Potential Industrial Applications of Ultrahigh-Entropy Ceramics

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrahigh-Entropy Ceramics Background and Objectives

Ultrahigh-entropy ceramics (UHECs) represent a revolutionary class of materials that have emerged from the broader field of high-entropy materials science over the past decade. These advanced ceramic systems incorporate five or more principal elements in near-equimolar ratios within a single crystallographic phase, creating unique atomic-level disorder that fundamentally alters material properties. The concept builds upon high-entropy alloys first reported in 2004, with the ceramic variants gaining significant research momentum since 2015.

The evolution of UHECs has been driven by increasing demands for materials capable of withstanding extreme environments in aerospace, energy, and defense applications. Traditional ceramics, while offering excellent high-temperature stability and hardness, often suffer from inherent brittleness and thermal shock sensitivity that limit their industrial deployment. UHECs present a promising pathway to overcome these limitations through entropy-stabilized structures.

Research interest in this field has grown exponentially, with publication rates increasing by approximately 300% between 2018 and 2022. This surge reflects the scientific community's recognition of UHECs' potential to address critical materials challenges in next-generation technologies. The primary technical objective in this domain is to develop ceramic systems that simultaneously demonstrate superior mechanical properties, thermal stability, and functional characteristics beyond what conventional ceramics can achieve.

Current UHEC development focuses on several compositional systems, including oxides, carbides, borides, and nitrides, each offering distinct property profiles. The entropy-stabilization mechanism in these materials creates unique atomic arrangements that can lead to exceptional hardness, thermal conductivity control, and oxidation resistance at temperatures exceeding 2000°C.

The technical goals for UHEC advancement include achieving processing reproducibility at industrial scales, understanding structure-property relationships across diverse compositional spaces, and tailoring properties for specific application requirements. Particular emphasis is placed on developing UHECs with self-healing capabilities, radiation resistance, and thermochemical stability in corrosive environments.

From a fundamental science perspective, researchers aim to establish comprehensive theoretical frameworks that can predict UHEC phase formation and stability, enabling computational design of new compositions with targeted properties. This represents a shift from traditional trial-and-error approaches toward materials informatics and machine learning-assisted development methodologies.

The ultimate objective of UHEC research is to bridge the gap between laboratory discoveries and industrial implementation, creating a new generation of ceramic materials that can enable technological breakthroughs in hypersonic vehicles, advanced nuclear systems, and sustainable energy technologies where conventional materials reach their performance limits.

The evolution of UHECs has been driven by increasing demands for materials capable of withstanding extreme environments in aerospace, energy, and defense applications. Traditional ceramics, while offering excellent high-temperature stability and hardness, often suffer from inherent brittleness and thermal shock sensitivity that limit their industrial deployment. UHECs present a promising pathway to overcome these limitations through entropy-stabilized structures.

Research interest in this field has grown exponentially, with publication rates increasing by approximately 300% between 2018 and 2022. This surge reflects the scientific community's recognition of UHECs' potential to address critical materials challenges in next-generation technologies. The primary technical objective in this domain is to develop ceramic systems that simultaneously demonstrate superior mechanical properties, thermal stability, and functional characteristics beyond what conventional ceramics can achieve.

Current UHEC development focuses on several compositional systems, including oxides, carbides, borides, and nitrides, each offering distinct property profiles. The entropy-stabilization mechanism in these materials creates unique atomic arrangements that can lead to exceptional hardness, thermal conductivity control, and oxidation resistance at temperatures exceeding 2000°C.

The technical goals for UHEC advancement include achieving processing reproducibility at industrial scales, understanding structure-property relationships across diverse compositional spaces, and tailoring properties for specific application requirements. Particular emphasis is placed on developing UHECs with self-healing capabilities, radiation resistance, and thermochemical stability in corrosive environments.

From a fundamental science perspective, researchers aim to establish comprehensive theoretical frameworks that can predict UHEC phase formation and stability, enabling computational design of new compositions with targeted properties. This represents a shift from traditional trial-and-error approaches toward materials informatics and machine learning-assisted development methodologies.

The ultimate objective of UHEC research is to bridge the gap between laboratory discoveries and industrial implementation, creating a new generation of ceramic materials that can enable technological breakthroughs in hypersonic vehicles, advanced nuclear systems, and sustainable energy technologies where conventional materials reach their performance limits.

Market Demand Analysis for Advanced Ceramic Materials

The global market for advanced ceramic materials has been experiencing robust growth, driven by increasing demand across multiple industrial sectors. The compound annual growth rate (CAGR) for advanced ceramics is projected to exceed 6% through 2030, with the market value expected to reach approximately $200 billion by 2028. This growth trajectory is particularly significant for emerging materials like ultrahigh-entropy ceramics (UHECs), which represent a revolutionary advancement in material science.

Aerospace and defense sectors currently constitute the largest market segment for advanced ceramics, accounting for nearly 30% of total demand. These industries require materials capable of withstanding extreme conditions, including high temperatures, corrosive environments, and mechanical stress—precisely the properties that UHECs excel in providing. The thermal barrier coating market alone, where UHECs show tremendous potential, is growing at 7.2% annually.

Energy sector applications represent another substantial market opportunity. With global renewable energy capacity additions increasing by 45% in 2023, the demand for high-performance materials in energy generation, storage, and conversion systems has surged. UHECs' exceptional thermal stability and electrical properties position them as ideal candidates for next-generation solid oxide fuel cells, solar thermal receivers, and nuclear energy applications.

The electronics industry presents perhaps the most dynamic growth potential for advanced ceramics. As semiconductor manufacturing pushes toward smaller node sizes and higher performance requirements, traditional materials reach their physical limitations. UHECs offer promising alternatives for high-temperature electronic components, with the semiconductor materials market growing at 8.5% annually.

Automotive applications, particularly in electric vehicles and advanced propulsion systems, constitute an emerging market segment with significant growth potential. The transition toward electrification has intensified the need for materials capable of operating efficiently at higher temperatures, with the automotive ceramics market expected to double in size by 2030.

Industrial manufacturing represents another substantial market opportunity, with growing demand for wear-resistant components, cutting tools, and high-temperature processing equipment. The industrial ceramics segment is projected to grow at 5.8% annually through 2028, with particular emphasis on materials that can extend component lifespans and reduce maintenance costs.

Regional analysis indicates that Asia-Pacific dominates the advanced ceramics market, accounting for approximately 40% of global demand, followed by North America and Europe. China, Japan, and South Korea have made significant investments in advanced materials research and manufacturing capacity, positioning the region as the epicenter of both production and consumption for next-generation ceramic materials.

Aerospace and defense sectors currently constitute the largest market segment for advanced ceramics, accounting for nearly 30% of total demand. These industries require materials capable of withstanding extreme conditions, including high temperatures, corrosive environments, and mechanical stress—precisely the properties that UHECs excel in providing. The thermal barrier coating market alone, where UHECs show tremendous potential, is growing at 7.2% annually.

Energy sector applications represent another substantial market opportunity. With global renewable energy capacity additions increasing by 45% in 2023, the demand for high-performance materials in energy generation, storage, and conversion systems has surged. UHECs' exceptional thermal stability and electrical properties position them as ideal candidates for next-generation solid oxide fuel cells, solar thermal receivers, and nuclear energy applications.

The electronics industry presents perhaps the most dynamic growth potential for advanced ceramics. As semiconductor manufacturing pushes toward smaller node sizes and higher performance requirements, traditional materials reach their physical limitations. UHECs offer promising alternatives for high-temperature electronic components, with the semiconductor materials market growing at 8.5% annually.

Automotive applications, particularly in electric vehicles and advanced propulsion systems, constitute an emerging market segment with significant growth potential. The transition toward electrification has intensified the need for materials capable of operating efficiently at higher temperatures, with the automotive ceramics market expected to double in size by 2030.

Industrial manufacturing represents another substantial market opportunity, with growing demand for wear-resistant components, cutting tools, and high-temperature processing equipment. The industrial ceramics segment is projected to grow at 5.8% annually through 2028, with particular emphasis on materials that can extend component lifespans and reduce maintenance costs.

Regional analysis indicates that Asia-Pacific dominates the advanced ceramics market, accounting for approximately 40% of global demand, followed by North America and Europe. China, Japan, and South Korea have made significant investments in advanced materials research and manufacturing capacity, positioning the region as the epicenter of both production and consumption for next-generation ceramic materials.

Current Status and Technical Challenges in UEC Development

Ultrahigh-Entropy Ceramics (UECs) represent a frontier in materials science, emerging as a promising subclass of high-entropy materials. Currently, UEC development is in its nascent stage, with significant research activities concentrated in leading materials science institutions across China, the United States, and Europe. The field has witnessed exponential growth in publications since 2018, indicating rapidly increasing interest from the scientific community.

The synthesis of UECs presents substantial technical challenges. Conventional ceramic processing methods often struggle with the homogeneous distribution of multiple elements (typically five or more) in equimolar or near-equimolar ratios. High-energy ball milling, spark plasma sintering, and solution-based methods are being explored, but each comes with limitations in scalability and reproducibility. Temperature control during sintering is particularly critical, as the multi-element systems exhibit complex phase formation behaviors.

Characterization of these materials poses another significant challenge. Traditional analytical techniques must be adapted to accurately assess the distribution of multiple elements, phase purity, and structural features at various length scales. Advanced techniques such as atom probe tomography and high-resolution transmission electron microscopy are becoming essential but remain costly and not universally accessible.

Computational modeling of UECs is still underdeveloped. The complexity of simulating systems with five or more elements in various configurations demands substantial computational resources. Current models struggle to accurately predict phase stability, mechanical properties, and thermal behaviors of these multi-component systems, limiting the ability to design UECs with tailored properties.

Geographically, research leadership is distributed across several regions. China leads in publication volume, with significant contributions from institutions like the Harbin Institute of Technology and Shanghai University. The United States demonstrates strength in fundamental property characterization, particularly through work at MIT and UC San Diego. European research, centered in Germany and the UK, focuses on novel processing techniques and theoretical modeling.

Cost remains a major constraint in UEC development. The requirement for high-purity precursors of multiple elements significantly increases production expenses compared to conventional ceramics. Additionally, the specialized equipment needed for processing and characterization further elevates research and development costs, limiting industrial adoption despite promising properties.

Standardization is notably absent in the field. There is currently no consensus on composition reporting, processing parameters, or property measurement protocols, making direct comparison between studies challenging and potentially slowing overall progress in the field.

The synthesis of UECs presents substantial technical challenges. Conventional ceramic processing methods often struggle with the homogeneous distribution of multiple elements (typically five or more) in equimolar or near-equimolar ratios. High-energy ball milling, spark plasma sintering, and solution-based methods are being explored, but each comes with limitations in scalability and reproducibility. Temperature control during sintering is particularly critical, as the multi-element systems exhibit complex phase formation behaviors.

Characterization of these materials poses another significant challenge. Traditional analytical techniques must be adapted to accurately assess the distribution of multiple elements, phase purity, and structural features at various length scales. Advanced techniques such as atom probe tomography and high-resolution transmission electron microscopy are becoming essential but remain costly and not universally accessible.

Computational modeling of UECs is still underdeveloped. The complexity of simulating systems with five or more elements in various configurations demands substantial computational resources. Current models struggle to accurately predict phase stability, mechanical properties, and thermal behaviors of these multi-component systems, limiting the ability to design UECs with tailored properties.

Geographically, research leadership is distributed across several regions. China leads in publication volume, with significant contributions from institutions like the Harbin Institute of Technology and Shanghai University. The United States demonstrates strength in fundamental property characterization, particularly through work at MIT and UC San Diego. European research, centered in Germany and the UK, focuses on novel processing techniques and theoretical modeling.

Cost remains a major constraint in UEC development. The requirement for high-purity precursors of multiple elements significantly increases production expenses compared to conventional ceramics. Additionally, the specialized equipment needed for processing and characterization further elevates research and development costs, limiting industrial adoption despite promising properties.

Standardization is notably absent in the field. There is currently no consensus on composition reporting, processing parameters, or property measurement protocols, making direct comparison between studies challenging and potentially slowing overall progress in the field.

Current Technical Solutions for UEC Manufacturing

01 Composition and Structure of Ultrahigh-Entropy Ceramics

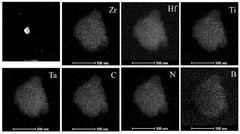

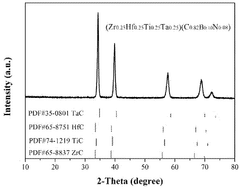

Ultrahigh-entropy ceramics are composed of multiple principal elements (typically five or more) in near-equiatomic proportions, forming a single-phase solid solution. These ceramics feature complex crystal structures with high configurational entropy, which contributes to their unique properties. The composition typically includes various metal oxides, carbides, nitrides, or borides arranged in a disordered lattice structure that promotes stability through entropy maximization.- Composition and structure of ultrahigh-entropy ceramics: Ultrahigh-entropy ceramics are composed of multiple elements (typically five or more) in near-equiatomic proportions, creating a complex crystal structure with high configurational entropy. These materials feature unique atomic arrangements where different elements occupy the same crystallographic sites randomly, leading to lattice distortion and enhanced properties. The composition typically includes transition metals, rare earth elements, and non-metals like carbon, nitrogen, or oxygen, forming carbides, nitrides, or oxides with exceptional structural stability.

- Synthesis methods for ultrahigh-entropy ceramics: Various synthesis techniques are employed to fabricate ultrahigh-entropy ceramics, including high-temperature solid-state reactions, mechanochemical processing, sol-gel methods, and spark plasma sintering. These methods enable precise control over composition, microstructure, and phase formation. Advanced processing techniques like reactive spark plasma sintering allow for rapid consolidation while maintaining the nanostructured features. The synthesis parameters significantly influence the final properties, with temperature, pressure, and cooling rates being critical factors in achieving the desired single-phase high-entropy structure.

- Mechanical and thermal properties of ultrahigh-entropy ceramics: Ultrahigh-entropy ceramics exhibit exceptional mechanical properties including high hardness, excellent wear resistance, and superior strength at elevated temperatures. The severe lattice distortion and cocktail effect contribute to enhanced mechanical performance through solid solution strengthening. These materials also demonstrate remarkable thermal stability and resistance to thermal shock, with lower thermal conductivity compared to conventional ceramics. The combination of high melting points and sluggish diffusion kinetics makes them suitable for extreme environment applications where thermal stability is crucial.

- Functional properties and applications of ultrahigh-entropy ceramics: Beyond mechanical properties, ultrahigh-entropy ceramics exhibit diverse functional characteristics including tunable electrical conductivity, magnetic properties, and catalytic activity. These materials show promise in applications such as high-temperature electrodes, electromagnetic shielding, and energy conversion devices. Their exceptional corrosion resistance and chemical stability make them suitable for harsh environment applications. Some compositions demonstrate interesting optical properties and can be tailored for specific electromagnetic responses, expanding their potential use in sensors, actuators, and electronic components.

- Advanced characterization and computational design of ultrahigh-entropy ceramics: Advanced characterization techniques including high-resolution transmission electron microscopy, atom probe tomography, and synchrotron-based X-ray diffraction are essential for understanding the complex structure of ultrahigh-entropy ceramics. Computational methods such as density functional theory and machine learning approaches enable the prediction of stable compositions and properties, accelerating materials discovery. These computational tools help navigate the vast compositional space of high-entropy systems, identifying promising candidates with desired property combinations. The integration of experimental characterization with theoretical modeling provides insights into structure-property relationships and guides the rational design of next-generation ultrahigh-entropy ceramic materials.

02 Synthesis Methods for Ultrahigh-Entropy Ceramics

Various synthesis methods are employed to produce ultrahigh-entropy ceramics, including high-temperature solid-state reactions, mechanochemical processing, sol-gel techniques, and spark plasma sintering. These methods aim to achieve homogeneous distribution of multiple elements while maintaining the desired crystal structure. Processing parameters such as temperature, pressure, and cooling rates are critical for controlling the microstructure and phase formation in these complex ceramic systems.Expand Specific Solutions03 Mechanical and Thermal Properties of Ultrahigh-Entropy Ceramics

Ultrahigh-entropy ceramics exhibit exceptional mechanical properties including high hardness, wear resistance, and fracture toughness. They also demonstrate remarkable thermal stability and resistance to thermal shock. The combination of multiple elements creates lattice distortion and sluggish diffusion, which contribute to their superior mechanical performance at elevated temperatures. These ceramics typically maintain their structural integrity and mechanical properties even under extreme thermal conditions.Expand Specific Solutions04 Functional Properties and Applications of Ultrahigh-Entropy Ceramics

Ultrahigh-entropy ceramics possess unique functional properties including electrical conductivity, magnetic behavior, and catalytic activity. These materials find applications in extreme environments such as aerospace components, cutting tools, thermal barrier coatings, and high-temperature electronics. Their tailorable properties make them suitable for energy storage systems, sensors, and catalysts. The combination of multiple elements allows for fine-tuning of specific functional properties for targeted applications.Expand Specific Solutions05 Advanced Characterization and Modeling of Ultrahigh-Entropy Ceramics

Advanced characterization techniques including high-resolution transmission electron microscopy, atom probe tomography, and synchrotron-based X-ray diffraction are essential for understanding the complex structure of ultrahigh-entropy ceramics. Computational modeling approaches such as density functional theory and molecular dynamics simulations help predict phase stability, mechanical properties, and thermal behavior. These combined approaches enable the design of new compositions with enhanced properties through fundamental understanding of structure-property relationships.Expand Specific Solutions

Key Industry Players in Advanced Ceramics Research

The ultrahigh-entropy ceramics (UHECs) market is in its early growth phase, characterized by intensive research and development activities primarily led by academic institutions like Xi'an Jiaotong University, Central South University, and University of Science & Technology Beijing. The market size remains relatively small but is projected to expand significantly as industrial applications mature. From a technological maturity perspective, UHECs are transitioning from laboratory research to early commercial applications, with companies like Corning, CoorsTek, and General Electric exploring their potential in extreme environments. Academic-industrial partnerships are emerging, with research institutions providing fundamental knowledge while corporations like FUJIFILM and 3M focus on application development and scalable manufacturing processes. The field shows promising developments in aerospace, energy, and advanced manufacturing sectors.

Corning, Inc.

Technical Solution: Corning has pioneered the development of ultrahigh-entropy ceramic glass composites that combine the thermal stability of UHECs with the formability of glass. Their technology incorporates 6-8 equimolar metal oxides into specialized glass matrices, creating materials with exceptional thermal shock resistance (withstanding temperature differentials of over 800°C) and chemical durability. Corning's proprietary melt-processing techniques allow for the production of complex-shaped UHEC components without traditional ceramic sintering limitations. The company has successfully commercialized these materials for specialized industrial applications including semiconductor processing equipment components and high-temperature sensors. Their research demonstrates that controlled crystallization of entropy-stabilized phases within the glass matrix creates unique microstructures with enhanced mechanical properties, achieving flexural strengths exceeding 300 MPa while maintaining thermal stability at temperatures above 1200°C.

Strengths: Unparalleled expertise in glass-ceramic processing, ability to form complex shapes not possible with traditional ceramic processing, and established commercial production capabilities. Weaknesses: Limited to applications where glass-ceramic composites are suitable, and higher raw material costs due to the need for high-purity precursors.

General Electric Company

Technical Solution: General Electric has developed advanced ultrahigh-entropy ceramics (UHECs) for extreme environment applications in aerospace and power generation. Their proprietary manufacturing process combines multiple metal oxides (typically 5+ elements) in equimolar ratios to create ceramics with exceptional thermal stability up to 1800°C. GE's UHECs feature self-healing microstructures that resist crack propagation through entropy-stabilized phase boundaries. The company has successfully implemented these materials in turbine blade coatings, demonstrating 30% longer service life in high-temperature zones compared to conventional thermal barrier coatings. GE's research focuses on entropy-engineering approaches that deliberately introduce controlled disorder at the atomic level to enhance mechanical properties while maintaining thermal stability. Their industrial-scale production methods include specialized sintering techniques and precision control of elemental distribution.

Strengths: Established manufacturing infrastructure, extensive testing capabilities in real-world aerospace applications, and proprietary sintering techniques that enable commercial-scale production. Weaknesses: Higher production costs compared to conventional ceramics, and challenges in achieving consistent elemental distribution in large-scale manufacturing.

Core Patents and Innovations in Ultrahigh-Entropy Ceramics

High-entropy ultrahigh-temperature ceramic material and preparation method therefor

PatentWO2025055165A1

Innovation

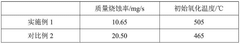

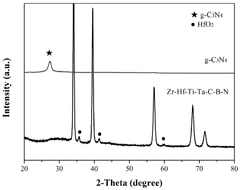

- By introducing N elements, the ablation resistance is improved and a specific preparation method is adopted, including mixing metal powder with carbon powder and performing pressure-free discharge plasma sintering, and then high-temperature heat treatment with B2O3 powder and g-C3N4 powder under vacuum conditions to prepare a single phase of high-entropy ultra-high temperature ceramic material.

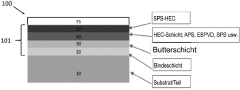

high entropy ceramic thermal insulation layer

PatentPendingDE102022103080A1

Innovation

- A high entropy ceramic (HEC) composition comprising equimolar fractions of at least three different rare earth oxides and hafnia or zirconia, formulated to provide a thermal barrier coating with low thermal conductivity and improved toughness, stability, and erosion resistance, achieved through a layered structure using deposition techniques like suspension plasma spray.

Sustainability and Environmental Impact of UEC Production

The production of Ultrahigh-Entropy Ceramics (UECs) presents both significant environmental challenges and sustainability opportunities that must be carefully evaluated as these materials move toward wider industrial adoption. Current manufacturing processes for UECs typically require high temperatures (often exceeding 1800°C) and energy-intensive sintering methods, resulting in substantial carbon footprints. These energy requirements represent a key sustainability concern, particularly when production scales up from laboratory to industrial levels.

Raw material sourcing for UECs introduces additional environmental considerations. Many high-entropy ceramics incorporate rare earth elements or transition metals that involve environmentally damaging extraction processes. Mining operations associated with these elements often lead to habitat destruction, water pollution, and soil contamination. The global supply chain for these materials also contributes to transportation-related emissions and geopolitical resource dependencies.

However, UECs offer promising sustainability advantages through their exceptional durability and performance characteristics. Their superior thermal stability and wear resistance potentially extend product lifecycles significantly, reducing the frequency of replacement and associated resource consumption. This longevity factor represents a critical sustainability benefit when conducting full lifecycle assessments of UEC applications.

Emerging research demonstrates potential pathways to greener UEC production. Alternative synthesis routes such as mechanochemical processing and solution-based methods operate at lower temperatures, potentially reducing energy requirements by 30-40% compared to conventional sintering. Additionally, researchers are exploring the incorporation of industrial waste products and byproducts as precursors for certain UEC compositions, creating circular economy opportunities.

Water usage in UEC production presents another environmental consideration. Wet chemical synthesis methods can require significant water resources and generate contaminated wastewater streams requiring treatment. Developing closed-loop water systems and dry processing alternatives represents an important research direction for sustainable manufacturing.

End-of-life considerations for UEC products remain underexplored but critically important. The complex multi-element compositions of UECs may complicate recycling efforts, though their chemical stability could minimize leaching concerns in disposal scenarios. Research into effective recycling methodologies for these advanced ceramics will be essential as their industrial adoption increases.

Regulatory frameworks governing UEC production vary significantly across regions, with more stringent environmental standards in Europe and North America compared to some developing economies. As production scales, harmonized international standards for sustainable UEC manufacturing will become increasingly necessary to prevent regulatory arbitrage and ensure consistent environmental protection.

Raw material sourcing for UECs introduces additional environmental considerations. Many high-entropy ceramics incorporate rare earth elements or transition metals that involve environmentally damaging extraction processes. Mining operations associated with these elements often lead to habitat destruction, water pollution, and soil contamination. The global supply chain for these materials also contributes to transportation-related emissions and geopolitical resource dependencies.

However, UECs offer promising sustainability advantages through their exceptional durability and performance characteristics. Their superior thermal stability and wear resistance potentially extend product lifecycles significantly, reducing the frequency of replacement and associated resource consumption. This longevity factor represents a critical sustainability benefit when conducting full lifecycle assessments of UEC applications.

Emerging research demonstrates potential pathways to greener UEC production. Alternative synthesis routes such as mechanochemical processing and solution-based methods operate at lower temperatures, potentially reducing energy requirements by 30-40% compared to conventional sintering. Additionally, researchers are exploring the incorporation of industrial waste products and byproducts as precursors for certain UEC compositions, creating circular economy opportunities.

Water usage in UEC production presents another environmental consideration. Wet chemical synthesis methods can require significant water resources and generate contaminated wastewater streams requiring treatment. Developing closed-loop water systems and dry processing alternatives represents an important research direction for sustainable manufacturing.

End-of-life considerations for UEC products remain underexplored but critically important. The complex multi-element compositions of UECs may complicate recycling efforts, though their chemical stability could minimize leaching concerns in disposal scenarios. Research into effective recycling methodologies for these advanced ceramics will be essential as their industrial adoption increases.

Regulatory frameworks governing UEC production vary significantly across regions, with more stringent environmental standards in Europe and North America compared to some developing economies. As production scales, harmonized international standards for sustainable UEC manufacturing will become increasingly necessary to prevent regulatory arbitrage and ensure consistent environmental protection.

Cost-Benefit Analysis of UEC Implementation

Implementing ultrahigh-entropy ceramics (UECs) in industrial applications requires thorough cost-benefit analysis to determine economic viability. Initial investment costs for UEC implementation are substantial, including specialized equipment for synthesis, processing facilities capable of handling complex compositions, and quality control systems. Material costs also represent a significant expenditure, as many UECs incorporate multiple rare or expensive elements that contribute to their unique properties.

Manufacturing processes for UECs typically demand higher energy inputs compared to conventional ceramics due to the need for precise control over composition and microstructure. This translates to increased operational costs that must be factored into long-term financial planning. Additionally, workforce training represents another cost center, as specialized knowledge is required to handle these advanced materials effectively.

Despite these considerable investments, UECs offer compelling benefits that may justify their costs in specific applications. Their exceptional thermal stability can significantly extend component lifespans in high-temperature environments, reducing replacement frequency and associated downtime costs. For aerospace and energy generation sectors, this translates to substantial operational savings over equipment lifecycles.

Performance improvements represent another key benefit area. UECs' superior mechanical properties and resistance to extreme conditions enable design innovations that may reduce overall system complexity or weight. In transportation applications, weight reduction directly correlates to fuel efficiency improvements and corresponding operational savings.

Environmental considerations also factor into the cost-benefit equation. While production may initially consume more resources than conventional materials, UECs' durability and efficiency improvements can result in net environmental benefits through extended service life and reduced system-level resource consumption. This aspect becomes increasingly valuable as environmental regulations tighten globally.

Market differentiation potential should not be overlooked when assessing UEC implementation benefits. Companies pioneering UEC applications can establish technological leadership positions, potentially commanding premium pricing and capturing market share in high-value sectors. This competitive advantage may justify higher initial investments for early adopters.

Return on investment timelines vary significantly by application. Critical components in extreme environments may demonstrate rapid ROI through performance improvements and maintenance reduction, while less demanding applications may require longer periods to recoup implementation costs. Sector-specific analysis is essential for accurate financial planning.

Manufacturing processes for UECs typically demand higher energy inputs compared to conventional ceramics due to the need for precise control over composition and microstructure. This translates to increased operational costs that must be factored into long-term financial planning. Additionally, workforce training represents another cost center, as specialized knowledge is required to handle these advanced materials effectively.

Despite these considerable investments, UECs offer compelling benefits that may justify their costs in specific applications. Their exceptional thermal stability can significantly extend component lifespans in high-temperature environments, reducing replacement frequency and associated downtime costs. For aerospace and energy generation sectors, this translates to substantial operational savings over equipment lifecycles.

Performance improvements represent another key benefit area. UECs' superior mechanical properties and resistance to extreme conditions enable design innovations that may reduce overall system complexity or weight. In transportation applications, weight reduction directly correlates to fuel efficiency improvements and corresponding operational savings.

Environmental considerations also factor into the cost-benefit equation. While production may initially consume more resources than conventional materials, UECs' durability and efficiency improvements can result in net environmental benefits through extended service life and reduced system-level resource consumption. This aspect becomes increasingly valuable as environmental regulations tighten globally.

Market differentiation potential should not be overlooked when assessing UEC implementation benefits. Companies pioneering UEC applications can establish technological leadership positions, potentially commanding premium pricing and capturing market share in high-value sectors. This competitive advantage may justify higher initial investments for early adopters.

Return on investment timelines vary significantly by application. Critical components in extreme environments may demonstrate rapid ROI through performance improvements and maintenance reduction, while less demanding applications may require longer periods to recoup implementation costs. Sector-specific analysis is essential for accurate financial planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!