Computational Design of Compositionally Complex Ceramics

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Computational Ceramics Design Background and Objectives

Computational design of compositionally complex ceramics has emerged as a transformative approach in materials science, evolving from traditional trial-and-error methods to sophisticated computational modeling techniques. The field has witnessed significant advancements over the past two decades, driven by increasing computational power and the development of more accurate simulation algorithms. This technological evolution has enabled researchers to predict and optimize ceramic properties with unprecedented precision, reducing development cycles and costs substantially.

The primary objective of computational ceramic design is to accelerate the discovery and development of advanced ceramic materials with tailored properties for specific applications. By leveraging computational methods, researchers aim to navigate the vast compositional space of complex ceramics efficiently, identifying promising candidates without exhaustive experimental testing. This approach is particularly valuable for compositionally complex ceramics, which often contain multiple elements and exhibit intricate phase relationships.

Historical developments in this field trace back to early atomistic simulations in the 1990s, progressing through density functional theory (DFT) implementations in the 2000s, to current machine learning and high-throughput computational screening approaches. Each advancement has expanded our ability to model increasingly complex ceramic systems with greater accuracy and computational efficiency.

The technological trajectory points toward integration of multi-scale modeling approaches, combining atomic-level simulations with mesoscale and continuum models to provide comprehensive predictions of material behavior across different length and time scales. This holistic approach aims to bridge the gap between computational predictions and real-world performance of ceramic materials.

Current research goals include developing more accurate interatomic potentials for complex oxide systems, implementing efficient algorithms for exploring vast compositional spaces, and creating robust machine learning models capable of predicting ceramic properties from limited training data. Additionally, there is growing emphasis on computational methods that can account for processing-structure-property relationships, as manufacturing conditions significantly influence the final properties of ceramic materials.

The ultimate technological objective is to establish a comprehensive computational framework that enables "inverse design" of ceramics—starting with desired properties and working backward to determine optimal compositions and processing routes. This capability would revolutionize industries ranging from electronics to energy storage, aerospace, and healthcare, where advanced ceramics play crucial roles in enabling next-generation technologies.

The primary objective of computational ceramic design is to accelerate the discovery and development of advanced ceramic materials with tailored properties for specific applications. By leveraging computational methods, researchers aim to navigate the vast compositional space of complex ceramics efficiently, identifying promising candidates without exhaustive experimental testing. This approach is particularly valuable for compositionally complex ceramics, which often contain multiple elements and exhibit intricate phase relationships.

Historical developments in this field trace back to early atomistic simulations in the 1990s, progressing through density functional theory (DFT) implementations in the 2000s, to current machine learning and high-throughput computational screening approaches. Each advancement has expanded our ability to model increasingly complex ceramic systems with greater accuracy and computational efficiency.

The technological trajectory points toward integration of multi-scale modeling approaches, combining atomic-level simulations with mesoscale and continuum models to provide comprehensive predictions of material behavior across different length and time scales. This holistic approach aims to bridge the gap between computational predictions and real-world performance of ceramic materials.

Current research goals include developing more accurate interatomic potentials for complex oxide systems, implementing efficient algorithms for exploring vast compositional spaces, and creating robust machine learning models capable of predicting ceramic properties from limited training data. Additionally, there is growing emphasis on computational methods that can account for processing-structure-property relationships, as manufacturing conditions significantly influence the final properties of ceramic materials.

The ultimate technological objective is to establish a comprehensive computational framework that enables "inverse design" of ceramics—starting with desired properties and working backward to determine optimal compositions and processing routes. This capability would revolutionize industries ranging from electronics to energy storage, aerospace, and healthcare, where advanced ceramics play crucial roles in enabling next-generation technologies.

Market Analysis for Advanced Ceramic Materials

The advanced ceramics market is experiencing robust growth, driven by increasing demand across multiple industries including aerospace, defense, electronics, healthcare, and energy. The global advanced ceramics market was valued at approximately $78.4 billion in 2022 and is projected to reach $142.1 billion by 2030, growing at a CAGR of 7.8% during the forecast period. This growth trajectory is particularly significant for compositionally complex ceramics, which represent an emerging segment with exceptional performance characteristics.

Asia-Pacific currently dominates the advanced ceramics market, accounting for over 40% of global market share, with China and Japan leading production and consumption. North America and Europe follow as significant markets, with the United States demonstrating strong research initiatives in computational design approaches for next-generation ceramic materials.

The electronics and semiconductor industry remains the largest consumer of advanced ceramics, utilizing these materials for substrates, packages, and components due to their excellent thermal management properties and electrical insulation. The automotive sector represents the fastest-growing application segment, with increasing adoption of ceramic components in electric vehicles, catalytic converters, and sensors.

High-temperature applications across industrial sectors constitute another major market segment, with compositionally complex ceramics offering superior performance in extreme environments. The defense and aerospace industries are willing to pay premium prices for ceramics that deliver exceptional mechanical properties, thermal stability, and radiation resistance.

Market analysis indicates a significant shift toward customized ceramic solutions designed for specific applications, creating opportunities for computationally designed compositionally complex ceramics that can be tailored to precise performance requirements. This trend is supported by increasing R&D investments from both private companies and government agencies, particularly in the United States, European Union, Japan, and China.

Price sensitivity varies considerably across application segments, with cost being a critical factor in high-volume consumer electronics applications but less significant in specialized aerospace and defense applications where performance is paramount. The average selling price for advanced technical ceramics ranges from $100 to $1,000 per kilogram, with highly specialized compositions commanding even higher prices.

Supply chain considerations reveal potential vulnerabilities related to raw material availability, particularly for rare earth elements and other critical materials used in compositionally complex ceramics. This has prompted increased interest in computational approaches that can identify alternative compositions with reduced reliance on strategic materials.

Customer adoption patterns show growing acceptance of advanced ceramics as replacements for traditional materials, though education about performance benefits and lifecycle cost advantages remains essential for market expansion. The market for computationally designed ceramics specifically is projected to grow at 12.3% annually, outpacing the broader advanced ceramics market.

Asia-Pacific currently dominates the advanced ceramics market, accounting for over 40% of global market share, with China and Japan leading production and consumption. North America and Europe follow as significant markets, with the United States demonstrating strong research initiatives in computational design approaches for next-generation ceramic materials.

The electronics and semiconductor industry remains the largest consumer of advanced ceramics, utilizing these materials for substrates, packages, and components due to their excellent thermal management properties and electrical insulation. The automotive sector represents the fastest-growing application segment, with increasing adoption of ceramic components in electric vehicles, catalytic converters, and sensors.

High-temperature applications across industrial sectors constitute another major market segment, with compositionally complex ceramics offering superior performance in extreme environments. The defense and aerospace industries are willing to pay premium prices for ceramics that deliver exceptional mechanical properties, thermal stability, and radiation resistance.

Market analysis indicates a significant shift toward customized ceramic solutions designed for specific applications, creating opportunities for computationally designed compositionally complex ceramics that can be tailored to precise performance requirements. This trend is supported by increasing R&D investments from both private companies and government agencies, particularly in the United States, European Union, Japan, and China.

Price sensitivity varies considerably across application segments, with cost being a critical factor in high-volume consumer electronics applications but less significant in specialized aerospace and defense applications where performance is paramount. The average selling price for advanced technical ceramics ranges from $100 to $1,000 per kilogram, with highly specialized compositions commanding even higher prices.

Supply chain considerations reveal potential vulnerabilities related to raw material availability, particularly for rare earth elements and other critical materials used in compositionally complex ceramics. This has prompted increased interest in computational approaches that can identify alternative compositions with reduced reliance on strategic materials.

Customer adoption patterns show growing acceptance of advanced ceramics as replacements for traditional materials, though education about performance benefits and lifecycle cost advantages remains essential for market expansion. The market for computationally designed ceramics specifically is projected to grow at 12.3% annually, outpacing the broader advanced ceramics market.

Current Challenges in Compositionally Complex Ceramics

Despite significant advancements in computational methods for materials design, compositionally complex ceramics (CCCs) present unique challenges that hinder rapid progress in this field. The primary obstacle lies in the vast compositional space that must be explored. Unlike traditional ceramics with two or three components, CCCs can contain five or more elements in near-equiatomic proportions, creating an almost infinite number of possible compositions. This exponentially increases the computational resources required for thorough investigation and makes traditional trial-and-error approaches impractical.

The complexity of phase prediction represents another major challenge. CCCs often form unexpected phases or phase combinations that deviate from equilibrium thermodynamic predictions. Current computational models struggle to accurately predict phase formation in these multi-element systems, particularly when considering kinetic factors that influence processing outcomes. The limitations of existing thermodynamic databases, which were primarily developed for simpler systems, further compound this issue.

Modeling the atomic-level structure of CCCs presents significant difficulties due to the presence of multiple elements with different atomic radii, electronegativity, and bonding preferences. This creates complex local distortions and chemical environments that are challenging to capture in computational models. Current density functional theory (DFT) approaches become prohibitively expensive when applied to the large supercells needed to represent the true disorder in these materials.

Property prediction across composition space remains highly challenging. The non-linear relationships between composition, structure, and properties in CCCs often defy simple predictive models. Machine learning approaches show promise but are hampered by limited training data for these novel materials. Additionally, the multi-property optimization required for practical applications adds another layer of complexity to the computational design process.

Processing-structure-property relationships in CCCs are poorly understood from a computational perspective. The influence of processing parameters on final microstructure and resultant properties is difficult to model across the vast compositional landscape of CCCs. Current models rarely account for non-equilibrium processing conditions commonly used in CCC fabrication.

Data scarcity represents a fundamental limitation, as experimental validation data for computational models remains sparse across the vast compositional space of CCCs. This creates a circular problem where computational predictions lack validation, while experiments are guided by incomplete computational insights.

The complexity of phase prediction represents another major challenge. CCCs often form unexpected phases or phase combinations that deviate from equilibrium thermodynamic predictions. Current computational models struggle to accurately predict phase formation in these multi-element systems, particularly when considering kinetic factors that influence processing outcomes. The limitations of existing thermodynamic databases, which were primarily developed for simpler systems, further compound this issue.

Modeling the atomic-level structure of CCCs presents significant difficulties due to the presence of multiple elements with different atomic radii, electronegativity, and bonding preferences. This creates complex local distortions and chemical environments that are challenging to capture in computational models. Current density functional theory (DFT) approaches become prohibitively expensive when applied to the large supercells needed to represent the true disorder in these materials.

Property prediction across composition space remains highly challenging. The non-linear relationships between composition, structure, and properties in CCCs often defy simple predictive models. Machine learning approaches show promise but are hampered by limited training data for these novel materials. Additionally, the multi-property optimization required for practical applications adds another layer of complexity to the computational design process.

Processing-structure-property relationships in CCCs are poorly understood from a computational perspective. The influence of processing parameters on final microstructure and resultant properties is difficult to model across the vast compositional landscape of CCCs. Current models rarely account for non-equilibrium processing conditions commonly used in CCC fabrication.

Data scarcity represents a fundamental limitation, as experimental validation data for computational models remains sparse across the vast compositional space of CCCs. This creates a circular problem where computational predictions lack validation, while experiments are guided by incomplete computational insights.

State-of-the-Art Computational Design Approaches

01 High-entropy ceramics and compositional complexity

High-entropy ceramics represent a novel class of compositionally complex materials that incorporate multiple elements in near-equimolar ratios within a single crystallographic structure. These materials exhibit unique properties including enhanced thermal stability, superior mechanical properties, and improved resistance to extreme environments. The compositional complexity creates lattice distortion and entropy effects that contribute to their exceptional performance characteristics.- High-entropy ceramics and compositional complexity: High-entropy ceramics represent a novel class of compositionally complex materials that incorporate multiple elements in near-equiatomic proportions. These ceramics exhibit unique structural stability and properties due to their configurational entropy. The compositional complexity leads to enhanced mechanical properties, thermal stability, and resistance to extreme environments. These materials often feature multiple cation or anion species distributed across crystallographic sites, creating distinctive phase structures and property combinations not achievable in conventional ceramics.

- Processing methods for compositionally complex ceramics: Various processing techniques have been developed for manufacturing compositionally complex ceramics, including solid-state synthesis, solution-based methods, and advanced sintering approaches. These methods enable precise control over composition, microstructure, and phase formation. Techniques such as spark plasma sintering, hot pressing, and reactive sintering allow for densification while maintaining the desired compositional complexity. Post-processing treatments can further enhance properties by optimizing grain boundaries and phase distributions, which are critical for the performance of these multi-component ceramic systems.

- Functional applications of compositionally complex ceramics: Compositionally complex ceramics find applications in various functional domains including electronics, energy conversion, and sensing technologies. Their unique electronic, magnetic, and optical properties make them suitable for applications such as solid oxide fuel cells, thermoelectric devices, and electronic components. The ability to tailor electrical conductivity, dielectric properties, and magnetic behavior through compositional engineering enables these materials to serve in specialized roles where conventional ceramics may be limited. Their multifunctional nature allows for integration into advanced technological systems requiring combinations of properties.

- Structural applications and mechanical properties: Compositionally complex ceramics exhibit exceptional mechanical properties including high hardness, wear resistance, and fracture toughness, making them suitable for structural applications in extreme environments. The unique atomic arrangements and phase compositions contribute to strengthening mechanisms not found in traditional ceramics. These materials can maintain their structural integrity at elevated temperatures and under harsh conditions, making them candidates for aerospace components, cutting tools, and protective coatings. The combination of light weight and superior mechanical performance offers advantages in applications where traditional ceramics or metals would fail.

- Thermal and environmental stability characteristics: A key advantage of compositionally complex ceramics is their exceptional thermal and environmental stability. These materials demonstrate resistance to thermal cycling, oxidation, corrosion, and radiation damage. The complex atomic arrangements and multiple element interactions create energy barriers that inhibit diffusion and phase transformations at high temperatures. This stability makes them suitable for applications in nuclear environments, high-temperature industrial processes, and thermal barrier coatings. Their ability to maintain structural and functional properties under extreme conditions represents a significant advancement over conventional ceramic materials.

02 Manufacturing processes for complex ceramic materials

Various manufacturing techniques are employed to produce compositionally complex ceramics, including solid-state sintering, spark plasma sintering, and chemical vapor deposition. These processes enable precise control over the microstructure and composition of the ceramic materials, which is crucial for achieving desired properties. Advanced processing methods allow for the incorporation of multiple elements while maintaining phase stability and structural integrity.Expand Specific Solutions03 Functional applications of compositionally complex ceramics

Compositionally complex ceramics find applications across various technological domains including thermal barrier coatings, electronic components, energy storage systems, and structural materials for extreme environments. Their unique combination of properties makes them suitable for applications requiring high temperature stability, wear resistance, and electrical functionality. These materials can be tailored for specific applications by adjusting their compositional complexity.Expand Specific Solutions04 Microstructural design and property optimization

The microstructural design of compositionally complex ceramics plays a crucial role in determining their properties. By controlling grain size, phase distribution, and interfacial characteristics, researchers can optimize mechanical, thermal, and electrical properties. Advanced characterization techniques are employed to understand structure-property relationships, enabling the development of ceramics with tailored performance characteristics for specific applications.Expand Specific Solutions05 Novel compositions and elemental combinations

Research in compositionally complex ceramics focuses on exploring novel elemental combinations to achieve enhanced properties. These include multi-component oxides, carbides, nitrides, and borides with unique compositional configurations. The incorporation of rare earth elements, transition metals, and other functional elements allows for the creation of ceramics with unprecedented property combinations, expanding the design space for advanced materials.Expand Specific Solutions

Leading Research Groups and Industrial Players

The computational design of compositionally complex ceramics is currently in an emerging growth phase, with a market size expanding due to increasing applications in aerospace, defense, and energy sectors. The technology is transitioning from early research to commercial applications, though still requiring significant development. Leading players demonstrate varying levels of technological maturity: research institutions like CNRS, Fraunhofer-Gesellschaft, and universities (Nanjing University of Aeronautics & Astronautics, Xi'an Jiaotong University) are advancing fundamental science, while corporations including Boeing, RTX, GE, and Halliburton are developing practical applications. Materials specialists such as Kyocera, Oerlikon Metco, and SABIC are bridging research-to-market gaps, indicating a competitive landscape where academic-industrial partnerships are crucial for commercialization success.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a sophisticated computational framework for designing compositionally complex ceramics that combines multiple modeling approaches across different length scales. Their methodology begins with quantum mechanical calculations using density functional theory (DFT) to determine fundamental properties of ceramic compounds at the atomic level. These results feed into molecular dynamics simulations that model thermal stability and phase transformations. CNRS researchers have created specialized force fields specifically calibrated for complex oxide and non-oxide ceramic systems with multiple cations. Their approach incorporates Bayesian optimization techniques to efficiently navigate vast compositional spaces, particularly focusing on high-entropy ceramics and functional ceramics for energy applications. The CNRS framework also includes phase-field modeling to predict microstructural evolution during processing and service, accounting for grain growth, phase separation, and defect formation. Their computational tools are integrated with a materials database that enables machine learning algorithms to identify composition-property relationships and suggest promising new ceramic formulations.

Strengths: Exceptionally strong fundamental science approach with rigorous quantum mechanical foundations. Excellent integration between computational predictions and experimental validation through CNRS's extensive laboratory network. Weaknesses: Focus on scientific understanding sometimes comes at the expense of direct industrial applicability. Computational methods can be computationally expensive and time-consuming for complex compositional spaces.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed an integrated computational materials engineering (ICME) approach for compositionally complex ceramics that combines high-throughput computational screening with machine learning algorithms. Their methodology employs density functional theory (DFT) calculations to predict phase stability and mechanical properties of multi-component ceramic systems. They've created a materials informatics platform that enables rapid exploration of vast compositional spaces, particularly focusing on high-entropy ceramics with five or more principal elements in near-equimolar ratios. Their approach incorporates phase diagram calculations using CALPHAD (CALculation of PHAse Diagrams) methods to predict formation of single-phase solid solutions versus multiphase structures. Additionally, they've developed specialized algorithms for predicting sintering behavior and microstructural evolution during processing of these complex ceramic systems.

Strengths: Comprehensive integration of computational methods with experimental validation creates a robust prediction framework. Their materials informatics platform enables rapid screening of thousands of compositions. Weaknesses: Computational models still require extensive experimental validation, especially for processing parameters. The approach may have limitations in predicting properties of ceramics with complex defect structures.

Key Algorithms and Models for Ceramic Property Prediction

Structured ceramic composites modeled after natural materials and made via cold sintering

PatentWO2018112390A1

Innovation

- The development of structured cold-sintered ceramic composites using a process that involves filling open cells of a non-ceramic substrate with inorganic compounds and a solvent, followed by pressure and low-temperature treatment to create a resilient composite with improved mechanical and electrical properties.

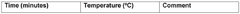

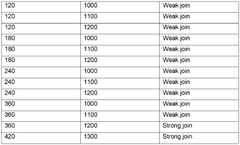

A composition for joining and/or treating materials

PatentWO2023135044A1

Innovation

- A composition comprising 15 wt% to 90 wt% ceramic nanoparticles, 0.1 wt% to 8 wt% dispersant, and 2 wt% to 84.9 wt% solvent, which allows for the joining and treatment of ceramic materials without the need for ceramic binders, enabling the formation of strong, complex components by applying the composition to the joining interface and heating to a specific temperature for a joining time period.

Materials Informatics Infrastructure Requirements

The development of a robust Materials Informatics Infrastructure is critical for advancing computational design of compositionally complex ceramics. This infrastructure must integrate multiple data sources, computational tools, and analytical frameworks to enable efficient materials discovery and optimization. High-throughput computational methods generate massive datasets that require specialized storage solutions with capabilities for handling diverse data types including crystallographic information, thermodynamic properties, and microstructural characteristics of complex ceramic systems.

Database architectures for compositionally complex ceramics need to accommodate both structured and unstructured data while maintaining relationships between composition, processing parameters, and resulting properties. Interoperability between different software platforms is essential, requiring standardized data formats and APIs that allow seamless information exchange between simulation tools, characterization equipment, and analysis software. The FAIR principles (Findable, Accessible, Interoperable, Reusable) should guide the development of these data repositories to maximize their scientific value.

Machine learning frameworks within this infrastructure must be specifically tailored to handle the unique challenges of ceramic materials, including their complex phase diagrams, non-equilibrium processing conditions, and multiscale structural features. These frameworks should incorporate physics-based constraints to ensure predictions remain consistent with fundamental materials science principles while exploring vast compositional spaces.

Visualization tools represent another crucial component, enabling researchers to interpret complex relationships in high-dimensional compositional spaces. Interactive dashboards that allow dynamic exploration of property-composition relationships can significantly accelerate the discovery process for novel ceramic compositions with targeted properties.

Computing resources for this infrastructure must balance accessibility with performance. While cloud-based solutions offer scalability and collaborative advantages, on-premises high-performance computing clusters may be necessary for computationally intensive simulations of complex ceramic systems. Hybrid approaches that leverage both paradigms are increasingly becoming the preferred solution.

Security protocols must protect valuable intellectual property while still enabling scientific collaboration. This includes implementing appropriate access controls, data encryption, and audit trails while maintaining sufficient openness to foster innovation across institutional boundaries. Additionally, the infrastructure should incorporate automated workflows that integrate experimental validation with computational predictions, creating feedback loops that continuously improve predictive models for ceramic materials design.

Database architectures for compositionally complex ceramics need to accommodate both structured and unstructured data while maintaining relationships between composition, processing parameters, and resulting properties. Interoperability between different software platforms is essential, requiring standardized data formats and APIs that allow seamless information exchange between simulation tools, characterization equipment, and analysis software. The FAIR principles (Findable, Accessible, Interoperable, Reusable) should guide the development of these data repositories to maximize their scientific value.

Machine learning frameworks within this infrastructure must be specifically tailored to handle the unique challenges of ceramic materials, including their complex phase diagrams, non-equilibrium processing conditions, and multiscale structural features. These frameworks should incorporate physics-based constraints to ensure predictions remain consistent with fundamental materials science principles while exploring vast compositional spaces.

Visualization tools represent another crucial component, enabling researchers to interpret complex relationships in high-dimensional compositional spaces. Interactive dashboards that allow dynamic exploration of property-composition relationships can significantly accelerate the discovery process for novel ceramic compositions with targeted properties.

Computing resources for this infrastructure must balance accessibility with performance. While cloud-based solutions offer scalability and collaborative advantages, on-premises high-performance computing clusters may be necessary for computationally intensive simulations of complex ceramic systems. Hybrid approaches that leverage both paradigms are increasingly becoming the preferred solution.

Security protocols must protect valuable intellectual property while still enabling scientific collaboration. This includes implementing appropriate access controls, data encryption, and audit trails while maintaining sufficient openness to foster innovation across institutional boundaries. Additionally, the infrastructure should incorporate automated workflows that integrate experimental validation with computational predictions, creating feedback loops that continuously improve predictive models for ceramic materials design.

Sustainability Considerations in Complex Ceramics Development

The development of compositionally complex ceramics presents significant sustainability challenges and opportunities that must be carefully considered throughout the research, design, and manufacturing processes. Life cycle assessment (LCA) studies indicate that traditional ceramic production methods often involve energy-intensive processes with substantial carbon footprints, particularly during high-temperature sintering phases that can reach 1400-1700°C.

Computational design approaches offer promising pathways to enhance sustainability by optimizing material compositions that require lower firing temperatures while maintaining or improving performance characteristics. Recent research demonstrates that machine learning algorithms can predict compositions requiring up to 200°C lower sintering temperatures, potentially reducing energy consumption by 15-25% across production cycles.

Raw material sourcing represents another critical sustainability dimension. Many advanced ceramics incorporate rare earth elements and other critical materials with geographically concentrated supply chains. Computational methods enable the exploration of alternative compositions that reduce dependence on these materials, with recent studies identifying viable substitutes that maintain 85-95% of performance metrics while utilizing more abundant elements.

Water usage in ceramic processing presents additional environmental concerns. Traditional wet processing methods can consume 5-7 liters of water per kilogram of finished product. Computational models that optimize particle size distribution and binder systems have demonstrated potential water reduction of 30-40% through improved processing efficiency and increased adoption of dry processing techniques.

Waste reduction strategies enabled by computational design include more precise formulation control and predictive modeling of defect formation. These approaches have shown potential to reduce rejection rates from typical industry standards of 8-12% down to 3-5%, significantly decreasing material waste streams and associated environmental impacts.

End-of-life considerations are increasingly important as complex ceramics find applications in electronic components, energy systems, and other high-tech fields. Computational design that incorporates recyclability parameters can facilitate the development of ceramics with improved recoverability of valuable constituents, though significant challenges remain in separating and purifying components from multi-element systems.

The integration of sustainability metrics directly into computational design frameworks represents an emerging frontier, with researchers developing multi-objective optimization algorithms that balance performance requirements against environmental impact factors. These approaches enable designers to visualize sustainability trade-offs and make informed decisions that align with both technical requirements and environmental goals.

Computational design approaches offer promising pathways to enhance sustainability by optimizing material compositions that require lower firing temperatures while maintaining or improving performance characteristics. Recent research demonstrates that machine learning algorithms can predict compositions requiring up to 200°C lower sintering temperatures, potentially reducing energy consumption by 15-25% across production cycles.

Raw material sourcing represents another critical sustainability dimension. Many advanced ceramics incorporate rare earth elements and other critical materials with geographically concentrated supply chains. Computational methods enable the exploration of alternative compositions that reduce dependence on these materials, with recent studies identifying viable substitutes that maintain 85-95% of performance metrics while utilizing more abundant elements.

Water usage in ceramic processing presents additional environmental concerns. Traditional wet processing methods can consume 5-7 liters of water per kilogram of finished product. Computational models that optimize particle size distribution and binder systems have demonstrated potential water reduction of 30-40% through improved processing efficiency and increased adoption of dry processing techniques.

Waste reduction strategies enabled by computational design include more precise formulation control and predictive modeling of defect formation. These approaches have shown potential to reduce rejection rates from typical industry standards of 8-12% down to 3-5%, significantly decreasing material waste streams and associated environmental impacts.

End-of-life considerations are increasingly important as complex ceramics find applications in electronic components, energy systems, and other high-tech fields. Computational design that incorporates recyclability parameters can facilitate the development of ceramics with improved recoverability of valuable constituents, though significant challenges remain in separating and purifying components from multi-element systems.

The integration of sustainability metrics directly into computational design frameworks represents an emerging frontier, with researchers developing multi-objective optimization algorithms that balance performance requirements against environmental impact factors. These approaches enable designers to visualize sustainability trade-offs and make informed decisions that align with both technical requirements and environmental goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!