UHECs for Aerospace and Hypersonic Structural Components

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHECs Development History and Objectives

Ultra-High-Entropy Ceramics (UHECs) represent a revolutionary class of materials that emerged from the broader field of high-entropy materials research. The concept of high-entropy alloys first appeared in the early 2000s, but the extension to ceramic systems only gained significant attention around 2015. UHECs are characterized by incorporating five or more principal elements in near-equimolar ratios within a single-phase ceramic structure, creating unique property combinations through entropy stabilization.

The development trajectory of UHECs has been marked by several key milestones. Initial research focused primarily on high-entropy oxides, with the first systematic studies published in 2015-2016. By 2018, researchers expanded the concept to non-oxide ceramics, including carbides, borides, and nitrides, which demonstrated exceptional thermal stability and mechanical properties at extreme temperatures. The period from 2019-2021 saw rapid acceleration in UHEC research globally, with particular emphasis on their potential for aerospace applications.

Current UHEC research is driven by the critical need for materials that can withstand the extreme conditions encountered in hypersonic flight environments. Conventional materials face severe limitations when exposed to temperatures exceeding 2000°C while simultaneously enduring oxidative atmospheres and mechanical stresses. This performance gap has become increasingly problematic as aerospace technologies advance toward hypersonic capabilities (Mach 5+).

The primary technical objectives for UHEC development center on achieving unprecedented combinations of properties: ultra-high temperature stability (>2500°C), exceptional oxidation resistance, superior mechanical strength retention at elevated temperatures, and thermal shock resistance. Additionally, researchers aim to develop scalable manufacturing processes that can transition these materials from laboratory curiosities to industrially viable components.

Recent advances in computational materials science have accelerated UHEC development through machine learning approaches that can predict promising elemental combinations from vast compositional possibilities. This computational guidance has significantly reduced experimental iterations required to discover optimal formulations. Concurrently, novel processing techniques including spark plasma sintering, additive manufacturing, and reactive hot pressing have emerged as viable fabrication routes.

The long-term objective of UHEC research extends beyond merely matching current material capabilities. The vision encompasses creating a new generation of structural ceramics that enable transformative aerospace technologies, including reusable hypersonic vehicles, advanced rocket propulsion systems, and thermal protection systems that can withstand multiple mission cycles without degradation. This would represent a paradigm shift in aerospace material capabilities, potentially unlocking new flight regimes and mission profiles previously considered impossible.

The development trajectory of UHECs has been marked by several key milestones. Initial research focused primarily on high-entropy oxides, with the first systematic studies published in 2015-2016. By 2018, researchers expanded the concept to non-oxide ceramics, including carbides, borides, and nitrides, which demonstrated exceptional thermal stability and mechanical properties at extreme temperatures. The period from 2019-2021 saw rapid acceleration in UHEC research globally, with particular emphasis on their potential for aerospace applications.

Current UHEC research is driven by the critical need for materials that can withstand the extreme conditions encountered in hypersonic flight environments. Conventional materials face severe limitations when exposed to temperatures exceeding 2000°C while simultaneously enduring oxidative atmospheres and mechanical stresses. This performance gap has become increasingly problematic as aerospace technologies advance toward hypersonic capabilities (Mach 5+).

The primary technical objectives for UHEC development center on achieving unprecedented combinations of properties: ultra-high temperature stability (>2500°C), exceptional oxidation resistance, superior mechanical strength retention at elevated temperatures, and thermal shock resistance. Additionally, researchers aim to develop scalable manufacturing processes that can transition these materials from laboratory curiosities to industrially viable components.

Recent advances in computational materials science have accelerated UHEC development through machine learning approaches that can predict promising elemental combinations from vast compositional possibilities. This computational guidance has significantly reduced experimental iterations required to discover optimal formulations. Concurrently, novel processing techniques including spark plasma sintering, additive manufacturing, and reactive hot pressing have emerged as viable fabrication routes.

The long-term objective of UHEC research extends beyond merely matching current material capabilities. The vision encompasses creating a new generation of structural ceramics that enable transformative aerospace technologies, including reusable hypersonic vehicles, advanced rocket propulsion systems, and thermal protection systems that can withstand multiple mission cycles without degradation. This would represent a paradigm shift in aerospace material capabilities, potentially unlocking new flight regimes and mission profiles previously considered impossible.

Aerospace Market Demand Analysis for UHECs

The aerospace industry is witnessing unprecedented demand for advanced materials capable of withstanding extreme conditions, particularly in hypersonic applications. The global aerospace materials market, valued at approximately $25.8 billion in 2022, is projected to reach $42.3 billion by 2030, with a CAGR of 6.4%. Within this expanding market, Ultra-High-Entropy Ceramics (UHECs) represent a revolutionary material class poised to address critical performance gaps.

Hypersonic vehicle development programs across major aerospace powers—United States, China, Russia, and emerging players like India—are driving substantial demand for thermal protection systems and structural components that can withstand temperatures exceeding 2000°C while maintaining structural integrity. The U.S. Department of Defense has allocated $3.8 billion specifically for hypersonic technology development in fiscal year 2023, with material solutions being a priority investment area.

Commercial space companies are simultaneously creating market pull for UHECs. SpaceX, Blue Origin, and others are developing reusable launch vehicles requiring materials that can survive multiple atmospheric re-entries. This reusability imperative has created a projected market segment for advanced ceramic materials estimated at $1.2 billion by 2028.

Defense applications represent the largest immediate market opportunity for UHECs. Hypersonic missiles, scramjet engines, and next-generation aircraft require materials that maintain performance under extreme thermal gradients and oxidative environments. The global hypersonic technology market is expected to grow at 8.5% annually through 2030, with materials accounting for approximately 22% of development costs.

Satellite manufacturers are increasingly seeking lightweight, high-temperature materials for thermal management systems and radiation shields. The small satellite market, growing at 16.4% annually, requires innovative materials solutions that reduce mass while improving thermal performance—a niche where UHECs show particular promise.

Market analysis reveals that aerospace customers prioritize three critical performance metrics for UHECs: temperature capability (particularly above 2200°C), oxidation resistance in high-velocity airflows, and mechanical property retention at elevated temperatures. Secondary considerations include manufacturing scalability, integration compatibility with existing aerospace systems, and long-term reliability under cyclic loading conditions.

Regional market distribution shows North America leading UHEC demand (42%), followed by Asia-Pacific (31%) and Europe (21%). This distribution aligns with major hypersonic development programs and defense spending patterns. Industry surveys indicate that 78% of aerospace materials engineers consider current material limitations a primary bottleneck in hypersonic vehicle development, highlighting the significant market opportunity for UHECs that can overcome these limitations.

Hypersonic vehicle development programs across major aerospace powers—United States, China, Russia, and emerging players like India—are driving substantial demand for thermal protection systems and structural components that can withstand temperatures exceeding 2000°C while maintaining structural integrity. The U.S. Department of Defense has allocated $3.8 billion specifically for hypersonic technology development in fiscal year 2023, with material solutions being a priority investment area.

Commercial space companies are simultaneously creating market pull for UHECs. SpaceX, Blue Origin, and others are developing reusable launch vehicles requiring materials that can survive multiple atmospheric re-entries. This reusability imperative has created a projected market segment for advanced ceramic materials estimated at $1.2 billion by 2028.

Defense applications represent the largest immediate market opportunity for UHECs. Hypersonic missiles, scramjet engines, and next-generation aircraft require materials that maintain performance under extreme thermal gradients and oxidative environments. The global hypersonic technology market is expected to grow at 8.5% annually through 2030, with materials accounting for approximately 22% of development costs.

Satellite manufacturers are increasingly seeking lightweight, high-temperature materials for thermal management systems and radiation shields. The small satellite market, growing at 16.4% annually, requires innovative materials solutions that reduce mass while improving thermal performance—a niche where UHECs show particular promise.

Market analysis reveals that aerospace customers prioritize three critical performance metrics for UHECs: temperature capability (particularly above 2200°C), oxidation resistance in high-velocity airflows, and mechanical property retention at elevated temperatures. Secondary considerations include manufacturing scalability, integration compatibility with existing aerospace systems, and long-term reliability under cyclic loading conditions.

Regional market distribution shows North America leading UHEC demand (42%), followed by Asia-Pacific (31%) and Europe (21%). This distribution aligns with major hypersonic development programs and defense spending patterns. Industry surveys indicate that 78% of aerospace materials engineers consider current material limitations a primary bottleneck in hypersonic vehicle development, highlighting the significant market opportunity for UHECs that can overcome these limitations.

Global Research Status and Technical Barriers

Ultra-High-Entropy Ceramics (UHECs) represent the frontier of materials science, with global research efforts intensifying over the past decade. Leading research institutions in the United States, including MIT, UC Berkeley, and national laboratories, have established dedicated programs focusing on UHECs for extreme environment applications. Their work has primarily centered on developing high-temperature stable compositions and understanding phase stability mechanisms.

European research, particularly in Germany and France, has made significant contributions to the fundamental understanding of entropy stabilization mechanisms in ceramic systems. The European Space Agency has funded several initiatives exploring UHECs for thermal protection systems in next-generation spacecraft, with notable advances in processing techniques for complex compositions.

In Asia, China has emerged as a major player with substantial investments in both academic and defense-related UHEC research. Chinese institutions have published extensively on novel synthesis methods and have demonstrated promising results in hypersonic vehicle applications. Japan and South Korea focus more on the electronic and functional properties of these materials, complementing the structural applications research.

Despite global progress, significant technical barriers persist. The primary challenge remains the processing of homogeneous UHECs with consistent properties. Traditional ceramic processing routes often result in compositional segregation or unwanted secondary phases when dealing with five or more principal elements. The extreme processing temperatures required (often exceeding 1800°C) also present equipment limitations and energy efficiency concerns.

Another critical barrier is the limited understanding of structure-property relationships in these complex systems. The vast compositional space of UHECs makes systematic investigation challenging, with current predictive models struggling to account for the complex interactions between multiple elements. This knowledge gap hinders targeted design of compositions for specific aerospace applications.

Testing under relevant hypersonic conditions presents another significant obstacle. Few facilities worldwide can accurately simulate the combined thermal, mechanical, and oxidative stresses experienced during hypersonic flight. This limitation creates a disconnect between laboratory characterization and actual performance prediction.

Additionally, scalability remains problematic. While laboratory-scale samples show promising properties, scaling production to component-level sizes while maintaining homogeneity and performance has proven difficult. This manufacturing barrier significantly impacts the technology readiness level of UHECs for actual aerospace implementation.

European research, particularly in Germany and France, has made significant contributions to the fundamental understanding of entropy stabilization mechanisms in ceramic systems. The European Space Agency has funded several initiatives exploring UHECs for thermal protection systems in next-generation spacecraft, with notable advances in processing techniques for complex compositions.

In Asia, China has emerged as a major player with substantial investments in both academic and defense-related UHEC research. Chinese institutions have published extensively on novel synthesis methods and have demonstrated promising results in hypersonic vehicle applications. Japan and South Korea focus more on the electronic and functional properties of these materials, complementing the structural applications research.

Despite global progress, significant technical barriers persist. The primary challenge remains the processing of homogeneous UHECs with consistent properties. Traditional ceramic processing routes often result in compositional segregation or unwanted secondary phases when dealing with five or more principal elements. The extreme processing temperatures required (often exceeding 1800°C) also present equipment limitations and energy efficiency concerns.

Another critical barrier is the limited understanding of structure-property relationships in these complex systems. The vast compositional space of UHECs makes systematic investigation challenging, with current predictive models struggling to account for the complex interactions between multiple elements. This knowledge gap hinders targeted design of compositions for specific aerospace applications.

Testing under relevant hypersonic conditions presents another significant obstacle. Few facilities worldwide can accurately simulate the combined thermal, mechanical, and oxidative stresses experienced during hypersonic flight. This limitation creates a disconnect between laboratory characterization and actual performance prediction.

Additionally, scalability remains problematic. While laboratory-scale samples show promising properties, scaling production to component-level sizes while maintaining homogeneity and performance has proven difficult. This manufacturing barrier significantly impacts the technology readiness level of UHECs for actual aerospace implementation.

Current UHEC Synthesis and Processing Methods

01 Composition and synthesis of UHECs

Ultra-High-Entropy Ceramics (UHECs) are composed of multiple principal elements (typically five or more) in near-equiatomic proportions, creating a high configurational entropy. These ceramics can be synthesized through various methods including high-temperature solid-state reactions, mechanochemical processing, and sol-gel techniques. The composition typically includes transition metals, rare earth elements, and non-metals like carbon, nitrogen, or oxygen, forming complex structures with enhanced stability due to the entropy effect.- Composition and structure of Ultra-High-Entropy Ceramics: Ultra-High-Entropy Ceramics (UHECs) are advanced materials composed of multiple principal elements (typically five or more) in near-equiatomic proportions. These ceramics feature a single-phase crystal structure with high configurational entropy, which contributes to their unique properties. The composition typically includes various metal elements combined with non-metals such as carbon, nitrogen, or oxygen to form carbides, nitrides, or oxides. The high-entropy effect stabilizes the crystal structure and enhances material properties through lattice distortion and solid solution strengthening mechanisms.

- Synthesis methods for UHECs: Various synthesis methods are employed to produce Ultra-High-Entropy Ceramics, including solid-state reaction, mechanochemical processing, spark plasma sintering, and sol-gel techniques. High-energy ball milling is commonly used to achieve homogeneous mixing of precursor powders, followed by high-temperature consolidation processes. Other approaches include self-propagating high-temperature synthesis, reactive spark plasma sintering, and chemical vapor deposition. These methods aim to achieve uniform element distribution and controlled microstructure, which are critical for optimizing the properties of UHECs.

- Mechanical and thermal properties of UHECs: Ultra-High-Entropy Ceramics exhibit exceptional mechanical and thermal properties, including high hardness, excellent wear resistance, and superior thermal stability. The unique atomic arrangement and strong bonding in these materials contribute to their high elastic modulus and fracture toughness. UHECs typically maintain their structural integrity and mechanical properties at elevated temperatures, making them suitable for extreme environment applications. The sluggish diffusion kinetics resulting from the high-entropy effect enhances their resistance to thermal degradation and creep, while the lattice distortion improves phonon scattering, leading to lower thermal conductivity.

- Functional applications of UHECs: Ultra-High-Entropy Ceramics find applications in various high-performance fields due to their unique combination of properties. They are used as cutting tools, wear-resistant components, and thermal barrier coatings in aerospace and automotive industries. Their excellent oxidation and corrosion resistance make them suitable for harsh chemical environments. UHECs also show promise in energy applications such as solid oxide fuel cells, thermoelectric devices, and radiation shielding materials. Additionally, some compositions exhibit interesting electromagnetic properties, making them potential candidates for electronic components and sensors operating under extreme conditions.

- Advanced characterization and modeling of UHECs: Advanced characterization techniques and computational modeling play crucial roles in understanding and developing Ultra-High-Entropy Ceramics. Methods such as high-resolution transmission electron microscopy, atom probe tomography, and synchrotron-based X-ray techniques are employed to analyze the atomic structure, element distribution, and phase composition. Computational approaches including density functional theory, molecular dynamics simulations, and CALPHAD modeling help predict phase stability, mechanical properties, and thermal behavior. These tools enable researchers to establish structure-property relationships, optimize compositions, and design new UHEC systems with tailored properties for specific applications.

02 Mechanical and thermal properties of UHECs

UHECs exhibit exceptional mechanical and thermal properties, including high hardness, fracture toughness, and thermal stability at elevated temperatures. The multi-element composition creates lattice distortion and solid solution strengthening, contributing to superior mechanical performance compared to conventional ceramics. These materials maintain structural integrity under extreme conditions, showing resistance to thermal shock and creep, making them suitable for high-temperature applications where conventional ceramics would fail.Expand Specific Solutions03 Functional properties and applications of UHECs

UHECs demonstrate unique functional properties including tailorable electrical conductivity, magnetic behavior, and catalytic activity. These ceramics can be engineered to exhibit semiconducting, dielectric, or even superconducting properties by adjusting their composition. Applications include high-temperature electronics, energy storage systems, catalysts for chemical reactions, and components for extreme environments such as aerospace, nuclear reactors, and cutting tools. The ability to fine-tune their properties makes them versatile materials for advanced technological applications.Expand Specific Solutions04 Microstructure and phase stability of UHECs

The microstructure of UHECs is characterized by unique phase compositions that can include single-phase solid solutions or controlled multi-phase structures. The high configurational entropy contributes to exceptional phase stability, suppressing phase separation even at elevated temperatures. Advanced characterization techniques reveal complex atomic arrangements, grain boundaries, and defect structures that influence material properties. The entropy-stabilized structures often show resistance to grain growth and phase transformation, maintaining their properties over extended periods under severe conditions.Expand Specific Solutions05 Processing techniques and performance optimization for UHECs

Various processing techniques are employed to fabricate UHECs with controlled microstructures and enhanced properties. These include spark plasma sintering, hot isostatic pressing, additive manufacturing, and thin film deposition methods. Post-processing treatments such as annealing and surface modifications can further optimize performance characteristics. Research focuses on developing cost-effective processing routes that enable scaling up production while maintaining the unique properties of these complex ceramic systems. Computational methods are increasingly used to predict optimal compositions and processing parameters.Expand Specific Solutions

Leading Institutions and Competitive Landscape

The Ultra-High-Entropy Ceramics (UHECs) market for aerospace and hypersonic applications is in its early growth phase, characterized by intensive R&D activities across academic, governmental, and industrial sectors. The global market is projected to expand significantly as hypersonic technology advances, with current estimates in the hundreds of millions but potential to reach billions within the decade. Leading players include national defense institutions (National University of Defense Technology, Naval Research Laboratory), major aerospace corporations (General Electric, Honeywell), specialized ceramic manufacturers (CoorsTek, NGK Insulators), and research-focused universities (Northwestern Polytechnical University, Central South University). Technical maturity remains moderate, with significant challenges in scalable manufacturing and performance validation under extreme conditions, though recent breakthroughs in multi-component ceramic systems by Shanghai Jiao Tong University and Lawrence Livermore National Laboratory are accelerating commercialization pathways.

Northwestern Polytechnical University

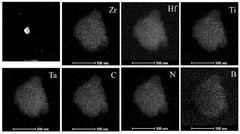

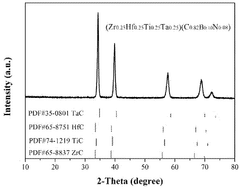

Technical Solution: Northwestern Polytechnical University (NPU) has established a comprehensive technical approach to Ultra-High-Entropy Ceramics focused on aerospace applications. Their solution employs a combination of sol-gel processing and reactive spark plasma sintering to create high-entropy ceramic composites with exceptional thermal and mechanical properties. NPU has developed (Zr,Hf,Ti,Ta,Nb)C and (Zr,Hf,Ti,Ta,Nb)B2 systems with controlled microstructures featuring grain sizes below 2 μm, which contribute to enhanced mechanical properties. Their research has demonstrated that these UHECs maintain structural stability at temperatures exceeding 2000°C with oxidation rates significantly lower than conventional ultra-high temperature ceramics. NPU's technical approach includes the incorporation of SiC as a secondary phase to improve fracture toughness, achieving values of 5-7 MPa·m1/2 while maintaining high-temperature stability[7]. Their materials exhibit thermal conductivity values of 12-18 W/m·K and thermal expansion coefficients of 6-8 × 10-6/K, making them suitable for thermal protection systems in hypersonic vehicles. NPU has also pioneered the development of gradient-structured UHECs that can withstand thermal shock conditions with temperature differentials exceeding 1200°C[8].

Strengths: Strong integration of fundamental research with practical aerospace applications; extensive experience in ceramic processing techniques; established collaboration network with Chinese aerospace industry. Weaknesses: Potential limitations in international collaboration due to strategic nature of research; challenges in scaling laboratory processes to industrial production; relatively newer entrant to the field compared to some Western institutions.

General Electric Company

Technical Solution: General Electric has developed a sophisticated technical approach to Ultra-High-Entropy Ceramics for aerospace applications, leveraging their extensive experience in high-temperature materials for jet engines. Their solution focuses on developing multi-principal element ceramic systems that combine carbides, borides, and nitrides to create tailored properties for specific aerospace applications. GE utilizes a proprietary reactive hot pressing technique that achieves near-theoretical density (>99%) while maintaining nanocrystalline grain structures below 500 nm. Their research has demonstrated that (Hf,Zr,Ta,Ti,Cr)C-based UHECs exhibit exceptional oxidation resistance at temperatures up to 1800°C, with parabolic rate constants an order of magnitude lower than traditional carbides[9]. GE has pioneered the integration of these materials into ceramic matrix composites (CMCs) for turbine components, achieving temperature capabilities 200-300°C higher than current superalloy systems. Their UHECs demonstrate creep resistance at 1600°C with strain rates below 10-8 s-1 under stresses of 100 MPa, making them suitable for long-duration hypersonic flight applications. GE has also developed specialized coating systems based on high-entropy oxides that provide additional oxidation protection while maintaining thermal barrier properties, with thermal conductivities as low as 1.5 W/m·K[10].

Strengths: Extensive industrial experience in high-temperature materials; established manufacturing infrastructure for scaling production; clear pathway to commercial implementation in aerospace systems. Weaknesses: Research primarily focused on proprietary applications may limit academic collaboration; higher production costs compared to conventional ceramics; challenges in certifying novel materials for aerospace applications.

Key Patents and Breakthroughs in UHEC Technology

Metallic multicomponent carbides

PatentActiveUS12017920B2

Innovation

- Multicomponent carbides comprising at least five transition metals with a valence electron concentration greater than 8.80, specifically designed to enhance mechanical properties through optimized valence electron configurations, allowing for increased ductility and toughness, are synthesized using varying transition metal compositions and sintering techniques.

High-entropy ultrahigh-temperature ceramic material and preparation method therefor

PatentWO2025055165A1

Innovation

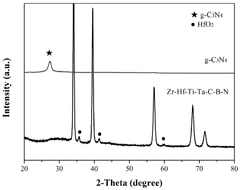

- By introducing N elements, the ablation resistance is improved and a specific preparation method is adopted, including mixing metal powder with carbon powder and performing pressure-free discharge plasma sintering, and then high-temperature heat treatment with B2O3 powder and g-C3N4 powder under vacuum conditions to prepare a single phase of high-entropy ultra-high temperature ceramic material.

Material Performance Testing Standards

The development of Ultra-High-Entropy Ceramics (UHECs) for aerospace applications necessitates rigorous performance testing standards to ensure material reliability under extreme conditions. Current testing frameworks for UHECs must evaluate thermal stability, mechanical integrity, and oxidation resistance at temperatures exceeding 2000°C and under hypersonic flight conditions.

Standard high-temperature mechanical testing protocols include four-point flexural strength tests (ASTM C1161), fracture toughness measurements (ASTM C1421), and creep resistance evaluations (ASTM C1291) modified for ultra-high temperature conditions. These tests must be conducted in controlled environments simulating reentry conditions, including rapid temperature fluctuations and oxidizing atmospheres.

Thermal shock resistance testing follows modified versions of ASTM C1525, with specimens subjected to rapid heating-cooling cycles between room temperature and 2000°C. The retention of mechanical properties after multiple thermal cycles serves as a critical performance indicator for UHECs in hypersonic applications.

Oxidation behavior testing requires specialized protocols beyond conventional standards. Weight change measurements during isothermal and cyclic oxidation at temperatures up to 2200°C in flowing air provide insights into oxidation kinetics. X-ray diffraction (XRD) and electron microscopy analyses of oxide scales complement these measurements to characterize phase stability and microstructural evolution.

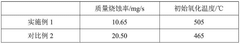

Ablation resistance testing employs oxyacetylene torch tests (ASTM E285) and plasma wind tunnel facilities to simulate aerothermal heating during hypersonic flight. Mass loss rates, recession rates, and surface temperature measurements during these tests serve as key performance metrics for UHECs as thermal protection materials.

Non-destructive evaluation techniques, including ultrasonic testing (ASTM E494) and thermography, have been adapted for UHECs to detect internal defects and assess material homogeneity. These methods are particularly valuable for quality control during manufacturing and for periodic inspection of components in service.

Specialized testing standards for UHECs must also address their unique multi-element compositions. Compositional homogeneity testing using electron probe microanalysis (EPMA) and atom probe tomography (APT) has become essential to verify the uniform distribution of five or more principal elements within the ceramic matrix, ensuring consistent performance across the material volume.

International standardization efforts for UHECs testing remain in nascent stages, with collaborative initiatives between NASA, ESA, and aerospace materials research institutions working to establish unified protocols. These emerging standards will be crucial for certification of UHEC components in next-generation hypersonic vehicles and spacecraft.

Standard high-temperature mechanical testing protocols include four-point flexural strength tests (ASTM C1161), fracture toughness measurements (ASTM C1421), and creep resistance evaluations (ASTM C1291) modified for ultra-high temperature conditions. These tests must be conducted in controlled environments simulating reentry conditions, including rapid temperature fluctuations and oxidizing atmospheres.

Thermal shock resistance testing follows modified versions of ASTM C1525, with specimens subjected to rapid heating-cooling cycles between room temperature and 2000°C. The retention of mechanical properties after multiple thermal cycles serves as a critical performance indicator for UHECs in hypersonic applications.

Oxidation behavior testing requires specialized protocols beyond conventional standards. Weight change measurements during isothermal and cyclic oxidation at temperatures up to 2200°C in flowing air provide insights into oxidation kinetics. X-ray diffraction (XRD) and electron microscopy analyses of oxide scales complement these measurements to characterize phase stability and microstructural evolution.

Ablation resistance testing employs oxyacetylene torch tests (ASTM E285) and plasma wind tunnel facilities to simulate aerothermal heating during hypersonic flight. Mass loss rates, recession rates, and surface temperature measurements during these tests serve as key performance metrics for UHECs as thermal protection materials.

Non-destructive evaluation techniques, including ultrasonic testing (ASTM E494) and thermography, have been adapted for UHECs to detect internal defects and assess material homogeneity. These methods are particularly valuable for quality control during manufacturing and for periodic inspection of components in service.

Specialized testing standards for UHECs must also address their unique multi-element compositions. Compositional homogeneity testing using electron probe microanalysis (EPMA) and atom probe tomography (APT) has become essential to verify the uniform distribution of five or more principal elements within the ceramic matrix, ensuring consistent performance across the material volume.

International standardization efforts for UHECs testing remain in nascent stages, with collaborative initiatives between NASA, ESA, and aerospace materials research institutions working to establish unified protocols. These emerging standards will be crucial for certification of UHEC components in next-generation hypersonic vehicles and spacecraft.

Supply Chain Security and Strategic Implications

The development and deployment of Ultra-High-Entropy Ceramics (UHECs) for aerospace and hypersonic applications present significant supply chain challenges and strategic implications that extend beyond technical considerations. The raw materials required for UHECs, including rare earth elements and specialized transition metals, are geographically concentrated in specific regions, creating potential vulnerabilities in the supply chain.

China currently dominates the global production of rare earth elements essential for certain UHEC formulations, controlling approximately 85% of processing capacity worldwide. This concentration creates strategic dependencies for Western aerospace manufacturers and defense contractors seeking to develop advanced hypersonic capabilities. Recent trade tensions and export restrictions have further highlighted the risks associated with such dependencies.

Alternative material sourcing strategies are emerging, with countries like Australia, Canada, and the United States investing in domestic rare earth mining and processing capabilities. However, establishing robust alternative supply chains requires significant time and capital investment, estimated at 5-10 years and billions of dollars to reach competitive scale.

The manufacturing processes for UHECs demand specialized equipment and expertise that are similarly concentrated among a limited number of suppliers. Key production technologies, such as spark plasma sintering and high-pressure high-temperature processing, rely on equipment from a small number of manufacturers in Japan, Germany, and the United States. This equipment concentration creates additional supply chain bottlenecks.

From a national security perspective, UHECs represent a critical technology with dual-use implications. Their exceptional performance characteristics at extreme temperatures make them valuable for both civilian aerospace applications and military hypersonic weapons systems. Consequently, several nations have implemented export controls and technology transfer restrictions related to advanced ceramic materials and manufacturing processes.

The strategic importance of UHECs has prompted increased government funding for research and development in this field. The United States Department of Defense has allocated over $500 million for advanced materials research related to hypersonic applications, while similar initiatives exist in China, Russia, and the European Union. These investments reflect recognition of UHECs as a strategically important technology domain with implications for military superiority and technological leadership.

Developing robust domestic supply chains for UHECs will likely require coordinated public-private partnerships, strategic stockpiling of critical materials, and international agreements with allied nations to ensure material availability during potential supply disruptions. Companies investing in UHEC technologies must carefully consider these geopolitical factors alongside technical performance metrics when planning long-term research and production strategies.

China currently dominates the global production of rare earth elements essential for certain UHEC formulations, controlling approximately 85% of processing capacity worldwide. This concentration creates strategic dependencies for Western aerospace manufacturers and defense contractors seeking to develop advanced hypersonic capabilities. Recent trade tensions and export restrictions have further highlighted the risks associated with such dependencies.

Alternative material sourcing strategies are emerging, with countries like Australia, Canada, and the United States investing in domestic rare earth mining and processing capabilities. However, establishing robust alternative supply chains requires significant time and capital investment, estimated at 5-10 years and billions of dollars to reach competitive scale.

The manufacturing processes for UHECs demand specialized equipment and expertise that are similarly concentrated among a limited number of suppliers. Key production technologies, such as spark plasma sintering and high-pressure high-temperature processing, rely on equipment from a small number of manufacturers in Japan, Germany, and the United States. This equipment concentration creates additional supply chain bottlenecks.

From a national security perspective, UHECs represent a critical technology with dual-use implications. Their exceptional performance characteristics at extreme temperatures make them valuable for both civilian aerospace applications and military hypersonic weapons systems. Consequently, several nations have implemented export controls and technology transfer restrictions related to advanced ceramic materials and manufacturing processes.

The strategic importance of UHECs has prompted increased government funding for research and development in this field. The United States Department of Defense has allocated over $500 million for advanced materials research related to hypersonic applications, while similar initiatives exist in China, Russia, and the European Union. These investments reflect recognition of UHECs as a strategically important technology domain with implications for military superiority and technological leadership.

Developing robust domestic supply chains for UHECs will likely require coordinated public-private partnerships, strategic stockpiling of critical materials, and international agreements with allied nations to ensure material availability during potential supply disruptions. Companies investing in UHEC technologies must carefully consider these geopolitical factors alongside technical performance metrics when planning long-term research and production strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!