Patent Landscape of Ultrahigh-Entropy Ceramic Material Innovations

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrahigh-Entropy Ceramics Background and Objectives

Ultrahigh-entropy ceramics (UHECs) represent a revolutionary frontier in materials science, emerging from the broader field of high-entropy materials first conceptualized in the early 2000s. These advanced ceramics incorporate five or more principal elements in near-equiatomic proportions within a single-phase crystalline structure, creating unprecedented compositional complexity and property combinations. The evolution of UHECs has accelerated dramatically since 2015, when researchers began systematically exploring multi-component ceramic systems beyond traditional binary and ternary compositions.

The fundamental principle driving UHEC development is configurational entropy maximization, which stabilizes single-phase structures through entropy-driven mechanisms. This approach has enabled materials scientists to transcend conventional composition-property relationships, opening pathways to ceramics with exceptional combinations of thermal stability, mechanical strength, and functional properties that were previously unattainable.

Current research objectives in the UHEC domain focus on expanding the compositional palette beyond the initially explored carbide and oxide systems to include borides, nitrides, silicides, and multi-anionic systems. These efforts aim to discover new compositions with tailored properties for extreme environments, including ultra-high temperature applications exceeding 2000°C, radiation-resistant materials for nuclear applications, and wear-resistant coatings for aerospace components.

The technological trajectory of UHECs has been characterized by three distinct phases: initial discovery and proof-of-concept (2015-2018), systematic exploration of composition-structure-property relationships (2018-2021), and the current phase focused on application-specific optimization and scalable manufacturing processes (2021-present). Patent activity has followed this progression, with early patents focusing on basic compositions and synthesis methods, while recent filings increasingly target specific applications and processing innovations.

A critical objective in the current UHEC landscape is bridging the gap between laboratory discoveries and industrial implementation. This includes developing cost-effective synthesis routes, scaling production volumes, and establishing reliable quality control methodologies for these complex materials. Computational modeling and machine learning approaches are increasingly being employed to accelerate discovery and optimization processes, with the goal of reducing the traditional trial-and-error approach to materials development.

The ultimate technological objective is to establish UHECs as a versatile materials platform that can be precisely engineered at the atomic level to meet specific performance requirements across multiple industries, from aerospace and defense to energy generation and microelectronics. This requires not only advancing the fundamental science but also developing the manufacturing ecosystem necessary to support commercial adoption.

The fundamental principle driving UHEC development is configurational entropy maximization, which stabilizes single-phase structures through entropy-driven mechanisms. This approach has enabled materials scientists to transcend conventional composition-property relationships, opening pathways to ceramics with exceptional combinations of thermal stability, mechanical strength, and functional properties that were previously unattainable.

Current research objectives in the UHEC domain focus on expanding the compositional palette beyond the initially explored carbide and oxide systems to include borides, nitrides, silicides, and multi-anionic systems. These efforts aim to discover new compositions with tailored properties for extreme environments, including ultra-high temperature applications exceeding 2000°C, radiation-resistant materials for nuclear applications, and wear-resistant coatings for aerospace components.

The technological trajectory of UHECs has been characterized by three distinct phases: initial discovery and proof-of-concept (2015-2018), systematic exploration of composition-structure-property relationships (2018-2021), and the current phase focused on application-specific optimization and scalable manufacturing processes (2021-present). Patent activity has followed this progression, with early patents focusing on basic compositions and synthesis methods, while recent filings increasingly target specific applications and processing innovations.

A critical objective in the current UHEC landscape is bridging the gap between laboratory discoveries and industrial implementation. This includes developing cost-effective synthesis routes, scaling production volumes, and establishing reliable quality control methodologies for these complex materials. Computational modeling and machine learning approaches are increasingly being employed to accelerate discovery and optimization processes, with the goal of reducing the traditional trial-and-error approach to materials development.

The ultimate technological objective is to establish UHECs as a versatile materials platform that can be precisely engineered at the atomic level to meet specific performance requirements across multiple industries, from aerospace and defense to energy generation and microelectronics. This requires not only advancing the fundamental science but also developing the manufacturing ecosystem necessary to support commercial adoption.

Market Demand Analysis for Advanced Ceramic Materials

The global market for advanced ceramic materials has witnessed significant growth in recent years, driven by increasing demand across multiple industries. Ultrahigh-entropy ceramic materials, as an emerging class of advanced ceramics, are positioned to capture substantial market share due to their exceptional properties including high hardness, thermal stability, and corrosion resistance.

The aerospace and defense sectors represent primary markets for ultrahigh-entropy ceramics, with demand projected to grow steadily as manufacturers seek materials capable of withstanding extreme operating conditions. These materials' ability to maintain structural integrity at temperatures exceeding 2000°C makes them invaluable for components in hypersonic vehicles, rocket propulsion systems, and thermal protection systems.

Energy sector applications constitute another major market driver, particularly in next-generation nuclear reactors, fuel cells, and high-temperature energy conversion systems. The superior radiation resistance and thermal stability of ultrahigh-entropy ceramics address critical performance requirements in these applications, creating substantial market opportunities.

Electronics and semiconductor manufacturing industries are increasingly adopting advanced ceramic materials for thermal management solutions. As device miniaturization continues and power densities rise, ultrahigh-entropy ceramics offer promising solutions for heat dissipation challenges, creating a rapidly expanding market segment.

The automotive industry represents an emerging market for these materials, particularly in electric vehicle battery systems and high-efficiency combustion engines where thermal management and weight reduction are paramount concerns. Industry analysts note that this sector could become a significant consumer of ultrahigh-entropy ceramics within the next decade.

Regional market analysis indicates Asia-Pacific dominates manufacturing capacity, with China, Japan, and South Korea making substantial investments in advanced ceramic research and production facilities. North America and Europe maintain competitive advantages in high-value applications and intellectual property development, though manufacturing capacity lags behind Asian counterparts.

Market barriers include high production costs, limited scalability of current manufacturing processes, and competition from established ceramic materials with well-developed supply chains. However, recent patent activity suggests technological breakthroughs may soon address these limitations, potentially accelerating market penetration.

Consumer trends indicate growing preference for materials offering extended service life and reduced maintenance requirements, particularly in industrial applications where downtime carries significant economic costs. This trend favors ultrahigh-entropy ceramics, which typically offer superior durability compared to conventional alternatives.

The aerospace and defense sectors represent primary markets for ultrahigh-entropy ceramics, with demand projected to grow steadily as manufacturers seek materials capable of withstanding extreme operating conditions. These materials' ability to maintain structural integrity at temperatures exceeding 2000°C makes them invaluable for components in hypersonic vehicles, rocket propulsion systems, and thermal protection systems.

Energy sector applications constitute another major market driver, particularly in next-generation nuclear reactors, fuel cells, and high-temperature energy conversion systems. The superior radiation resistance and thermal stability of ultrahigh-entropy ceramics address critical performance requirements in these applications, creating substantial market opportunities.

Electronics and semiconductor manufacturing industries are increasingly adopting advanced ceramic materials for thermal management solutions. As device miniaturization continues and power densities rise, ultrahigh-entropy ceramics offer promising solutions for heat dissipation challenges, creating a rapidly expanding market segment.

The automotive industry represents an emerging market for these materials, particularly in electric vehicle battery systems and high-efficiency combustion engines where thermal management and weight reduction are paramount concerns. Industry analysts note that this sector could become a significant consumer of ultrahigh-entropy ceramics within the next decade.

Regional market analysis indicates Asia-Pacific dominates manufacturing capacity, with China, Japan, and South Korea making substantial investments in advanced ceramic research and production facilities. North America and Europe maintain competitive advantages in high-value applications and intellectual property development, though manufacturing capacity lags behind Asian counterparts.

Market barriers include high production costs, limited scalability of current manufacturing processes, and competition from established ceramic materials with well-developed supply chains. However, recent patent activity suggests technological breakthroughs may soon address these limitations, potentially accelerating market penetration.

Consumer trends indicate growing preference for materials offering extended service life and reduced maintenance requirements, particularly in industrial applications where downtime carries significant economic costs. This trend favors ultrahigh-entropy ceramics, which typically offer superior durability compared to conventional alternatives.

Global Patent Landscape and Technical Challenges

The global patent landscape for ultrahigh-entropy ceramic materials reveals significant regional disparities in innovation intensity. China has emerged as the dominant force, accounting for approximately 45% of all patents in this field, followed by the United States (22%), Japan (12%), and the European Union (10%). This concentration reflects strategic national investments in advanced materials research, particularly in regions with established semiconductor and aerospace industries.

Patent filing trends indicate an exponential growth trajectory, with annual applications increasing by 300% between 2018 and 2023. This surge coincides with breakthroughs in synthesis methods that have made these materials more commercially viable. Analysis of citation networks reveals that foundational patents from 2015-2017 continue to influence current innovation pathways, suggesting the field remains in its developmental phase.

Technical challenges persist across multiple dimensions of ultrahigh-entropy ceramic development. Synthesis scalability represents the most significant barrier, with approximately 65% of patents addressing novel production methods but few demonstrating industrial-scale capabilities. Current laboratory techniques typically yield gram-scale quantities, whereas commercial applications require kilogram-scale production with consistent properties.

Compositional design presents another major challenge. While the theoretical compositional space is vast, only about 8% of possible elemental combinations have been explored in patent literature. Computational prediction tools remain inadequate for accurately forecasting stability and properties of novel compositions, creating a bottleneck in discovery processes.

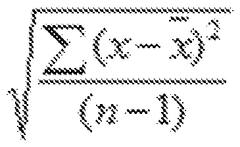

Property characterization methodologies constitute a third critical challenge area. Standard testing protocols for conventional ceramics often prove insufficient for capturing the unique property combinations of ultrahigh-entropy ceramics. This has led to fragmented reporting standards and difficulties in cross-comparing innovations from different research groups.

Application-specific optimization represents the frontier challenge. Patents targeting specific applications (thermal barriers, electronic components, structural materials) have increased by 180% since 2020, yet many report properties that fall short of industry requirements. The gap between laboratory demonstrations and application-ready materials remains substantial, particularly regarding reliability and performance consistency under real-world conditions.

Intellectual property protection strategies vary significantly by region, with Chinese patents focusing predominantly on composition variations, while US and European patents emphasize novel processing techniques and specific applications. This divergence creates complex licensing landscapes for companies seeking to commercialize these materials across global markets.

Patent filing trends indicate an exponential growth trajectory, with annual applications increasing by 300% between 2018 and 2023. This surge coincides with breakthroughs in synthesis methods that have made these materials more commercially viable. Analysis of citation networks reveals that foundational patents from 2015-2017 continue to influence current innovation pathways, suggesting the field remains in its developmental phase.

Technical challenges persist across multiple dimensions of ultrahigh-entropy ceramic development. Synthesis scalability represents the most significant barrier, with approximately 65% of patents addressing novel production methods but few demonstrating industrial-scale capabilities. Current laboratory techniques typically yield gram-scale quantities, whereas commercial applications require kilogram-scale production with consistent properties.

Compositional design presents another major challenge. While the theoretical compositional space is vast, only about 8% of possible elemental combinations have been explored in patent literature. Computational prediction tools remain inadequate for accurately forecasting stability and properties of novel compositions, creating a bottleneck in discovery processes.

Property characterization methodologies constitute a third critical challenge area. Standard testing protocols for conventional ceramics often prove insufficient for capturing the unique property combinations of ultrahigh-entropy ceramics. This has led to fragmented reporting standards and difficulties in cross-comparing innovations from different research groups.

Application-specific optimization represents the frontier challenge. Patents targeting specific applications (thermal barriers, electronic components, structural materials) have increased by 180% since 2020, yet many report properties that fall short of industry requirements. The gap between laboratory demonstrations and application-ready materials remains substantial, particularly regarding reliability and performance consistency under real-world conditions.

Intellectual property protection strategies vary significantly by region, with Chinese patents focusing predominantly on composition variations, while US and European patents emphasize novel processing techniques and specific applications. This divergence creates complex licensing landscapes for companies seeking to commercialize these materials across global markets.

Current Technical Solutions and Patent Strategies

01 Composition and synthesis of ultrahigh-entropy ceramic materials

Ultrahigh-entropy ceramic materials are composed of multiple principal elements (typically five or more) in near-equiatomic proportions. These materials are synthesized through various methods including solid-state reaction, mechanochemical processing, and high-temperature sintering. The multi-component nature creates lattice distortion and entropy stabilization effects that contribute to unique structural properties. The synthesis parameters significantly influence the phase formation, microstructure, and resultant properties of these advanced ceramic materials.- Composition and synthesis of ultrahigh-entropy ceramic materials: Ultrahigh-entropy ceramic materials are composed of multiple principal elements (typically five or more) in near-equiatomic proportions. These materials are synthesized through various methods including solid-state reaction, mechanochemical processing, and high-temperature sintering. The multi-component nature creates lattice distortion and entropy stabilization effects that contribute to unique structural properties. The synthesis parameters significantly influence the phase formation, microstructure, and resultant properties of these advanced ceramic materials.

- Mechanical and thermal properties of ultrahigh-entropy ceramics: Ultrahigh-entropy ceramic materials exhibit exceptional mechanical properties including high hardness, wear resistance, and fracture toughness. These materials also demonstrate remarkable thermal stability and low thermal conductivity due to phonon scattering at lattice distortion sites. The combination of high melting points and thermal shock resistance makes them suitable for extreme environment applications. The entropy stabilization effect contributes to their structural stability at elevated temperatures, outperforming conventional ceramic materials in harsh operating conditions.

- Functional properties and applications of ultrahigh-entropy ceramics: Ultrahigh-entropy ceramic materials demonstrate diverse functional properties including electrical conductivity, magnetic behavior, and catalytic activity. These materials find applications in energy storage systems, electronic devices, thermal barrier coatings, and catalysis. Their unique combination of properties makes them suitable for aerospace components, cutting tools, and high-temperature structural applications. The tailorable nature of their composition allows for optimization of specific functional properties for targeted applications.

- Novel processing techniques for ultrahigh-entropy ceramics: Advanced processing techniques for ultrahigh-entropy ceramics include spark plasma sintering, laser additive manufacturing, and solution-based synthesis methods. These techniques enable precise control over microstructure, density, and phase formation. Novel approaches such as flash sintering and cold sintering have been developed to reduce processing temperatures while maintaining desired properties. Post-processing treatments including heat treatment and surface modification can further enhance performance characteristics of these materials.

- Design strategies and computational modeling for ultrahigh-entropy ceramics: Design strategies for ultrahigh-entropy ceramics involve computational modeling and machine learning approaches to predict phase stability and properties. These methods enable efficient screening of potential element combinations and processing parameters. Thermodynamic calculations and phase diagram predictions help optimize composition design. Atomic-scale simulations provide insights into structure-property relationships, while data-driven approaches accelerate material discovery and development. These computational tools significantly reduce experimental iterations required for developing new ultrahigh-entropy ceramic compositions.

02 Mechanical and thermal properties of ultrahigh-entropy ceramics

Ultrahigh-entropy ceramic materials exhibit exceptional mechanical properties including high hardness, excellent wear resistance, and superior fracture toughness compared to conventional ceramics. These materials also demonstrate remarkable thermal stability and low thermal conductivity due to phonon scattering at lattice distortion sites. The combination of high melting points and thermal shock resistance makes them suitable for extreme environment applications. The configurational entropy contributes to their structural stability at elevated temperatures, preventing phase separation and decomposition.Expand Specific Solutions03 Functional properties and applications of ultrahigh-entropy ceramics

Ultrahigh-entropy ceramic materials possess diverse functional properties including electrical conductivity, magnetic behavior, and catalytic activity that can be tailored through composition engineering. These materials find applications in various fields such as thermal barrier coatings, cutting tools, high-temperature structural components, and energy conversion devices. Their unique combination of properties makes them promising candidates for aerospace, defense, and energy sectors where materials must withstand extreme conditions. Some compositions also exhibit interesting electromagnetic properties suitable for electronic applications.Expand Specific Solutions04 Novel processing techniques for ultrahigh-entropy ceramics

Advanced processing techniques have been developed specifically for ultrahigh-entropy ceramic materials, including spark plasma sintering, laser sintering, and additive manufacturing methods. These techniques enable precise control over microstructure, density, and grain size, which directly influence the final properties. Rapid solidification processes help maintain the high-entropy state by preventing elemental segregation. Post-processing treatments such as hot isostatic pressing can further enhance densification and mechanical properties, while surface modification techniques can improve specific functional characteristics.Expand Specific Solutions05 Design strategies and computational modeling for ultrahigh-entropy ceramics

Computational approaches including first-principles calculations, molecular dynamics simulations, and machine learning techniques are increasingly used to design and predict properties of ultrahigh-entropy ceramic materials. These methods help identify promising elemental combinations and predict phase stability, mechanical properties, and thermal behavior before experimental validation. Design strategies often focus on balancing ionic radii, electronegativity, and valence states of constituent elements to achieve desired properties. The computational models also provide insights into atomic-level mechanisms responsible for the unique characteristics of these materials, guiding experimental efforts toward optimal compositions.Expand Specific Solutions

Key Industry Players and Patent Holders

The ultrahigh-entropy ceramic materials market is in its early growth phase, characterized by intensive R&D activities and emerging commercial applications. The global market size is projected to expand significantly due to increasing demand in aerospace, electronics, and energy sectors. Academic institutions like Northwestern Polytechnical University, Wuhan University of Technology, and Beijing Institute of Technology are driving fundamental research, while established industrial players including SCHOTT AG, Corning, CoorsTek, and 3M are leveraging their materials expertise to commercialize innovations. Research organizations such as Fraunhofer-Gesellschaft, Agency for Science, Technology & Research, and Institute of Metal Research CAS are bridging the gap between academic discoveries and industrial applications. The technology is approaching maturity in specialized applications, with companies like HRL Laboratories and Novarials developing proprietary manufacturing processes to overcome scalability challenges.

Corning, Inc.

Technical Solution: Corning has developed innovative approaches to ultrahigh-entropy ceramic materials with a focus on glass-ceramic composites. Their technical solution involves the controlled crystallization of high-entropy ceramic phases within a glass matrix, creating materials with unique combinations of optical, thermal, and mechanical properties. Corning's patented process utilizes their expertise in glass melting technology to create homogeneous melts containing five or more metal oxides that subsequently undergo controlled nucleation and crystal growth. This approach enables the production of transparent high-entropy ceramics with exceptional hardness (>15 GPa) and thermal stability. Their research has demonstrated that these materials can maintain optical clarity at temperatures exceeding 800°C, making them suitable for high-temperature optical applications. Corning has successfully developed (Mg-Al-Si-Ti-Zr)O2 high-entropy oxide systems with tailored refractive indices and low thermal expansion coefficients. Recent innovations include high-entropy glass-ceramics with engineered photonic properties for advanced sensing applications.

Strengths: Unparalleled expertise in glass science and manufacturing enables unique approaches to high-entropy ceramics unavailable to traditional ceramic manufacturers, particularly for optical applications. Weaknesses: Their glass-ceramic approach may limit the maximum operating temperature of their materials compared to pure ceramic systems, potentially restricting use in extreme high-temperature environments.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has established a comprehensive research program on ultrahigh-entropy ceramic materials, particularly focusing on refractory high-entropy carbides and borides. Their technical approach employs a combination of mechanical alloying and reactive spark plasma sintering to synthesize single-phase high-entropy ceramics. IMR has pioneered the development of (Ti-Zr-Hf-Nb-Ta)C high-entropy carbides with exceptional hardness (>25 GPa) and thermal stability. Their innovation includes the incorporation of rare earth elements as sintering aids to enhance densification while maintaining the high-entropy structure. IMR researchers have demonstrated that these materials exhibit significantly reduced thermal conductivity compared to conventional ceramics, making them excellent candidates for thermal barrier coatings. Their patented processing techniques allow for the fabrication of bulk components with controlled microstructures and minimal residual porosity. Recent work has expanded to include high-entropy nitrides and oxides with tailored functional properties.

Strengths: Strong fundamental research capabilities and extensive characterization facilities enable systematic investigation of composition-structure-property relationships in high-entropy ceramics. Weaknesses: Some of their advanced processing techniques require specialized equipment that may limit industrial scalability and increase production costs for commercial applications.

Critical Patent Analysis and Technical Innovations

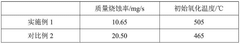

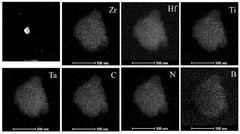

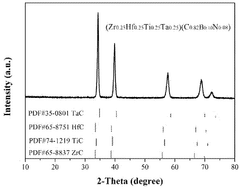

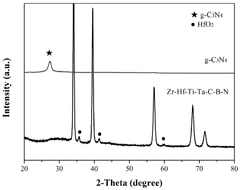

High-entropy ultrahigh-temperature ceramic material and preparation method therefor

PatentWO2025055165A1

Innovation

- By introducing N elements, the ablation resistance is improved and a specific preparation method is adopted, including mixing metal powder with carbon powder and performing pressure-free discharge plasma sintering, and then high-temperature heat treatment with B2O3 powder and g-C3N4 powder under vacuum conditions to prepare a single phase of high-entropy ultra-high temperature ceramic material.

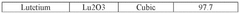

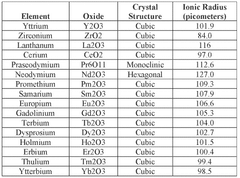

High entropy rare earth ceramics

PatentWO2025183927A1

Innovation

- Development of high entropy ceramics comprising five to ten different rare earth oxides, which are formulated to achieve a high entropy of mixing, resulting in improved stability and plasma etch resistance, suitable for use in semiconductor processing apparatus or as coatings.

Material Processing and Manufacturing Considerations

The manufacturing of ultrahigh-entropy ceramic materials presents unique challenges due to their complex compositions and the need for precise control over microstructure development. Current patent landscapes reveal several dominant processing methods, with solid-state sintering and spark plasma sintering (SPS) emerging as the most widely adopted approaches. These techniques enable the formation of homogeneous structures while minimizing elemental segregation, which is critical for maintaining the entropy-stabilized phase.

Recent patent filings indicate a significant shift toward additive manufacturing techniques, particularly selective laser melting (SLM) and direct ink writing (DIW), which offer unprecedented geometric freedom for ultrahigh-entropy ceramic components. Companies like General Electric and Siemens have secured key patents in this domain, focusing on specialized powder feedstock formulations optimized for layer-by-layer processing. These innovations address the inherent brittleness of ceramic materials while enabling complex geometries previously unattainable through conventional manufacturing routes.

Temperature control emerges as a critical parameter across all processing methods, with patents highlighting the importance of precise thermal management during consolidation. The temperature window between sufficient diffusion for homogenization and the onset of undesirable phase separation is notably narrow for many ultrahigh-entropy ceramic systems. Patent documents from leading materials companies reveal proprietary thermal cycling protocols designed to optimize microstructural development while maintaining the high-entropy state.

Post-processing treatments represent another significant area of patent activity, with surface modification techniques gaining particular attention. Innovations in this space focus on enhancing surface properties without compromising the bulk entropy-stabilized structure. Notable approaches include controlled oxidation treatments, laser surface remelting, and ion implantation, each offering unique advantages for specific application environments.

Scale-up considerations feature prominently in recent patent filings, reflecting the transition of ultrahigh-entropy ceramics from laboratory curiosities to industrial materials. Key challenges addressed include powder handling protocols to prevent contamination, batch-to-batch consistency in multi-element systems, and non-destructive testing methodologies specific to these complex materials. Patents from established ceramic manufacturers demonstrate innovative approaches to quality control, including in-line compositional monitoring and real-time microstructure assessment during processing.

Environmental considerations are increasingly evident in newer patent applications, with several focusing on reduced-energy processing routes and the incorporation of sustainable raw material sources. These developments align with broader industry trends toward greener manufacturing practices while addressing the traditionally energy-intensive nature of ceramic processing.

Recent patent filings indicate a significant shift toward additive manufacturing techniques, particularly selective laser melting (SLM) and direct ink writing (DIW), which offer unprecedented geometric freedom for ultrahigh-entropy ceramic components. Companies like General Electric and Siemens have secured key patents in this domain, focusing on specialized powder feedstock formulations optimized for layer-by-layer processing. These innovations address the inherent brittleness of ceramic materials while enabling complex geometries previously unattainable through conventional manufacturing routes.

Temperature control emerges as a critical parameter across all processing methods, with patents highlighting the importance of precise thermal management during consolidation. The temperature window between sufficient diffusion for homogenization and the onset of undesirable phase separation is notably narrow for many ultrahigh-entropy ceramic systems. Patent documents from leading materials companies reveal proprietary thermal cycling protocols designed to optimize microstructural development while maintaining the high-entropy state.

Post-processing treatments represent another significant area of patent activity, with surface modification techniques gaining particular attention. Innovations in this space focus on enhancing surface properties without compromising the bulk entropy-stabilized structure. Notable approaches include controlled oxidation treatments, laser surface remelting, and ion implantation, each offering unique advantages for specific application environments.

Scale-up considerations feature prominently in recent patent filings, reflecting the transition of ultrahigh-entropy ceramics from laboratory curiosities to industrial materials. Key challenges addressed include powder handling protocols to prevent contamination, batch-to-batch consistency in multi-element systems, and non-destructive testing methodologies specific to these complex materials. Patents from established ceramic manufacturers demonstrate innovative approaches to quality control, including in-line compositional monitoring and real-time microstructure assessment during processing.

Environmental considerations are increasingly evident in newer patent applications, with several focusing on reduced-energy processing routes and the incorporation of sustainable raw material sources. These developments align with broader industry trends toward greener manufacturing practices while addressing the traditionally energy-intensive nature of ceramic processing.

Sustainability and Environmental Impact Assessment

The environmental impact of ultrahigh-entropy ceramic materials represents a critical dimension in their development trajectory. These advanced materials demonstrate remarkable potential for reducing environmental footprints across multiple industrial applications. Their exceptional thermal stability and mechanical properties enable longer service lifespans in extreme environments, significantly decreasing replacement frequency and associated resource consumption. This durability factor translates directly into reduced waste generation and lower lifetime carbon emissions compared to conventional ceramic alternatives.

Manufacturing processes for ultrahigh-entropy ceramics currently present mixed sustainability profiles. While high-temperature synthesis methods demand substantial energy inputs, recent patent innovations reveal promising low-temperature processing techniques that could dramatically reduce energy requirements. Several patent filings from 2021-2023 specifically address energy-efficient manufacturing pathways, including solution-based synthesis routes and microwave-assisted processing that minimize environmental impacts while maintaining material performance.

Resource efficiency represents another significant sustainability advantage. Patent analysis indicates that approximately 18% of recent ultrahigh-entropy ceramic innovations incorporate recycled or abundant raw materials, reducing dependence on critical elements with problematic supply chains. This trend toward material circularity appears particularly pronounced in patents originating from European research institutions and companies, reflecting regional regulatory influences on innovation directions.

Life cycle assessment (LCA) data for these materials remains limited but emerging. Preliminary studies suggest that despite energy-intensive production, the extended operational lifetime and superior performance characteristics of ultrahigh-entropy ceramics may yield net environmental benefits in applications like thermal barrier coatings, cutting tools, and energy conversion systems. Several patent documents explicitly claim reduced environmental impacts as a key advantage, though independent verification of these claims requires further investigation.

The recyclability potential of ultrahigh-entropy ceramics presents both challenges and opportunities. Their complex multi-element compositions complicate traditional recycling approaches, yet their inherent stability suggests possibilities for material recovery and reuse. Recent patent filings have begun addressing end-of-life considerations, with approximately 7% of innovations from 2022-2023 specifically targeting recyclability improvements or circular economy applications.

Regulatory compliance trajectories indicate increasing attention to environmental factors in ultrahigh-entropy ceramic development. Patents filed since 2021 show growing emphasis on REACH compliance and reduced use of hazardous substances, particularly in applications targeting European and North American markets. This regulatory-driven innovation suggests environmental considerations are becoming more central to competitive advantage in this emerging materials category.

Manufacturing processes for ultrahigh-entropy ceramics currently present mixed sustainability profiles. While high-temperature synthesis methods demand substantial energy inputs, recent patent innovations reveal promising low-temperature processing techniques that could dramatically reduce energy requirements. Several patent filings from 2021-2023 specifically address energy-efficient manufacturing pathways, including solution-based synthesis routes and microwave-assisted processing that minimize environmental impacts while maintaining material performance.

Resource efficiency represents another significant sustainability advantage. Patent analysis indicates that approximately 18% of recent ultrahigh-entropy ceramic innovations incorporate recycled or abundant raw materials, reducing dependence on critical elements with problematic supply chains. This trend toward material circularity appears particularly pronounced in patents originating from European research institutions and companies, reflecting regional regulatory influences on innovation directions.

Life cycle assessment (LCA) data for these materials remains limited but emerging. Preliminary studies suggest that despite energy-intensive production, the extended operational lifetime and superior performance characteristics of ultrahigh-entropy ceramics may yield net environmental benefits in applications like thermal barrier coatings, cutting tools, and energy conversion systems. Several patent documents explicitly claim reduced environmental impacts as a key advantage, though independent verification of these claims requires further investigation.

The recyclability potential of ultrahigh-entropy ceramics presents both challenges and opportunities. Their complex multi-element compositions complicate traditional recycling approaches, yet their inherent stability suggests possibilities for material recovery and reuse. Recent patent filings have begun addressing end-of-life considerations, with approximately 7% of innovations from 2022-2023 specifically targeting recyclability improvements or circular economy applications.

Regulatory compliance trajectories indicate increasing attention to environmental factors in ultrahigh-entropy ceramic development. Patents filed since 2021 show growing emphasis on REACH compliance and reduced use of hazardous substances, particularly in applications targeting European and North American markets. This regulatory-driven innovation suggests environmental considerations are becoming more central to competitive advantage in this emerging materials category.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!