High-Temperature Oxidation and Evaporation Behavior of UHECs

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHEC Oxidation Background and Research Objectives

Ultra-high entropy ceramics (UHECs) represent a revolutionary class of materials that have emerged as potential candidates for extreme environment applications, particularly in aerospace, nuclear, and hypersonic vehicle sectors. These ceramics, characterized by their incorporation of five or more principal elements in near-equiatomic proportions, exhibit exceptional thermodynamic stability and unique property combinations that conventional ceramics cannot match. The development of UHECs has evolved from high-entropy alloys research, with the first significant publications appearing around 2015, marking the beginning of an exponential growth in research interest worldwide.

The oxidation behavior of UHECs at ultra-high temperatures (above 1600°C) remains one of the most critical aspects determining their practical applicability in extreme environments. Historical attempts to develop materials capable of withstanding such conditions have been limited by catastrophic oxidation failure, material evaporation, and microstructural degradation. Previous generations of ultra-high temperature ceramics (UHTCs) based on transition metal diborides and carbides showed promise but still suffered from accelerated oxidation at temperatures exceeding 2000°C.

The fundamental challenge lies in understanding the complex phase transformations, oxidation kinetics, and evaporation mechanisms that occur when multi-principal element ceramics are exposed to high-temperature oxidizing environments. Traditional oxidation theories developed for conventional ceramics often fail to accurately predict the behavior of these compositionally complex systems, necessitating new theoretical frameworks and experimental methodologies.

Current research objectives in this field focus on several interconnected areas. First, establishing comprehensive oxidation mechanism models specific to UHECs that account for their unique compositional complexity and entropy effects. Second, quantifying the relationship between compositional design and oxidation resistance to enable rational material development. Third, investigating the role of entropy stabilization in preventing catastrophic oxidation and enhancing phase stability at extreme temperatures.

Additionally, this research aims to develop advanced characterization techniques capable of in-situ monitoring of oxidation processes at temperatures exceeding 2000°C, which presents significant technical challenges. The ultimate goal is to establish design principles for next-generation UHECs with predictable and controlled oxidation behavior, enabling their implementation in critical applications such as hypersonic vehicle thermal protection systems, rocket propulsion components, and advanced nuclear systems.

The technological significance of this research extends beyond materials science, potentially enabling transformative capabilities in aerospace propulsion, space exploration, and energy generation systems where current materials represent a limiting factor in system performance and reliability.

The oxidation behavior of UHECs at ultra-high temperatures (above 1600°C) remains one of the most critical aspects determining their practical applicability in extreme environments. Historical attempts to develop materials capable of withstanding such conditions have been limited by catastrophic oxidation failure, material evaporation, and microstructural degradation. Previous generations of ultra-high temperature ceramics (UHTCs) based on transition metal diborides and carbides showed promise but still suffered from accelerated oxidation at temperatures exceeding 2000°C.

The fundamental challenge lies in understanding the complex phase transformations, oxidation kinetics, and evaporation mechanisms that occur when multi-principal element ceramics are exposed to high-temperature oxidizing environments. Traditional oxidation theories developed for conventional ceramics often fail to accurately predict the behavior of these compositionally complex systems, necessitating new theoretical frameworks and experimental methodologies.

Current research objectives in this field focus on several interconnected areas. First, establishing comprehensive oxidation mechanism models specific to UHECs that account for their unique compositional complexity and entropy effects. Second, quantifying the relationship between compositional design and oxidation resistance to enable rational material development. Third, investigating the role of entropy stabilization in preventing catastrophic oxidation and enhancing phase stability at extreme temperatures.

Additionally, this research aims to develop advanced characterization techniques capable of in-situ monitoring of oxidation processes at temperatures exceeding 2000°C, which presents significant technical challenges. The ultimate goal is to establish design principles for next-generation UHECs with predictable and controlled oxidation behavior, enabling their implementation in critical applications such as hypersonic vehicle thermal protection systems, rocket propulsion components, and advanced nuclear systems.

The technological significance of this research extends beyond materials science, potentially enabling transformative capabilities in aerospace propulsion, space exploration, and energy generation systems where current materials represent a limiting factor in system performance and reliability.

Market Analysis for High-Temperature Materials

The high-temperature materials market has experienced substantial growth in recent years, driven primarily by increasing demands in aerospace, defense, energy, and industrial sectors. The global market for ultra-high-temperature ceramics (UHTCs) and ultra-high entropy ceramics (UHECs) was valued at approximately $4.8 billion in 2022 and is projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 7.1%.

Aerospace and defense applications currently dominate the market share, accounting for nearly 40% of the total demand. This is largely attributed to the critical need for materials capable of withstanding extreme temperatures in hypersonic vehicles, rocket propulsion systems, and thermal protection systems. The commercial space industry's rapid expansion has further accelerated demand, with companies like SpaceX, Blue Origin, and established aerospace manufacturers increasing their procurement of advanced high-temperature materials.

The energy sector represents the second-largest market segment, with applications in gas turbines, nuclear reactors, and concentrated solar power systems. This sector is expected to grow at the fastest rate due to global energy transition initiatives and increasing investments in next-generation nuclear technologies. The industrial sector, particularly in glass manufacturing, metal processing, and chemical production, constitutes approximately 25% of the market.

Regionally, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the highest growth rate, driven by China's ambitious aerospace and energy programs, along with Japan's and South Korea's investments in advanced materials research.

Customer requirements are increasingly focused on materials that can maintain structural integrity and resist oxidation at temperatures exceeding 2000°C. The market shows a clear preference for materials with improved oxidation resistance, as evidenced by the 30% premium commanded by oxidation-resistant variants compared to their conventional counterparts.

Supply chain challenges represent a significant market constraint, with rare earth elements and specialized processing equipment facing availability issues. This has resulted in price volatility, with some high-temperature materials experiencing price increases of 15-20% in the past two years. Additionally, the specialized nature of manufacturing processes has created a concentrated supplier landscape, with the top five manufacturers controlling approximately 60% of global production capacity.

Market forecasts indicate continued strong growth, particularly for materials demonstrating superior oxidation and evaporation resistance at ultra-high temperatures, as these properties directly address the performance limitations in current extreme environment applications.

Aerospace and defense applications currently dominate the market share, accounting for nearly 40% of the total demand. This is largely attributed to the critical need for materials capable of withstanding extreme temperatures in hypersonic vehicles, rocket propulsion systems, and thermal protection systems. The commercial space industry's rapid expansion has further accelerated demand, with companies like SpaceX, Blue Origin, and established aerospace manufacturers increasing their procurement of advanced high-temperature materials.

The energy sector represents the second-largest market segment, with applications in gas turbines, nuclear reactors, and concentrated solar power systems. This sector is expected to grow at the fastest rate due to global energy transition initiatives and increasing investments in next-generation nuclear technologies. The industrial sector, particularly in glass manufacturing, metal processing, and chemical production, constitutes approximately 25% of the market.

Regionally, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the highest growth rate, driven by China's ambitious aerospace and energy programs, along with Japan's and South Korea's investments in advanced materials research.

Customer requirements are increasingly focused on materials that can maintain structural integrity and resist oxidation at temperatures exceeding 2000°C. The market shows a clear preference for materials with improved oxidation resistance, as evidenced by the 30% premium commanded by oxidation-resistant variants compared to their conventional counterparts.

Supply chain challenges represent a significant market constraint, with rare earth elements and specialized processing equipment facing availability issues. This has resulted in price volatility, with some high-temperature materials experiencing price increases of 15-20% in the past two years. Additionally, the specialized nature of manufacturing processes has created a concentrated supplier landscape, with the top five manufacturers controlling approximately 60% of global production capacity.

Market forecasts indicate continued strong growth, particularly for materials demonstrating superior oxidation and evaporation resistance at ultra-high temperatures, as these properties directly address the performance limitations in current extreme environment applications.

Current Challenges in UHEC Oxidation Resistance

Ultra-high entropy ceramics (UHECs) represent a frontier in materials science, offering exceptional mechanical properties and thermal stability. However, their oxidation resistance at extreme temperatures remains a significant challenge that impedes broader industrial application. Current UHECs typically begin to exhibit accelerated oxidation at temperatures exceeding 1200°C, with dramatic degradation occurring above 1600°C in oxygen-containing environments.

The primary oxidation mechanism involves the formation of complex oxide scales that often lack protective qualities due to their porous nature and poor adherence to the substrate. Unlike traditional ceramics, UHECs contain multiple principal elements (typically five or more) in near-equimolar ratios, creating unique oxidation behaviors where preferential oxidation of certain elements disrupts the formation of continuous protective scales.

Volatilization of oxide species presents another critical challenge. Several common elements in UHECs form volatile oxides at high temperatures, including molybdenum, tungsten, and certain borides. This evaporation process creates continuous mass loss and prevents the establishment of stable oxide barriers, particularly problematic in high-velocity gas flows typical in aerospace applications.

Phase stability during oxidation represents a third major hurdle. The multi-element composition of UHECs leads to complex phase transformations during oxidation, often resulting in volume changes that induce cracking and spallation of protective scales. The entropy stabilization effect, while beneficial for mechanical properties, becomes compromised during oxidation as oxygen diffusion pathways develop along phase boundaries.

Interdiffusion between substrate and oxide layers further complicates the oxidation resistance. The migration of elements across this interface creates composition gradients that can trigger the formation of undesirable phases with poor mechanical properties. This phenomenon is particularly pronounced in UHECs containing transition metals with multiple oxidation states.

Current testing methodologies also present limitations in accurately predicting long-term oxidation behavior. Standard isothermal and cyclic oxidation tests often fail to replicate the complex service conditions UHECs would encounter in applications like hypersonic vehicles or advanced turbine systems. The lack of standardized testing protocols specifically designed for UHECs hampers comparative analysis across different material systems.

Manufacturing inconsistencies further exacerbate oxidation challenges. Variations in processing parameters lead to microstructural heterogeneities that create preferential oxidation sites. Achieving consistent density and eliminating processing defects remain significant hurdles in producing UHECs with reproducible oxidation resistance properties.

The primary oxidation mechanism involves the formation of complex oxide scales that often lack protective qualities due to their porous nature and poor adherence to the substrate. Unlike traditional ceramics, UHECs contain multiple principal elements (typically five or more) in near-equimolar ratios, creating unique oxidation behaviors where preferential oxidation of certain elements disrupts the formation of continuous protective scales.

Volatilization of oxide species presents another critical challenge. Several common elements in UHECs form volatile oxides at high temperatures, including molybdenum, tungsten, and certain borides. This evaporation process creates continuous mass loss and prevents the establishment of stable oxide barriers, particularly problematic in high-velocity gas flows typical in aerospace applications.

Phase stability during oxidation represents a third major hurdle. The multi-element composition of UHECs leads to complex phase transformations during oxidation, often resulting in volume changes that induce cracking and spallation of protective scales. The entropy stabilization effect, while beneficial for mechanical properties, becomes compromised during oxidation as oxygen diffusion pathways develop along phase boundaries.

Interdiffusion between substrate and oxide layers further complicates the oxidation resistance. The migration of elements across this interface creates composition gradients that can trigger the formation of undesirable phases with poor mechanical properties. This phenomenon is particularly pronounced in UHECs containing transition metals with multiple oxidation states.

Current testing methodologies also present limitations in accurately predicting long-term oxidation behavior. Standard isothermal and cyclic oxidation tests often fail to replicate the complex service conditions UHECs would encounter in applications like hypersonic vehicles or advanced turbine systems. The lack of standardized testing protocols specifically designed for UHECs hampers comparative analysis across different material systems.

Manufacturing inconsistencies further exacerbate oxidation challenges. Variations in processing parameters lead to microstructural heterogeneities that create preferential oxidation sites. Achieving consistent density and eliminating processing defects remain significant hurdles in producing UHECs with reproducible oxidation resistance properties.

State-of-the-Art Oxidation Protection Solutions

01 Composition and structure of UHECs for oxidation resistance

Ultra-High Entropy Ceramics can be designed with specific compositions and structures to enhance oxidation resistance. These compositions typically include multiple principal elements (5 or more) in near-equiatomic ratios that create high configurational entropy. The structural design often incorporates elements with strong oxide-forming tendencies such as Al, Cr, or Si that form protective oxide scales. The high entropy effect can slow down diffusion processes, thereby reducing oxidation rates at elevated temperatures.- Composition design for oxidation resistance in UHECs: Ultra-high entropy ceramics can be designed with specific elemental compositions to enhance oxidation resistance. By incorporating elements with high oxygen affinity such as Al, Si, or Cr, protective oxide scales can form on the surface during high-temperature exposure. These compositions typically include multiple principal elements (5 or more) in near-equiatomic ratios to maximize configurational entropy while maintaining structural stability under oxidizing conditions.

- Microstructural engineering to prevent evaporation: Controlling the microstructure of UHECs is crucial for minimizing evaporation at high temperatures. Techniques such as grain boundary engineering, densification optimization, and phase distribution control can significantly reduce material loss through evaporation. Dense microstructures with minimal porosity and stable grain boundaries help contain volatile components within the ceramic matrix, while specially designed interfaces can act as diffusion barriers to prevent selective evaporation of certain elements.

- Surface modification and coating technologies: Surface treatments and protective coatings can be applied to UHECs to enhance their oxidation resistance and reduce evaporation. These include environmental barrier coatings, self-healing surface layers, and reactive element additions that modify oxidation kinetics. Multi-layer coating systems can provide both oxidation protection and evaporation suppression by creating diffusion barriers and promoting the formation of stable oxide scales that adhere well to the substrate.

- High-temperature behavior and phase stability: Understanding the high-temperature behavior of UHECs is essential for predicting and controlling oxidation and evaporation processes. This includes phase stability analysis, transformation kinetics, and thermodynamic modeling of multi-component systems. UHECs with stable phase compositions throughout their operating temperature range show improved resistance to oxidation and evaporation, as phase transformations can create pathways for accelerated oxidation or lead to the formation of volatile compounds.

- Testing methodologies and performance evaluation: Specialized testing methodologies have been developed to evaluate the oxidation resistance and evaporation behavior of UHECs under extreme conditions. These include cyclic oxidation tests, thermogravimetric analysis, high-temperature mass spectrometry, and post-exposure characterization techniques. Long-term performance evaluation under simulated service conditions helps identify degradation mechanisms and validate protective strategies, enabling the development of more durable UHEC systems for high-temperature applications.

02 High-temperature oxidation behavior of UHECs

The oxidation behavior of Ultra-High Entropy Ceramics at high temperatures involves complex mechanisms including selective oxidation, formation of protective oxide scales, and potential phase transformations. When exposed to oxidizing environments at elevated temperatures, UHECs typically form multi-layered oxide scales with varying compositions. The oxidation kinetics often follow parabolic or sub-parabolic rate laws, indicating diffusion-controlled processes. The high configurational entropy can stabilize the crystal structure and slow down diffusion pathways, contributing to improved oxidation resistance.Expand Specific Solutions03 Evaporation mechanisms and volatility control in UHECs

Evaporation in Ultra-High Entropy Ceramics occurs through various mechanisms including direct sublimation, decomposition reactions, and formation of volatile oxide species. The multi-element composition of UHECs can lead to preferential evaporation of certain elements, potentially changing the surface composition over time. Controlling volatility in UHECs involves strategic element selection to minimize formation of volatile species, microstructural design to limit diffusion pathways, and creation of stable phases that resist decomposition at high temperatures. The entropy stabilization effect can help reduce evaporation rates by increasing the energy barrier for atom removal from the crystal lattice.Expand Specific Solutions04 Processing techniques for oxidation-resistant UHECs

Various processing techniques can be employed to produce Ultra-High Entropy Ceramics with enhanced oxidation resistance. These include spark plasma sintering, hot pressing, reactive spark plasma sintering, and solution-based synthesis methods. The processing parameters significantly influence the microstructure, density, and phase composition of UHECs, which in turn affect their oxidation behavior. Post-processing treatments such as surface modifications or coatings can further improve oxidation resistance by creating protective barriers against oxygen diffusion. Controlling grain size and boundary characteristics during processing is crucial for optimizing oxidation performance.Expand Specific Solutions05 Testing and characterization methods for UHEC oxidation and evaporation

Various testing and characterization methods are employed to evaluate the oxidation and evaporation behavior of Ultra-High Entropy Ceramics. These include thermogravimetric analysis to measure mass changes during oxidation, high-temperature exposure tests in controlled atmospheres, and post-oxidation microstructural analysis using scanning electron microscopy and X-ray diffraction. Advanced techniques such as transmission electron microscopy and atom probe tomography can reveal atomic-scale mechanisms of oxidation and evaporation. In-situ characterization methods allow real-time observation of oxidation processes and phase transformations. Computational modeling approaches complement experimental techniques by predicting oxidation kinetics and identifying rate-limiting steps.Expand Specific Solutions

Leading Research Institutions and Material Manufacturers

The high-temperature oxidation and evaporation behavior of Ultra-High Entropy Ceramics (UHECs) market is in its early growth stage, with increasing research interest but limited commercial applications. The global market size remains relatively small but is expected to expand significantly as these materials find applications in aerospace, energy, and defense sectors. From a technical maturity perspective, academic institutions like Xi'an Jiaotong University, Northwestern Polytechnical University, and Institute of Metal Research Chinese Academy of Sciences are leading fundamental research, while companies such as Topsoe A/S, Linde GmbH, and Tokyo Electron are beginning to explore industrial applications. The technology remains predominantly in the research and development phase, with significant challenges in scaling production and optimizing performance under extreme conditions.

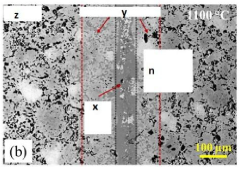

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University's State Key Laboratory for Mechanical Behavior of Materials has established a comprehensive research program on the high-temperature behavior of UHECs, with particular emphasis on oxidation mechanisms and microstructural evolution. Their approach combines advanced in-situ characterization techniques with theoretical modeling to understand the fundamental processes governing oxidation resistance. The university has developed novel (Hf,Zr,Ti,Ta,Nb)C-based UHECs with tailored grain boundary chemistry that demonstrates exceptional oxidation resistance at temperatures exceeding 1700°C. Their research has revealed that the formation of complex oxide scales with high configurational entropy can significantly reduce oxygen diffusion rates compared to conventional ceramics. Additionally, they have pioneered the use of reactive sintering techniques to create UHECs with engineered porosity distributions that enhance thermal shock resistance without compromising oxidation performance. Their recent work has focused on understanding the role of point defects and grain boundary segregation in controlling high-temperature stability and developing predictive models for lifetime assessment under extreme conditions.

Strengths: Exceptional microstructural characterization capabilities including high-resolution TEM and atom probe tomography specifically optimized for ceramic materials; strong integration of computational modeling with experimental validation. Weaknesses: Limited industrial-scale validation of laboratory findings; research primarily focused on carbide-based systems with less emphasis on borides and nitrides.

Central South University

Technical Solution: Central South University has developed a systematic approach to studying the high-temperature oxidation and evaporation behavior of UHECs through their State Key Laboratory of Powder Metallurgy. Their research focuses on the development of (Ti,Zr,Hf,Nb,Ta)C and (Ti,Zr,Hf,Nb,Ta)B2 systems with controlled microstructures achieved through spark plasma sintering and hot pressing techniques. CSU researchers have pioneered the investigation of oxidation kinetics using thermogravimetric analysis coupled with evolved gas analysis to precisely track mass changes and volatile species formation at temperatures up to 1800°C. Their work has revealed that the formation of complex oxide scales with high configurational entropy can significantly reduce oxygen diffusion rates compared to conventional ceramics. Additionally, they have established correlations between starting powder characteristics (particle size distribution, impurity content) and final oxidation behavior, demonstrating that nano-scale starting powders can lead to enhanced densification and improved oxidation resistance. Their recent studies have focused on the role of grain boundary engineering in controlling high-temperature stability.

Strengths: Exceptional powder processing capabilities allowing precise control of starting material characteristics; comprehensive thermogravimetric analysis facilities specifically designed for high-temperature ceramic oxidation studies. Weaknesses: Limited work on the mechanical property evolution during oxidation processes; research primarily focused on static oxidation conditions rather than dynamic environments with thermal cycling.

Critical Patents and Literature on UHEC Oxidation Mechanisms

Method of joining hafnium-and zirconium-diborides based ultra-high temperature ceramic and composites thereof using nickel interlayer

PatentActiveIN202111041006A

Innovation

- The use of a Nickel interlayer in conjunction with spark plasma sintering (SPS) to join Hafnium and Zirconium diborides-based UHTCs at lower temperatures and shorter durations, facilitating the formation of a well-bonded interface with homogeneous microstructure and uniform mechanical properties.

Environmental Impact of UHEC Manufacturing and Application

The manufacturing and application of Ultra-High Entropy Ceramics (UHECs) present significant environmental considerations that must be addressed as these materials gain prominence in high-temperature applications. The production processes for UHECs typically involve energy-intensive methods such as spark plasma sintering, hot pressing, or reactive spark plasma sintering, which contribute substantially to carbon emissions and resource consumption. These manufacturing techniques often require temperatures exceeding 1800°C, resulting in considerable energy expenditure and associated greenhouse gas emissions.

Raw material extraction for UHECs compounds these environmental concerns. The mining and processing of constituent elements like zirconium, hafnium, tantalum, and rare earth metals involve substantial land disturbance, water usage, and potential release of toxic substances into ecosystems. Particularly concerning is the extraction of refractory metals, which often requires environmentally damaging acid leaching processes and generates significant quantities of waste material.

During high-temperature applications, the oxidation and evaporation behavior of UHECs presents additional environmental challenges. When exposed to extreme temperatures in oxygen-containing atmospheres, certain UHEC compositions may release volatile oxide species. These emissions can include potentially harmful metal oxides that contribute to air pollution and may pose health risks in industrial settings. The evaporation of elements like molybdenum and tungsten at high temperatures creates particulate matter that requires sophisticated filtration systems to prevent environmental contamination.

Waste management throughout the UHEC lifecycle presents further environmental considerations. The production of these advanced ceramics generates various waste streams, including chemical byproducts, unused raw materials, and rejected components. Additionally, end-of-life disposal of UHEC-containing products requires specialized handling due to the potential leaching of constituent elements into groundwater systems if improperly managed.

Despite these challenges, UHECs offer potential environmental benefits through their exceptional performance characteristics. Their superior oxidation resistance and thermal stability enable more efficient high-temperature processes in aerospace, energy generation, and industrial applications. This efficiency can translate to reduced fuel consumption and lower lifetime emissions from systems incorporating these materials. Furthermore, the extended service life of UHEC components compared to conventional materials may reduce the environmental impact associated with frequent replacement and maintenance.

Emerging research focuses on developing more sustainable manufacturing routes for UHECs, including lower-temperature synthesis methods, recycling of precursor materials, and optimization of processing parameters to reduce energy consumption. These advancements, coupled with comprehensive lifecycle assessments, will be crucial in minimizing the environmental footprint of these promising materials as they transition from laboratory research to widespread industrial application.

Raw material extraction for UHECs compounds these environmental concerns. The mining and processing of constituent elements like zirconium, hafnium, tantalum, and rare earth metals involve substantial land disturbance, water usage, and potential release of toxic substances into ecosystems. Particularly concerning is the extraction of refractory metals, which often requires environmentally damaging acid leaching processes and generates significant quantities of waste material.

During high-temperature applications, the oxidation and evaporation behavior of UHECs presents additional environmental challenges. When exposed to extreme temperatures in oxygen-containing atmospheres, certain UHEC compositions may release volatile oxide species. These emissions can include potentially harmful metal oxides that contribute to air pollution and may pose health risks in industrial settings. The evaporation of elements like molybdenum and tungsten at high temperatures creates particulate matter that requires sophisticated filtration systems to prevent environmental contamination.

Waste management throughout the UHEC lifecycle presents further environmental considerations. The production of these advanced ceramics generates various waste streams, including chemical byproducts, unused raw materials, and rejected components. Additionally, end-of-life disposal of UHEC-containing products requires specialized handling due to the potential leaching of constituent elements into groundwater systems if improperly managed.

Despite these challenges, UHECs offer potential environmental benefits through their exceptional performance characteristics. Their superior oxidation resistance and thermal stability enable more efficient high-temperature processes in aerospace, energy generation, and industrial applications. This efficiency can translate to reduced fuel consumption and lower lifetime emissions from systems incorporating these materials. Furthermore, the extended service life of UHEC components compared to conventional materials may reduce the environmental impact associated with frequent replacement and maintenance.

Emerging research focuses on developing more sustainable manufacturing routes for UHECs, including lower-temperature synthesis methods, recycling of precursor materials, and optimization of processing parameters to reduce energy consumption. These advancements, coupled with comprehensive lifecycle assessments, will be crucial in minimizing the environmental footprint of these promising materials as they transition from laboratory research to widespread industrial application.

International Standards and Testing Protocols for UHECs

The evaluation of Ultra-High Entropy Ceramics (UHECs) requires standardized testing protocols to ensure consistent assessment of their high-temperature oxidation and evaporation behaviors across different research institutions and industries. Currently, several international organizations have established standards specifically addressing these materials under extreme conditions.

The International Organization for Standardization (ISO) has developed ISO 21608, which outlines procedures for evaluating ceramic materials' oxidation resistance at temperatures exceeding 1600°C. This standard specifically addresses testing methodologies for multi-principal element ceramics, including protocols for sample preparation, exposure conditions, and post-test analysis techniques.

ASTM International provides complementary standards through ASTM C1835 for high-temperature mass loss measurements in ceramic materials, which has been adapted to accommodate the unique characteristics of UHECs. The standard specifies precise environmental parameters, including oxygen partial pressure, flow rates, and temperature ramp profiles that are critical for reproducible evaporation behavior assessment.

The European Committee for Standardization (CEN) has established EN 1402-5, focusing on thermogravimetric analysis protocols for advanced ceramics at elevated temperatures. This standard has been particularly valuable for quantifying the oxidation kinetics and evaporation rates of UHECs in various atmospheric conditions.

Testing protocols typically involve cyclic oxidation tests, isothermal oxidation exposure, and thermogravimetric analysis under controlled atmospheres. For UHECs specifically, modified protocols have emerged that account for their complex phase compositions and unique oxidation mechanisms. These include specialized procedures for characterizing oxide scale morphology, phase stability, and volatilization rates.

Inter-laboratory round-robin testing initiatives have been instrumental in validating these protocols across different facilities. The High-Temperature Materials Testing Consortium (HTMTC) coordinates such efforts, ensuring that oxidation and evaporation data for UHECs can be reliably compared regardless of testing location.

Recent developments include the integration of in-situ characterization techniques into standardized protocols. Advanced methods such as high-temperature environmental scanning electron microscopy (HT-ESEM) and synchrotron-based X-ray diffraction are now being incorporated into testing standards to provide real-time observations of oxidation processes and phase transformations in UHECs.

Compliance with these international standards is increasingly becoming a prerequisite for material qualification in aerospace, energy, and defense applications where UHECs show the greatest promise. The continued refinement of these protocols remains essential as UHECs evolve and their application environments become more demanding.

The International Organization for Standardization (ISO) has developed ISO 21608, which outlines procedures for evaluating ceramic materials' oxidation resistance at temperatures exceeding 1600°C. This standard specifically addresses testing methodologies for multi-principal element ceramics, including protocols for sample preparation, exposure conditions, and post-test analysis techniques.

ASTM International provides complementary standards through ASTM C1835 for high-temperature mass loss measurements in ceramic materials, which has been adapted to accommodate the unique characteristics of UHECs. The standard specifies precise environmental parameters, including oxygen partial pressure, flow rates, and temperature ramp profiles that are critical for reproducible evaporation behavior assessment.

The European Committee for Standardization (CEN) has established EN 1402-5, focusing on thermogravimetric analysis protocols for advanced ceramics at elevated temperatures. This standard has been particularly valuable for quantifying the oxidation kinetics and evaporation rates of UHECs in various atmospheric conditions.

Testing protocols typically involve cyclic oxidation tests, isothermal oxidation exposure, and thermogravimetric analysis under controlled atmospheres. For UHECs specifically, modified protocols have emerged that account for their complex phase compositions and unique oxidation mechanisms. These include specialized procedures for characterizing oxide scale morphology, phase stability, and volatilization rates.

Inter-laboratory round-robin testing initiatives have been instrumental in validating these protocols across different facilities. The High-Temperature Materials Testing Consortium (HTMTC) coordinates such efforts, ensuring that oxidation and evaporation data for UHECs can be reliably compared regardless of testing location.

Recent developments include the integration of in-situ characterization techniques into standardized protocols. Advanced methods such as high-temperature environmental scanning electron microscopy (HT-ESEM) and synchrotron-based X-ray diffraction are now being incorporated into testing standards to provide real-time observations of oxidation processes and phase transformations in UHECs.

Compliance with these international standards is increasingly becoming a prerequisite for material qualification in aerospace, energy, and defense applications where UHECs show the greatest promise. The continued refinement of these protocols remains essential as UHECs evolve and their application environments become more demanding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!