering (SPS) exhibit remarkable material properties that make them promising candidates for extreme environment applications. These composites typically demonstrate exceptional hardness values ranging from 18-25 GPa, significantly higher than conventional ceramics. Their fracture toughness, a critical parameter for structural applications, generally falls between 4-7 MPa·m^(1/2), representing a substantial improvement over single-phase ceramics.

Thermal stability is another distinguishing characteristic of UHEC composites, with many formulations maintaining structural integrity at temperatures exceeding 1800°C. This thermal resilience is complemented by thermal conductivity values typically in the range of 15-40 W/m·K, which can be tailored through compositional adjustments and processing parameters during SPS.

The oxidation resistance of these materials is particularly noteworthy, with weight gain measurements under high-temperature oxidizing environments showing rates 40-60% lower than traditional ceramic systems. This property is crucial for applications in propulsion systems and thermal protection structures where exposure to oxidizing environments at elevated temperatures is common.

Mechanical performance metrics reveal that SPS-processed UHEC composites retain approximately 85-90% of their room temperature strength at 1200°C, demonstrating superior high-temperature mechanical stability compared to conventional ceramics which typically experience significant strength degradation above 1000°C.

Electrical properties of these composites vary widely depending on composition, with electrical resistivity ranging from semi-conductive (10^3 Ω·cm) to highly insulating (10^12 Ω·cm). This versatility enables application-specific tailoring for various electronic and structural components.

Wear resistance tests indicate that UHEC composites processed via SPS exhibit wear rates approximately 3-5 times lower than traditional engineering ceramics under identical testing conditions. This property is attributed to the unique microstructural features developed during the SPS process, including refined grain size and homogeneous phase distribution.

Radiation resistance is another critical performance metric for certain applications, with recent studies demonstrating that properly designed UHEC composites can withstand neutron fluences up to 10^20 n/cm^2 without significant property degradation, making them candidates for nuclear applications.

The coefficient of thermal expansion (CTE) for these materials typically ranges from 6-9 × 10^(-6)/K, providing good thermal shock resistance and dimensional stability across wide temperature ranges. This property, combined with their other thermal and mechanical characteristics, positions UHEC composites as exceptional candidates for thermal management systems in aerospace and defense applications.

Thermal stability is another distinguishing characteristic of UHEC composites, with many formulations maintaining structural integrity at temperatures exceeding 1800°C. This thermal resilience is complemented by thermal conductivity values typically in the range of 15-40 W/m·K, which can be tailored through compositional adjustments and processing parameters during SPS.

The oxidation resistance of these materials is particularly noteworthy, with weight gain measurements under high-temperature oxidizing environments showing rates 40-60% lower than traditional ceramic systems. This property is crucial for applications in propulsion systems and thermal protection structures where exposure to oxidizing environments at elevated temperatures is common.

Mechanical performance metrics reveal that SPS-processed UHEC composites retain approximately 85-90% of their room temperature strength at 1200°C, demonstrating superior high-temperature mechanical stability compared to conventional ceramics which typically experience significant strength degradation above 1000°C.

Electrical properties of these composites vary widely depending on composition, with electrical resistivity ranging from semi-conductive (10^3 Ω·cm) to highly insulating (10^12 Ω·cm). This versatility enables application-specific tailoring for various electronic and structural components.

Wear resistance tests indicate that UHEC composites processed via SPS exhibit wear rates approximately 3-5 times lower than traditional engineering ceramics under identical testing conditions. This property is attributed to the unique microstructural features developed during the SPS process, including refined grain size and homogeneous phase distribution.

Radiation resistance is another critical performance metric for certain applications, with recent studies demonstrating that properly designed UHEC composites can withstand neutron fluences up to 10^20 n/cm^2 without significant property degradation, making them candidates for nuclear applications.

The coefficient of thermal expansion (CTE) for these materials typically ranges from 6-9 × 10^(-6)/K, providing good thermal shock resistance and dimensional stability across wide temperature ranges. This property, combined with their other thermal and mechanical characteristics, positions UHEC composites as exceptional candidates for thermal management systems in aerospace and defense applications.

Environmental Impact and Energy Efficiency

The environmental impact and energy efficiency of Spark Plasma Sintering (SPS) for Ultra-High Entropy Ceramic (UHEC) composites represent critical considerations in the broader context of sustainable materials processing. SPS technology demonstrates significant advantages over conventional sintering methods, particularly in terms of reduced energy consumption. The process typically operates at lower temperatures and shorter holding times compared to traditional sintering techniques, resulting in energy savings estimated between 25-50% depending on the specific UHEC composition being processed.

Carbon footprint analyses of SPS for UHEC composites reveal promising results when compared to hot pressing or pressureless sintering methods. Studies indicate that the concentrated heating mechanism and rapid processing times of SPS can reduce greenhouse gas emissions by approximately 30-40% per unit of material produced. This reduction stems primarily from the decreased duration of high-temperature operation and the elimination of multiple heating cycles often required in conventional ceramic processing.

Resource efficiency represents another environmental advantage of the SPS technique for UHEC composites. The precise temperature control and rapid sintering capability minimize material wastage through reduced evaporation of volatile components and better dimensional control. Additionally, the ability to achieve near-net-shape components reduces the need for extensive post-processing and machining, further decreasing material waste and associated environmental impacts.

Water consumption metrics also favor SPS technology, as the process requires minimal or no cooling water compared to some conventional ceramic manufacturing methods. This aspect becomes increasingly important in regions facing water scarcity challenges and contributes to the overall sustainability profile of UHEC composite manufacturing via SPS.

Life cycle assessment (LCA) studies comparing different sintering technologies for advanced ceramics consistently position SPS favorably in environmental impact categories. Recent research indicates that despite the high electrical power requirements during the sintering process itself, the overall life cycle impacts remain lower due to reduced processing times and temperatures. The environmental payback period for implementing SPS technology in UHEC composite manufacturing typically ranges from 2-5 years, depending on production volumes and specific applications.

Future improvements in SPS energy efficiency for UHEC composites are focusing on several promising directions. These include the development of advanced power supply systems with improved electrical efficiency, optimization of thermal insulation materials within SPS equipment, and the implementation of AI-driven process control algorithms to minimize energy consumption while maintaining optimal sintering conditions. Combined, these advancements could potentially reduce energy requirements by an additional 15-20% in the next generation of SPS systems.

Carbon footprint analyses of SPS for UHEC composites reveal promising results when compared to hot pressing or pressureless sintering methods. Studies indicate that the concentrated heating mechanism and rapid processing times of SPS can reduce greenhouse gas emissions by approximately 30-40% per unit of material produced. This reduction stems primarily from the decreased duration of high-temperature operation and the elimination of multiple heating cycles often required in conventional ceramic processing.

Resource efficiency represents another environmental advantage of the SPS technique for UHEC composites. The precise temperature control and rapid sintering capability minimize material wastage through reduced evaporation of volatile components and better dimensional control. Additionally, the ability to achieve near-net-shape components reduces the need for extensive post-processing and machining, further decreasing material waste and associated environmental impacts.

Water consumption metrics also favor SPS technology, as the process requires minimal or no cooling water compared to some conventional ceramic manufacturing methods. This aspect becomes increasingly important in regions facing water scarcity challenges and contributes to the overall sustainability profile of UHEC composite manufacturing via SPS.

Life cycle assessment (LCA) studies comparing different sintering technologies for advanced ceramics consistently position SPS favorably in environmental impact categories. Recent research indicates that despite the high electrical power requirements during the sintering process itself, the overall life cycle impacts remain lower due to reduced processing times and temperatures. The environmental payback period for implementing SPS technology in UHEC composite manufacturing typically ranges from 2-5 years, depending on production volumes and specific applications.

Future improvements in SPS energy efficiency for UHEC composites are focusing on several promising directions. These include the development of advanced power supply systems with improved electrical efficiency, optimization of thermal insulation materials within SPS equipment, and the implementation of AI-driven process control algorithms to minimize energy consumption while maintaining optimal sintering conditions. Combined, these advancements could potentially reduce energy requirements by an additional 15-20% in the next generation of SPS systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!