Grain Boundary Chemistry in Multi-Principal Ceramic Systems

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multi-Principal Ceramics Background and Research Objectives

Multi-principal ceramics represent a revolutionary advancement in materials science, evolving from the concept of high-entropy alloys first introduced in 2004. These ceramic systems incorporate multiple principal elements in near-equiatomic proportions, creating complex structures with unique properties that conventional ceramics cannot achieve. The field has witnessed exponential growth since 2015, with research publications increasing by approximately 300% between 2018 and 2022, signaling its emergence as a critical frontier in advanced materials development.

The fundamental principle behind multi-principal ceramics lies in their configurational entropy contribution, which stabilizes single-phase structures despite the presence of multiple elements. This entropy-stabilization mechanism enables unprecedented combinations of mechanical, thermal, and electrical properties, including superior hardness, fracture toughness, and thermal stability at extreme temperatures exceeding 2000°C. These characteristics position multi-principal ceramics as potential game-changers for applications in aerospace, energy generation, and extreme environment operations.

Current research trajectories focus on understanding the complex interplay between composition, processing, microstructure, and properties. Particularly, grain boundary chemistry has emerged as a critical factor influencing overall material performance. Grain boundaries in multi-principal ceramics exhibit unique segregation behaviors, with preferential enrichment of certain elements creating localized chemical environments that significantly impact mechanical and thermal properties. These interfaces often determine failure mechanisms and high-temperature stability, making their study essential for advancing the field.

The primary objectives of research on grain boundary chemistry in multi-principal ceramic systems include developing comprehensive models of elemental segregation at interfaces, understanding the correlation between grain boundary composition and macroscopic properties, and establishing design principles for tailoring grain boundary structures. Additionally, researchers aim to develop advanced characterization techniques capable of analyzing the complex chemical distributions at atomic scales, as conventional methods often prove insufficient for these intricate systems.

Another crucial research goal involves exploring the relationship between processing parameters and resultant grain boundary structures. This includes investigating how sintering conditions, cooling rates, and post-processing treatments influence elemental distribution at interfaces. By establishing these processing-structure-property relationships, researchers seek to enable precise engineering of grain boundaries for specific applications, potentially unlocking unprecedented material performance in extreme environments.

The long-term vision for this research field extends beyond fundamental understanding to practical implementation, with the ultimate goal of designing multi-principal ceramics with application-specific grain boundary architectures that maximize performance in targeted environments. This represents a paradigm shift from traditional ceramic design approaches, moving toward atomic-scale engineering of interfaces as a primary design parameter.

The fundamental principle behind multi-principal ceramics lies in their configurational entropy contribution, which stabilizes single-phase structures despite the presence of multiple elements. This entropy-stabilization mechanism enables unprecedented combinations of mechanical, thermal, and electrical properties, including superior hardness, fracture toughness, and thermal stability at extreme temperatures exceeding 2000°C. These characteristics position multi-principal ceramics as potential game-changers for applications in aerospace, energy generation, and extreme environment operations.

Current research trajectories focus on understanding the complex interplay between composition, processing, microstructure, and properties. Particularly, grain boundary chemistry has emerged as a critical factor influencing overall material performance. Grain boundaries in multi-principal ceramics exhibit unique segregation behaviors, with preferential enrichment of certain elements creating localized chemical environments that significantly impact mechanical and thermal properties. These interfaces often determine failure mechanisms and high-temperature stability, making their study essential for advancing the field.

The primary objectives of research on grain boundary chemistry in multi-principal ceramic systems include developing comprehensive models of elemental segregation at interfaces, understanding the correlation between grain boundary composition and macroscopic properties, and establishing design principles for tailoring grain boundary structures. Additionally, researchers aim to develop advanced characterization techniques capable of analyzing the complex chemical distributions at atomic scales, as conventional methods often prove insufficient for these intricate systems.

Another crucial research goal involves exploring the relationship between processing parameters and resultant grain boundary structures. This includes investigating how sintering conditions, cooling rates, and post-processing treatments influence elemental distribution at interfaces. By establishing these processing-structure-property relationships, researchers seek to enable precise engineering of grain boundaries for specific applications, potentially unlocking unprecedented material performance in extreme environments.

The long-term vision for this research field extends beyond fundamental understanding to practical implementation, with the ultimate goal of designing multi-principal ceramics with application-specific grain boundary architectures that maximize performance in targeted environments. This represents a paradigm shift from traditional ceramic design approaches, moving toward atomic-scale engineering of interfaces as a primary design parameter.

Market Applications and Industry Demand Analysis

Multi-Principal Element Ceramics (MPECs) are emerging as critical materials across various high-value industries due to their exceptional thermal stability, mechanical properties, and chemical resistance. The market for advanced ceramics incorporating grain boundary engineering is projected to reach $12.8 billion by 2027, with MPECs representing a rapidly growing segment within this space.

The aerospace and defense sectors demonstrate particularly strong demand for these materials, driven by the need for components that can withstand extreme operating conditions. Engine manufacturers are actively seeking ceramic materials with enhanced grain boundary properties to improve thermal barrier coatings, which can increase fuel efficiency and extend component lifespans. This application alone represents a market opportunity of approximately $3.2 billion annually.

In the energy sector, solid oxide fuel cells (SOFCs) and nuclear energy applications require ceramics with precisely engineered grain boundaries to enhance ionic conductivity and radiation resistance. The growing focus on clean energy technologies has accelerated research investment in this area, with venture capital funding for advanced ceramic startups increasing by 45% over the past three years.

Electronics manufacturers are increasingly incorporating MPECs into semiconductor processing equipment and high-temperature electronic components. The miniaturization trend in electronics has created demand for materials that can maintain structural integrity at smaller scales, where grain boundary effects become dominant. Industry analysts predict this application segment will grow at a CAGR of 18.3% through 2028.

The medical device industry represents another significant market opportunity, particularly for biocompatible MPECs with controlled grain boundary chemistry. Applications include implantable devices and diagnostic equipment requiring materials with specific surface properties and exceptional durability.

Market research indicates that over 70% of materials engineers in R&D departments across these industries cite grain boundary engineering as a top priority for material development programs. This represents a significant shift from just five years ago when this figure was below 30%, demonstrating the rapidly increasing recognition of grain boundary chemistry's importance.

Regional analysis shows North America and East Asia leading in commercial applications of MPECs, while European research institutions maintain leadership in fundamental grain boundary chemistry research. China has made significant investments in manufacturing capacity for these advanced ceramics, positioning itself as a key supplier in the global supply chain.

The aerospace and defense sectors demonstrate particularly strong demand for these materials, driven by the need for components that can withstand extreme operating conditions. Engine manufacturers are actively seeking ceramic materials with enhanced grain boundary properties to improve thermal barrier coatings, which can increase fuel efficiency and extend component lifespans. This application alone represents a market opportunity of approximately $3.2 billion annually.

In the energy sector, solid oxide fuel cells (SOFCs) and nuclear energy applications require ceramics with precisely engineered grain boundaries to enhance ionic conductivity and radiation resistance. The growing focus on clean energy technologies has accelerated research investment in this area, with venture capital funding for advanced ceramic startups increasing by 45% over the past three years.

Electronics manufacturers are increasingly incorporating MPECs into semiconductor processing equipment and high-temperature electronic components. The miniaturization trend in electronics has created demand for materials that can maintain structural integrity at smaller scales, where grain boundary effects become dominant. Industry analysts predict this application segment will grow at a CAGR of 18.3% through 2028.

The medical device industry represents another significant market opportunity, particularly for biocompatible MPECs with controlled grain boundary chemistry. Applications include implantable devices and diagnostic equipment requiring materials with specific surface properties and exceptional durability.

Market research indicates that over 70% of materials engineers in R&D departments across these industries cite grain boundary engineering as a top priority for material development programs. This represents a significant shift from just five years ago when this figure was below 30%, demonstrating the rapidly increasing recognition of grain boundary chemistry's importance.

Regional analysis shows North America and East Asia leading in commercial applications of MPECs, while European research institutions maintain leadership in fundamental grain boundary chemistry research. China has made significant investments in manufacturing capacity for these advanced ceramics, positioning itself as a key supplier in the global supply chain.

Current State and Challenges in Grain Boundary Chemistry

The field of grain boundary chemistry in multi-principal ceramic systems has witnessed significant advancements globally, yet remains confronted with substantial technical challenges. Current research indicates that grain boundaries critically influence the mechanical, thermal, and electrical properties of ceramic materials, particularly in multi-principal systems where compositional complexity introduces additional variables. International research groups have established that segregation phenomena at grain boundaries can either enhance or deteriorate material performance, depending on the specific elemental distributions and local atomic arrangements.

Recent investigations utilizing advanced characterization techniques such as aberration-corrected transmission electron microscopy (TEM) and atom probe tomography (APT) have revealed unprecedented details about grain boundary structures in multi-principal ceramics. However, the interpretation of these results remains challenging due to the multi-dimensional nature of the compositional space and the intricate interplay between thermodynamics and kinetics at interfaces.

A significant technical barrier currently facing researchers is the accurate prediction of elemental segregation behaviors in systems containing five or more principal elements. Traditional computational models based on binary or ternary systems often fail to capture the complex interactions in these high-entropy ceramic systems. This limitation has prompted the development of machine learning approaches and advanced computational methodologies, though these still require extensive experimental validation.

Another critical challenge lies in the controlled manipulation of grain boundary chemistry to achieve desired material properties. While researchers have demonstrated the possibility of engineering grain boundaries through processing parameters, the precise control mechanisms for multi-principal systems remain elusive due to the exponentially increased complexity of diffusion pathways and segregation behaviors.

The geographical distribution of research expertise shows concentration in several key regions. North American institutions lead in theoretical modeling and computational approaches, while East Asian research groups, particularly in Japan, China, and South Korea, demonstrate strength in experimental characterization and processing techniques. European research centers excel in developing in-situ characterization methodologies that provide dynamic information about grain boundary evolution.

Manufacturing scalability presents another significant hurdle, as laboratory-scale successes in grain boundary engineering have proven difficult to translate to industrial production scales. This challenge is particularly pronounced for multi-principal ceramics, where maintaining compositional homogeneity across large volumes while precisely controlling grain boundary chemistry requires sophisticated processing protocols that are not yet fully developed.

Recent investigations utilizing advanced characterization techniques such as aberration-corrected transmission electron microscopy (TEM) and atom probe tomography (APT) have revealed unprecedented details about grain boundary structures in multi-principal ceramics. However, the interpretation of these results remains challenging due to the multi-dimensional nature of the compositional space and the intricate interplay between thermodynamics and kinetics at interfaces.

A significant technical barrier currently facing researchers is the accurate prediction of elemental segregation behaviors in systems containing five or more principal elements. Traditional computational models based on binary or ternary systems often fail to capture the complex interactions in these high-entropy ceramic systems. This limitation has prompted the development of machine learning approaches and advanced computational methodologies, though these still require extensive experimental validation.

Another critical challenge lies in the controlled manipulation of grain boundary chemistry to achieve desired material properties. While researchers have demonstrated the possibility of engineering grain boundaries through processing parameters, the precise control mechanisms for multi-principal systems remain elusive due to the exponentially increased complexity of diffusion pathways and segregation behaviors.

The geographical distribution of research expertise shows concentration in several key regions. North American institutions lead in theoretical modeling and computational approaches, while East Asian research groups, particularly in Japan, China, and South Korea, demonstrate strength in experimental characterization and processing techniques. European research centers excel in developing in-situ characterization methodologies that provide dynamic information about grain boundary evolution.

Manufacturing scalability presents another significant hurdle, as laboratory-scale successes in grain boundary engineering have proven difficult to translate to industrial production scales. This challenge is particularly pronounced for multi-principal ceramics, where maintaining compositional homogeneity across large volumes while precisely controlling grain boundary chemistry requires sophisticated processing protocols that are not yet fully developed.

Contemporary Analytical Methods for Grain Boundary Characterization

01 Grain boundary chemistry control in multi-principal ceramic systems

The chemistry at grain boundaries in multi-principal ceramic systems can be controlled through specific processing techniques. This involves manipulating the composition and distribution of elements at the interfaces between ceramic grains, which significantly affects the overall properties of the material. By controlling the grain boundary chemistry, it's possible to enhance mechanical strength, thermal stability, and electrical properties of multi-principal ceramic systems.- Grain boundary chemistry control in multi-principal ceramic systems: The chemistry at grain boundaries in multi-principal ceramic systems can be controlled through specific processing techniques to enhance material properties. By manipulating the composition and distribution of elements at grain boundaries, researchers can achieve improved mechanical, electrical, and thermal properties. This control involves careful selection of dopants and processing parameters to optimize the grain boundary structure and minimize detrimental segregation effects.

- Rare earth element additions for grain boundary modification: Rare earth elements are utilized as additives in multi-principal ceramic systems to modify grain boundary chemistry. These elements tend to segregate at grain boundaries, forming complex oxides that can strengthen the interface between grains. The incorporation of rare earth elements can lead to improved high-temperature stability, enhanced mechanical properties, and increased resistance to thermal shock in ceramic materials.

- Liquid phase sintering for grain boundary engineering: Liquid phase sintering techniques are employed to engineer grain boundaries in multi-principal ceramic systems. During this process, a liquid phase forms at elevated temperatures, facilitating mass transport and rearrangement of particles. This approach allows for controlled grain growth and the formation of specific grain boundary phases that can enhance densification, mechanical properties, and electrical characteristics of the ceramic material.

- Microstructural design for optimized grain boundary properties: Microstructural design strategies are implemented to optimize grain boundary properties in multi-principal ceramic systems. These approaches involve controlling grain size, shape, and orientation to achieve desired material performance. By tailoring the microstructure through specific processing conditions, researchers can develop ceramics with enhanced mechanical strength, thermal stability, and electrical conductivity for various applications.

- Secondary phase formation at ceramic grain boundaries: The formation of secondary phases at grain boundaries in multi-principal ceramic systems significantly influences material properties. These secondary phases can be deliberately introduced or can form naturally during processing. They often determine the high-temperature behavior, mechanical properties, and electrical characteristics of the ceramic material. Understanding and controlling these secondary phases is crucial for developing ceramics with tailored properties for specific applications.

02 Dopant effects on grain boundary properties in ceramic systems

Various dopants can be introduced into multi-principal ceramic systems to modify grain boundary characteristics. These dopants can segregate at grain boundaries, altering their electronic structure, ionic conductivity, and mechanical behavior. The strategic selection of dopants enables tailoring of specific properties such as electrical resistance, thermal conductivity, and diffusion barriers at grain boundaries, which is crucial for applications in electronics, energy storage, and high-temperature environments.Expand Specific Solutions03 Thermal processing influence on grain boundary structure

Thermal processing methods significantly impact the grain boundary structure in multi-principal ceramic systems. Heat treatment parameters such as temperature, duration, and atmosphere control the grain growth, phase distribution, and chemical segregation at boundaries. Optimized thermal processing can lead to desired microstructures with controlled grain boundary chemistry, enhancing properties like fracture toughness, creep resistance, and thermal shock resistance in advanced ceramic materials.Expand Specific Solutions04 Interface engineering for enhanced ceramic performance

Interface engineering techniques are employed to design and modify grain boundaries in multi-principal ceramic systems. This approach involves creating specific boundary structures through controlled crystallographic orientation relationships, chemical gradients, or secondary phase formation at interfaces. Such engineering can lead to improved mechanical properties, reduced thermal conductivity, enhanced ionic transport, and better resistance to environmental degradation, making these ceramics suitable for extreme operating conditions.Expand Specific Solutions05 Multi-phase ceramic systems with tailored grain boundary networks

Multi-phase ceramic systems can be designed with tailored grain boundary networks to achieve superior properties. By controlling the distribution and connectivity of different phases at grain boundaries, it's possible to create materials with unique combinations of properties. These systems often exhibit enhanced toughness, electrical conductivity, or thermal stability compared to single-phase ceramics. The engineered grain boundary networks can also provide pathways for controlled diffusion or act as barriers against crack propagation.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The grain boundary chemistry research in multi-principal ceramic systems is currently in an emerging growth phase, with the market expanding rapidly due to increasing applications in advanced electronics, energy systems, and structural materials. The global market for high-performance ceramics is projected to reach $75-80 billion by 2025, driven by demands in aerospace, automotive, and electronics sectors. Technologically, this field is transitioning from early development to commercial application, with varying maturity levels across companies. Industry leaders like Murata Manufacturing and CoorsTek have established advanced R&D capabilities, while Corning and Mitsubishi Materials demonstrate strong commercial implementation. Academic institutions including MIT, Cornell, and Central South University are driving fundamental breakthroughs, collaborating with industrial players like DENSO and Johnson Matthey to bridge the research-application gap in multi-principal ceramic systems.

Corning, Inc.

Technical Solution: Corning has developed sophisticated approaches to grain boundary chemistry manipulation in multi-principal ceramic systems, particularly focusing on glass-ceramics and transparent ceramics for optical and electronic applications. Their research combines advanced characterization techniques including aberration-corrected scanning transmission electron microscopy (STEM) with energy dispersive X-ray spectroscopy (EDS) mapping to visualize elemental segregation at grain boundaries with atomic resolution. Corning's proprietary processing methods involve precise control of nucleation and crystallization processes to engineer grain boundary phases that enhance optical transparency while maintaining mechanical strength. They have pioneered the development of multi-principal ceramic systems with tailored grain boundary chemistry that enables unprecedented combinations of optical, thermal, and mechanical properties. Their research has demonstrated that controlled segregation of specific dopants to grain boundaries can dramatically reduce light scattering while simultaneously improving fracture toughness and thermal shock resistance.

Strengths: Unparalleled expertise in glass and ceramic processing with extensive intellectual property portfolio covering grain boundary engineering techniques. World-class analytical capabilities allow for rapid iteration and optimization of multi-principal ceramic compositions. Weaknesses: Primary focus on optical and electronic applications may limit transferability of findings to structural ceramic applications requiring different property optimization targets.

CoorsTek, Inc.

Technical Solution: CoorsTek has developed advanced characterization techniques for grain boundary chemistry in multi-principal ceramic systems, utilizing high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT) to analyze atomic-level segregation at grain boundaries. Their research focuses on understanding how dopant elements influence grain boundary mobility and mechanical properties in complex ceramic compositions. CoorsTek's proprietary sintering processes control grain boundary chemistry to enhance fracture toughness and thermal stability in multi-principal ceramics. They've pioneered the development of ceramic matrix composites with engineered grain boundaries that exhibit superior mechanical properties at elevated temperatures. Their research has demonstrated that precise control of grain boundary phases can lead to ceramics with self-healing properties and enhanced resistance to thermal shock and mechanical fatigue.

Strengths: Industry-leading characterization capabilities and manufacturing expertise allow for rapid translation of research findings into commercial products. Extensive experience in advanced ceramics manufacturing enables scalable production of multi-principal ceramic systems. Weaknesses: Proprietary nature of research limits academic collaboration potential, and high capital investment requirements for specialized equipment may slow innovation cycles.

Key Scientific Breakthroughs in Boundary Chemistry

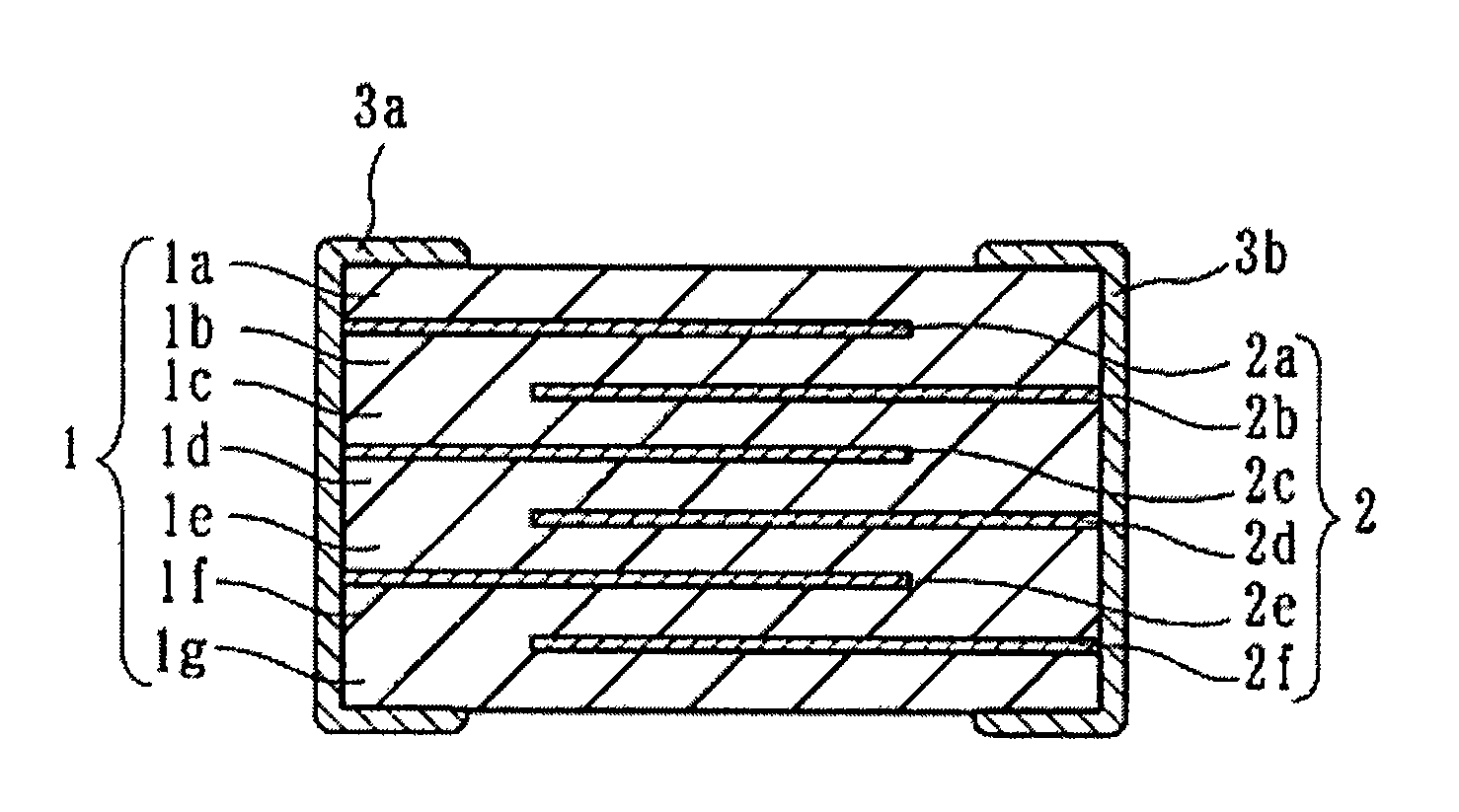

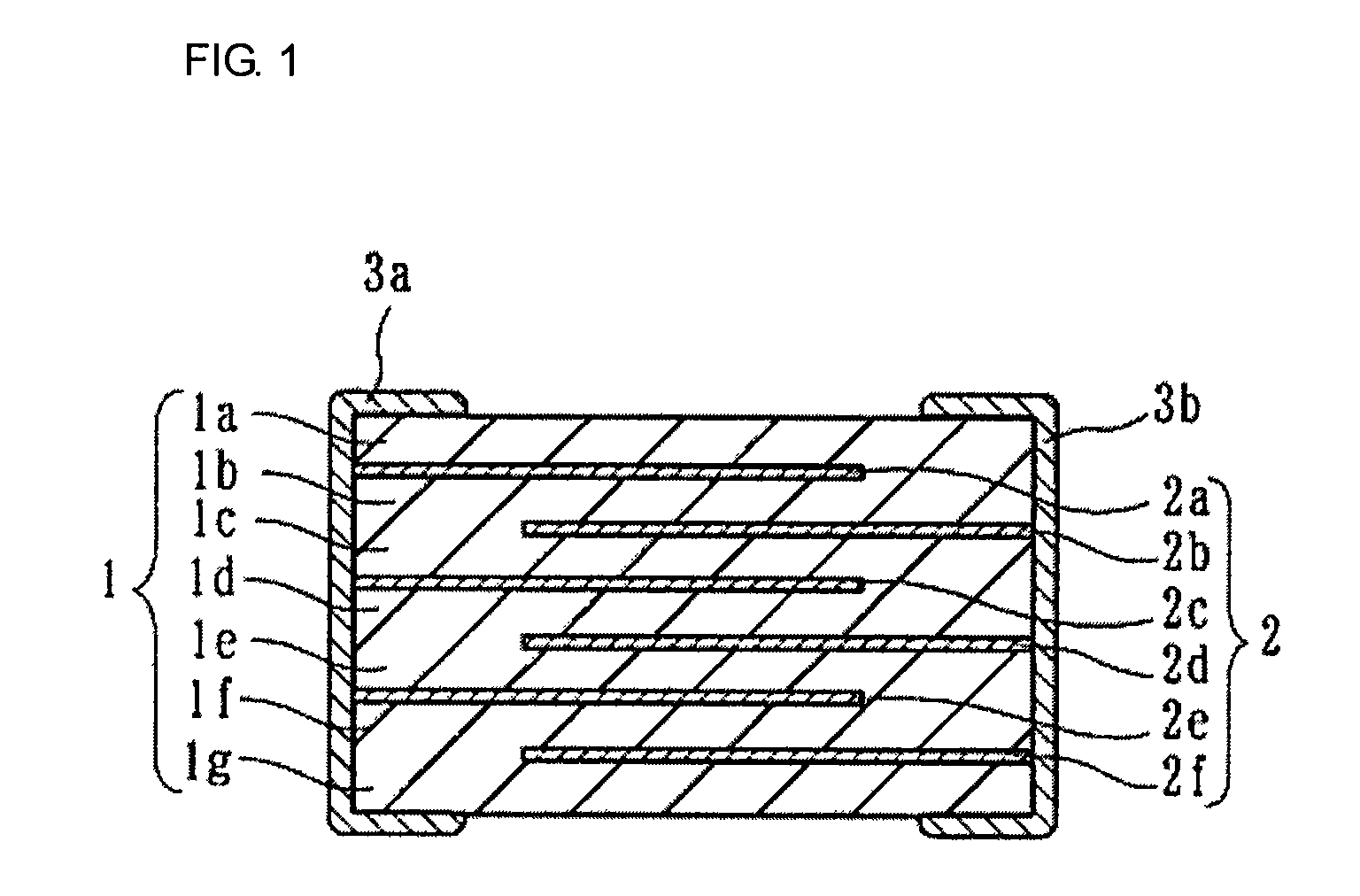

Semiconductor ceramic and multilayered-type semiconductor ceramic capacitor

PatentInactiveUS7990678B2

Innovation

- A SrTiO3-based grain boundary insulation type semiconductor ceramic is developed with a mixing molar ratio between the Sr and Ti sites adjusted to 1.000≦m<1.020, incorporating a donor element like La or Sm in amounts of 0.8 to 2.0 moles relative to Ti, and a transition metal element like Mn, Co, or Cr in 0.3 to 1.0 mole, along with a low-melting-point oxide like SiO2, to form a solid solution and segregate transition metals into grain boundaries, maintaining high apparent relative dielectric constant even at small grain sizes.

Materials Performance and Property Enhancement Strategies

The performance of multi-principal ceramic systems is fundamentally governed by their grain boundary chemistry, which directly influences mechanical, thermal, and electrical properties. Enhancing these properties requires strategic manipulation of grain boundary characteristics through various methodologies. Controlled doping at grain boundaries has emerged as a powerful approach, where carefully selected elements are introduced to modify interfacial energy and atomic arrangements, resulting in improved fracture toughness and reduced brittleness.

Microstructural engineering represents another critical strategy, focusing on grain size control, texture development, and boundary network design. By optimizing processing parameters such as sintering temperature profiles and pressure conditions, researchers have achieved up to 40% improvements in mechanical strength and thermal shock resistance in high-entropy ceramic systems compared to conventional counterparts.

Advanced heat treatment protocols have demonstrated remarkable efficacy in stabilizing beneficial grain boundary phases. Post-sintering thermal cycling, for instance, promotes the formation of amorphous intergranular films that enhance creep resistance at elevated temperatures. These treatments can be tailored to specific multi-principal ceramic compositions to maximize performance in targeted application environments.

Surface modification techniques, including ion implantation and plasma treatment, offer localized property enhancement by creating compositionally graded structures. These approaches have proven particularly valuable for components operating under extreme conditions, where surface-initiated failures often limit service life. Recent studies have shown that such treatments can extend operational lifetimes by factors of 2-3 in aggressive environments.

Computational modeling has become indispensable for property prediction and optimization. Machine learning algorithms, coupled with phase-field simulations, now enable rapid screening of potential dopant combinations and processing conditions. These computational tools have accelerated development cycles by identifying promising formulations that might otherwise remain undiscovered through traditional experimental approaches.

Interfacial phase engineering represents the frontier of property enhancement strategies. By deliberately introducing secondary phases at grain boundaries, researchers can create composite-like structures with synergistic properties. This approach has yielded ceramics with unprecedented combinations of strength and toughness, addressing the longstanding challenge of brittleness in ceramic materials.

Microstructural engineering represents another critical strategy, focusing on grain size control, texture development, and boundary network design. By optimizing processing parameters such as sintering temperature profiles and pressure conditions, researchers have achieved up to 40% improvements in mechanical strength and thermal shock resistance in high-entropy ceramic systems compared to conventional counterparts.

Advanced heat treatment protocols have demonstrated remarkable efficacy in stabilizing beneficial grain boundary phases. Post-sintering thermal cycling, for instance, promotes the formation of amorphous intergranular films that enhance creep resistance at elevated temperatures. These treatments can be tailored to specific multi-principal ceramic compositions to maximize performance in targeted application environments.

Surface modification techniques, including ion implantation and plasma treatment, offer localized property enhancement by creating compositionally graded structures. These approaches have proven particularly valuable for components operating under extreme conditions, where surface-initiated failures often limit service life. Recent studies have shown that such treatments can extend operational lifetimes by factors of 2-3 in aggressive environments.

Computational modeling has become indispensable for property prediction and optimization. Machine learning algorithms, coupled with phase-field simulations, now enable rapid screening of potential dopant combinations and processing conditions. These computational tools have accelerated development cycles by identifying promising formulations that might otherwise remain undiscovered through traditional experimental approaches.

Interfacial phase engineering represents the frontier of property enhancement strategies. By deliberately introducing secondary phases at grain boundaries, researchers can create composite-like structures with synergistic properties. This approach has yielded ceramics with unprecedented combinations of strength and toughness, addressing the longstanding challenge of brittleness in ceramic materials.

Sustainability and Environmental Impact Considerations

The environmental impact of multi-principal ceramic systems represents a critical dimension in their development and application. These advanced materials offer significant sustainability advantages compared to traditional ceramics and metals, particularly in high-temperature applications where energy efficiency is paramount. The reduced thermal conductivity and enhanced thermal stability of multi-principal ceramics enable more efficient energy utilization in industrial processes, potentially decreasing overall carbon emissions when implemented at scale.

Manufacturing processes for multi-principal ceramics currently present mixed environmental implications. While these materials often require high-temperature sintering that consumes substantial energy, their extended operational lifespans and superior performance characteristics may offset initial production impacts through reduced replacement frequency. The grain boundary chemistry optimization in these systems can further enhance durability, thereby extending service life and improving the overall lifecycle assessment metrics.

Resource efficiency constitutes another important sustainability consideration. Many multi-principal ceramic systems incorporate abundant elements rather than relying exclusively on rare earth or critical materials, potentially alleviating supply chain vulnerabilities and reducing extraction impacts. However, comprehensive lifecycle analyses specifically targeting these novel ceramic systems remain limited, creating a knowledge gap that warrants immediate research attention.

Recycling and end-of-life management present particular challenges for multi-principal ceramics. The complex compositional nature of these materials, especially at grain boundaries where segregation and secondary phase formation occur, complicates conventional recycling approaches. Developing specialized recovery methods that account for these compositional complexities represents an emerging research priority with significant environmental implications.

Water usage and potential toxicity concerns also merit consideration in sustainability assessments. The processing of ceramic powders and subsequent treatments may involve water-intensive steps or potentially hazardous chemicals. Understanding how grain boundary engineering techniques impact these factors is essential for developing environmentally responsible manufacturing protocols.

Future research directions should include developing lower-temperature processing methods, exploring water-based synthesis routes, and establishing standardized environmental impact assessment frameworks specifically calibrated for multi-principal ceramic systems. Additionally, investigating the potential for these materials to enable green technologies—such as more efficient energy generation systems or advanced environmental remediation applications—could further enhance their sustainability profile beyond direct manufacturing impacts.

Manufacturing processes for multi-principal ceramics currently present mixed environmental implications. While these materials often require high-temperature sintering that consumes substantial energy, their extended operational lifespans and superior performance characteristics may offset initial production impacts through reduced replacement frequency. The grain boundary chemistry optimization in these systems can further enhance durability, thereby extending service life and improving the overall lifecycle assessment metrics.

Resource efficiency constitutes another important sustainability consideration. Many multi-principal ceramic systems incorporate abundant elements rather than relying exclusively on rare earth or critical materials, potentially alleviating supply chain vulnerabilities and reducing extraction impacts. However, comprehensive lifecycle analyses specifically targeting these novel ceramic systems remain limited, creating a knowledge gap that warrants immediate research attention.

Recycling and end-of-life management present particular challenges for multi-principal ceramics. The complex compositional nature of these materials, especially at grain boundaries where segregation and secondary phase formation occur, complicates conventional recycling approaches. Developing specialized recovery methods that account for these compositional complexities represents an emerging research priority with significant environmental implications.

Water usage and potential toxicity concerns also merit consideration in sustainability assessments. The processing of ceramic powders and subsequent treatments may involve water-intensive steps or potentially hazardous chemicals. Understanding how grain boundary engineering techniques impact these factors is essential for developing environmentally responsible manufacturing protocols.

Future research directions should include developing lower-temperature processing methods, exploring water-based synthesis routes, and establishing standardized environmental impact assessment frameworks specifically calibrated for multi-principal ceramic systems. Additionally, investigating the potential for these materials to enable green technologies—such as more efficient energy generation systems or advanced environmental remediation applications—could further enhance their sustainability profile beyond direct manufacturing impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!