Radiation Tolerance and Ionic Transport in UHECs

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHECs Development History and Research Objectives

Ultra-High Entropy Ceramics (UHECs) emerged as an extension of the high entropy alloy concept, first introduced in the early 2000s. The foundational work on high entropy materials began with metallic systems, where researchers discovered that incorporating five or more principal elements in near-equiatomic proportions could create single-phase solid solutions with exceptional properties. This concept was later extended to ceramic systems around 2015, with the first high entropy oxides reported by Rost et al.

The evolution toward UHECs specifically began around 2018-2019, when researchers started exploring ceramic systems with even higher configurational entropy by incorporating six or more elements in the cation sublattice. This development was driven by the need for advanced materials capable of withstanding extreme environments, particularly in nuclear applications, aerospace, and next-generation energy systems.

The field has experienced exponential growth in publications since 2019, with research groups worldwide investigating various UHEC systems including oxides, carbides, borides, and nitrides. The configurational entropy in these systems creates unique atomic arrangements that potentially offer superior radiation tolerance and novel ionic transport properties compared to conventional ceramics.

Radiation tolerance in materials has traditionally been addressed through microstructural engineering or compositional modifications. UHECs represent a paradigm shift in this approach, as their inherent atomic disorder and complex energy landscapes may naturally suppress radiation damage accumulation through enhanced defect recombination and reduced defect migration.

Ionic transport in ceramics is critical for applications in solid-state electrolytes, sensors, and catalysts. The multiple cation species and unique defect structures in UHECs create complex energy landscapes that can potentially facilitate enhanced ionic conductivity through modified migration pathways and activation energies.

The primary objectives of current research on radiation tolerance and ionic transport in UHECs include: understanding the fundamental mechanisms of radiation damage resistance at the atomic scale; establishing structure-property relationships between compositional complexity and functional properties; developing predictive models for designing UHECs with tailored radiation response; optimizing ionic conductivity through compositional and microstructural control; and scaling up synthesis processes for practical applications.

Additionally, researchers aim to explore the synergistic effects between radiation tolerance and ionic transport, as these properties are often interconnected through defect formation and migration processes. The ultimate goal is to develop next-generation ceramic materials that can maintain structural integrity and functional performance under extreme conditions, enabling advances in nuclear energy, space exploration, and sustainable energy technologies.

The evolution toward UHECs specifically began around 2018-2019, when researchers started exploring ceramic systems with even higher configurational entropy by incorporating six or more elements in the cation sublattice. This development was driven by the need for advanced materials capable of withstanding extreme environments, particularly in nuclear applications, aerospace, and next-generation energy systems.

The field has experienced exponential growth in publications since 2019, with research groups worldwide investigating various UHEC systems including oxides, carbides, borides, and nitrides. The configurational entropy in these systems creates unique atomic arrangements that potentially offer superior radiation tolerance and novel ionic transport properties compared to conventional ceramics.

Radiation tolerance in materials has traditionally been addressed through microstructural engineering or compositional modifications. UHECs represent a paradigm shift in this approach, as their inherent atomic disorder and complex energy landscapes may naturally suppress radiation damage accumulation through enhanced defect recombination and reduced defect migration.

Ionic transport in ceramics is critical for applications in solid-state electrolytes, sensors, and catalysts. The multiple cation species and unique defect structures in UHECs create complex energy landscapes that can potentially facilitate enhanced ionic conductivity through modified migration pathways and activation energies.

The primary objectives of current research on radiation tolerance and ionic transport in UHECs include: understanding the fundamental mechanisms of radiation damage resistance at the atomic scale; establishing structure-property relationships between compositional complexity and functional properties; developing predictive models for designing UHECs with tailored radiation response; optimizing ionic conductivity through compositional and microstructural control; and scaling up synthesis processes for practical applications.

Additionally, researchers aim to explore the synergistic effects between radiation tolerance and ionic transport, as these properties are often interconnected through defect formation and migration processes. The ultimate goal is to develop next-generation ceramic materials that can maintain structural integrity and functional performance under extreme conditions, enabling advances in nuclear energy, space exploration, and sustainable energy technologies.

Market Applications and Demand Analysis for UHECs

The market for Ultra-High Entropy Ceramics (UHECs) is experiencing significant growth driven by their exceptional properties, particularly radiation tolerance and ionic transport capabilities. These advanced materials are increasingly sought after in nuclear energy applications, where their ability to withstand extreme radiation environments makes them ideal candidates for reactor components, fuel cladding, and waste containment systems. The global nuclear energy market, valued at approximately $350 billion, presents a substantial opportunity for UHECs implementation.

Aerospace and defense sectors represent another major market for UHECs, with particular demand for thermal protection systems in hypersonic vehicles and spacecraft. The extreme operating conditions of these applications require materials that can maintain structural integrity under both radiation exposure and thermal cycling. Industry analysts project the advanced aerospace materials market to grow at 6.7% annually through 2030, with radiation-resistant ceramics capturing an increasing share.

The semiconductor industry is emerging as a promising application area for UHECs, particularly in radiation-hardened electronics for space applications and nuclear facilities. As miniaturization continues and electronic components are deployed in increasingly harsh environments, the demand for radiation-tolerant materials is expected to rise substantially. The radiation-hardened electronics market currently exceeds $1.5 billion and is projected to expand at over 3% annually.

Energy storage systems represent another growth sector for UHECs, leveraging their unique ionic transport properties. Solid-state batteries and fuel cells utilizing high-entropy ceramic electrolytes could potentially overcome current limitations in energy density and operating temperature ranges. The global energy storage market, growing at 20% annually, presents significant opportunities for innovative materials with enhanced ionic conductivity.

Medical applications, particularly in radiotherapy equipment and radiation shielding, constitute a specialized but high-value market segment for UHECs. Their ability to maintain performance under repeated radiation exposure makes them valuable in diagnostic and treatment technologies. The medical radiation shielding market is expected to reach $1.1 billion by 2027.

Regional market analysis indicates that North America and Europe currently lead in UHEC research and application development, driven by established nuclear and aerospace industries. However, Asia-Pacific markets, particularly China, Japan, and South Korea, are investing heavily in advanced ceramics research, suggesting future market expansion in these regions.

Customer demand is increasingly focused on customizable UHEC formulations that can be optimized for specific operating environments and performance requirements, indicating a trend toward application-specific material development rather than one-size-fits-all solutions.

Aerospace and defense sectors represent another major market for UHECs, with particular demand for thermal protection systems in hypersonic vehicles and spacecraft. The extreme operating conditions of these applications require materials that can maintain structural integrity under both radiation exposure and thermal cycling. Industry analysts project the advanced aerospace materials market to grow at 6.7% annually through 2030, with radiation-resistant ceramics capturing an increasing share.

The semiconductor industry is emerging as a promising application area for UHECs, particularly in radiation-hardened electronics for space applications and nuclear facilities. As miniaturization continues and electronic components are deployed in increasingly harsh environments, the demand for radiation-tolerant materials is expected to rise substantially. The radiation-hardened electronics market currently exceeds $1.5 billion and is projected to expand at over 3% annually.

Energy storage systems represent another growth sector for UHECs, leveraging their unique ionic transport properties. Solid-state batteries and fuel cells utilizing high-entropy ceramic electrolytes could potentially overcome current limitations in energy density and operating temperature ranges. The global energy storage market, growing at 20% annually, presents significant opportunities for innovative materials with enhanced ionic conductivity.

Medical applications, particularly in radiotherapy equipment and radiation shielding, constitute a specialized but high-value market segment for UHECs. Their ability to maintain performance under repeated radiation exposure makes them valuable in diagnostic and treatment technologies. The medical radiation shielding market is expected to reach $1.1 billion by 2027.

Regional market analysis indicates that North America and Europe currently lead in UHEC research and application development, driven by established nuclear and aerospace industries. However, Asia-Pacific markets, particularly China, Japan, and South Korea, are investing heavily in advanced ceramics research, suggesting future market expansion in these regions.

Customer demand is increasingly focused on customizable UHEC formulations that can be optimized for specific operating environments and performance requirements, indicating a trend toward application-specific material development rather than one-size-fits-all solutions.

Current Status and Challenges in UHECs Research

Ultra-High Entropy Ceramics (UHECs) represent an emerging frontier in materials science, with global research efforts intensifying over the past five years. Currently, research teams across North America, Europe, and East Asia are making significant strides in understanding the fundamental properties and potential applications of these complex ceramic systems. The incorporation of five or more principal elements in near-equimolar ratios has created materials with unprecedented structural complexity and promising performance characteristics.

The current state of UHECs research demonstrates remarkable progress in synthesis methodologies, with solid-state reaction, high-energy ball milling, and solution-based approaches showing varying degrees of success. However, achieving phase purity and compositional homogeneity remains challenging, particularly for systems with elements having significantly different ionic radii or electronegativity values. Recent advances in spark plasma sintering and flash sintering have improved densification processes, though optimal parameters vary widely across different UHEC compositions.

Radiation tolerance studies of UHECs are still in nascent stages, with preliminary results suggesting exceptional resistance to amorphization under ion irradiation compared to conventional ceramics. This enhanced radiation tolerance is hypothesized to stem from the inherent lattice distortion and chemical disorder that create energy dissipation pathways. However, systematic studies correlating entropy effects with radiation damage mechanisms are limited, creating a significant knowledge gap in the field.

Ionic transport properties in UHECs present another critical research challenge. The complex interplay between multiple cations creates unique defect structures and diffusion pathways that are not fully understood. Initial studies indicate that some UHEC compositions exhibit superior ionic conductivity compared to their conventional counterparts, potentially due to the high concentration of lattice distortions facilitating ion migration. Nevertheless, comprehensive investigations of transport mechanisms across diverse UHEC systems are lacking.

Computational modeling of UHECs faces substantial hurdles due to the combinatorial complexity of these systems. Current density functional theory approaches struggle with the large supercells required to accurately represent the statistical distribution of elements. Machine learning potentials show promise but require extensive experimental validation data that is not yet widely available.

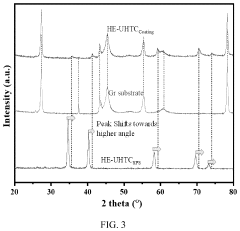

Characterization techniques also present limitations, as traditional X-ray diffraction analysis becomes increasingly challenging with the addition of more elements and resultant peak broadening. Advanced techniques such as atom probe tomography and aberration-corrected transmission electron microscopy are proving essential but are not universally accessible to all research groups.

The scalable production of UHECs represents perhaps the most significant barrier to industrial application, with current laboratory-scale synthesis methods proving difficult to scale while maintaining compositional control and microstructural uniformity. This manufacturing challenge must be addressed before the promising radiation tolerance and ionic transport properties of UHECs can be harnessed in practical applications.

The current state of UHECs research demonstrates remarkable progress in synthesis methodologies, with solid-state reaction, high-energy ball milling, and solution-based approaches showing varying degrees of success. However, achieving phase purity and compositional homogeneity remains challenging, particularly for systems with elements having significantly different ionic radii or electronegativity values. Recent advances in spark plasma sintering and flash sintering have improved densification processes, though optimal parameters vary widely across different UHEC compositions.

Radiation tolerance studies of UHECs are still in nascent stages, with preliminary results suggesting exceptional resistance to amorphization under ion irradiation compared to conventional ceramics. This enhanced radiation tolerance is hypothesized to stem from the inherent lattice distortion and chemical disorder that create energy dissipation pathways. However, systematic studies correlating entropy effects with radiation damage mechanisms are limited, creating a significant knowledge gap in the field.

Ionic transport properties in UHECs present another critical research challenge. The complex interplay between multiple cations creates unique defect structures and diffusion pathways that are not fully understood. Initial studies indicate that some UHEC compositions exhibit superior ionic conductivity compared to their conventional counterparts, potentially due to the high concentration of lattice distortions facilitating ion migration. Nevertheless, comprehensive investigations of transport mechanisms across diverse UHEC systems are lacking.

Computational modeling of UHECs faces substantial hurdles due to the combinatorial complexity of these systems. Current density functional theory approaches struggle with the large supercells required to accurately represent the statistical distribution of elements. Machine learning potentials show promise but require extensive experimental validation data that is not yet widely available.

Characterization techniques also present limitations, as traditional X-ray diffraction analysis becomes increasingly challenging with the addition of more elements and resultant peak broadening. Advanced techniques such as atom probe tomography and aberration-corrected transmission electron microscopy are proving essential but are not universally accessible to all research groups.

The scalable production of UHECs represents perhaps the most significant barrier to industrial application, with current laboratory-scale synthesis methods proving difficult to scale while maintaining compositional control and microstructural uniformity. This manufacturing challenge must be addressed before the promising radiation tolerance and ionic transport properties of UHECs can be harnessed in practical applications.

Current Methodologies for Enhancing Radiation Tolerance

01 Radiation tolerance mechanisms in UHECs

Ultra-High Entropy Ceramics (UHECs) exhibit exceptional radiation tolerance due to their unique atomic structure and compositional complexity. The high entropy configuration creates numerous defect sinks and recombination sites that can effectively absorb and neutralize radiation damage. The multiple principal elements in these ceramics create distorted lattices that can accommodate radiation-induced defects without significant structural degradation, making them promising materials for nuclear applications and space environments where radiation exposure is severe.- Radiation tolerance mechanisms in UHECs: Ultra-High Entropy Ceramics (UHECs) exhibit exceptional radiation tolerance due to their unique atomic structure and compositional complexity. The multiple elements in these ceramics create distorted lattices that can effectively absorb and dissipate radiation energy. The high configurational entropy in these materials leads to enhanced defect recombination and self-healing properties when exposed to radiation. This intrinsic radiation resistance makes UHECs promising materials for nuclear applications and space technology where radiation exposure is significant.

- Ionic transport properties in UHECs: The ionic transport behavior in Ultra-High Entropy Ceramics is characterized by complex diffusion pathways created by the diverse atomic species present in the material. The high configurational entropy and lattice distortion in UHECs create numerous low-energy migration paths for ions, potentially enhancing ionic conductivity. These properties can be tailored by adjusting the elemental composition and processing conditions, making UHECs promising for applications in solid-state electrolytes, fuel cells, and other energy storage and conversion technologies.

- Synthesis and processing techniques for UHECs: Advanced synthesis methods for Ultra-High Entropy Ceramics include high-energy ball milling, spark plasma sintering, and solution-based approaches. These techniques are crucial for achieving homogeneous elemental distribution and controlling the microstructure, which directly impacts the radiation tolerance and ionic transport properties. Post-processing treatments such as annealing can further optimize the atomic arrangement and defect concentration in UHECs, enhancing their performance in extreme environments. The processing parameters significantly influence the phase stability and functional properties of these complex ceramic systems.

- Compositional design strategies for UHECs: The performance of Ultra-High Entropy Ceramics can be systematically enhanced through strategic compositional design. By incorporating elements with varying atomic radii, electronegativity, and valence states, researchers can create UHECs with tailored properties for specific applications. The selection of constituent elements affects the material's radiation tolerance by influencing defect formation energies and recombination rates. Similarly, ionic transport can be optimized by including elements that create favorable diffusion channels or modify the local charge environment. Computational methods are increasingly being used to predict optimal compositions before experimental validation.

- Applications of UHECs in extreme environments: Ultra-High Entropy Ceramics are finding applications in environments where conventional materials fail due to extreme conditions. Their exceptional radiation tolerance makes them suitable for nuclear reactor components, waste immobilization matrices, and space vehicle thermal protection systems. The enhanced ionic transport properties of certain UHEC compositions enable their use in high-temperature electrochemical devices operating in harsh environments. Additionally, these materials show promise for fusion energy systems, where they must withstand intense neutron bombardment while maintaining structural integrity and functional properties. The multifunctional nature of UHECs allows them to address multiple challenges simultaneously in extreme operating conditions.

02 Ionic transport properties in UHECs

The ionic transport behavior in Ultra-High Entropy Ceramics is characterized by complex diffusion pathways created by the diverse atomic species present in the lattice. This compositional disorder leads to varied energy barriers for ion migration, which can be tailored to enhance specific ionic conductivity properties. The high configurational entropy in these materials creates numerous interstitial sites and vacancies that facilitate ion movement, making them potential candidates for solid-state electrolytes and other applications requiring controlled ionic transport.Expand Specific Solutions03 Synthesis methods for radiation-resistant UHECs

Advanced synthesis techniques have been developed to create Ultra-High Entropy Ceramics with enhanced radiation resistance. These methods include high-energy ball milling, spark plasma sintering, and solution-based approaches that enable precise control over composition and microstructure. By optimizing processing parameters such as temperature, pressure, and cooling rates, researchers can create UHECs with tailored grain boundaries and phase distributions that maximize radiation tolerance while maintaining desired mechanical and thermal properties.Expand Specific Solutions04 Compositional design strategies for UHECs

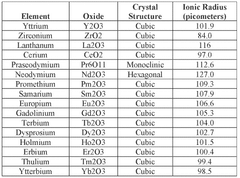

Strategic selection of constituent elements in Ultra-High Entropy Ceramics can significantly enhance both radiation tolerance and ionic transport properties. By incorporating elements with varied atomic radii and electronegativity, researchers can create engineered disorder that traps radiation-induced defects while facilitating specific ionic movement. The incorporation of rare earth elements, transition metals, and metalloids in specific ratios has been shown to create synergistic effects that improve performance under extreme radiation conditions while maintaining structural stability.Expand Specific Solutions05 Characterization techniques for radiation effects in UHECs

Specialized characterization methods have been developed to evaluate radiation damage and ionic transport in Ultra-High Entropy Ceramics. These include in-situ transmission electron microscopy during ion irradiation, positron annihilation spectroscopy to detect atomic-scale defects, and impedance spectroscopy to measure ionic conductivity changes. Advanced computational modeling approaches, including molecular dynamics simulations and density functional theory, complement experimental techniques by predicting radiation damage mechanisms and ionic diffusion pathways at atomic scales, enabling rational design of more radiation-resistant materials.Expand Specific Solutions

Leading Research Institutions and Industry Players

Ultra-High Entropy Ceramics (UHECs) research for radiation tolerance and ionic transport is in an early development stage, with growing interest due to potential applications in extreme environments. The market is expanding, driven by aerospace, nuclear, and electronics sectors, though still relatively niche compared to established ceramic markets. Technical maturity varies significantly among key players: academic institutions like MIT, National University of Defense Technology, and Central South University lead fundamental research, while companies including Air Products & Chemicals, Sumitomo Electric, and 3M are advancing practical applications. Research collaborations between national laboratories (Lawrence Livermore, Sandia) and universities are accelerating development, with significant progress in understanding structure-property relationships in these complex ceramic systems.

National University of Defense Technology

Technical Solution: The National University of Defense Technology has established a specialized research center focused on Ultra-High Entropy Ceramics for nuclear and defense applications. Their approach combines theoretical modeling with experimental validation to design radiation-resistant ceramic materials. They've developed novel high-entropy oxide and carbide systems with exceptional radiation tolerance, particularly (Ti,Zr,Hf,Nb,Ta)C and (Y,Yb,Sc,Gd,Eu)2O3 compositions. Their research methodology employs advanced ion beam facilities to simulate radiation damage, coupled with in-situ TEM observation to track defect evolution in real-time. They've demonstrated that the severe lattice distortion and chemical disorder in UHECs create efficient defect sinks that enhance radiation tolerance. For ionic transport studies, they've pioneered the use of advanced impedance spectroscopy techniques to characterize ion migration in these complex systems. Their research has shown that certain UHEC compositions can maintain structural integrity after heavy ion irradiation at doses exceeding 150 dpa, while simultaneously exhibiting controlled ionic conductivity that can be tuned through composition and processing.

Strengths: Strong integration of theory and experiment allows for rational design of UHEC compositions with targeted properties. Their specialized ion beam facilities enable precise characterization of radiation effects. Weaknesses: Research is primarily focused on defense applications, potentially limiting broader commercial applications and international collaboration opportunities.

Central South University

Technical Solution: Central South University has developed a comprehensive research program on Ultra-High Entropy Ceramics with dual focus on radiation tolerance and ionic transport properties. Their approach centers on novel synthesis methods including sol-gel processing and reactive spark plasma sintering to create high-density UHECs with controlled grain structures. They've pioneered the development of high-entropy rare-earth silicates (RE,RE',RE'',RE''',RE'''')2SiO5 systems that demonstrate exceptional radiation resistance due to their complex crystal structures and energy dissipation mechanisms. Their research has revealed that the high configurational entropy in these systems creates numerous defect sinks that enhance radiation tolerance by promoting defect recombination rather than accumulation. For ionic transport studies, they've developed specialized impedance spectroscopy techniques to characterize ion migration pathways and activation energies in these complex ceramic systems. Their work has demonstrated that certain UHEC compositions can maintain structural integrity after heavy ion irradiation at doses exceeding 100 dpa while exhibiting controlled ionic conductivity that can be tuned through composition and processing parameters.

Strengths: Exceptional capabilities in synthesis and characterization of rare-earth containing UHECs, with specialized facilities for radiation testing and ionic transport measurements. Their integrated approach allows for systematic investigation of composition-structure-property relationships. Weaknesses: Heavy focus on silicate-based systems may limit the exploration of other promising UHEC compositions with potentially superior properties.

Key Mechanisms of Ionic Transport in UHECs

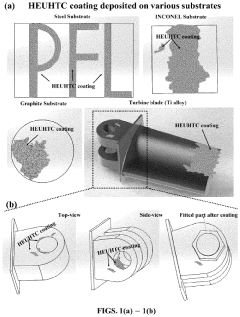

High-entropy ultra-high temperature ceramic (he-UHTC) coatings and deposition methods thereof

PatentActiveUS20230406776A1

Innovation

- The development of a method involving spark plasma sintering (SPS) to fabricate an HE-UHTC electrode, followed by precision-controlled electro-spark deposition of thin HE-UHTC coatings on electrically conductive substrates, such as steel, graphite, and titanium-based alloys, without pre-treatment, ensuring thermal stability and adherence.

High entropy rare earth ceramics

PatentWO2025183927A1

Innovation

- Development of high entropy ceramics comprising five to ten different rare earth oxides, which are formulated to achieve a high entropy of mixing, resulting in improved stability and plasma etch resistance, suitable for use in semiconductor processing apparatus or as coatings.

Safety Standards and Nuclear Regulatory Considerations

The implementation of Ultra-High Entropy Ceramics (UHECs) in nuclear environments necessitates adherence to stringent safety standards and regulatory frameworks. Current nuclear regulatory bodies, including the International Atomic Energy Agency (IAEA), the Nuclear Regulatory Commission (NRC) in the United States, and the European Nuclear Safety Regulators Group (ENSREG), have established comprehensive guidelines for materials used in nuclear applications.

These regulatory frameworks primarily focus on radiation shielding capabilities, structural integrity under extreme conditions, and long-term stability of materials. UHECs must demonstrate compliance with standards such as 10 CFR Part 50 (USA) and IAEA Safety Standards Series No. SSR-2/1, which outline requirements for design and operation of nuclear power plants, including material specifications.

Radiation tolerance testing protocols for UHECs must align with established methodologies like ASTM E521 for neutron irradiation effects and ASTM E1649 for charged-particle irradiation. Additionally, the ionic transport properties of UHECs require evaluation under standards such as ASTM C1174 for waste form performance testing, particularly relevant for applications in nuclear waste immobilization.

The licensing process for new materials in nuclear applications involves multiple stages of verification and validation. UHECs must undergo accelerated aging tests to simulate decades of radiation exposure, with data collection on microstructural changes, mechanical property degradation, and ionic transport behavior under various radiation conditions.

Environmental impact assessments represent another critical regulatory consideration. Regulations such as the Environmental Protection Agency's 40 CFR Part 190 establish environmental radiation protection standards for nuclear operations, requiring thorough evaluation of UHECs' environmental footprint throughout their lifecycle.

International harmonization of standards presents ongoing challenges, as different countries maintain varying regulatory requirements. The IAEA's efforts to standardize nuclear safety frameworks globally through its Safety Standards Series provide a foundation for cross-border acceptance of UHECs technologies.

Future regulatory developments will likely focus on establishing specific standards for advanced materials like UHECs, potentially creating dedicated testing protocols that address their unique multi-element compositions and complex phase structures. Research institutions developing UHECs should maintain active engagement with regulatory bodies to ensure alignment between innovation trajectories and evolving safety standards.

These regulatory frameworks primarily focus on radiation shielding capabilities, structural integrity under extreme conditions, and long-term stability of materials. UHECs must demonstrate compliance with standards such as 10 CFR Part 50 (USA) and IAEA Safety Standards Series No. SSR-2/1, which outline requirements for design and operation of nuclear power plants, including material specifications.

Radiation tolerance testing protocols for UHECs must align with established methodologies like ASTM E521 for neutron irradiation effects and ASTM E1649 for charged-particle irradiation. Additionally, the ionic transport properties of UHECs require evaluation under standards such as ASTM C1174 for waste form performance testing, particularly relevant for applications in nuclear waste immobilization.

The licensing process for new materials in nuclear applications involves multiple stages of verification and validation. UHECs must undergo accelerated aging tests to simulate decades of radiation exposure, with data collection on microstructural changes, mechanical property degradation, and ionic transport behavior under various radiation conditions.

Environmental impact assessments represent another critical regulatory consideration. Regulations such as the Environmental Protection Agency's 40 CFR Part 190 establish environmental radiation protection standards for nuclear operations, requiring thorough evaluation of UHECs' environmental footprint throughout their lifecycle.

International harmonization of standards presents ongoing challenges, as different countries maintain varying regulatory requirements. The IAEA's efforts to standardize nuclear safety frameworks globally through its Safety Standards Series provide a foundation for cross-border acceptance of UHECs technologies.

Future regulatory developments will likely focus on establishing specific standards for advanced materials like UHECs, potentially creating dedicated testing protocols that address their unique multi-element compositions and complex phase structures. Research institutions developing UHECs should maintain active engagement with regulatory bodies to ensure alignment between innovation trajectories and evolving safety standards.

Environmental Impact and Sustainability of UHECs

The environmental impact and sustainability of Ultra-High Entropy Ceramics (UHECs) represent critical considerations as these advanced materials gain prominence in various applications. UHECs offer significant environmental advantages compared to traditional ceramics and metals, particularly in their potential for reduced energy consumption during manufacturing processes. The multi-element composition of UHECs allows for lower sintering temperatures, potentially decreasing the carbon footprint associated with high-temperature ceramic production.

Resource efficiency constitutes another important environmental benefit of UHECs. Their exceptional radiation tolerance and ionic transport properties enable longer service lifetimes in extreme environments, reducing the frequency of replacement and consequently minimizing waste generation. This aspect is particularly valuable in nuclear applications, where component longevity directly impacts the sustainability of energy production systems.

The raw material sourcing for UHECs presents both challenges and opportunities from a sustainability perspective. While some constituent elements may involve environmentally intensive mining operations, the high entropy design principle allows for compositional flexibility. This adaptability creates potential for incorporating more abundant and less environmentally harmful elements without compromising performance characteristics.

End-of-life considerations for UHECs remain an emerging area of research. Their complex multi-element compositions may complicate recycling processes compared to simpler materials. However, preliminary studies suggest that selective recovery of valuable elements from spent UHECs could be economically viable, potentially creating closed-loop material cycles that minimize environmental impact.

The application of UHECs in clean energy technologies further enhances their sustainability profile. Their superior performance in extreme environments makes them ideal candidates for next-generation nuclear reactors, hydrogen production systems, and advanced energy storage devices. By enabling these technologies, UHECs may indirectly contribute to broader decarbonization efforts beyond their direct manufacturing impacts.

Life cycle assessment (LCA) studies of UHECs remain limited but are essential for comprehensive sustainability evaluation. Initial comparative analyses suggest that despite potentially higher environmental impacts during production phases, the extended service life and enhanced performance of UHECs may yield net environmental benefits over complete product lifecycles when compared to conventional alternatives.

Regulatory frameworks governing the environmental aspects of UHEC production and application are still evolving. As research progresses, establishing appropriate environmental standards and best practices for this emerging material class will be crucial to ensure their development aligns with broader sustainability goals and circular economy principles.

Resource efficiency constitutes another important environmental benefit of UHECs. Their exceptional radiation tolerance and ionic transport properties enable longer service lifetimes in extreme environments, reducing the frequency of replacement and consequently minimizing waste generation. This aspect is particularly valuable in nuclear applications, where component longevity directly impacts the sustainability of energy production systems.

The raw material sourcing for UHECs presents both challenges and opportunities from a sustainability perspective. While some constituent elements may involve environmentally intensive mining operations, the high entropy design principle allows for compositional flexibility. This adaptability creates potential for incorporating more abundant and less environmentally harmful elements without compromising performance characteristics.

End-of-life considerations for UHECs remain an emerging area of research. Their complex multi-element compositions may complicate recycling processes compared to simpler materials. However, preliminary studies suggest that selective recovery of valuable elements from spent UHECs could be economically viable, potentially creating closed-loop material cycles that minimize environmental impact.

The application of UHECs in clean energy technologies further enhances their sustainability profile. Their superior performance in extreme environments makes them ideal candidates for next-generation nuclear reactors, hydrogen production systems, and advanced energy storage devices. By enabling these technologies, UHECs may indirectly contribute to broader decarbonization efforts beyond their direct manufacturing impacts.

Life cycle assessment (LCA) studies of UHECs remain limited but are essential for comprehensive sustainability evaluation. Initial comparative analyses suggest that despite potentially higher environmental impacts during production phases, the extended service life and enhanced performance of UHECs may yield net environmental benefits over complete product lifecycles when compared to conventional alternatives.

Regulatory frameworks governing the environmental aspects of UHEC production and application are still evolving. As research progresses, establishing appropriate environmental standards and best practices for this emerging material class will be crucial to ensure their development aligns with broader sustainability goals and circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!