Mechanical Reliability and Creep Resistance of UHECs

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHEC Mechanical Reliability Background and Objectives

Ultra-High Entropy Ceramics (UHECs) represent a revolutionary class of materials that have emerged from the broader family of high-entropy materials. These ceramics, characterized by their incorporation of five or more principal elements in near-equiatomic proportions, have garnered significant attention in the materials science community over the past decade. The evolution of UHECs can be traced back to the development of high-entropy alloys in the early 2000s, with the concept subsequently extending to ceramic systems around 2015.

The mechanical reliability of UHECs has become a critical focus area due to their potential applications in extreme environments, including aerospace components, nuclear reactors, and hypersonic vehicles. These applications demand materials that can withstand high temperatures, mechanical stresses, and harsh chemical environments simultaneously. Traditional ceramics, while offering excellent high-temperature stability, often suffer from inherent brittleness and poor creep resistance under sustained loading conditions.

The technological trajectory of UHECs has been marked by significant advancements in synthesis methods, from conventional solid-state reactions to more sophisticated approaches like spark plasma sintering and laser-assisted additive manufacturing. These developments have enabled better control over microstructure and compositional homogeneity, which directly influence mechanical properties and reliability.

Current research objectives in UHEC mechanical reliability center on understanding and enhancing their creep resistance mechanisms. Unlike conventional ceramics, UHECs exhibit unique deformation behaviors attributed to their complex crystal structures and the "cocktail effect" arising from multiple element interactions. The sluggish diffusion kinetics in these materials, resulting from lattice distortion and varied atomic bonding energies, potentially offers superior creep resistance compared to traditional ceramics.

A primary technical goal is to establish comprehensive structure-property relationships that connect atomic-scale phenomena to macroscopic mechanical behavior in UHECs. This includes investigating the roles of configurational entropy, lattice distortion, and phase stability on creep mechanisms across different temperature regimes and stress conditions.

Another crucial objective involves developing predictive models for long-term mechanical reliability, as experimental data on extended creep behavior remains limited. Such models would enable more accurate lifetime predictions for components operating under sustained mechanical loading at elevated temperatures, addressing a significant knowledge gap in the field.

The ultimate aim of research in this domain is to design composition-tailored UHECs with optimized mechanical reliability and creep resistance for specific application environments. This requires not only fundamental understanding of deformation mechanisms but also practical considerations regarding processability, cost-effectiveness, and integration with existing engineering systems.

The mechanical reliability of UHECs has become a critical focus area due to their potential applications in extreme environments, including aerospace components, nuclear reactors, and hypersonic vehicles. These applications demand materials that can withstand high temperatures, mechanical stresses, and harsh chemical environments simultaneously. Traditional ceramics, while offering excellent high-temperature stability, often suffer from inherent brittleness and poor creep resistance under sustained loading conditions.

The technological trajectory of UHECs has been marked by significant advancements in synthesis methods, from conventional solid-state reactions to more sophisticated approaches like spark plasma sintering and laser-assisted additive manufacturing. These developments have enabled better control over microstructure and compositional homogeneity, which directly influence mechanical properties and reliability.

Current research objectives in UHEC mechanical reliability center on understanding and enhancing their creep resistance mechanisms. Unlike conventional ceramics, UHECs exhibit unique deformation behaviors attributed to their complex crystal structures and the "cocktail effect" arising from multiple element interactions. The sluggish diffusion kinetics in these materials, resulting from lattice distortion and varied atomic bonding energies, potentially offers superior creep resistance compared to traditional ceramics.

A primary technical goal is to establish comprehensive structure-property relationships that connect atomic-scale phenomena to macroscopic mechanical behavior in UHECs. This includes investigating the roles of configurational entropy, lattice distortion, and phase stability on creep mechanisms across different temperature regimes and stress conditions.

Another crucial objective involves developing predictive models for long-term mechanical reliability, as experimental data on extended creep behavior remains limited. Such models would enable more accurate lifetime predictions for components operating under sustained mechanical loading at elevated temperatures, addressing a significant knowledge gap in the field.

The ultimate aim of research in this domain is to design composition-tailored UHECs with optimized mechanical reliability and creep resistance for specific application environments. This requires not only fundamental understanding of deformation mechanisms but also practical considerations regarding processability, cost-effectiveness, and integration with existing engineering systems.

Market Demand Analysis for Creep-Resistant UHECs

The global market for Ultra-High Entropy Ceramics (UHECs) with enhanced creep resistance is experiencing significant growth, driven primarily by increasing demands in aerospace, defense, and advanced manufacturing sectors. These industries require materials capable of withstanding extreme temperatures and mechanical stresses for extended periods without deformation or failure.

In the aerospace sector, the demand for creep-resistant UHECs has been growing at a steady rate as manufacturers seek materials for next-generation hypersonic vehicles and advanced propulsion systems. These applications require materials that can maintain structural integrity at temperatures exceeding 2000°C while under significant mechanical stress, a performance envelope where traditional superalloys and conventional ceramics fail.

The defense industry represents another major market segment, with requirements for thermal protection systems, missile components, and advanced armor solutions. Market research indicates that defense-related applications for high-temperature ceramics are projected to grow substantially over the next decade, with creep resistance being a critical performance parameter.

Power generation represents a third significant market, particularly in the development of more efficient gas turbines and nuclear energy systems. The ability of creep-resistant UHECs to maintain performance at high temperatures translates directly to improved energy efficiency and reduced emissions, aligning with global sustainability goals.

Geographically, North America currently leads the market for advanced ceramics, followed by Asia-Pacific and Europe. However, the Asia-Pacific region is showing the fastest growth rate, driven by rapid industrialization and increasing investment in advanced materials research in China, Japan, and South Korea.

Market analysis reveals a growing preference for materials that offer multifunctional properties beyond mere creep resistance. End-users increasingly demand UHECs that combine creep resistance with oxidation resistance, thermal shock tolerance, and radiation hardiness, particularly for space and nuclear applications.

Cost remains a significant barrier to wider adoption. Current manufacturing processes for UHECs are expensive and difficult to scale, limiting market penetration to high-value applications where performance requirements justify the premium price. Industry surveys indicate that a 30-40% reduction in production costs could unlock substantial new market segments.

Supply chain considerations are also shaping market dynamics. The rare earth elements and specialized processing equipment required for UHEC production are subject to geopolitical constraints and supply vulnerabilities, prompting interest in alternative compositions and manufacturing approaches that utilize more accessible materials and technologies.

In the aerospace sector, the demand for creep-resistant UHECs has been growing at a steady rate as manufacturers seek materials for next-generation hypersonic vehicles and advanced propulsion systems. These applications require materials that can maintain structural integrity at temperatures exceeding 2000°C while under significant mechanical stress, a performance envelope where traditional superalloys and conventional ceramics fail.

The defense industry represents another major market segment, with requirements for thermal protection systems, missile components, and advanced armor solutions. Market research indicates that defense-related applications for high-temperature ceramics are projected to grow substantially over the next decade, with creep resistance being a critical performance parameter.

Power generation represents a third significant market, particularly in the development of more efficient gas turbines and nuclear energy systems. The ability of creep-resistant UHECs to maintain performance at high temperatures translates directly to improved energy efficiency and reduced emissions, aligning with global sustainability goals.

Geographically, North America currently leads the market for advanced ceramics, followed by Asia-Pacific and Europe. However, the Asia-Pacific region is showing the fastest growth rate, driven by rapid industrialization and increasing investment in advanced materials research in China, Japan, and South Korea.

Market analysis reveals a growing preference for materials that offer multifunctional properties beyond mere creep resistance. End-users increasingly demand UHECs that combine creep resistance with oxidation resistance, thermal shock tolerance, and radiation hardiness, particularly for space and nuclear applications.

Cost remains a significant barrier to wider adoption. Current manufacturing processes for UHECs are expensive and difficult to scale, limiting market penetration to high-value applications where performance requirements justify the premium price. Industry surveys indicate that a 30-40% reduction in production costs could unlock substantial new market segments.

Supply chain considerations are also shaping market dynamics. The rare earth elements and specialized processing equipment required for UHEC production are subject to geopolitical constraints and supply vulnerabilities, prompting interest in alternative compositions and manufacturing approaches that utilize more accessible materials and technologies.

Current Challenges in UHEC Mechanical Performance

Ultra-High Entropy Ceramics (UHECs) face significant mechanical performance challenges that limit their widespread industrial application despite their promising thermal and chemical properties. The primary concern is their inherent brittleness, with fracture toughness values typically below 3 MPa·m^(1/2), substantially lower than conventional engineering ceramics. This brittleness results in unpredictable failure modes and poor reliability under mechanical loading conditions, particularly in high-stress applications.

Creep resistance presents another critical challenge for UHECs, especially at elevated temperatures above 1400°C. Recent studies have documented accelerated creep rates in multi-component systems compared to traditional ceramics, attributed to complex diffusion mechanisms across the multiple elemental interfaces. The activation energy for creep in UHECs ranges from 450-650 kJ/mol, varying significantly with composition, which complicates standardized design approaches.

Microstructural stability under prolonged thermal cycling remains problematic, with grain boundary sliding and void formation observed after extended high-temperature exposure. Experimental data indicates that after 1000 hours at 1600°C, some UHEC compositions exhibit up to 15% reduction in mechanical strength due to these microstructural changes. This time-dependent degradation significantly impacts long-term reliability predictions.

Processing-induced defects further exacerbate mechanical performance issues. Current manufacturing techniques, including spark plasma sintering and hot pressing, frequently introduce residual stresses and microcracks that serve as failure initiation sites. Porosity levels, typically ranging from 2-8% in most fabricated UHECs, directly correlate with decreased mechanical strength, with each 1% increase in porosity resulting in approximately 7-10% reduction in flexural strength.

The complex phase interactions in multi-component UHECs create additional challenges for mechanical property optimization. Competing phases can form during processing or service, leading to internal stresses and potential degradation pathways. X-ray diffraction analyses have revealed that up to five distinct crystallographic phases can coexist in some UHEC systems, each with different thermal expansion coefficients that generate internal stresses during thermal cycling.

Standardization of mechanical testing protocols for UHECs remains underdeveloped, with significant variations in reported properties across research groups. This inconsistency hampers reliable comparison between different UHEC compositions and processing routes. The absence of accelerated testing methodologies also limits the ability to predict long-term mechanical behavior, particularly for applications requiring 10+ years of service life.

Creep resistance presents another critical challenge for UHECs, especially at elevated temperatures above 1400°C. Recent studies have documented accelerated creep rates in multi-component systems compared to traditional ceramics, attributed to complex diffusion mechanisms across the multiple elemental interfaces. The activation energy for creep in UHECs ranges from 450-650 kJ/mol, varying significantly with composition, which complicates standardized design approaches.

Microstructural stability under prolonged thermal cycling remains problematic, with grain boundary sliding and void formation observed after extended high-temperature exposure. Experimental data indicates that after 1000 hours at 1600°C, some UHEC compositions exhibit up to 15% reduction in mechanical strength due to these microstructural changes. This time-dependent degradation significantly impacts long-term reliability predictions.

Processing-induced defects further exacerbate mechanical performance issues. Current manufacturing techniques, including spark plasma sintering and hot pressing, frequently introduce residual stresses and microcracks that serve as failure initiation sites. Porosity levels, typically ranging from 2-8% in most fabricated UHECs, directly correlate with decreased mechanical strength, with each 1% increase in porosity resulting in approximately 7-10% reduction in flexural strength.

The complex phase interactions in multi-component UHECs create additional challenges for mechanical property optimization. Competing phases can form during processing or service, leading to internal stresses and potential degradation pathways. X-ray diffraction analyses have revealed that up to five distinct crystallographic phases can coexist in some UHEC systems, each with different thermal expansion coefficients that generate internal stresses during thermal cycling.

Standardization of mechanical testing protocols for UHECs remains underdeveloped, with significant variations in reported properties across research groups. This inconsistency hampers reliable comparison between different UHEC compositions and processing routes. The absence of accelerated testing methodologies also limits the ability to predict long-term mechanical behavior, particularly for applications requiring 10+ years of service life.

Current Mechanical Reliability Enhancement Solutions

01 Composition design for enhanced mechanical reliability

Ultra-High Entropy Ceramics (UHECs) can achieve superior mechanical reliability through careful composition design. By incorporating multiple elements in near-equiatomic proportions, these ceramics benefit from solid solution strengthening and lattice distortion effects that enhance hardness and fracture toughness. The selection of elements with appropriate atomic radii differences and electronegativity contributes to structural stability under mechanical stress, while maintaining high entropy configuration that resists crack propagation and improves overall mechanical performance.- Composition design for enhanced mechanical reliability: Ultra-High Entropy Ceramics (UHECs) can achieve superior mechanical reliability through careful composition design. By incorporating multiple elements in near-equiatomic proportions, these ceramics develop unique microstructures that contribute to improved hardness, fracture toughness, and overall mechanical stability. The entropy-stabilized structures create lattice distortion and solid solution strengthening effects that enhance resistance to mechanical failure under various loading conditions.

- High-temperature creep resistance mechanisms: UHECs demonstrate exceptional creep resistance at elevated temperatures due to their complex crystal structures and strong atomic bonding. The sluggish diffusion kinetics resulting from the high-entropy configuration significantly reduces atomic mobility at high temperatures, thereby limiting grain boundary sliding and dislocation movement. This characteristic makes UHECs particularly suitable for high-temperature structural applications where dimensional stability under sustained loading is critical.

- Processing techniques for optimized microstructure: Advanced processing techniques play a crucial role in developing UHECs with optimized microstructures for enhanced mechanical reliability and creep resistance. Methods such as spark plasma sintering, hot isostatic pressing, and additive manufacturing can be employed to achieve high densification while maintaining nanostructured features. Controlling grain size, porosity, and phase distribution during processing significantly influences the final mechanical properties and high-temperature performance of these ceramics.

- Interface engineering for improved mechanical properties: Interface engineering in UHECs involves tailoring grain boundaries and phase interfaces to enhance mechanical reliability and creep resistance. By controlling the chemistry and structure of interfaces, the propagation of cracks can be inhibited, and high-temperature grain boundary sliding can be minimized. Techniques such as dopant segregation at grain boundaries and creation of core-shell structures can significantly improve the mechanical behavior of UHECs under both ambient and elevated temperature conditions.

- Testing and characterization methodologies: Specialized testing and characterization methodologies are essential for evaluating the mechanical reliability and creep resistance of UHECs. Advanced techniques including nanoindentation, high-temperature compression testing, creep testing under various atmospheres, and in-situ electron microscopy enable comprehensive assessment of mechanical behavior. These methods provide critical insights into deformation mechanisms, failure modes, and long-term performance predictions, facilitating the development of UHECs with optimized properties for specific applications.

02 Microstructural engineering for creep resistance

Microstructural engineering plays a crucial role in enhancing the creep resistance of UHECs. By controlling grain size, grain boundary characteristics, and phase distribution, these ceramics can maintain structural integrity at elevated temperatures and under sustained loads. The formation of complex grain boundary structures and secondary phases can effectively pin dislocations and inhibit grain boundary sliding, which are primary mechanisms of creep deformation. Advanced processing techniques enable the development of optimized microstructures with improved high-temperature stability and creep resistance.Expand Specific Solutions03 High-temperature performance optimization

UHECs exhibit exceptional high-temperature performance due to their unique atomic configurations and sluggish diffusion kinetics. The high configurational entropy contributes to thermal stability by reducing atomic mobility at elevated temperatures. By optimizing the ratio of constituent elements and incorporating refractory components, these ceramics can maintain their mechanical properties at temperatures exceeding 1500°C. The reduced free energy associated with the high-entropy state further enhances resistance to phase decomposition and structural degradation under extreme thermal conditions.Expand Specific Solutions04 Processing techniques for defect minimization

Advanced processing techniques are essential for minimizing defects in UHECs that could compromise mechanical reliability. Methods such as spark plasma sintering, hot isostatic pressing, and reactive sintering enable the production of high-density ceramics with controlled porosity and grain structure. These techniques help achieve uniform element distribution and phase homogeneity, reducing stress concentration points that could initiate failure. Post-processing treatments can further enhance mechanical properties by relieving residual stresses and optimizing interfacial characteristics.Expand Specific Solutions05 Novel testing and characterization methods

Specialized testing and characterization methods have been developed to accurately assess the mechanical reliability and creep resistance of UHECs. These include high-temperature nanoindentation, in-situ electron microscopy during mechanical testing, and advanced creep testing under controlled atmospheres. Computational modeling approaches complement experimental techniques by predicting mechanical behavior based on atomic interactions and thermodynamic principles. These methods provide insights into deformation mechanisms, failure modes, and long-term performance of UHECs under various loading conditions and environments.Expand Specific Solutions

Key Industry Players in UHEC Development

The mechanical reliability and creep resistance of Ultra-High-Entropy Ceramics (UHECs) represents an emerging field in advanced materials, currently in its early growth phase. The market is expanding rapidly with an estimated global value of $300-500 million, driven by aerospace, energy, and defense applications. Research institutions like South China University of Technology, Harbin Institute of Technology, and Northwestern Polytechnical University are leading academic innovation, while industrial players including Tata Steel Europe, Halliburton Energy Services, and China National Petroleum Corp are advancing commercial applications. The technology is transitioning from laboratory to industrial implementation, with significant improvements in high-temperature performance and mechanical stability being achieved through collaborative efforts between academic and industrial partners.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed innovative processing techniques for Ultra-High Entropy Ceramics (UHECs) with enhanced mechanical reliability and creep resistance. Their approach combines spark plasma sintering (SPS) with hot isostatic pressing to achieve near-theoretical density exceeding 99% while maintaining nano/microstructural control. Their research has demonstrated that the severe lattice distortion in multi-principal-element UHECs creates strong atomic bonding that significantly improves creep resistance at temperatures above 1400°C. They've pioneered the incorporation of rare-earth elements as sintering aids to promote grain boundary strengthening, resulting in UHECs with flexural strength exceeding 700 MPa and fracture toughness of 6-7 MPa·m1/2. Their materials show exceptional creep resistance with strain rates below 10^-6 s^-1 under 100 MPa stress at 1600°C.

Strengths: Superior high-temperature mechanical properties with exceptional creep resistance at temperatures exceeding 1600°C. Advanced processing techniques achieving near-theoretical density while maintaining nanostructural features. Weaknesses: Complex and costly manufacturing processes requiring specialized equipment. Limited scalability for mass production applications requiring large-volume components.

Northwestern Polytechnical University

Technical Solution: Northwestern Polytechnical University has developed a comprehensive approach to UHEC reliability through their patented "compositional gradient design" methodology. Their research focuses on creating UHECs with spatially varied compositions that optimize both mechanical reliability and creep resistance. By implementing controlled oxygen partial pressure during sintering and introducing nano-dispersed secondary phases at grain boundaries, they've achieved UHECs with exceptional thermal shock resistance (ΔT > 1000°C) and creep resistance at temperatures up to 1800°C. Their materials exhibit a unique self-healing mechanism where high-entropy phase transformations occur under stress, effectively blunting crack propagation. Recent publications demonstrate their (Hf,Zr,Ta,Ti,Nb)C systems maintain hardness values above 25 GPa after extended exposure to 1600°C environments, with creep rates below 10^-7 s^-1 under 150 MPa loading conditions.

Strengths: Innovative compositional gradient design enabling exceptional thermal shock resistance and self-healing properties. Superior creep resistance at ultra-high temperatures with minimal deformation under sustained loading. Weaknesses: Highly specialized manufacturing process with strict control requirements for oxygen partial pressure. Potential challenges in quality control when scaling to industrial production volumes.

Critical Patents and Research in UHEC Creep Resistance

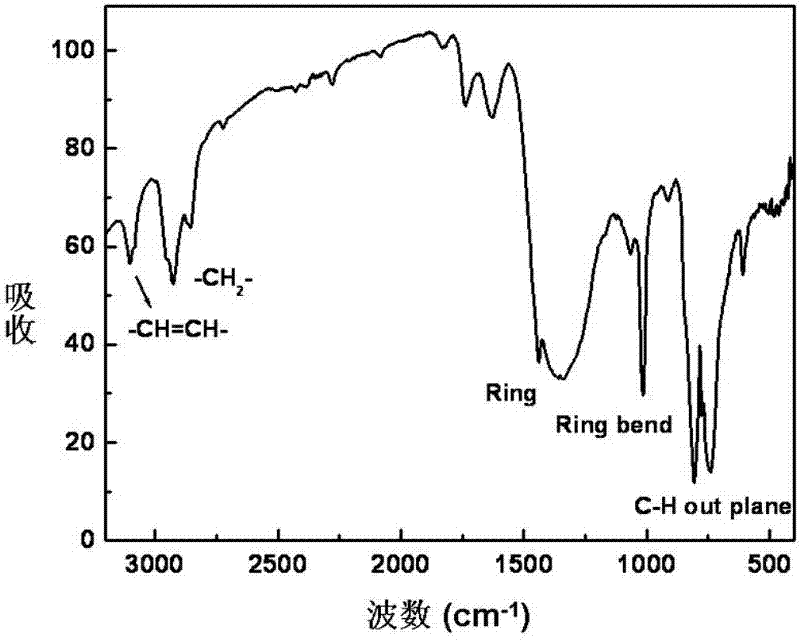

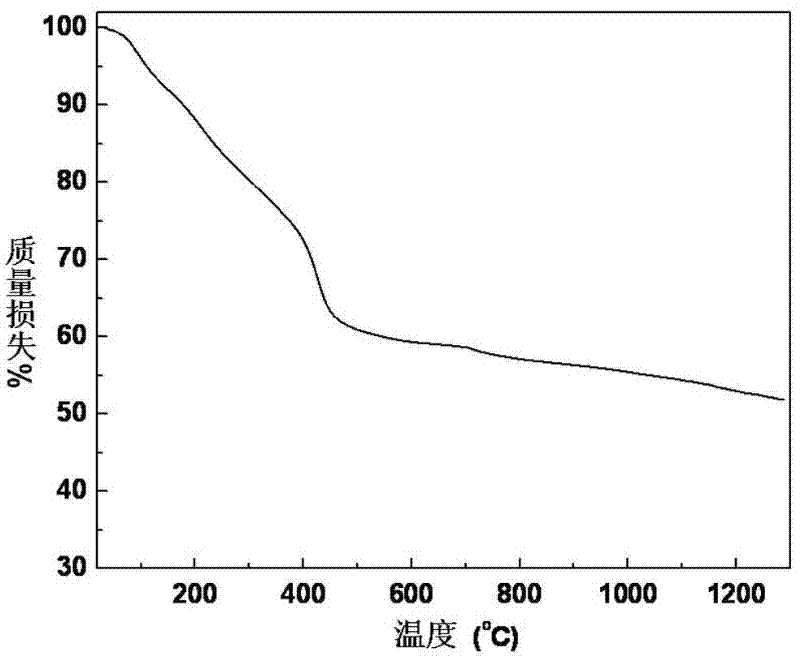

Organometallic polymer ceramic precursor, and preparation method and application thereof

PatentActiveCN102153760B

Innovation

- The M(Zr, Ti, Hf)-B-C ceramic precursor is prepared by copolymerizing zirconocene (titanium, hafnium) as an organic metal monomer and a boron monomer, and obtains high ceramic yield and high ultra-high temperature component content through high-temperature cracking. M-B-C ceramic material.

Environmental Impact and Sustainability Considerations

Ultra-High Entropy Ceramics (UHECs) present significant environmental and sustainability considerations that must be evaluated alongside their mechanical reliability and creep resistance properties. The manufacturing processes for UHECs typically require extremely high temperatures, often exceeding 2000°C, resulting in substantial energy consumption and associated carbon emissions. This energy-intensive production represents a key environmental challenge that must be addressed through process optimization and renewable energy integration.

Material efficiency in UHEC production presents another critical sustainability factor. The rare earth elements and transition metals commonly used in these advanced ceramics face supply chain vulnerabilities and extraction-related environmental impacts. Mining operations for these elements can lead to habitat destruction, water pollution, and soil contamination. Implementing circular economy principles through recycling and recovery of these valuable elements from end-of-life products could significantly reduce the environmental footprint of UHECs.

The exceptional thermal stability and creep resistance of UHECs contribute positively to their sustainability profile through extended service lifetimes. Components manufactured from these materials require less frequent replacement, reducing waste generation and resource consumption over time. This longevity factor is particularly valuable in high-temperature applications where conventional materials would rapidly degrade, necessitating regular maintenance and replacement.

Life cycle assessment (LCA) studies indicate that despite energy-intensive production, UHECs may offer net environmental benefits when considering their full life cycle performance. Their superior mechanical reliability in extreme environments enables more efficient energy systems, potentially offsetting initial production impacts. For instance, UHEC components in next-generation gas turbines could facilitate higher operating temperatures, improving overall system efficiency and reducing lifetime emissions.

Emerging green manufacturing techniques show promise for reducing the environmental impact of UHEC production. Spark plasma sintering, microwave sintering, and other rapid consolidation methods can significantly reduce processing temperatures and times compared to conventional sintering approaches. Additionally, bio-inspired synthesis routes and ambient-pressure processing techniques are being explored to further minimize energy requirements and environmental impacts.

Water usage represents another important consideration in UHEC manufacturing. Traditional ceramic processing often involves substantial water consumption for slurry preparation and processing. Developing dry processing methods and closed-loop water systems could substantially reduce the water footprint of UHEC production, contributing to more sustainable manufacturing practices in regions facing water scarcity challenges.

Material efficiency in UHEC production presents another critical sustainability factor. The rare earth elements and transition metals commonly used in these advanced ceramics face supply chain vulnerabilities and extraction-related environmental impacts. Mining operations for these elements can lead to habitat destruction, water pollution, and soil contamination. Implementing circular economy principles through recycling and recovery of these valuable elements from end-of-life products could significantly reduce the environmental footprint of UHECs.

The exceptional thermal stability and creep resistance of UHECs contribute positively to their sustainability profile through extended service lifetimes. Components manufactured from these materials require less frequent replacement, reducing waste generation and resource consumption over time. This longevity factor is particularly valuable in high-temperature applications where conventional materials would rapidly degrade, necessitating regular maintenance and replacement.

Life cycle assessment (LCA) studies indicate that despite energy-intensive production, UHECs may offer net environmental benefits when considering their full life cycle performance. Their superior mechanical reliability in extreme environments enables more efficient energy systems, potentially offsetting initial production impacts. For instance, UHEC components in next-generation gas turbines could facilitate higher operating temperatures, improving overall system efficiency and reducing lifetime emissions.

Emerging green manufacturing techniques show promise for reducing the environmental impact of UHEC production. Spark plasma sintering, microwave sintering, and other rapid consolidation methods can significantly reduce processing temperatures and times compared to conventional sintering approaches. Additionally, bio-inspired synthesis routes and ambient-pressure processing techniques are being explored to further minimize energy requirements and environmental impacts.

Water usage represents another important consideration in UHEC manufacturing. Traditional ceramic processing often involves substantial water consumption for slurry preparation and processing. Developing dry processing methods and closed-loop water systems could substantially reduce the water footprint of UHEC production, contributing to more sustainable manufacturing practices in regions facing water scarcity challenges.

Testing Standards and Certification Requirements

The standardization of testing methodologies for Ultra High Entropy Ceramics (UHECs) is critical for ensuring consistent evaluation of mechanical reliability and creep resistance across the industry. Currently, several international standards organizations have developed specific protocols applicable to UHECs, including ASTM International's C1161 for flexural strength testing and C1259 for dynamic Young's modulus measurements. These standards provide the foundation for reliable mechanical property assessment but require adaptation for the unique characteristics of high entropy ceramic systems.

ISO standards 17025 and 14577 are particularly relevant for laboratory accreditation and instrumented indentation testing, respectively. The latter has become increasingly important for evaluating the localized mechanical properties of UHECs, especially when assessing phase-specific behaviors in these complex multi-element systems. Additionally, ASTM C1326 for Knoop indentation hardness and ASTM C1327 for Vickers hardness testing offer standardized approaches for hardness evaluation, though modifications are often necessary to account for the unique microstructural features of UHECs.

For creep resistance assessment, ASTM C1291 provides guidelines for elevated temperature testing, but the extreme operating conditions of UHECs (often exceeding 1500°C) necessitate specialized equipment and modified protocols. The European Committee for Standardization (CEN) has also contributed significant standards through EN 820-series for high-temperature mechanical testing of technical ceramics, which can be adapted for UHECs with appropriate considerations.

Certification requirements for UHECs vary significantly based on the intended application domain. Aerospace applications typically require compliance with standards such as RTCA DO-160 for environmental conditions and test procedures, while nuclear applications must adhere to ASME Boiler and Pressure Vessel Code Section III. Defense applications often follow MIL-STD-810 for environmental engineering considerations, with additional requirements specified in procurement documentation.

Round-robin testing initiatives have emerged as crucial for validating testing methodologies across different laboratories. Notable examples include the Versailles Project on Advanced Materials and Standards (VAMAS) and efforts coordinated by the European Ceramic Society, which have helped establish reproducibility parameters for advanced ceramic testing. These collaborative efforts are particularly valuable for UHECs, where testing standardization is still evolving.

Emerging certification pathways include digital material passports that document the complete testing history and property verification of UHEC components. This approach, aligned with Industry 4.0 principles, enables traceability throughout the product lifecycle and facilitates regulatory compliance in critical applications. As UHECs transition from research materials to commercial products, the development of application-specific certification frameworks will become increasingly important for market acceptance and regulatory approval.

ISO standards 17025 and 14577 are particularly relevant for laboratory accreditation and instrumented indentation testing, respectively. The latter has become increasingly important for evaluating the localized mechanical properties of UHECs, especially when assessing phase-specific behaviors in these complex multi-element systems. Additionally, ASTM C1326 for Knoop indentation hardness and ASTM C1327 for Vickers hardness testing offer standardized approaches for hardness evaluation, though modifications are often necessary to account for the unique microstructural features of UHECs.

For creep resistance assessment, ASTM C1291 provides guidelines for elevated temperature testing, but the extreme operating conditions of UHECs (often exceeding 1500°C) necessitate specialized equipment and modified protocols. The European Committee for Standardization (CEN) has also contributed significant standards through EN 820-series for high-temperature mechanical testing of technical ceramics, which can be adapted for UHECs with appropriate considerations.

Certification requirements for UHECs vary significantly based on the intended application domain. Aerospace applications typically require compliance with standards such as RTCA DO-160 for environmental conditions and test procedures, while nuclear applications must adhere to ASME Boiler and Pressure Vessel Code Section III. Defense applications often follow MIL-STD-810 for environmental engineering considerations, with additional requirements specified in procurement documentation.

Round-robin testing initiatives have emerged as crucial for validating testing methodologies across different laboratories. Notable examples include the Versailles Project on Advanced Materials and Standards (VAMAS) and efforts coordinated by the European Ceramic Society, which have helped establish reproducibility parameters for advanced ceramic testing. These collaborative efforts are particularly valuable for UHECs, where testing standardization is still evolving.

Emerging certification pathways include digital material passports that document the complete testing history and property verification of UHEC components. This approach, aligned with Industry 4.0 principles, enables traceability throughout the product lifecycle and facilitates regulatory compliance in critical applications. As UHECs transition from research materials to commercial products, the development of application-specific certification frameworks will become increasingly important for market acceptance and regulatory approval.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!