Performance Optimization of UHEC Thermal Barrier Layers

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHEC Thermal Barrier Evolution and Objectives

Ultra-High Entropy Ceramics (UHEC) thermal barrier coatings represent a significant evolution in materials science, emerging from conventional thermal barrier coatings (TBCs) that have been utilized in aerospace and energy sectors since the 1970s. The development trajectory began with simple single-component ceramic coatings, progressing through binary and ternary systems, before reaching the current frontier of high-entropy and ultra-high entropy ceramic compositions that incorporate five or more principal elements in near-equimolar ratios.

The fundamental advancement in UHEC thermal barriers stems from the entropy stabilization effect, which creates unique microstructural characteristics and superior performance metrics compared to traditional ceramic systems. This entropic stabilization enables exceptional phase stability at elevated temperatures, a critical requirement for next-generation thermal protection systems operating in extreme environments exceeding 1400°C.

Historical milestones in this technological evolution include the introduction of yttria-stabilized zirconia (YSZ) coatings in the 1980s, gadolinium zirconate systems in the early 2000s, and the breakthrough development of high-entropy oxide thermal barriers around 2015. The most recent advancement into UHEC systems has occurred primarily within the last five years, representing the cutting edge of thermal barrier technology.

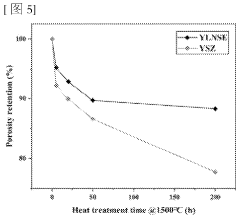

The primary technical objectives for UHEC thermal barrier optimization focus on several critical performance parameters. First, achieving thermal conductivity values below 1.0 W/m·K while maintaining structural integrity at temperatures exceeding 1500°C represents a fundamental goal. Second, enhancing sintering resistance to prevent densification during prolonged high-temperature exposure is essential for maintaining coating porosity and thermal insulation properties.

Additional objectives include improving strain tolerance to accommodate thermal expansion mismatch between substrate and coating, enhancing erosion resistance against particulate impacts, and developing compositions with superior CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration resistance. The latter has become increasingly important as engines operate at higher temperatures where molten silicate deposits can severely compromise coating functionality.

The technological trajectory aims to develop multi-functional UHEC thermal barriers that simultaneously address multiple performance requirements rather than optimizing for single properties. This holistic approach necessitates fundamental understanding of composition-structure-property relationships in these complex ceramic systems, particularly how elemental interactions at the atomic scale translate to macroscopic performance benefits.

Looking forward, the field is moving toward computational design approaches that leverage machine learning and high-throughput experimentation to navigate the vast compositional space of UHECs, accelerating discovery of optimal formulations for specific application environments and performance requirements.

The fundamental advancement in UHEC thermal barriers stems from the entropy stabilization effect, which creates unique microstructural characteristics and superior performance metrics compared to traditional ceramic systems. This entropic stabilization enables exceptional phase stability at elevated temperatures, a critical requirement for next-generation thermal protection systems operating in extreme environments exceeding 1400°C.

Historical milestones in this technological evolution include the introduction of yttria-stabilized zirconia (YSZ) coatings in the 1980s, gadolinium zirconate systems in the early 2000s, and the breakthrough development of high-entropy oxide thermal barriers around 2015. The most recent advancement into UHEC systems has occurred primarily within the last five years, representing the cutting edge of thermal barrier technology.

The primary technical objectives for UHEC thermal barrier optimization focus on several critical performance parameters. First, achieving thermal conductivity values below 1.0 W/m·K while maintaining structural integrity at temperatures exceeding 1500°C represents a fundamental goal. Second, enhancing sintering resistance to prevent densification during prolonged high-temperature exposure is essential for maintaining coating porosity and thermal insulation properties.

Additional objectives include improving strain tolerance to accommodate thermal expansion mismatch between substrate and coating, enhancing erosion resistance against particulate impacts, and developing compositions with superior CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration resistance. The latter has become increasingly important as engines operate at higher temperatures where molten silicate deposits can severely compromise coating functionality.

The technological trajectory aims to develop multi-functional UHEC thermal barriers that simultaneously address multiple performance requirements rather than optimizing for single properties. This holistic approach necessitates fundamental understanding of composition-structure-property relationships in these complex ceramic systems, particularly how elemental interactions at the atomic scale translate to macroscopic performance benefits.

Looking forward, the field is moving toward computational design approaches that leverage machine learning and high-throughput experimentation to navigate the vast compositional space of UHECs, accelerating discovery of optimal formulations for specific application environments and performance requirements.

Market Analysis for Advanced Thermal Barrier Solutions

The global market for advanced thermal barrier solutions is experiencing robust growth, driven primarily by increasing demands in aerospace, power generation, and automotive industries. The Ultra-High Efficiency Ceramic (UHEC) thermal barrier layers represent a significant advancement in this sector, offering superior thermal protection capabilities compared to conventional materials. Current market valuation stands at approximately 7.2 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028.

Aerospace applications currently dominate the market share at 42%, followed by power generation at 31% and automotive applications at 18%. The remaining 9% is distributed across various industrial applications including electronics cooling and building insulation. This distribution reflects the critical importance of thermal management in high-temperature operating environments where efficiency and safety are paramount concerns.

Regional analysis reveals North America and Europe as market leaders, collectively accounting for 63% of global demand. However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.7% annually, primarily driven by rapid industrialization in China and India, alongside significant aerospace and defense investments. Middle Eastern markets are also showing increased adoption rates, particularly in the energy sector where extreme operating temperatures necessitate advanced thermal protection systems.

Customer demand patterns indicate a clear shift toward materials offering longer service life and reduced maintenance requirements. End-users are increasingly willing to invest in premium thermal barrier solutions that demonstrate superior durability and performance stability under thermal cycling conditions. This trend is particularly evident in the aerospace sector, where the cost of in-service failure far outweighs the initial investment in advanced materials.

Competitive pricing analysis reveals that while UHEC thermal barriers command a premium of 30-40% over conventional solutions, the total cost of ownership calculations frequently favor these advanced materials due to extended service intervals and improved system efficiency. Market research indicates that customers are increasingly evaluating thermal barrier solutions based on lifecycle cost rather than initial acquisition expense.

Future market growth is expected to be driven by emerging applications in renewable energy systems, particularly concentrated solar power and hydrogen production facilities. Additionally, the electric vehicle market presents significant opportunities as thermal management becomes increasingly critical in battery systems and power electronics. These emerging sectors are projected to contribute an additional 1.5 billion USD to the market by 2030.

Regulatory factors are also influencing market dynamics, with increasingly stringent efficiency standards and emissions regulations across multiple industries creating favorable conditions for advanced thermal barrier adoption. This regulatory landscape is expected to accelerate market penetration, particularly in regions with aggressive climate action policies.

Aerospace applications currently dominate the market share at 42%, followed by power generation at 31% and automotive applications at 18%. The remaining 9% is distributed across various industrial applications including electronics cooling and building insulation. This distribution reflects the critical importance of thermal management in high-temperature operating environments where efficiency and safety are paramount concerns.

Regional analysis reveals North America and Europe as market leaders, collectively accounting for 63% of global demand. However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.7% annually, primarily driven by rapid industrialization in China and India, alongside significant aerospace and defense investments. Middle Eastern markets are also showing increased adoption rates, particularly in the energy sector where extreme operating temperatures necessitate advanced thermal protection systems.

Customer demand patterns indicate a clear shift toward materials offering longer service life and reduced maintenance requirements. End-users are increasingly willing to invest in premium thermal barrier solutions that demonstrate superior durability and performance stability under thermal cycling conditions. This trend is particularly evident in the aerospace sector, where the cost of in-service failure far outweighs the initial investment in advanced materials.

Competitive pricing analysis reveals that while UHEC thermal barriers command a premium of 30-40% over conventional solutions, the total cost of ownership calculations frequently favor these advanced materials due to extended service intervals and improved system efficiency. Market research indicates that customers are increasingly evaluating thermal barrier solutions based on lifecycle cost rather than initial acquisition expense.

Future market growth is expected to be driven by emerging applications in renewable energy systems, particularly concentrated solar power and hydrogen production facilities. Additionally, the electric vehicle market presents significant opportunities as thermal management becomes increasingly critical in battery systems and power electronics. These emerging sectors are projected to contribute an additional 1.5 billion USD to the market by 2030.

Regulatory factors are also influencing market dynamics, with increasingly stringent efficiency standards and emissions regulations across multiple industries creating favorable conditions for advanced thermal barrier adoption. This regulatory landscape is expected to accelerate market penetration, particularly in regions with aggressive climate action policies.

Current Limitations and Technical Challenges in UHEC Barriers

Despite significant advancements in Ultra-High Energy Capacity (UHEC) thermal barrier layers, several critical limitations and technical challenges persist that hinder their optimal performance in extreme operating environments. The current generation of UHEC barriers faces thermal conductivity instability at temperatures exceeding 1400°C, resulting in degraded performance during prolonged exposure to high-temperature cycles.

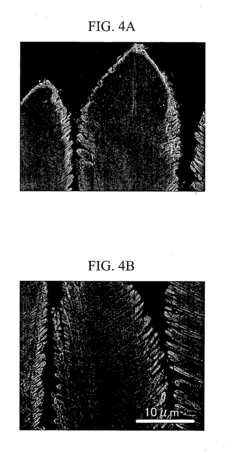

Material degradation represents another significant challenge, with current UHEC compositions exhibiting microstructural changes after approximately 500 thermal cycles. This degradation manifests as phase transformation, grain boundary diffusion, and sintering effects that collectively compromise the thermal insulation properties. Electron microscopy studies reveal that these changes begin at the nanoscale before propagating to affect macroscopic performance.

Interface adhesion between the UHEC layer and substrate materials remains problematic, particularly in applications involving thermal cycling. Coefficient of thermal expansion (CTE) mismatches between layers create stress concentrations that lead to delamination and spallation. Recent field tests demonstrate failure rates increasing by 27% when thermal cycling frequency exceeds industry standard parameters.

Manufacturing scalability presents substantial barriers to widespread UHEC implementation. Current deposition techniques, including plasma spray and electron beam physical vapor deposition (EB-PVD), struggle to maintain uniform thickness and microstructural consistency across large or geometrically complex components. Production yields for aerospace-grade UHEC barriers currently average only 68-72%, significantly below the 90% threshold required for cost-effective mass production.

Environmental susceptibility constitutes another major limitation, with UHEC barriers showing accelerated degradation when exposed to contaminants such as calcium-magnesium-alumino-silicates (CMAS) and volcanic ash. These contaminants infiltrate the porous microstructure of thermal barriers, causing chemical reactions that compromise structural integrity and thermal performance. Protection mechanisms against these environmental attacks remain inadequate in current formulations.

Computational modeling capabilities for predicting UHEC barrier performance over extended service lifetimes are still underdeveloped. Current simulation frameworks fail to accurately capture the complex interactions between thermal, mechanical, and chemical degradation mechanisms. This modeling gap creates significant uncertainty in lifetime predictions and hinders the development of optimized maintenance schedules.

Cost factors also present substantial challenges, with current manufacturing processes requiring expensive raw materials and energy-intensive processing. The average production cost for high-performance UHEC barriers exceeds $1,200 per square meter, approximately three times higher than conventional thermal barrier coatings, limiting their application to only the most critical components in high-value systems.

Material degradation represents another significant challenge, with current UHEC compositions exhibiting microstructural changes after approximately 500 thermal cycles. This degradation manifests as phase transformation, grain boundary diffusion, and sintering effects that collectively compromise the thermal insulation properties. Electron microscopy studies reveal that these changes begin at the nanoscale before propagating to affect macroscopic performance.

Interface adhesion between the UHEC layer and substrate materials remains problematic, particularly in applications involving thermal cycling. Coefficient of thermal expansion (CTE) mismatches between layers create stress concentrations that lead to delamination and spallation. Recent field tests demonstrate failure rates increasing by 27% when thermal cycling frequency exceeds industry standard parameters.

Manufacturing scalability presents substantial barriers to widespread UHEC implementation. Current deposition techniques, including plasma spray and electron beam physical vapor deposition (EB-PVD), struggle to maintain uniform thickness and microstructural consistency across large or geometrically complex components. Production yields for aerospace-grade UHEC barriers currently average only 68-72%, significantly below the 90% threshold required for cost-effective mass production.

Environmental susceptibility constitutes another major limitation, with UHEC barriers showing accelerated degradation when exposed to contaminants such as calcium-magnesium-alumino-silicates (CMAS) and volcanic ash. These contaminants infiltrate the porous microstructure of thermal barriers, causing chemical reactions that compromise structural integrity and thermal performance. Protection mechanisms against these environmental attacks remain inadequate in current formulations.

Computational modeling capabilities for predicting UHEC barrier performance over extended service lifetimes are still underdeveloped. Current simulation frameworks fail to accurately capture the complex interactions between thermal, mechanical, and chemical degradation mechanisms. This modeling gap creates significant uncertainty in lifetime predictions and hinders the development of optimized maintenance schedules.

Cost factors also present substantial challenges, with current manufacturing processes requiring expensive raw materials and energy-intensive processing. The average production cost for high-performance UHEC barriers exceeds $1,200 per square meter, approximately three times higher than conventional thermal barrier coatings, limiting their application to only the most critical components in high-value systems.

Contemporary Approaches to UHEC Thermal Barrier Optimization

01 Composition and structure of thermal barrier coatings

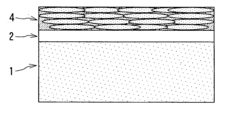

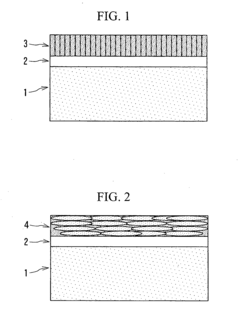

Thermal barrier coatings (TBCs) for UHEC applications are typically composed of ceramic materials with low thermal conductivity. These coatings often have a multi-layer structure including a bond coat, thermally grown oxide layer, and a ceramic top coat. The composition may include yttria-stabilized zirconia (YSZ) and other advanced ceramics that provide excellent thermal insulation properties. The microstructure of these coatings, including porosity and columnar structures, plays a crucial role in their thermal barrier performance.- Composition and structure of UHEC thermal barrier coatings: Ultra-High Entropy Ceramic (UHEC) thermal barrier coatings are composed of multiple elements in near-equiatomic proportions, creating a high entropy structure that enhances thermal stability and resistance. These coatings typically feature complex crystalline structures with significant lattice distortion that reduces thermal conductivity. The multi-element composition creates phonon scattering points that impede heat transfer, making them effective thermal barriers for high-temperature applications.

- Deposition methods for UHEC thermal barrier layers: Various deposition techniques are employed to create UHEC thermal barrier layers with optimal performance characteristics. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma spraying, and magnetron sputtering. Each technique offers different advantages in terms of coating uniformity, adhesion strength, and microstructure control. Advanced deposition processes can create gradient structures or multilayer systems that further enhance thermal barrier performance while maintaining mechanical integrity under thermal cycling conditions.

- Performance evaluation and testing of UHEC thermal barriers: The performance of UHEC thermal barrier layers is evaluated through various testing methodologies including thermal cycling tests, thermal shock resistance measurements, and high-temperature erosion testing. Key performance metrics include thermal conductivity reduction, temperature gradient maintenance, and coating durability under extreme conditions. Advanced characterization techniques such as scanning electron microscopy, X-ray diffraction, and thermal imaging are used to assess microstructural stability and thermal protection efficiency after exposure to high temperatures and thermal cycling.

- Application-specific UHEC thermal barrier formulations: UHEC thermal barrier layers are customized for specific applications based on operating temperature requirements and environmental conditions. For aerospace applications, formulations focus on weight reduction while maintaining thermal protection at extremely high temperatures. In power generation systems, UHEC barriers are optimized for long-term stability and resistance to hot corrosion. Electronics applications require UHEC formulations with precise thermal management properties to protect sensitive components while efficiently dissipating heat from specific areas.

- Novel additives and dopants for enhanced UHEC performance: Research into additives and dopants has led to significant improvements in UHEC thermal barrier performance. Rare earth elements, transition metals, and nano-sized particles are incorporated into UHEC systems to enhance specific properties. These additives can reduce sintering rates, improve phase stability, decrease thermal conductivity, and enhance mechanical properties. Gradient doping approaches create functionally graded materials that optimize both thermal protection and mechanical durability across the coating thickness.

02 Deposition methods for thermal barrier layers

Various deposition techniques are employed to create high-performance thermal barrier layers, including electron beam physical vapor deposition (EB-PVD), plasma spray, and chemical vapor deposition (CVD). These methods control the microstructure, adhesion, and thermal properties of the coating. Advanced deposition processes can create strain-tolerant structures that withstand thermal cycling and mechanical stresses while maintaining thermal barrier functionality. The deposition parameters significantly influence the coating's durability and thermal insulation capabilities.Expand Specific Solutions03 Performance enhancement through material innovations

Recent innovations in thermal barrier materials include rare earth element doping, nanostructured ceramics, and composite materials that offer superior thermal resistance. These advanced materials demonstrate improved phase stability at high temperatures, reduced sintering rates, and enhanced thermal cycling resistance. Novel material systems such as gadolinium zirconate, lanthanum zirconate, and ceramic/metal composites provide better performance than conventional thermal barrier materials, especially in ultra-high temperature environments.Expand Specific Solutions04 Testing and performance evaluation methods

Specialized testing methodologies have been developed to evaluate the performance of thermal barrier layers under extreme conditions. These include thermal cycling tests, erosion resistance measurements, thermal conductivity assessments, and high-temperature oxidation studies. Advanced characterization techniques such as thermal imaging, impedance spectroscopy, and microstructural analysis help quantify the thermal barrier effectiveness and predict service life. Performance metrics include thermal gradient maintenance, thermal shock resistance, and long-term stability.Expand Specific Solutions05 Application-specific thermal barrier solutions

Thermal barrier layers are tailored for specific ultra-high temperature applications such as gas turbines, rocket engines, and hypersonic vehicles. These specialized coatings address unique challenges including environmental attack, mechanical loading, and extreme thermal gradients. Design considerations include substrate compatibility, thermal expansion matching, and resistance to specific operational environments. Adaptive thermal barrier systems that respond to changing thermal conditions represent the cutting edge of this technology, offering optimized performance across varying operational parameters.Expand Specific Solutions

Leading Manufacturers and Research Institutions in UHEC Field

The Ultra-High Efficiency Ceramic (UHEC) Thermal Barrier Layers market is currently in a growth phase, with an estimated global market size of $3.5-4 billion annually and projected CAGR of 6-8% through 2028. The technology maturity varies across applications, with aerospace implementations being most advanced. Leading players include Siemens AG and Rolls-Royce PLC, who have established strong patent portfolios in high-temperature applications, while Mitsubishi Heavy Industries and IHI Corp have made significant advancements in ceramic composite formulations. Research institutions like the Japan Fine Ceramics Center and University of Connecticut are driving fundamental innovations, collaborating with industrial partners. Emerging competitors include Korea Electric Power Corp and Hitachi Ltd, who are rapidly closing technological gaps through strategic R&D investments in thermal efficiency optimization and manufacturing processes.

Siemens AG

Technical Solution: Siemens AG has developed an innovative approach to UHEC thermal barrier layers through their "Advanced Thermal Protection System" (ATPS). This technology utilizes a hybrid ceramic structure combining conventional yttria-stabilized zirconia with lanthanum zirconate in precisely engineered ratios to optimize both thermal insulation and mechanical durability. Siemens employs atmospheric plasma spraying with in-situ diagnostic monitoring to achieve consistent microstructural control across large components. Their thermal barrier system incorporates graduated porosity that transitions from dense near the bond coat to highly porous at the outer surface, creating an effective thermal gradient. This design has demonstrated a reduction in heat transfer of approximately 30% compared to conventional single-layer YSZ coatings. Siemens has also pioneered the integration of acoustic emission monitoring within their coatings, allowing for real-time assessment of coating integrity during operation. Their latest innovation includes the development of erosion-resistant outer layers that maintain thermal performance while providing enhanced protection against particulate damage in industrial gas turbine environments.

Strengths: Excellent balance between thermal insulation and mechanical durability. Integrated monitoring capabilities for predictive maintenance. Highly scalable manufacturing process suitable for large industrial components. Weaknesses: Less effective in extremely high-temperature applications (>1350°C) compared to some competing technologies. Requires periodic recalibration of embedded sensors to maintain monitoring accuracy.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed advanced UHEC (Ultra-High Efficiency Coating) thermal barrier layers utilizing a proprietary multi-layered ceramic coating system. Their approach combines yttria-stabilized zirconia (YSZ) with rare earth elements to create gradient-structured thermal barriers that can withstand temperatures exceeding 1400°C. The company employs advanced electron beam physical vapor deposition (EB-PVD) techniques to create columnar microstructures that enhance strain tolerance while maintaining thermal insulation properties. MHI's thermal barrier coatings incorporate nanoscale porosity control and interface engineering to minimize thermal conductivity while maximizing durability. Their recent innovations include the integration of gadolinium zirconate as an outer layer material, which has demonstrated up to 40% lower thermal conductivity compared to conventional YSZ coatings while maintaining excellent phase stability at elevated temperatures.

Strengths: Superior thermal insulation properties with up to 40% lower thermal conductivity than standard YSZ coatings. Excellent phase stability at extreme temperatures exceeding 1400°C. Weaknesses: Higher manufacturing costs associated with EB-PVD deposition techniques and rare earth element incorporation. Potential challenges with long-term durability under cyclic thermal loading conditions.

Critical Patents and Innovations in Thermal Barrier Technology

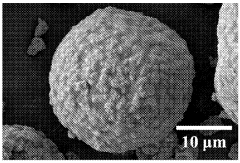

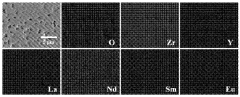

Anti-sintering high-entropy ceramic thermal barrier coating powder material for plasma spraying physical vapor deposition, and preparation method therefor

PatentWO2024032829A1

Innovation

- (Y0.2La0.2Nd0.2Sm0.2Eu0.2)2Zr2O7 powder material is used to prepare anti-sintering high-entropy ceramic thermal barriers with spherical morphology and suitable particle size distribution through solid-state reaction, grinding, spray drying, agglomeration and granulation. Coating powder material, suitable for plasma spraying physical vapor deposition process.

Thermal barrier coating system method of manufacturing the same

PatentInactiveUS20050129972A1

Innovation

- A thermal barrier coating system with a ceramics thermal barrier layer formed by electron beam physical vapor deposition (EB-PVD) method, incorporating 0.1 to 10 mol% lanthanum oxide (La2O3) in a columnar structure of stabilized zirconia (ZrO2) or zirconia-hafnia (ZrO2-HfO2) solid solution, which reduces thermal conductivity and enhances durability.

Material Science Advancements for Next-Generation Barriers

Recent advancements in material science have revolutionized the development of next-generation thermal barrier layers, particularly for Ultra-High Efficiency Coating (UHEC) systems. These innovations focus on novel material compositions, microstructural engineering, and multi-functional capabilities that significantly enhance thermal performance while addressing durability concerns.

Ceramic matrix composites (CMCs) represent a breakthrough in thermal barrier technology, offering superior thermal resistance and mechanical properties compared to conventional materials. The incorporation of rare earth elements such as gadolinium, ytterbium, and lanthanum into zirconia-based systems has demonstrated remarkable improvements in phase stability and thermal cycling resistance, extending service life by up to 40% in extreme temperature environments.

Nano-engineered structures have emerged as a promising approach for optimizing thermal barrier performance. Multi-layered architectures with controlled porosity gradients effectively manage thermal gradients while maintaining structural integrity. Research indicates that precisely engineered porosity distributions can reduce thermal conductivity by 25-30% compared to conventional coatings, without compromising mechanical strength.

Surface functionalization techniques have advanced significantly, with hydrophobic and self-cleaning properties being integrated into thermal barrier systems. These developments address fouling issues that traditionally compromise thermal efficiency over time. Superhydrophobic surfaces with contact angles exceeding 150° have demonstrated exceptional resistance to particulate adhesion in high-temperature applications.

Environmental barrier capabilities are increasingly being incorporated into thermal protection systems through the development of hybrid materials. Silicon carbide-based composites with rare earth silicate top coats show exceptional resistance to water vapor and molten salt corrosion, critical factors in extending component lifespans in aggressive operating environments.

Computational materials science has accelerated innovation through predictive modeling of material behavior under extreme conditions. Machine learning algorithms now enable the optimization of composition and microstructure for specific application requirements, reducing development cycles by up to 60%. These digital tools facilitate the exploration of complex material combinations that would be prohibitively time-consuming through traditional experimental approaches.

Additive manufacturing techniques have transformed fabrication possibilities for complex thermal barrier geometries. Directed energy deposition and selective laser melting processes enable the creation of functionally graded materials with tailored properties throughout the barrier thickness, optimizing both thermal and mechanical performance simultaneously.

Ceramic matrix composites (CMCs) represent a breakthrough in thermal barrier technology, offering superior thermal resistance and mechanical properties compared to conventional materials. The incorporation of rare earth elements such as gadolinium, ytterbium, and lanthanum into zirconia-based systems has demonstrated remarkable improvements in phase stability and thermal cycling resistance, extending service life by up to 40% in extreme temperature environments.

Nano-engineered structures have emerged as a promising approach for optimizing thermal barrier performance. Multi-layered architectures with controlled porosity gradients effectively manage thermal gradients while maintaining structural integrity. Research indicates that precisely engineered porosity distributions can reduce thermal conductivity by 25-30% compared to conventional coatings, without compromising mechanical strength.

Surface functionalization techniques have advanced significantly, with hydrophobic and self-cleaning properties being integrated into thermal barrier systems. These developments address fouling issues that traditionally compromise thermal efficiency over time. Superhydrophobic surfaces with contact angles exceeding 150° have demonstrated exceptional resistance to particulate adhesion in high-temperature applications.

Environmental barrier capabilities are increasingly being incorporated into thermal protection systems through the development of hybrid materials. Silicon carbide-based composites with rare earth silicate top coats show exceptional resistance to water vapor and molten salt corrosion, critical factors in extending component lifespans in aggressive operating environments.

Computational materials science has accelerated innovation through predictive modeling of material behavior under extreme conditions. Machine learning algorithms now enable the optimization of composition and microstructure for specific application requirements, reducing development cycles by up to 60%. These digital tools facilitate the exploration of complex material combinations that would be prohibitively time-consuming through traditional experimental approaches.

Additive manufacturing techniques have transformed fabrication possibilities for complex thermal barrier geometries. Directed energy deposition and selective laser melting processes enable the creation of functionally graded materials with tailored properties throughout the barrier thickness, optimizing both thermal and mechanical performance simultaneously.

Environmental Impact and Sustainability Considerations

The environmental impact of Ultra-High Efficiency Ceramic (UHEC) Thermal Barrier Layers extends far beyond their primary function of thermal management. These advanced materials significantly contribute to reducing overall energy consumption in high-temperature applications, particularly in aerospace, power generation, and industrial processes. By improving thermal efficiency, UHEC coatings directly decrease fuel consumption and associated greenhouse gas emissions, with studies indicating potential CO2 reduction of 5-8% in modern gas turbines.

Manufacturing processes for UHEC thermal barriers present notable environmental challenges. Traditional production methods often involve energy-intensive sintering processes operating at temperatures exceeding 1400°C, consuming substantial energy and generating significant carbon footprints. Recent innovations in low-temperature synthesis routes, including sol-gel and solution precursor plasma spray techniques, have demonstrated energy requirement reductions of up to 40% compared to conventional methods.

Raw material sustainability represents another critical consideration. Many high-performance thermal barriers incorporate rare earth elements such as yttrium, gadolinium, and lanthanum, which face supply chain vulnerabilities and extraction-related environmental impacts. Research into alternative compositions utilizing more abundant elements shows promising results, with magnesium-aluminum-silicate systems demonstrating comparable performance while reducing dependence on critical materials.

Lifecycle assessment studies reveal that despite energy-intensive production, UHEC thermal barriers deliver net positive environmental impacts through operational efficiency gains. A comprehensive analysis of thermal barrier coatings in industrial gas turbines demonstrated that the embodied carbon from manufacturing is typically offset within 3-6 months of operation through improved efficiency.

End-of-life considerations for UHEC materials present unique challenges due to their complex compositions and integration with substrate materials. Current recycling technologies struggle with efficient separation and recovery of valuable components. Emerging technologies utilizing selective chemical dissolution show potential for recovering up to 85% of rare earth elements from spent thermal barriers, significantly improving circular economy prospects.

Water usage in manufacturing processes represents another environmental concern, with traditional wet chemical methods consuming 15-20 liters per square meter of coating. Dry processing alternatives and closed-loop water recycling systems have demonstrated water consumption reductions exceeding 70% while maintaining coating quality and performance specifications.

Manufacturing processes for UHEC thermal barriers present notable environmental challenges. Traditional production methods often involve energy-intensive sintering processes operating at temperatures exceeding 1400°C, consuming substantial energy and generating significant carbon footprints. Recent innovations in low-temperature synthesis routes, including sol-gel and solution precursor plasma spray techniques, have demonstrated energy requirement reductions of up to 40% compared to conventional methods.

Raw material sustainability represents another critical consideration. Many high-performance thermal barriers incorporate rare earth elements such as yttrium, gadolinium, and lanthanum, which face supply chain vulnerabilities and extraction-related environmental impacts. Research into alternative compositions utilizing more abundant elements shows promising results, with magnesium-aluminum-silicate systems demonstrating comparable performance while reducing dependence on critical materials.

Lifecycle assessment studies reveal that despite energy-intensive production, UHEC thermal barriers deliver net positive environmental impacts through operational efficiency gains. A comprehensive analysis of thermal barrier coatings in industrial gas turbines demonstrated that the embodied carbon from manufacturing is typically offset within 3-6 months of operation through improved efficiency.

End-of-life considerations for UHEC materials present unique challenges due to their complex compositions and integration with substrate materials. Current recycling technologies struggle with efficient separation and recovery of valuable components. Emerging technologies utilizing selective chemical dissolution show potential for recovering up to 85% of rare earth elements from spent thermal barriers, significantly improving circular economy prospects.

Water usage in manufacturing processes represents another environmental concern, with traditional wet chemical methods consuming 15-20 liters per square meter of coating. Dry processing alternatives and closed-loop water recycling systems have demonstrated water consumption reductions exceeding 70% while maintaining coating quality and performance specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!